Ensuring the longevity and optimal performance of a vehicle requires a thorough understanding of its components and systems. This section offers a detailed exploration of essential procedures, maintenance schedules, and troubleshooting techniques that can enhance the reliability of your automobile. With the right knowledge, you can tackle common issues and ensure your vehicle remains in excellent condition.

By following the guidelines outlined herein, you will gain valuable insights into various aspects of upkeep and repair processes. The information provided serves as a roadmap, guiding you through each step, from routine checks to more complex interventions. Emphasizing practical advice, this resource aims to empower you to make informed decisions regarding the care of your vehicle.

Additionally, familiarity with the intricacies of your automobile can lead to improved safety and performance on the road. Understanding how to effectively address potential challenges not only saves time and money but also enhances your confidence as a driver. With this resource, you will be well-equipped to navigate the complexities of vehicle maintenance and care.

Overview of the 1994 Toyota Truck

This section provides a comprehensive look at a notable vehicle model known for its reliability and performance in various conditions. Designed to meet the needs of both urban and rural drivers, this vehicle has garnered a reputation for its durability and versatility.

Key Features

The highlighted model boasts a range of features that enhance both functionality and comfort. With a robust engine lineup and a well-designed chassis, it offers excellent handling and stability. The spacious interior ensures a comfortable ride, making it suitable for both daily commuting and adventurous outings.

Performance and Specifications

Equipped with advanced engineering, this model delivers impressive power and efficiency. Its towing capacity is noteworthy, allowing for the transport of heavier loads with ease. The vehicle’s suspension system is designed to absorb shocks, contributing to a smooth driving experience on various terrains.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for effective maintenance tasks. A well-equipped workspace not only enhances efficiency but also ensures safety while working on various components. Below is a list of fundamental tools that are beneficial for any automotive enthusiast.

Basic Hand Tools

- Wrenches: A set of adjustable and fixed wrenches for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are essential for different fastening needs.

- Pliers: Useful for gripping, twisting, and cutting wire.

- Ratchet and Socket Set: Ideal for quick and easy fastening in tight spaces.

Specialty Tools

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

- Multimeter: Essential for diagnosing electrical issues and measuring voltage.

- Oil Filter Wrench: Facilitates the removal of oil filters without damage.

- Jack and Jack Stands: Necessary for lifting the vehicle safely for undercarriage access.

Investing in these key tools will greatly enhance your ability to address maintenance tasks effectively and efficiently.

Common Mechanical Issues

Vehicles of a certain vintage often experience a range of typical mechanical challenges that can impact their performance and reliability. Understanding these common problems can aid in maintaining optimal functionality and ensuring longevity.

| Issue | Description | Symptoms |

|---|---|---|

| Engine Overheating | Insufficient coolant or a malfunctioning thermostat may lead to excessive temperatures. | Temperature gauge in the red, steam from the engine bay. |

| Transmission Slipping | Worn components or low fluid levels can cause engagement issues. | Delayed acceleration, unusual noises when shifting. |

| Brake Wear | Frequent use leads to deterioration of pads and rotors, affecting stopping power. | Squeaking or grinding noises, reduced braking efficiency. |

| Suspension Problems | Worn shocks or struts can compromise ride quality and handling. | Bouncing on uneven surfaces, noise when going over bumps. |

| Electrical Issues | Corroded connections or failing components may disrupt the electrical system. | Inconsistent power to lights and accessories, starting problems. |

Electrical System Troubleshooting

This section provides a comprehensive approach to diagnosing and resolving issues within the electrical framework of a vehicle. Understanding the various components and their interactions is crucial for effective troubleshooting. By systematically evaluating the electrical system, one can identify faults and implement appropriate corrective actions.

Common Symptoms of Electrical Failures

Recognizing the signs of electrical malfunctions can aid in prompt diagnosis. Common indicators include:

- Dim or flickering lights: This may suggest a weak battery or poor connections.

- Unresponsive electrical components: Devices that fail to operate could indicate a blown fuse or faulty wiring.

- Strange noises: Unusual sounds when turning the key may point to starter motor issues.

Troubleshooting Steps

To effectively troubleshoot electrical problems, follow these steps:

- Inspect the battery: Ensure connections are secure and check for corrosion.

- Test fuses: Replace any blown fuses to restore functionality.

- Examine wiring: Look for frayed or damaged wires that may disrupt the circuit.

- Utilize a multimeter: Measure voltage and continuity to pinpoint faulty components.

By following these guidelines, diagnosing and rectifying electrical issues becomes a structured and manageable process.

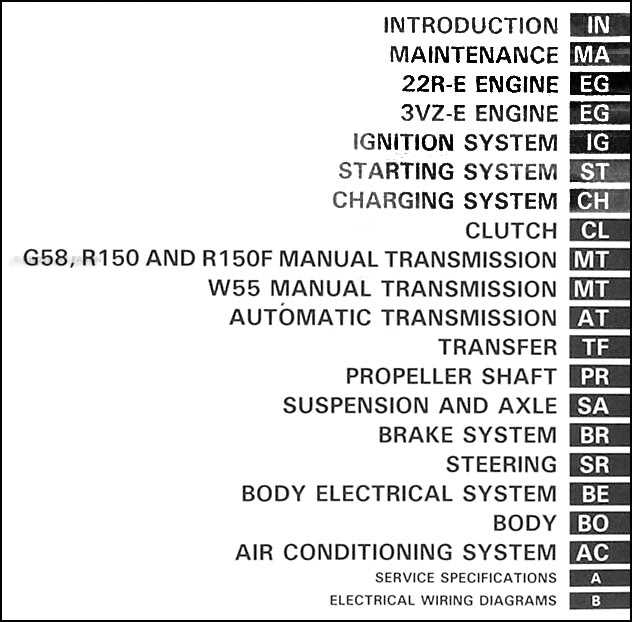

Engine Maintenance Guidelines

Regular upkeep of the power unit is crucial for ensuring optimal performance and longevity. Adhering to specific protocols not only enhances efficiency but also minimizes the likelihood of significant breakdowns. By following established practices, owners can maintain their vehicle’s health and avoid costly repairs.

Routine Inspections: Conduct frequent checks on vital components such as the oil levels, coolant, and belts. Regular inspections help identify potential issues before they escalate into major problems.

Oil Changes: Change the lubricant at recommended intervals to ensure proper engine function. Clean oil reduces friction and helps in dissipating heat, prolonging the life of internal parts.

Air Filter Maintenance: Replace or clean the air intake filter as needed. A clean filter promotes optimal airflow, enhancing combustion and improving fuel efficiency.

Coolant System Checks: Regularly inspect the cooling system, including hoses and connections. Proper coolant levels prevent overheating and maintain the engine’s operating temperature.

Fuel System Care: Use quality fuel and consider periodic cleaning of the fuel injectors. This practice supports efficient fuel delivery and combustion, ensuring the engine runs smoothly.

Following these guidelines will help maintain the engine’s performance and reliability, ultimately enhancing the overall driving experience.

Transmission Repair Techniques

When addressing issues related to the power transfer system of a vehicle, understanding effective methods for maintenance and troubleshooting is essential. These approaches not only enhance the longevity of components but also improve overall performance.

Diagnosis is the first critical step in addressing transmission complications. Utilizing diagnostic tools can help identify specific issues, such as fluid leaks or unusual noises. Regular checks of fluid levels and quality can also prevent potential problems before they escalate.

Disassembly of the transmission unit is often necessary for thorough examination and repair. This process requires careful attention to detail, ensuring that each component is documented and handled with care. Proper organization of parts can facilitate a smoother reassembly and prevent misplacement of critical components.

During the repair process, replacing worn or damaged parts is vital. This may involve installing new seals, gaskets, or clutches. Utilizing high-quality components can significantly impact the reliability and functionality of the system.

Finally, reassembly should be conducted meticulously. Ensuring all connections are secure and fluid levels are adequate is essential for optimal performance. Conducting a test drive after reassembly allows for verification of successful repairs and adjustment if necessary.

Suspension System Adjustments

Proper alignment and tuning of the suspension system are crucial for ensuring optimal vehicle performance and comfort. This section explores the key considerations for adjusting the suspension components to maintain stability, enhance ride quality, and prolong the lifespan of the system.

To achieve the desired handling characteristics, it is essential to periodically inspect and adjust various elements such as shock absorbers, springs, and alignment settings. Ensuring that these components are within specified tolerances will help mitigate issues related to uneven tire wear and compromised steering response.

Additionally, monitoring the ride height is vital, as it affects the overall handling and load distribution of the vehicle. Adjustments may involve modifying the spring preload or replacing worn-out parts to restore proper clearance and functionality.

Regular maintenance and timely adjustments not only improve the driving experience but also enhance safety by ensuring that the suspension system performs as intended under various driving conditions.

Brake System Maintenance Tips

Regular upkeep of the braking mechanism is essential for ensuring safety and optimal performance of your vehicle. By following a few straightforward guidelines, you can prolong the lifespan of your brake components and enhance overall driving experience.

1. Inspect Brake Pads and Rotors: Periodically check the condition of brake pads and rotors for wear and tear. Worn pads can lead to decreased stopping power and increased damage to rotors, which can be costly to replace.

2. Monitor Brake Fluid Levels: Keep an eye on brake fluid levels and top up as necessary. Low fluid can affect brake performance and signal potential leaks in the system.

3. Listen for Unusual Noises: Be attentive to any strange sounds when applying brakes, such as squeaking or grinding. These noises can indicate worn components or the need for immediate attention.

4. Check Brake Lines: Inspect brake lines for any signs of corrosion or leaks. Damaged lines can compromise the hydraulic system, leading to brake failure.

5. Schedule Professional Inspections: Regularly consult a qualified technician for thorough inspections. Professionals can identify issues that may not be immediately apparent and recommend necessary repairs or replacements.

By adhering to these maintenance tips, you can ensure your vehicle’s braking system remains reliable and effective, promoting safer journeys on the road.

Bodywork and Paint Repair

This section focuses on the essential techniques and practices for restoring the outer surfaces of vehicles. Whether addressing minor blemishes or extensive damage, understanding the proper methods can significantly enhance both aesthetics and longevity.

Common Damage Types

Vehicles can suffer from various types of exterior imperfections. The most frequent issues include scratches, dents, rust, and paint fading. Identifying the specific type of damage is crucial for selecting the appropriate repair method.

Repair Techniques

| Damage Type | Recommended Method |

|---|---|

| Scratches | Buffing and polishing with compound |

| Dents | Using a heat source and a pulling tool |

| Rust | Sandblasting and applying rust inhibitor |

| Faded Paint | Repainting and clear coating |

Following the correct procedures will ensure a smooth finish and prevent further deterioration. Regular maintenance is also recommended to keep the exterior in optimal condition.

Guidelines for Fluid Changes

Regular maintenance of various fluids is crucial for the optimal performance and longevity of your vehicle. Adhering to a systematic approach can enhance reliability and ensure that all components function effectively.

Here are some essential steps to follow when changing fluids:

- Consult the owner’s guide for recommended intervals and fluid specifications.

- Gather necessary tools and materials, including new fluids, funnels, and containers for disposal.

When performing fluid changes, consider the following:

- Check fluid levels regularly to identify any leaks or deficiencies.

- Use the appropriate type of fluid, ensuring it meets the manufacturer’s requirements.

- Dispose of old fluids responsibly by taking them to designated recycling centers.

Following these guidelines will help maintain the efficiency and performance of your vehicle while promoting safe and responsible practices.

Understanding OEM Parts and Accessories

When maintaining a vehicle, selecting the right components is crucial for optimal performance and longevity. Original Equipment Manufacturer (OEM) parts are designed to match the specifications of the original assembly, ensuring compatibility and reliability. These components are engineered to provide the same quality and performance as those initially installed in the vehicle.

OEM parts offer several advantages, including enhanced durability and a perfect fit. Because they are made by the same manufacturer, they undergo rigorous testing to meet strict standards. This commitment to quality translates to fewer issues and a better overall driving experience.

On the other hand, accessories complement the vehicle’s functionality and aesthetics. From floor mats to advanced audio systems, these additions can personalize and improve the driving experience. Choosing OEM accessories ensures that they integrate seamlessly with existing systems, maintaining both performance and value.

In summary, understanding the importance of OEM components and accessories can significantly impact vehicle maintenance and enhancement. Investing in these parts not only preserves the vehicle’s integrity but also supports long-term satisfaction and performance.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial for preventing accidents and injuries. Adopting proper measures helps create a secure environment, allowing the process to be efficient and effective.

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and masks to shield against hazards.

- Work in a well-ventilated area to avoid inhaling harmful fumes and to ensure proper airflow.

- Keep your workspace organized to minimize risks of trips, falls, or misplaced tools.

- Ensure all tools and equipment are in good condition and suited for the task at hand.

- Disconnect the battery or remove the power source before starting any work to prevent electrical shock or unintentional starts.

By adhering to these essential guidelines, individuals can significantly reduce the likelihood of accidents and enhance their overall experience during maintenance activities.