This section provides an in-depth look at the essential practices for maintaining a high-performance vehicle. Understanding the intricacies of your automobile can enhance its longevity and ensure optimal functioning. A well-informed owner is better equipped to tackle any issues that may arise, fostering a deeper connection with their machine.

Within these pages, you will find valuable insights into troubleshooting, routine upkeep, and detailed procedures tailored to keep your automobile in prime condition. Whether you are a seasoned enthusiast or a newcomer, this resource aims to equip you with the knowledge necessary for effective management and care.

From understanding the intricate systems at play to exploring common challenges and solutions, this guide serves as a practical companion. It emphasizes the importance of proactive measures and informed decisions in achieving peak performance and reliability.

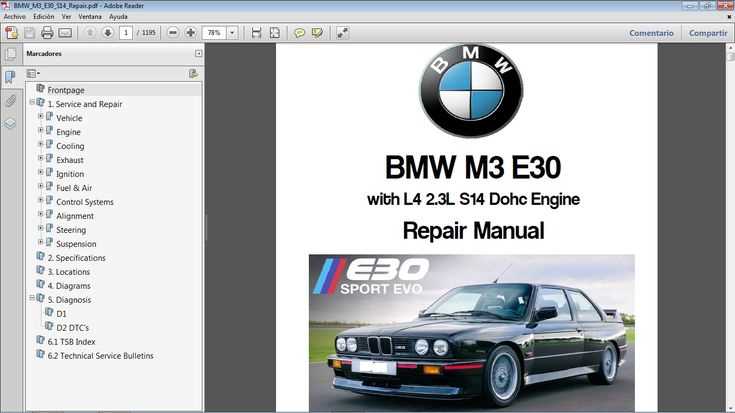

Comprehensive Guide to BMW M3 Repairs

This section provides an extensive overview of the essential processes and considerations involved in maintaining and fixing the high-performance vehicle. Whether dealing with common issues or routine upkeep, understanding the intricacies of this automobile is crucial for optimal performance and longevity.

Here are key areas to focus on:

- Engine Maintenance: Regular checks and services to ensure smooth operation.

- Transmission Troubles: Addressing shifting issues and fluid replacements.

- Suspension Systems: Understanding wear and tear for improved handling.

- Electrical Components: Diagnostics and repairs for electronic systems.

- Braking System: Importance of timely inspections and replacements.

By following these guidelines, owners can ensure their vehicle remains in peak condition, enhancing both performance and safety on the road.

Understanding Common Issues in 2002 Model

This section highlights frequent challenges encountered in a specific automotive model known for its performance and driving dynamics. Owners often report various concerns that can impact the overall experience, necessitating attention and potential solutions.

Engine Performance Concerns

One of the notable issues involves the engine’s responsiveness, which may include hesitation during acceleration or unusual noises. These symptoms can stem from various sources, including fuel delivery problems or ignition system failures. Regular diagnostics can help identify the root cause and ensure optimal function.

Electrical System Malfunctions

Another area of concern is the electrical system, where owners might experience problems such as flickering lights or difficulties with electronic components. Such issues could be related to the battery, wiring, or alternator, all of which play crucial roles in the vehicle’s functionality. Timely inspections are essential to prevent more significant disruptions.

Essential Tools for Effective Maintenance

To ensure optimal performance and longevity of your vehicle, having the right equipment is crucial. Various instruments facilitate routine upkeep, enabling enthusiasts and professionals alike to address issues efficiently and effectively.

Basic Hand Tools: A reliable set of hand tools is fundamental. This typically includes wrenches, screwdrivers, and pliers. These instruments allow for easy access to various components, making adjustments and repairs straightforward.

Diagnostic Equipment: Investing in diagnostic tools is highly beneficial. Devices that read error codes and monitor system performance provide valuable insights, helping to identify potential problems before they escalate.

Fluid Management: Proper maintenance often involves fluid changes. A quality oil extractor and funnel can streamline this process, ensuring cleanliness and efficiency when replacing essential fluids.

Safety Gear: Never overlook the importance of safety equipment. Items such as gloves and goggles protect against debris and chemicals, promoting a safer working environment.

Incorporating these essential tools into your maintenance routine will enhance your ability to maintain vehicle performance and ensure a smooth driving experience.

Step-by-Step Engine Overhaul Procedures

This section outlines the comprehensive approach to revitalizing a power unit. Following these detailed steps ensures optimal performance and longevity, allowing for effective restoration of engine functionality.

-

Preparation: Gather all necessary tools and components. Create a clean workspace to facilitate an organized process.

-

Disassembly: Carefully remove the engine from the vehicle. Document each step for reference during reassembly.

- Detach all electrical connections.

- Remove the exhaust and intake manifolds.

- Take off the cylinder head and timing components.

-

Inspection: Examine all components for wear and damage. Replace any parts that do not meet specifications.

-

Cleaning: Thoroughly clean all parts to remove carbon buildup and debris. Use appropriate solvents and brushes.

-

Reassembly: Begin reassembling the engine in reverse order of disassembly. Ensure all bolts are torqued to the manufacturer’s specifications.

- Install new gaskets and seals.

- Reattach the cylinder head and torque to specification.

- Reconnect all electrical and mechanical components.

-

Testing: Once reassembled, perform tests to verify functionality. Check for leaks and listen for unusual sounds during operation.

Following this structured approach will lead to a successful overhaul, enhancing the overall performance and reliability of the power unit.

Transmission Troubleshooting Techniques

When facing issues with the shifting mechanism of a vehicle, a systematic approach to diagnostics is essential. Understanding the underlying causes of transmission problems can help streamline the repair process and ensure effective solutions. This section outlines various methods to identify and address common concerns related to the transmission system.

Visual Inspection: Begin by examining the transmission components for signs of wear, leaks, or damage. Check for any fluid accumulation around the seals and connections, as well as inspect the fluid level and condition. Clear indicators of potential issues can often be detected through a thorough visual assessment.

Diagnostic Tools: Utilizing specialized tools, such as code readers and pressure gauges, can provide valuable insights into the operational status of the transmission. Scanning for error codes can reveal electronic malfunctions, while measuring fluid pressure can help identify mechanical problems within the system.

Test Drive Evaluation: Conducting a test drive allows for real-time observation of transmission performance. Pay attention to any unusual noises, slipping sensations, or erratic shifting patterns. Noting these symptoms can guide further diagnostics and pinpoint the specific areas needing attention.

Fluid Analysis: Analyzing the transmission fluid can reveal critical information about its condition and potential contaminants. Changes in color, odor, or texture may indicate overheating or internal degradation. Regular fluid checks can help prevent more serious issues from developing.

Component Testing: In some cases, individual components such as solenoids, sensors, and clutches may need testing to confirm their functionality. Employing a multimeter or other testing equipment can assist in determining whether these parts are operating correctly or require replacement.

By applying these techniques, one can effectively troubleshoot and resolve transmission-related issues, leading to improved vehicle performance and longevity.

Brake System Inspection and Repair

Maintaining the braking mechanism is essential for vehicle safety and performance. Regular examination ensures that components function properly and helps identify any issues that may arise over time. This section covers critical aspects of assessing and fixing the braking system, emphasizing the importance of timely interventions to prevent more significant problems.

Identifying Common Issues

Begin by visually inspecting the braking components for signs of wear or damage. Look for cracks in the brake pads, uneven wear patterns, and any leaks in the hydraulic system. Listening for unusual noises while braking can also indicate underlying issues. If a grinding or squeaking sound is present, it may be time to replace certain parts. Additionally, check the brake fluid level and quality, as contaminated fluid can lead to reduced effectiveness.

Conducting Repairs

Once potential problems are identified, it is crucial to address them promptly. Replacing worn brake pads and ensuring the rotors are in good condition are fundamental steps in maintaining the braking system. Bleeding the brake lines may also be necessary to remove air bubbles and restore proper pressure. Always use high-quality components to ensure reliability and performance. After repairs, a test drive is essential to confirm that the system functions correctly and safely.

Suspension Components: Care and Repair

The proper maintenance of suspension elements is crucial for ensuring optimal vehicle performance and safety. This section focuses on essential practices for keeping these components in excellent condition, helping to enhance driving experience and longevity.

Key Components and Their Functions

Suspension systems consist of various parts, each playing a vital role in vehicle handling and comfort. Understanding the function of these components is the first step toward effective maintenance. Below is a table outlining the primary parts and their roles:

| Component | Function |

|---|---|

| Shock Absorbers | Control vehicle stability and comfort by dampening oscillations. |

| Springs | Support the vehicle’s weight and absorb shocks from the road. |

| Control Arms | Connect the suspension to the vehicle’s frame, allowing for controlled movement. |

| Ball Joints | Facilitate smooth movement between the steering and suspension components. |

| Stabilizer Bar | Reduces body roll during turns, enhancing stability. |

Maintenance Tips

Regular inspections and timely replacements are vital for the longevity of suspension elements. Look for signs of wear, such as unusual noises or decreased handling responsiveness. Additionally, ensure that all components are properly lubricated and free from corrosion to maintain optimal performance.

Electrical System Diagnostics Made Easy

Understanding the intricacies of a vehicle’s power framework can seem daunting, yet with the right approach, it can become a straightforward task. This section aims to simplify the process of identifying issues within the electrical setup, allowing for efficient troubleshooting and resolution.

Key Components to Examine

To effectively assess the functionality of the electrical system, focus on several crucial elements. These components work in harmony to ensure optimal performance and must be regularly checked for any signs of malfunction.

| Component | Function | Common Issues |

|---|---|---|

| Battery | Stores electrical energy for starting the engine and powering accessories. | Corrosion, low charge, leaks. |

| Alternator | Generates electrical power while the engine is running. | Failing diodes, worn bearings, poor connections. |

| Fuses | Protects circuits by breaking the connection in case of overload. | Blown fuses, incorrect ratings. |

| Wiring Harness | Facilitates the distribution of electrical signals throughout the vehicle. | Frayed wires, loose connections, shorts. |

Diagnostic Techniques

Utilizing systematic diagnostic methods can greatly enhance the accuracy of your evaluations. Start by visually inspecting components for any obvious damage, followed by using specialized tools to measure voltage and continuity where necessary. Regular maintenance and proactive checks can prevent minor issues from escalating into significant problems.

Bodywork Repairs: Techniques and Tips

When it comes to enhancing the exterior aesthetics of your vehicle, mastering various methods and strategies is essential. Whether addressing minor dents, scratches, or more extensive damage, having a solid understanding of the techniques can make the process more efficient and effective.

Common Techniques for Exterior Restoration

One widely used approach involves the application of filler materials to smooth out imperfections. This method not only helps in achieving a seamless finish but also strengthens the affected areas. Sandblasting is another effective technique, particularly for removing rust or paint, ensuring a clean surface for repainting.

Tips for Successful Outcomes

Proper surface preparation is crucial; always ensure that the area is clean and dry before beginning any work. Using high-quality materials can significantly impact the final results, so invest in reputable products. Additionally, patience is key–allow adequate time for each layer to dry and cure properly to avoid complications later on.

Cooling System Maintenance Essentials

Regular upkeep of the cooling mechanism is crucial for optimal vehicle performance and longevity. This component plays a vital role in preventing overheating and ensuring that the engine operates within the ideal temperature range.

To maintain the cooling system effectively, consider the following key practices:

- Regular Fluid Checks: Periodically inspect the coolant level and quality. Ensure that the fluid is free of contaminants and at the appropriate level.

- Leak Inspection: Look for any signs of leaks in hoses, connections, and the radiator. Address any leaks promptly to avoid system failure.

- Cooling Fan Functionality: Test the operation of the cooling fans to ensure they engage at the correct temperatures. Malfunctioning fans can lead to overheating.

- Thermostat Condition: Regularly assess the thermostat for proper function. A faulty thermostat can disrupt the engine’s temperature regulation.

- Radiator Maintenance: Keep the radiator clean and free of debris. Flushing the radiator periodically helps remove any buildup that could hinder cooling efficiency.

- Inspection of Hoses: Examine all hoses for signs of wear, cracking, or swelling. Replace any damaged hoses to maintain a tight seal and prevent leaks.

By adhering to these maintenance essentials, you can enhance the reliability and efficiency of the cooling system, ultimately contributing to the overall health of the vehicle.

Fuel System Troubleshooting and Solutions

Troubleshooting issues within the fuel delivery system is crucial for optimal vehicle performance. This section focuses on common problems encountered and offers practical solutions to enhance functionality and reliability. By understanding the key components and their interactions, you can identify faults that may arise in the system.

One frequent issue is insufficient fuel delivery, which can stem from clogged filters or failing pumps. Regularly inspecting and replacing fuel filters ensures smooth operation, while testing the pump’s pressure can confirm its effectiveness. If the pump is found to be inadequate, replacing it may restore proper fuel flow.

Another area to examine is the fuel injectors. Dirty or malfunctioning injectors can lead to poor engine performance or rough idling. Cleaning or replacing these components can significantly improve fuel atomization and combustion efficiency. It’s essential to assess injector function through diagnostics to pinpoint any irregularities.

Additionally, monitoring fuel pressure is vital. Low pressure can indicate leaks or blockages within the system. Utilizing a fuel pressure gauge allows for accurate measurements, helping to identify the source of the issue. Addressing leaks promptly prevents further complications and ensures safe operation.

In summary, methodical examination of the fuel system components is key to resolving common issues. Implementing routine maintenance practices can prevent many problems before they occur, contributing to the longevity and reliability of your vehicle’s performance.

Regular Maintenance Schedule Recommendations

Establishing a consistent upkeep routine is essential for the longevity and optimal performance of your vehicle. Adhering to a structured schedule not only enhances reliability but also minimizes potential issues, ensuring that all components function smoothly. By following these guidelines, you can help maintain your automobile in top condition.

Key Maintenance Intervals

Routine inspections should be conducted at specified intervals. It is advisable to check fluid levels, including oil, coolant, and brake fluid, at least every month. Additionally, tire pressure and tread depth should be assessed regularly to ensure safe handling and efficiency. Major service tasks, such as replacing the air filter and spark plugs, are typically recommended every 30,000 miles, while brake system components should be examined every 20,000 miles.

Seasonal Considerations

Seasonal changes can impact vehicle performance. Before winter, it’s crucial to inspect the battery and antifreeze levels to prevent starting issues in cold weather. Conversely, prior to summer, checking the air conditioning system and coolant is important for comfort and efficiency during hotter months. Maintaining a detailed log of all maintenance activities can also help track progress and ensure no tasks are overlooked.