This section aims to provide essential insights for addressing common issues encountered with household cooling units. Understanding the basic components and functions is crucial for effectively diagnosing problems and implementing solutions.

With a variety of models available, each unit may exhibit unique challenges that require specific approaches. Familiarity with the fundamental principles of operation will empower users to troubleshoot effectively and maintain optimal performance.

Whether dealing with temperature inconsistencies, unusual noises, or power supply concerns, this guide offers a comprehensive overview to assist in navigating the complexities of these essential home devices. Empower yourself with the knowledge to restore functionality and enhance the longevity of your appliance.

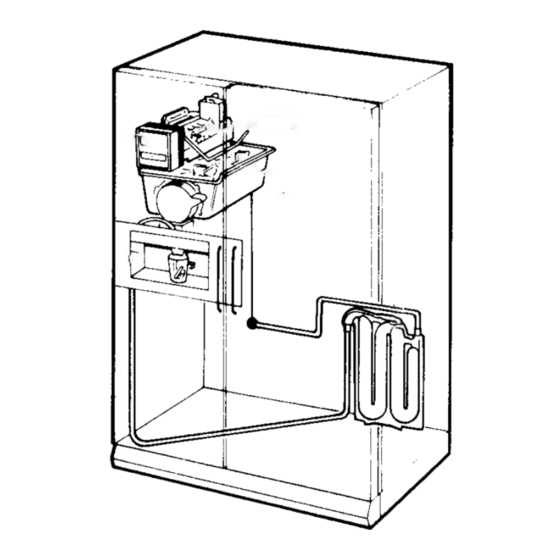

Understanding Refrigerator Components

Every cooling appliance consists of various essential parts that work together to maintain optimal temperatures and ensure proper functioning. Recognizing these components can enhance your understanding of how the system operates and what might go wrong.

Compressor: This vital element acts as the heart of the cooling cycle, compressing refrigerant gas and circulating it through the system.

Evaporator Coils: These coils absorb heat from the interior, allowing the appliance to cool down. They play a crucial role in the heat exchange process.

Condenser Coils: Located at the back or bottom of the unit, these coils release the heat absorbed by the refrigerant, allowing it to return to a liquid state.

Expansion Valve: This component regulates the flow of refrigerant into the evaporator, ensuring that the system operates efficiently by controlling pressure and temperature.

Thermostat: Serving as the control center, this device monitors the internal temperature and adjusts the compressor’s operation to maintain the desired cooling level.

Understanding these key components enables better troubleshooting and maintenance practices, ensuring longevity and efficiency of the cooling appliance.

Troubleshooting Temperature Problems

Addressing temperature-related issues is essential for maintaining optimal performance. This section outlines common causes of temperature fluctuations and provides guidance on how to identify and rectify these problems effectively.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Inadequate Cooling | Blocked vents, faulty thermostat, or door seal issues | Ensure vents are clear, check and adjust the thermostat, inspect the door seal for damage |

| Excessive Cooling | Thermostat set too low, malfunctioning temperature sensor | Increase thermostat setting, test or replace the temperature sensor |

| Temperature Fluctuations | Frequent door openings, overloading, or appliance location | Avoid excessive door openings, organize contents for proper airflow, relocate away from heat sources |

Identifying Noise and Vibration Sources

Understanding the origins of unusual sounds and vibrations in your cooling appliance is essential for maintaining its performance. Various factors can contribute to these disturbances, and identifying them promptly can help prevent further issues.

- Check for loose components or fittings that may cause rattling noises.

- Inspect the leveling of the unit to ensure it is stable and balanced.

- Examine the condenser fan and evaporator fan for any obstructions.

- Listen for compressor sounds; abnormal noise might indicate a problem.

Regular maintenance can significantly reduce the likelihood of disruptive noises. Pay attention to any changes in sound patterns, as they can provide clues about underlying issues.

Repairing Door Seal Issues

The integrity of the door seal is crucial for maintaining optimal temperature and energy efficiency in cooling appliances. Over time, these seals can wear out, leading to air leaks that compromise functionality. Addressing these concerns promptly ensures the appliance operates effectively and prolongs its lifespan.

To identify seal problems, inspect the edges of the door for signs of wear or damage. A simple test involves closing the door on a piece of paper; if the paper slides out easily, the seal may need adjustment or replacement. Cleaning the seal with warm soapy water can also improve its performance.

If the seal is damaged, consider replacing it with a compatible part. Ensure the new seal fits snugly by following the manufacturer’s guidelines. For proper installation, remove the old seal, clean the surface, and carefully position the new one, making sure it adheres well to prevent any gaps.

Replacing the Refrigerator Light Bulb

Illumination within your cooling appliance is essential for visibility and organization. When the light source fails, it can be inconvenient, but replacing it is a straightforward task. This section outlines the necessary steps to restore light functionality effectively.

Before starting, ensure you have the appropriate replacement bulb. Follow these steps for a seamless process:

- Unplug the Appliance: Safety first! Disconnect the power supply to avoid any electrical hazards.

- Locate the Light Fixture: Identify the area where the light is situated, often found on the ceiling or side walls.

- Remove the Cover: If applicable, gently detach any plastic cover or lens protecting the bulb.

- Take Out the Old Bulb: Carefully twist or pull the old bulb to remove it from the socket.

- Insert the New Bulb: Align and secure the replacement bulb in the socket, ensuring a snug fit.

- Reattach the Cover: If a cover was present, replace it to safeguard the new bulb.

- Reconnect Power: Plug the appliance back in and check that the new bulb illuminates properly.

Following these simple steps will ensure your cooling unit is well-lit and functional once more.

Dealing with Frost Build-Up

Excessive ice accumulation can hinder the efficiency of cooling appliances, leading to potential issues with temperature regulation and overall functionality. Addressing this concern promptly can enhance performance and extend the lifespan of your unit.

Understanding the Causes

Several factors contribute to the formation of ice, including improper door sealing, high humidity levels, and frequent opening of the door. Recognizing these causes is crucial in effectively managing frost development.

Steps to Prevent Ice Accumulation

Implementing regular maintenance routines can significantly reduce frost build-up. Here are some recommended practices:

| Action | Frequency |

|---|---|

| Check door seals | Monthly |

| Defrost manually if needed | As required |

| Adjust temperature settings | Seasonally |

| Clean drain holes | Every 3 months |

By following these guidelines, you can minimize ice formation and ensure optimal operation of your cooling appliance.

Maintaining Proper Drainage Systems

Ensuring efficient drainage is crucial for optimal appliance performance. A well-functioning drainage system prevents water accumulation, which can lead to various operational issues. Regular attention to this aspect can enhance longevity and efficiency.

Regular Inspection: Routine checks of drainage pathways help identify any blockages or obstructions. Clear pathways ensure that excess moisture is directed away effectively.

Cleaning Practices: Employing appropriate cleaning techniques for drainage components is vital. Use gentle cleaners to remove buildup without causing damage. This practice can significantly reduce the risk of clogs.

Monitoring Performance: Keep an eye on how the drainage system operates. If there are signs of slow drainage or leaks, it may indicate a need for immediate attention. Quick intervention can prevent further complications.

Professional Assistance: When in doubt, consulting a technician can provide insights into maintaining and repairing drainage issues. Their expertise can offer tailored solutions to enhance system functionality.

Electrical Failures and Solutions

Electrical issues can significantly impact the functionality of cooling appliances. Identifying these problems early is crucial for maintaining efficiency and preventing further damage. Below are common electrical malfunctions and their respective solutions.

-

Power Supply Issues:

Inconsistent power sources may lead to operational failures. Check the outlet for proper voltage and ensure the appliance is securely plugged in.

-

Faulty Thermostat:

A malfunctioning thermostat can prevent the system from regulating temperature correctly. Test the thermostat settings and replace it if necessary.

-

Defective Start Relay:

If the unit fails to start, the start relay may be damaged. Inspect the relay and replace it to restore functionality.

-

Wiring Problems:

Frayed or damaged wiring can disrupt electrical flow. Examine the wiring for any visible signs of wear and repair or replace as needed.

-

Compressor Issues:

A malfunctioning compressor can lead to insufficient cooling. Listen for unusual sounds and consider consulting a professional for a thorough inspection.

Addressing these electrical failures promptly can enhance the longevity and performance of cooling units, ensuring they operate smoothly.

When to Call a Professional

Identifying the right moments to seek expert assistance can significantly impact the longevity and efficiency of your appliance. While some issues may seem manageable, there are certain signs that indicate professional intervention is necessary to avoid further complications.

Signs of Severe Malfunction

Persistent unusual noises, irregular temperature fluctuations, or leaks often suggest underlying problems that require specialized knowledge. If you notice these issues, it’s wise to consult a technician who can accurately diagnose and resolve the situation.

Complex Repairs Beyond Basic Skills

Attempting to fix intricate components without the proper training can lead to additional damage. If the task involves electrical systems or advanced mechanics, calling an expert ensures safety and restores functionality efficiently.