In the world of automotive maintenance, understanding the intricacies of power units is essential for enthusiasts and professionals alike. A thorough knowledge of the components and systems involved can significantly enhance performance and longevity. This section aims to provide valuable insights into the processes and techniques required for effective unit rejuvenation.

Addressing issues within these vital mechanical assemblies requires precision and attention to detail. From disassembly to reassembly, each step must be executed with care to ensure optimal functionality. Whether you’re tackling minor adjustments or extensive modifications, a solid foundation in the underlying principles is crucial for success.

As you delve into the intricacies of these systems, you’ll encounter various challenges and opportunities for enhancement. Equipped with the right information and techniques, you can confidently navigate the complexities involved, ultimately leading to improved performance and reliability. This guide serves as a comprehensive resource for anyone looking to master the art of power unit refurbishment.

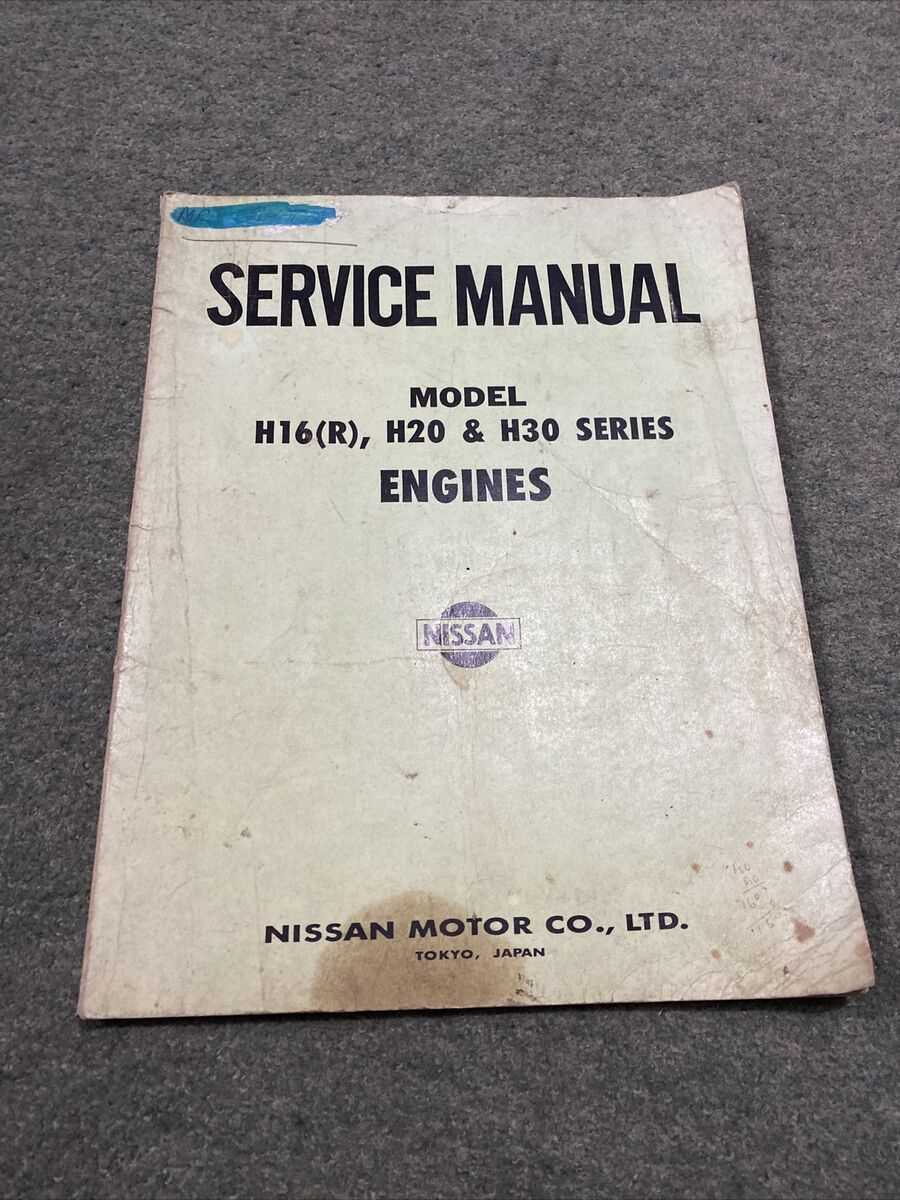

Nissan H20 Engine Overview

This section provides a comprehensive understanding of a specific power unit known for its reliability and performance. Designed with simplicity in mind, this motor features a straightforward construction that appeals to both enthusiasts and mechanics alike.

Characterized by its inline configuration and modest displacement, this unit offers a balanced blend of efficiency and power output. Its design allows for easy maintenance and accessibility, making it a popular choice among various vehicle models. The components work harmoniously, ensuring smooth operation and longevity under normal driving conditions.

Developed with a focus on durability, this power unit is equipped with essential features that enhance its overall performance. Whether used for daily commuting or light-duty applications, it delivers consistent results, making it a trusted option for many vehicle owners.

Understanding the specifications and operational principles of this motor is crucial for anyone looking to optimize its performance or carry out necessary maintenance tasks. With proper care, this unit can provide dependable service for years to come.

Common Issues with H20 Engines

Understanding the typical problems associated with certain automotive power units can significantly enhance maintenance and longevity. Owners often encounter a range of malfunctions that can stem from various factors, including design flaws, manufacturing defects, or inadequate upkeep.

Frequent Problems

- Overheating: Insufficient coolant flow or a malfunctioning thermostat can lead to excessive temperatures.

- Oil Leaks: Deteriorating seals or gaskets may result in lubrication loss, impacting performance.

- Poor Fuel Efficiency: Clogged injectors or air filters can decrease mileage and increase emissions.

- Starting Difficulties: Issues with the ignition system or battery can cause unreliable starting.

Identifying Symptoms

Being aware of specific indicators can aid in early diagnosis. Common signs include:

- Unusual noises from the power unit.

- Warning lights illuminating on the dashboard.

- Excessive smoke from the exhaust.

- Vibrations during operation.

Regular inspections and prompt attention to these symptoms can help mitigate long-term damage and ensure optimal performance.

Tools Needed for Repairs

Successful maintenance of any automotive system requires a variety of instruments tailored to specific tasks. These tools facilitate efficient troubleshooting and enable precise adjustments, ensuring optimal functionality. Having the right equipment at hand is crucial for both novices and experienced technicians, making the process smoother and more effective.

Essential Hand Tools

A well-stocked toolkit should include wrenches, screwdrivers, pliers, and sockets in various sizes. These basic instruments are fundamental for loosening or tightening components. Additionally, torque wrenches are vital for applying the correct amount of force to fasteners, preventing damage and ensuring safety.

Specialized Equipment

Beyond standard hand tools, certain specialized devices may be necessary for specific tasks. Diagnostic scanners help identify issues by reading error codes, while compression testers assess the health of the system. Oil filters, replacement belts, and gaskets are also important to have on hand for routine upkeep.

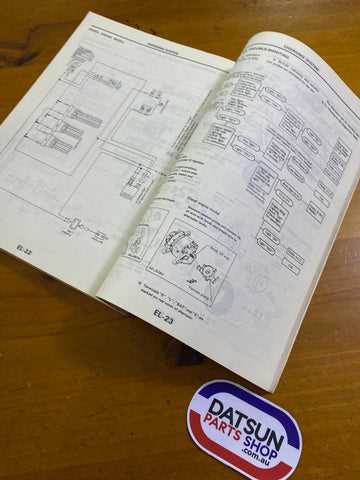

Step-by-Step Repair Process

This section outlines a comprehensive guide for the systematic approach to overhauling and rejuvenating the internal components of a specific automotive unit. Following a structured method ensures efficiency and effectiveness throughout the task, minimizing the risk of complications and enhancing overall performance.

Preparation and Initial Assessment

Before diving into the task, it is crucial to prepare adequately and conduct a thorough evaluation. Gather the necessary tools and materials, and assess the condition of the components to identify any visible damage or wear. This initial step is essential for planning subsequent actions.

Disassembly and Inspection

Once the initial assessment is complete, proceed with disassembling the various parts carefully. Document each step to facilitate reassembly. During this phase, inspect each component for signs of wear, corrosion, or other issues that may require attention.

| Component | Common Issues | Recommended Actions |

|---|---|---|

| Piston | Scoring, Cracking | Replace or Refinish |

| Crankshaft | Wear, Misalignment | Regrind or Replace |

| Camshaft | Wear, Bending | Inspect and Replace if Necessary |

Careful attention to detail during these stages will significantly influence the longevity and performance of the entire system once it is reassembled. After addressing any issues, prepare for reassembly with the necessary parts and tools at hand.

Engine Disassembly Techniques

Disassembling a power unit requires careful planning and a systematic approach to ensure all components are handled correctly. Mastering the art of dismantling can enhance your understanding of the unit’s architecture and facilitate effective reassembly.

Here are essential techniques to consider when embarking on this task:

- Preparation:

- Gather all necessary tools and equipment.

- Ensure a clean and organized workspace.

- Review relevant documentation to familiarize yourself with the assembly layout.

- Labeling Components:

- Use tags or markers to identify parts as they are removed.

- Take photographs during the disassembly process for reference.

- Systematic Approach:

- Follow a logical order, starting from the exterior and moving inward.

- Keep track of fasteners and small parts in labeled containers.

- Handling Sensitive Parts:

- Use caution with fragile components, ensuring they are supported properly.

- Apply appropriate techniques for removing seals and gaskets to avoid damage.

- Documentation:

- Take notes during the process to document any challenges or observations.

- Record torque specifications for reassembly purposes.

By following these methods, you will not only safeguard the integrity of the components but also streamline the process of reassembly, making your project more efficient and successful.

Replacing Worn Components

Maintaining optimal performance in machinery often involves the timely substitution of degraded parts. This process not only enhances efficiency but also prolongs the lifespan of the entire system. Identifying and replacing these components is crucial to avoid further damage and ensure smooth operation.

Identifying Worn Parts

Before any replacements can occur, it is essential to accurately assess which parts require attention. Regular inspections can reveal signs of wear. Here are some indicators to watch for:

- Unusual noises during operation

- Increased vibration levels

- Fluid leaks or discoloration

- Decreased performance or efficiency

Replacement Process

Once worn components have been identified, the next step is to execute their replacement. Follow these general steps for effective component substitution:

- Gather necessary tools and replacement parts.

- Disconnect power sources to prevent accidental activation.

- Carefully remove the damaged components, noting any specific installation configurations.

- Install new parts, ensuring proper alignment and secure fitting.

- Reconnect power sources and perform a thorough check for any issues.

By diligently replacing worn components, one can maintain operational integrity and enhance the overall functionality of the system.

Reassembly and Torque Specifications

The process of reassembling mechanical components requires careful attention to detail and adherence to precise measurements. Ensuring that each part is fitted correctly and secured with the appropriate force is essential for optimal performance and longevity. This section outlines the necessary guidelines to follow during reassembly, focusing on torque settings to prevent potential issues in the future.

Reassembly Steps

Begin by thoroughly cleaning all components to remove any debris or old sealants. Align the parts as per the specifications and ensure that all surfaces are free from damage. Use new gaskets and seals where applicable to avoid leaks. When positioning the components, double-check that all alignment marks are properly matched to maintain the integrity of the assembly.

Torque Specifications

Proper torque settings are critical to ensure that each connection is secure. Use a calibrated torque wrench for accuracy. It is recommended to follow a specific sequence when tightening fasteners, often starting from the center and moving outward. Refer to the provided specifications for the exact torque values, typically measured in foot-pounds or Newton-meters. Always adhere to the manufacturer’s guidelines, as overtightening can lead to material failure, while undertightening may result in loose connections.

Remember: Regularly verify the calibration of your tools and consider re-checking torque values after a short operational period to ensure continued reliability.

Testing Engine Performance After Repair

Ensuring optimal functionality of a power unit following maintenance is crucial for the longevity and efficiency of the vehicle. Conducting a series of evaluations helps in verifying that all components are operating as intended and that the overall performance meets expected standards.

Initial Diagnostics

Before any performance tests, it is essential to carry out preliminary diagnostics. This includes checking for any error codes using a diagnostic scanner, inspecting fluid levels, and ensuring all connections are secure. Addressing any detected issues at this stage can prevent complications during performance evaluations.

Performance Testing Procedures

Once initial diagnostics are complete, various tests can be performed to assess the unit’s output. Acceleration tests can reveal responsiveness, while idle tests help evaluate stability at low RPMs. Monitoring fuel consumption and exhaust emissions during these evaluations provides insight into the efficiency and environmental impact of the system. Gathering data from these tests will confirm whether the maintenance work has achieved the desired results.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle involves regular care and attention. Adopting proactive measures can significantly extend the lifespan and performance of critical components. Here are some essential practices to keep in mind.

- Regular Oil Changes: Frequent oil changes help maintain lubrication and reduce wear on moving parts.

- Fluid Checks: Regularly inspect and top off fluids, including coolant, transmission fluid, and brake fluid, to prevent overheating and system failures.

- Air Filter Replacement: Keep the air intake clean by replacing the air filter as needed to ensure optimal airflow and efficiency.

- Inspect Belts and Hoses: Periodically check for signs of wear or cracking in belts and hoses to avoid breakdowns.

- Tire Maintenance: Regularly check tire pressure and tread depth, and rotate tires to promote even wear and improve handling.

By incorporating these simple yet effective maintenance routines, you can enhance the reliability and longevity of your vehicle, ensuring it remains in excellent condition for years to come.

FAQs About H20 Engine Repairs

This section addresses common inquiries related to maintenance and troubleshooting for specific automotive components. Understanding these aspects can significantly aid in ensuring optimal performance and longevity.

What are the signs that indicate a need for maintenance?

Look for unusual noises, decreased performance, or warning lights on the dashboard. Regular checks can help catch issues early.

How often should regular checks be performed?

It is advisable to conduct assessments every few thousand miles or as specified in your vehicle’s specifications. Consistent monitoring can prevent larger problems.

Can I perform maintenance tasks myself?

Many basic tasks, such as checking fluid levels or replacing filters, can be done at home. However, complex issues may require professional assistance.

What tools are essential for basic maintenance?

A set of wrenches, screwdrivers, and a torque wrench are fundamental. Additionally, having a diagnostic tool can be beneficial for identifying specific issues.

How can I ensure quality parts are used?

Always source components from reputable suppliers. Researching brands and reading reviews can lead to informed decisions.

What should I do if I encounter an unfamiliar problem?

Consulting a specialist is recommended if you encounter unexpected issues. They possess the expertise to diagnose and resolve complications efficiently.