When it comes to maintaining a two-wheeled vehicle, having access to comprehensive guidelines is essential. These documents provide detailed insights into the various components and systems that make up the machine, ensuring that riders can keep their vehicles in optimal condition. Understanding how to troubleshoot common issues and perform regular upkeep is crucial for longevity and performance.

Within these guidelines, you will find structured information on everything from engine specifications to electrical systems. The emphasis is on practical advice, enabling enthusiasts and mechanics alike to approach maintenance tasks with confidence. By following the suggested procedures, owners can effectively manage their vehicles, preventing minor problems from escalating into major repairs.

Moreover, this resource serves as a valuable reference for anyone looking to enhance their knowledge of motorcycle mechanics. Whether you are a seasoned rider or a newcomer, familiarizing yourself with the essential practices outlined will help you achieve a deeper appreciation for the engineering behind your vehicle. Ultimately, the goal is to foster a safe and enjoyable riding experience.

Suzuki DRZ 400 Repair Manual

This section aims to provide essential guidance for maintaining and troubleshooting a popular off-road vehicle. Understanding the various components and procedures involved in keeping the machine in optimal condition is crucial for any enthusiast. Whether you’re a novice or an experienced rider, having a reliable reference can enhance your overall experience.

Maintenance Guidelines

Regular upkeep is vital to ensure the longevity and performance of your vehicle. Basic tasks such as oil changes, air filter cleaning, and chain adjustments should be performed periodically. Following a structured maintenance schedule not only keeps the machine running smoothly but also prevents potential issues from escalating.

Troubleshooting Common Issues

When facing problems, it is essential to diagnose them accurately. Common challenges may include starting difficulties, unusual noises, or performance drops. A systematic approach to troubleshooting can help identify the root cause and facilitate effective solutions. Referencing detailed procedures will assist in resolving these issues efficiently.

Understanding the Engine Components

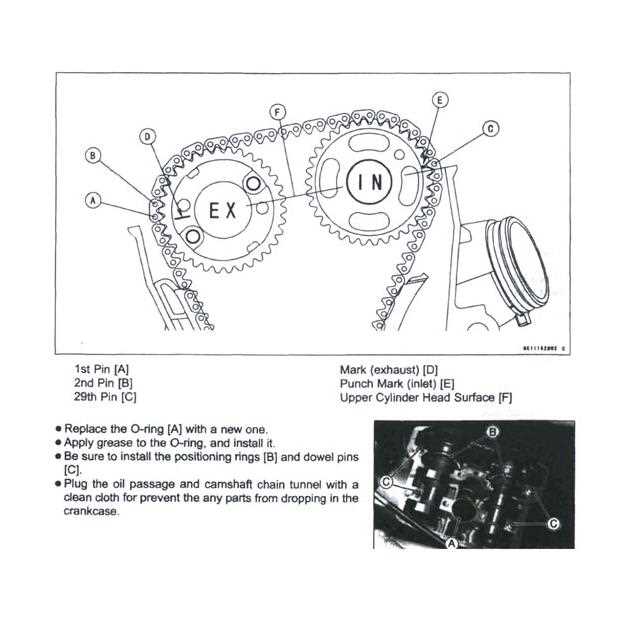

Grasping the intricacies of the power unit is essential for optimal performance and maintenance of any two-wheeled vehicle. This segment delves into the various elements that make up the engine, shedding light on their functions and interrelationships, ultimately contributing to the overall efficiency of the machine.

Core Elements of the Power Unit

The primary constituents of the engine include the cylinder, piston, and crankshaft. The cylinder serves as the chamber where fuel combustion occurs, while the piston moves up and down within it, transforming the energy from the burning fuel into mechanical motion. The crankshaft then converts this linear movement into rotational energy, powering the drivetrain and enabling motion.

Supporting Systems and Their Roles

In addition to the core components, auxiliary systems such as the lubrication and cooling systems play crucial roles in maintaining engine health. The lubrication system ensures that moving parts are adequately coated, reducing friction and wear, while the cooling system prevents overheating, allowing the engine to operate within its optimal temperature range.

Routine Maintenance Procedures Explained

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. This section outlines fundamental tasks that should be conducted consistently to maintain functionality and safety. Adopting these practices can prevent costly repairs and enhance the riding experience.

Essential Upkeep Tasks

The following table summarizes key maintenance activities and their recommended frequency:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 3,000 miles or annually |

| Air Filter Inspection | Every 2,000 miles |

| Tire Pressure Check | Monthly |

| Brake Fluid Replacement | Every 2 years |

| Chain Lubrication | Every 500 miles |

Importance of Consistency

Following a regular maintenance schedule not only extends the life of your vehicle but also enhances safety. Consistent checks and servicing allow for the early detection of potential issues, enabling timely interventions and reducing the likelihood of breakdowns.

Troubleshooting Common Issues

Identifying and resolving frequent problems can significantly enhance the performance and longevity of your two-wheeled vehicle. By understanding typical symptoms and their potential causes, riders can take informed steps toward effective solutions, ensuring a smoother and safer riding experience.

Engine Performance Problems

One of the most common issues riders encounter is a decline in engine performance. Symptoms may include difficulty starting, stalling, or loss of power while accelerating. These issues can often stem from fuel delivery problems, such as a clogged filter or issues with the carburetor. Regular maintenance and inspection of fuel components are essential for optimal functionality.

Electrical System Failures

Another frequent concern involves electrical system malfunctions. Signs of electrical issues include dim lights, faulty indicators, or a dead battery. These problems can arise from corroded connections, worn-out components, or inadequate charging. It is vital to regularly check wiring and connections to prevent unexpected breakdowns.

Electrical System Diagnostics

Diagnosing issues within the electrical framework of a two-wheeled vehicle is crucial for ensuring optimal performance and reliability. This process involves assessing various components to identify malfunctions and facilitate effective repairs. Understanding the interconnectedness of the electrical parts helps in pinpointing faults efficiently.

Key Components to Examine

Begin by inspecting the battery, as it serves as the primary power source. Check for proper voltage levels and physical condition. Next, examine wiring harnesses for any signs of wear or damage, as frayed wires can lead to short circuits. Additionally, evaluate the ignition system components, including the spark plug and coils, ensuring they function correctly.

Diagnostic Tools and Techniques

Utilizing a multimeter is essential for measuring voltage, current, and resistance throughout the system. By following a systematic approach, such as starting from the battery and working through each component, technicians can isolate problems more effectively. Regular diagnostic checks can help maintain the health of the electrical system and prevent future issues.

Transmission and Gear Adjustments

The efficiency of a motorcycle’s power delivery largely depends on the quality of its transmission system and the proper alignment of gears. Understanding how to make adjustments and perform maintenance on these components can significantly enhance performance and prolong the lifespan of the vehicle.

Importance of Proper Gear Alignment

Accurate gear alignment is crucial for smooth operation. Misalignment can lead to excessive wear and can affect acceleration and overall riding experience. Regular checks should be conducted to ensure optimal performance.

Adjustment Procedures

To adjust the transmission system effectively, follow these guidelines:

| Step | Action |

|---|---|

| 1 | Inspect the gear linkage for any wear or damage. |

| 2 | Adjust the cable tension to achieve proper shifting. |

| 3 | Ensure the clutch engages smoothly and does not slip. |

| 4 | Check the oil level in the transmission for optimal lubrication. |

Brake System Inspection Techniques

Proper evaluation of the braking mechanism is crucial for ensuring safety and optimal performance of any vehicle. Regular checks can help identify potential issues before they become significant problems. This section outlines various techniques that can be employed to assess the functionality and integrity of the braking system effectively.

Begin by visually examining all components for signs of wear, damage, or corrosion. Focus on brake pads, discs, and calipers, ensuring that no abnormal wear patterns are present. It is also essential to check the fluid levels and look for leaks around the brake lines and fittings, as fluid loss can severely impact braking efficiency.

Next, perform a physical inspection by testing the responsiveness of the brakes. Engage the brake lever and assess the feel; it should provide a firm resistance without excessive travel. Additionally, consider checking the alignment of the wheels to ensure proper contact with the braking surfaces. Any misalignment can lead to uneven wear and reduced effectiveness.

Finally, conduct a functional test while the vehicle is in a controlled environment. This should include gradual braking from various speeds to evaluate performance under different conditions. Pay attention to any unusual noises, vibrations, or pulling to one side, as these can indicate underlying issues requiring further attention.

Suspension Setup and Tuning

Achieving optimal performance from your off-road vehicle relies heavily on proper adjustment of the suspension system. This process involves fine-tuning various components to enhance handling, comfort, and stability across different terrains. Understanding the key aspects of suspension configuration is essential for maximizing both safety and enjoyment during rides.

Adjusting Spring Preload

Spring preload plays a crucial role in determining the ride height and overall feel of the suspension. By adjusting the preload, you can change how the vehicle reacts to bumps and rough surfaces. Increasing preload stiffens the suspension, making it better suited for aggressive riding, while reducing it allows for a softer feel, ideal for navigating obstacles smoothly.

Fine-Tuning Compression and Rebound Damping

Compression and rebound damping settings control how quickly the suspension responds to impacts and recovers after compression. Properly tuning these settings helps in maintaining traction and stability. A firmer compression setting can provide better control during fast riding, while a slower rebound can help absorb larger impacts without causing the suspension to bottom out.

Wheel and Tire Maintenance

Proper care and upkeep of wheels and tires are essential for optimal performance and safety. Regular inspection and maintenance can significantly extend the lifespan of these components while enhancing overall handling and stability. Understanding key practices is vital for maintaining functionality and preventing potential issues.

Regular Inspection Procedures

Routine checks should include examining tread depth, looking for any signs of damage, and ensuring proper inflation levels. Worn or damaged tires can affect traction and braking efficiency, making it critical to address any concerns promptly. Additionally, monitoring for uneven wear patterns can indicate alignment or suspension issues that require attention.

Inflation and Pressure Guidelines

Maintaining the correct tire pressure is crucial for both performance and safety. Under-inflated tires can lead to overheating and increased wear, while over-inflation can cause reduced traction and handling difficulties. Always refer to the manufacturer’s specifications for recommended pressure levels and check them regularly to ensure optimal performance.

Fuel System Cleaning Methods

Maintaining a clean fuel delivery system is essential for optimal engine performance. Over time, contaminants can build up, affecting fuel flow and combustion efficiency. Implementing effective cleaning techniques can help restore functionality and extend the lifespan of the system.

Mechanical Cleaning: This method involves the physical removal of deposits and debris from various components, such as injectors and fuel lines. Specialized tools, including brushes and ultrasonic cleaners, can be utilized to ensure thorough cleaning without damaging sensitive parts.

Chemical Cleaning: Utilizing cleaning agents designed to dissolve varnish and sludge can significantly improve fuel system performance. These products are often introduced through the fuel tank or directly into the fuel rail, effectively breaking down build-up and enhancing the overall fuel flow.

Routine Maintenance: Regular inspections and maintenance can prevent major build-up issues. Replacing fuel filters and using quality fuel additives can help maintain a clean system, ensuring consistent performance and reducing the risk of clogs.

Bodywork and Fairing Repairs

Maintaining the exterior components of your vehicle is essential for both aesthetics and functionality. This section provides guidance on how to address common issues with the outer coverings and associated parts. Proper care and attention can extend the life of these elements and enhance the overall appearance of your machine.

Identifying Common Damage

Visual inspections play a crucial role in recognizing wear and tear on outer surfaces. Look for cracks, scratches, or dents that may compromise structural integrity or visual appeal. Promptly addressing these imperfections can prevent further deterioration and costly replacements.

Repair Techniques

Several methods exist for fixing damaged components. For minor scratches, polishing compounds can effectively restore shine. In cases of deeper cracks, using appropriate adhesives or fillers may be necessary. Ensure to follow the manufacturer’s recommendations for best practices to achieve durable results.

Upgrading Performance Parts

Enhancing the efficiency and capabilities of your motorcycle can lead to a more exhilarating riding experience. By focusing on specific components, enthusiasts can significantly improve speed, handling, and overall performance. This section explores various upgrades that can transform your machine into a high-performing powerhouse.

Engine Modifications: Upgrading the engine can unleash additional horsepower and torque. Consider investing in high-performance air filters, exhaust systems, and tuning kits that optimize fuel delivery. These enhancements can greatly improve throttle response and acceleration.

Suspension Improvements: A well-tuned suspension is crucial for stability and comfort. Upgrading to adjustable shocks and springs allows riders to customize their setup for different terrains. Enhanced dampening and preload adjustments can lead to better handling and a smoother ride.

Brake System Enhancements: Safety is paramount, and improving your braking system can make a significant difference. Consider installing larger rotors, high-performance brake pads, and braided stainless steel lines. These modifications provide better stopping power and increased responsiveness.

Safety Checks Before Riding

Before embarking on any journey, it is crucial to ensure that your vehicle is in optimal condition. Regular inspections help prevent accidents and ensure a smooth ride. A comprehensive safety check can significantly enhance your riding experience and maintain the longevity of your machine.

Essential Components to Inspect

- Tires: Check for proper inflation and tread wear.

- Brakes: Ensure brake pads are sufficient and brake fluid is at the correct level.

- Lights: Test headlights, taillights, and turn signals for functionality.

- Chain: Inspect for wear and adequate lubrication.

Additional Considerations

- Ensure that mirrors are correctly adjusted for optimal visibility.

- Verify that all fluids, including oil and coolant, are at appropriate levels.

- Confirm that safety gear is in good condition and readily available.

By performing these checks, you can enhance safety and confidence while riding. Prioritizing maintenance not only protects you but also contributes to the well-being of others on the road.