Ensuring optimal performance and longevity of small engine equipment is crucial for both hobbyists and professionals. Understanding the intricacies of these machines helps users troubleshoot issues effectively. This section delves into essential practices for maintaining and restoring these power units, equipping you with the knowledge needed to enhance their efficiency.

Every engine, regardless of its brand, requires routine attention to remain in peak condition. By familiarizing yourself with fundamental components and their functions, you can easily identify common problems. This guide emphasizes practical solutions and preventative measures that will empower you to take charge of your machinery’s upkeep.

Through careful examination and consistent maintenance, you can significantly extend the life of your equipment. Engaging with this informative resource will enable you to navigate the various aspects of engine care, ultimately leading to improved performance and reliability.

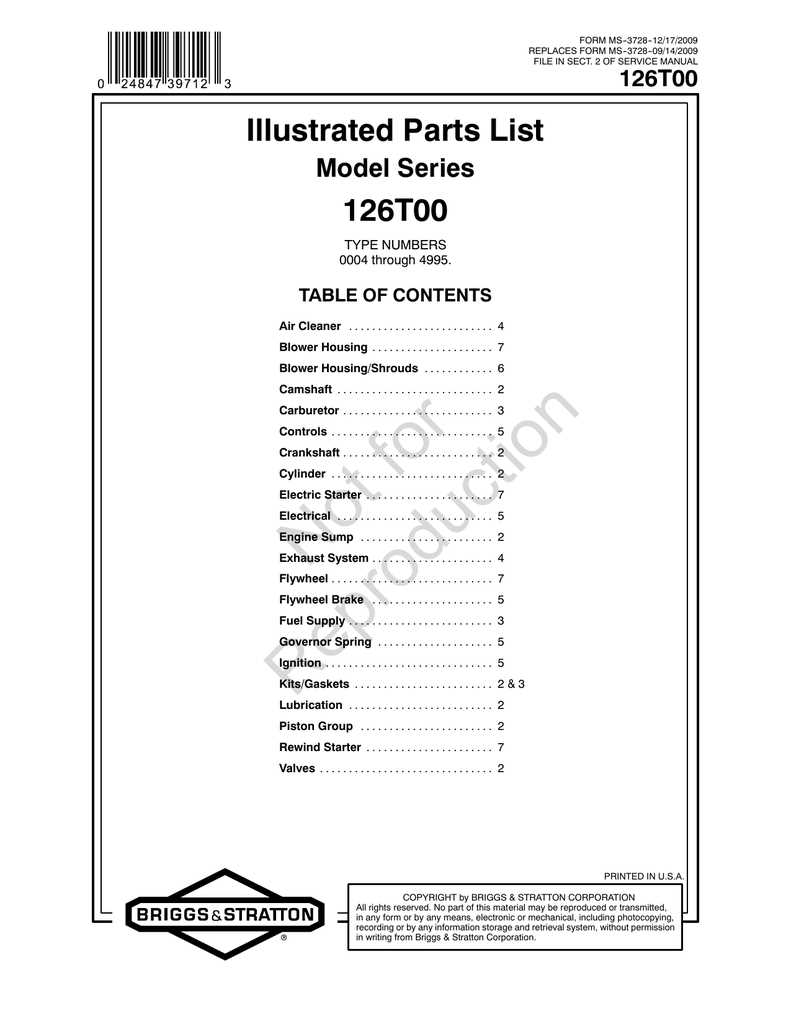

Understanding Briggs Stratton 126T02

This section delves into the essential aspects of a specific engine model, focusing on its features and functionality. Knowledge of this machinery is crucial for effective maintenance and troubleshooting, ensuring optimal performance in various applications.

The engine in question is widely recognized for its durability and efficiency. It is commonly employed in numerous outdoor power equipment, showcasing its versatility across different tasks. Understanding the specifications and operating principles can significantly enhance the user’s ability to manage the equipment effectively.

Familiarity with the common issues associated with this model can aid in timely interventions, thus extending its lifespan. Regular checks and basic servicing are recommended practices that can prevent more significant problems in the future. This approach not only preserves the engine’s functionality but also ensures safety during operation.

Common Issues and Solutions

This section addresses frequent challenges encountered with outdoor power equipment, providing practical solutions to enhance performance and longevity. Understanding these common problems can help users maintain their devices effectively.

Engine Won’t Start

If the engine fails to start, it may be due to fuel supply issues, a dead battery, or a malfunctioning spark plug. Ensure that the fuel is fresh and correctly mixed. Check the battery charge and connections. Inspect the spark plug for wear and replace it if necessary.

Overheating

Overheating can result from a clogged air filter, low oil levels, or blocked cooling fins. Regularly clean or replace the air filter, maintain proper oil levels, and ensure that the cooling fins are free of debris.

Uneven Power Output

Inconsistent power may be attributed to a dirty carburetor or fuel line obstructions. Cleaning the carburetor and inspecting the fuel lines for blockages can restore stable performance.

Excessive Vibration

Vibrations can occur due to loose components or imbalanced blades. Tighten all screws and bolts, and check the blades for damage or imbalance. Replacing worn blades can also alleviate excessive shaking.

Tools Needed for Repairs

Having the right equipment is essential for successful maintenance tasks. Proper tools not only facilitate the process but also ensure safety and efficiency during work. Familiarity with the necessary instruments can make a significant difference in achieving optimal results.

Essential Instruments

Various instruments are crucial for effective maintenance. A basic toolkit typically includes wrenches, screwdrivers, and pliers. These tools allow for easy disassembly and reassembly of components. Additionally, a torque wrench ensures that fasteners are secured to the correct specifications, preventing damage.

Specialized Equipment

Some tasks may require specialized instruments. A multimeter is invaluable for diagnosing electrical issues, while a compression tester can evaluate engine performance. Safety gear, such as gloves and goggles, should also be on hand to protect the technician during the process.

Step-by-Step Repair Guide

This section provides a comprehensive overview of the processes involved in fixing small engine issues. The aim is to equip users with the knowledge and techniques necessary to address common problems effectively. By following the outlined steps, you can ensure optimal performance and longevity of your equipment.

Begin by gathering all essential tools and materials, ensuring a clean and organized workspace. This preparation facilitates smoother progress through each phase of the task. Take time to understand the engine’s components and their functions, as this knowledge is crucial for successful troubleshooting.

Next, identify the symptoms that indicate malfunction. Observing unusual noises, vibrations, or performance declines can guide you to the root cause. Once you have pinpointed the issue, refer to the troubleshooting checklist, which outlines potential problems and corresponding solutions.

As you proceed, document each step taken, including any parts replaced or adjusted. This log will be invaluable for future reference and maintenance. Always prioritize safety by disconnecting the spark plug before starting any disassembly.

Finally, after completing the necessary adjustments, reassemble all components carefully. Conduct a thorough inspection to ensure everything is properly secured. Once reassembled, perform a test run to confirm that the engine operates smoothly and effectively.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your outdoor equipment. By following a few simple guidelines, you can significantly extend the lifespan of your machinery and maintain its optimal performance. Regular attention to details will help prevent common issues that may arise over time.

Here are some key practices to keep in mind:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Check oil levels | Every use | Prevents engine wear and overheating |

| Clean air filter | Monthly | Improves airflow and efficiency |

| Inspect spark plug | Every season | Ensures reliable starting and performance |

| Sharpen blades | As needed | Enhances cutting efficiency and quality |

| Check for leaks | Regularly | Prevents fluid loss and environmental hazards |

By implementing these straightforward practices, you will not only enhance the reliability of your equipment but also enjoy its benefits for years to come. Consistent maintenance is key to avoiding costly repairs and ensuring smooth operation.

Parts Identification and Replacement

Understanding the components of a small engine is essential for effective maintenance and functionality. Recognizing individual parts allows for timely interventions and helps in prolonging the lifespan of the equipment. This section focuses on identifying essential components and their appropriate substitutes.

When examining the engine, key parts include the carburetor, spark plug, and fuel filter. Each of these elements plays a vital role in ensuring smooth operation. Carburetors mix air and fuel, while spark plugs ignite the mixture, and fuel filters clean the fuel before it reaches the engine.

For replacement, it is crucial to select compatible parts that meet the specifications of the engine model. Checking the manufacturer’s guidelines or consulting with a knowledgeable dealer can assist in sourcing the correct items. Regular inspections can also prevent unexpected breakdowns by identifying worn or damaged components early on.

Engine Specifications Overview

This section provides a comprehensive look at the fundamental characteristics of the engine in question. Understanding these specifications is essential for effective operation and maintenance, ensuring optimal performance over time.

Key Features

- Type: Four-stroke, air-cooled engine

- Displacement: Approximately 150 cc

- Power Output: Ranges between 3 to 5 horsepower

- Fuel Type: Unleaded gasoline

- Oil Capacity: Typically around 0.6 liters

Performance Metrics

- Operating Speed: Standard RPM range of 3600

- Torque: Peak torque delivered at around 2500 RPM

- Cooling System: Air-cooled design for efficient temperature management

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Understanding potential hazards and implementing appropriate measures can significantly reduce risks associated with the process.

First and foremost, always wear suitable protective gear, including gloves, goggles, and sturdy footwear. This equipment serves as a barrier against sharp objects, chemicals, and heavy components.

Before starting any work, ensure the equipment is powered down and disconnected from any power source. This action minimizes the chances of accidental activation, which can lead to serious injuries.

Additionally, maintain a clean and organized workspace. Clutter can create hazards and increase the likelihood of mishaps. Keep tools and materials in designated areas to facilitate safe and efficient work.

Finally, familiarize yourself with the specific features and functions of the equipment you are handling. Understanding the machinery will aid in identifying potential risks and employing appropriate safety measures.

Troubleshooting Common Problems

This section provides guidance on identifying and resolving frequent issues that may arise with small engines. Understanding these common challenges can facilitate efficient maintenance and enhance the performance of the machinery.

Some typical problems include:

- Engine Won’t Start: Ensure the fuel is fresh, the battery is charged, and all connections are secure.

- Inefficient Performance: Check the air filter for clogs and inspect the spark plug for wear.

- Unusual Noises: Listen for any abnormal sounds which may indicate loose parts or low oil levels.

- Overheating: Verify that the cooling fins are clean and unobstructed, and that the oil level is adequate.

By systematically addressing these areas, one can often resolve issues effectively and maintain optimal operation.

Importance of Regular Servicing

Maintaining machinery is crucial for ensuring optimal performance and longevity. Regular servicing helps identify potential issues before they escalate, ultimately saving time and resources. It contributes to the smooth operation of equipment, minimizing unexpected breakdowns and enhancing efficiency.

Frequent checks allow for the timely replacement of worn components, which can prevent costly repairs in the long run. Additionally, servicing ensures that all parts are functioning correctly and safely, promoting a secure working environment.

| Benefits of Regular Maintenance | Description |

|---|---|

| Increased Lifespan | Routine care significantly extends the operational life of the equipment. |

| Enhanced Performance | Well-maintained machines operate more efficiently, improving overall productivity. |

| Cost Savings | Early detection of issues can lead to reduced repair costs and downtime. |

| Safety Assurance | Regular inspections help ensure that equipment meets safety standards, protecting users. |

Where to Find Replacement Parts

Finding suitable components for your machinery is essential for maintaining optimal performance and longevity. Numerous sources offer a wide variety of parts, ensuring you can easily access what you need for repairs or upgrades.

- Local Hardware Stores: Many community hardware outlets stock common replacement components and can assist with special orders.

- Online Retailers: Numerous websites specialize in selling parts, often providing detailed descriptions and specifications to help you select the correct items.

- Manufacturer’s Websites: Directly visiting the manufacturer’s site can yield original parts and may include helpful resources for identification.

- Specialty Parts Suppliers: Some suppliers focus exclusively on parts for specific machinery types, often providing expert advice and assistance.

- Second-Hand Marketplaces: Online platforms for used goods can be a cost-effective solution for sourcing rare or discontinued components.

Exploring these options will enhance your chances of finding the appropriate items for your needs, ensuring your equipment remains functional and efficient.