When it comes to the longevity and performance of heavy machinery, effective upkeep is essential. Comprehensive resources provide vital insights into maintaining complex systems, ensuring they operate smoothly under demanding conditions. Knowledge of troubleshooting techniques and maintenance schedules empowers operators to tackle issues proactively, reducing downtime and enhancing productivity.

In-depth guidance on engine components and functionality is invaluable for technicians and enthusiasts alike. Familiarity with various parts, their interrelationships, and common failure points equips users with the tools needed to identify problems early. Such awareness not only saves time but also minimizes repair costs by addressing issues before they escalate.

Resources that delve into systematic approaches for servicing engines serve as a roadmap for best practices. By understanding the nuances of engine operation, users can develop a tailored maintenance strategy that aligns with specific operational demands. This not only maximizes efficiency but also ensures that machinery remains in peak condition for years to come.

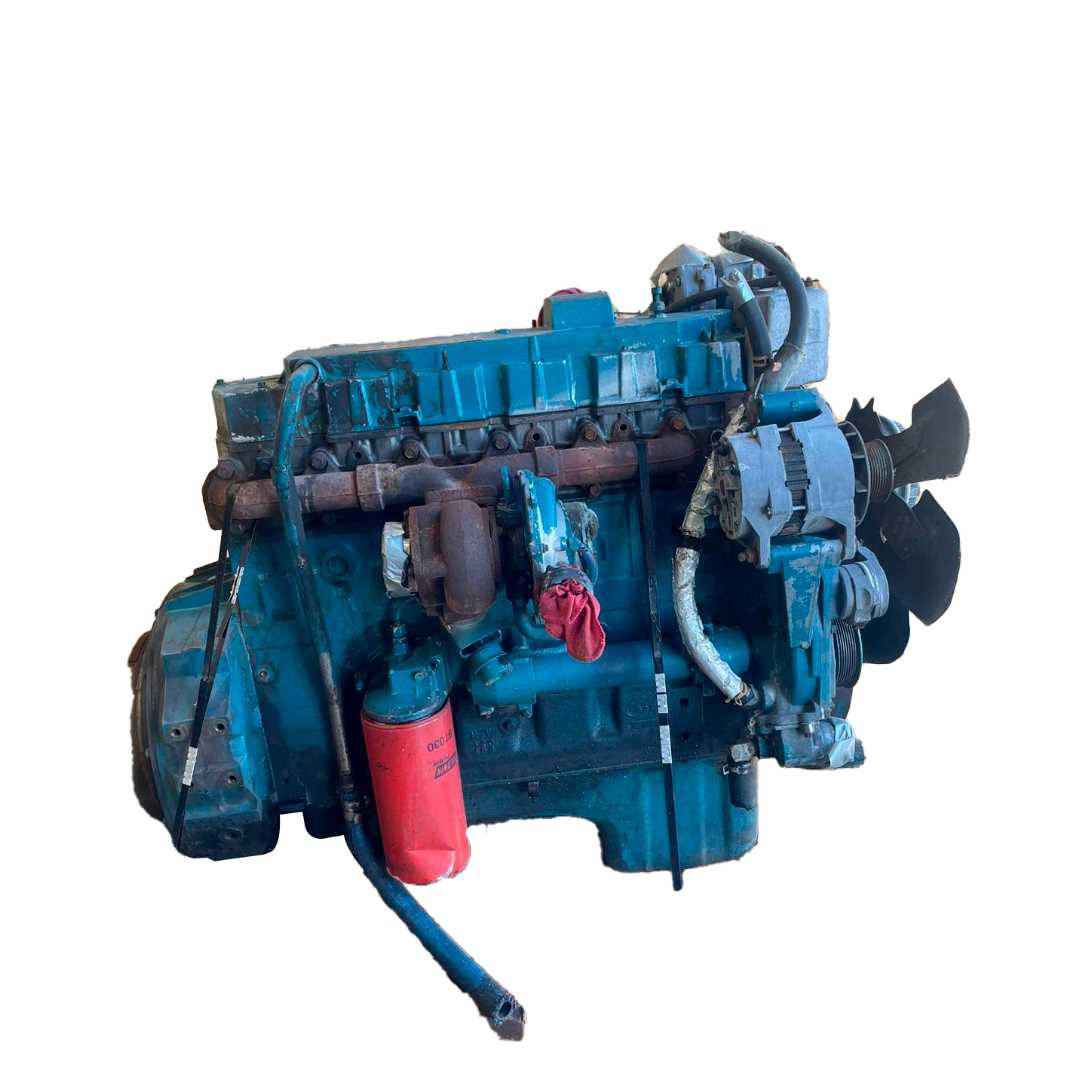

Overview of Navistar DT466E Engine

The engine in question is known for its robust design and reliability, making it a preferred choice in various heavy-duty applications. It combines advanced engineering with high performance, ensuring that it meets the demands of both commercial and industrial use. This powertrain is characterized by its durability, efficiency, and ease of maintenance, which contribute to its longstanding popularity in the market.

Key Features

This power unit features a powerful inline configuration, which allows for a smooth operation and effective torque delivery. Additionally, it is equipped with modern fuel injection technology that enhances fuel efficiency and reduces emissions. The construction materials used are selected to withstand harsh environments, ensuring longevity and consistent performance over time.

Applications

Common Issues with DT466E Engines

Engines of this particular type are known for their durability and reliability, yet they can experience certain challenges over time. Understanding these frequent problems can aid in maintaining performance and extending the lifespan of the unit.

Oil Leakage is a prevalent concern, often stemming from worn gaskets or seals. This can lead to significant oil loss, resulting in decreased lubrication and potential engine damage if not addressed promptly.

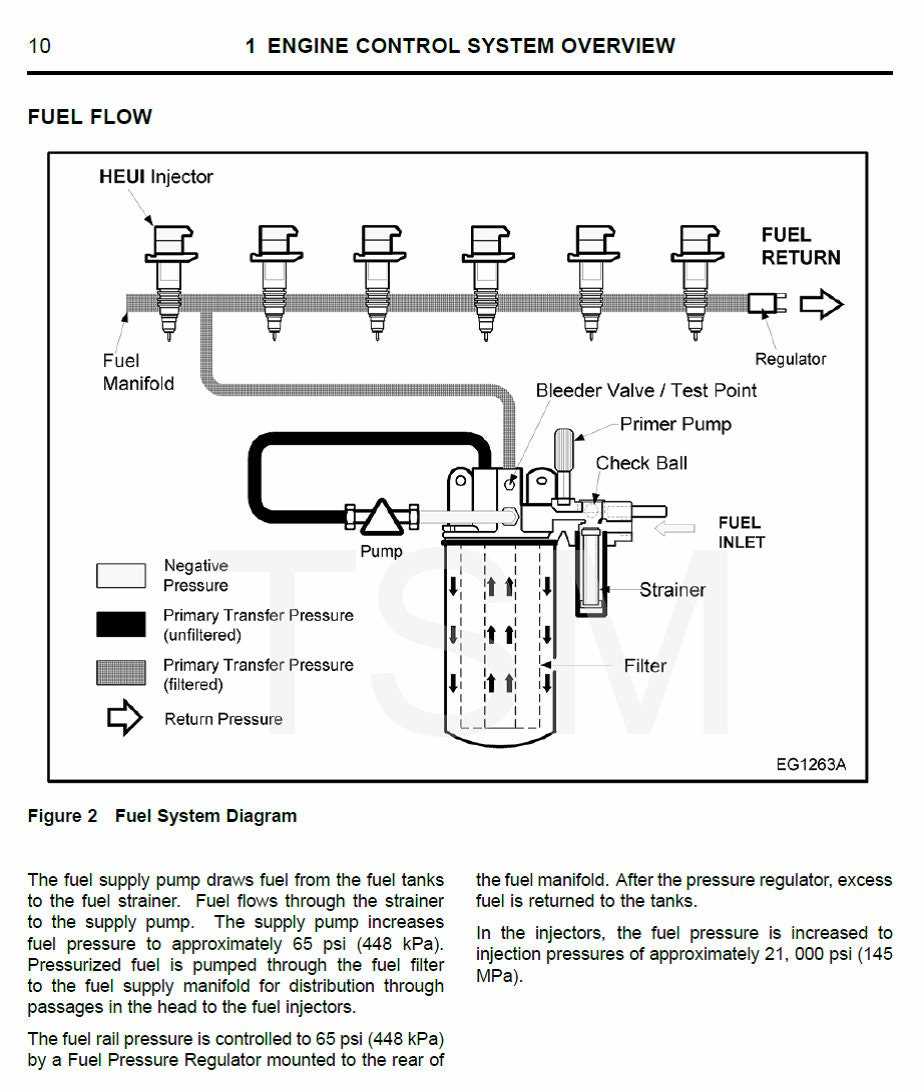

Fuel System Malfunctions are also common, with issues such as clogged filters or failing injectors. These problems can lead to poor fuel delivery, affecting overall efficiency and power output.

Cooling System Failures can occur, primarily due to radiator blockages or water pump malfunctions. Overheating can severely impact engine performance and may cause irreversible damage if not corrected.

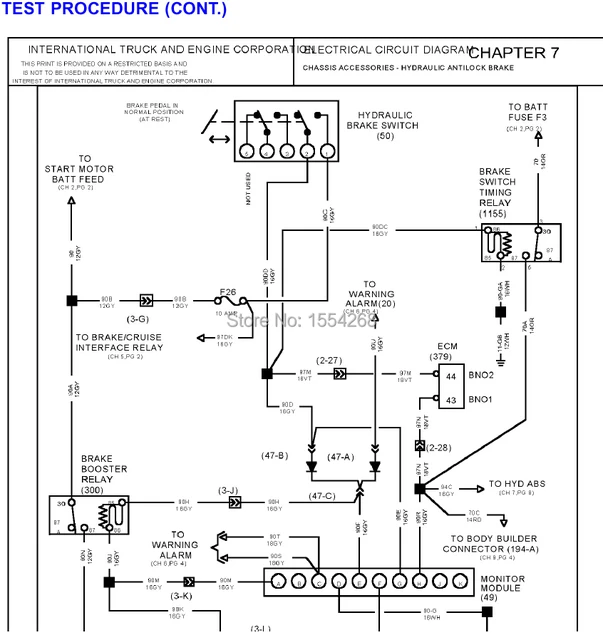

Another issue to be aware of is electrical system failures, which can disrupt the starting process and overall functionality. Inspecting wiring and connections regularly can help prevent these complications.

Lastly, exhaust system blockages may lead to increased back pressure, resulting in reduced performance. Regular maintenance can help keep this system clear and functioning properly.

Essential Tools for Repairs

Having the right equipment is crucial when it comes to maintaining and fixing engines. This section focuses on the fundamental instruments that facilitate effective service, ensuring both efficiency and accuracy in tasks. A well-equipped toolkit not only enhances productivity but also contributes to the longevity of the machinery being serviced.

Basic Hand Tools

Every technician should have a reliable set of hand tools. Essential items include wrenches, screwdrivers, and pliers. These instruments are indispensable for loosening or tightening various components. Opt for tools made from durable materials to withstand rigorous use and provide longevity.

Diagnostic Equipment

In addition to hand tools, having diagnostic instruments is vital for identifying issues. Multimeters and oscilloscopes allow for precise measurements and evaluations of electrical systems. Utilizing these devices can significantly streamline the troubleshooting process, leading to quicker and more effective resolutions.

Step-by-Step Repair Procedures

This section provides a comprehensive guide for addressing common issues that may arise in your engine system. By following a structured approach, you can effectively troubleshoot, disassemble, and reassemble components, ensuring optimal performance and longevity. Each procedure is designed to be straightforward, enabling both experienced technicians and beginners to navigate the tasks with confidence.

Identification and Troubleshooting

Begin by identifying the symptoms of the problem. Listen for unusual noises, check for leaks, and monitor performance metrics. Utilize diagnostic tools to gather data, which will guide you in pinpointing the root cause. Document your findings, as this information will be essential for the subsequent steps.

Disassembly and Inspection

Once the issue has been identified, proceed with disassembly. Carefully remove the necessary components, taking care to label parts for easy reassembly. Inspect each piece for wear and damage, noting any that require replacement. Clean all surfaces to prepare for reinstallation, ensuring that new gaskets and seals are ready to prevent future leaks.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your engine requires a dedicated approach to upkeep. Regular maintenance not only enhances performance but also extends the lifespan of your equipment. Implementing consistent care practices can prevent unexpected failures and costly repairs.

Regular Checks

- Inspect fluid levels frequently, including oil and coolant, to ensure they are within optimal ranges.

- Examine belts and hoses for wear and tear, replacing them as needed to avoid breakdowns.

- Monitor air and fuel filters, cleaning or replacing them regularly to maintain efficient operation.

Scheduled Servicing

- Adhere to a maintenance schedule based on manufacturer recommendations for servicing intervals.

- Conduct periodic thorough inspections, focusing on critical components such as the exhaust and transmission.

- Keep records of all maintenance activities to track performance and identify patterns over time.

By following these guidelines, you can significantly enhance the reliability and efficiency of your machinery, ensuring it remains in peak condition for years to come.

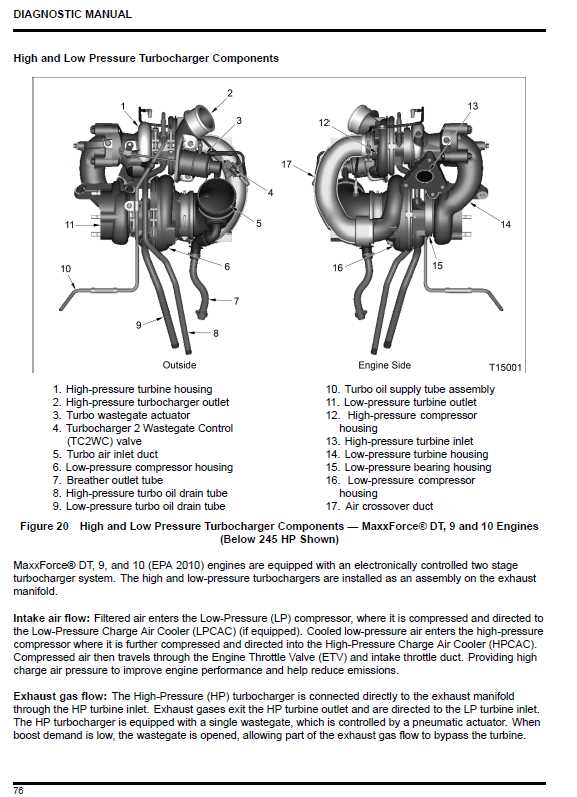

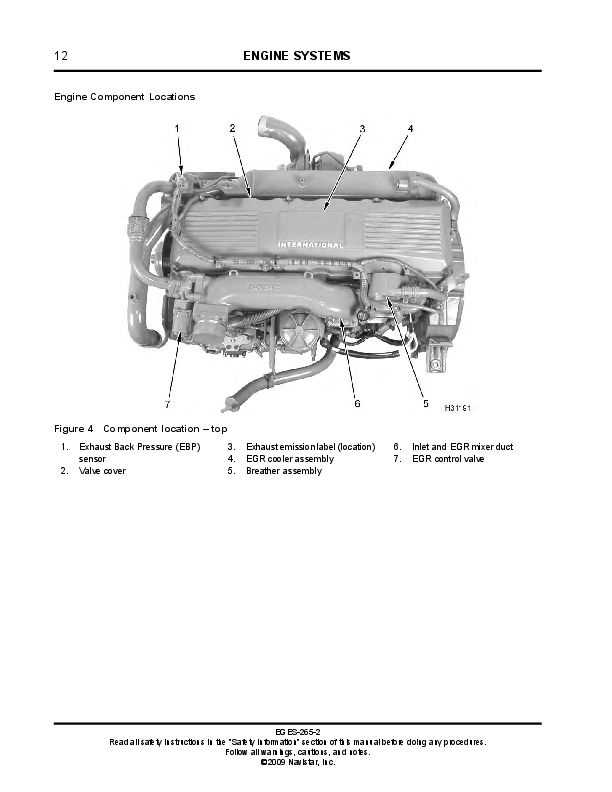

Understanding Engine Components

Engines are intricate machines composed of various elements that work in unison to generate power. A comprehensive grasp of these components is crucial for anyone interested in the mechanics of engines. Each part plays a specific role, contributing to the overall functionality and efficiency of the system.

Key Components of an Engine

- Crankshaft: This component transforms linear motion into rotational motion, providing the necessary force to turn the vehicle’s wheels.

- Pistons: Located within the cylinders, pistons move up and down, compressing the fuel-air mixture and driving the crankshaft.

- Cylinders: These are the chambers where combustion occurs, crucial for generating power.

- Valves: These control the intake of air and fuel as well as the exhaust of gases, ensuring optimal engine performance.

- Camshaft: This part regulates the timing of valve openings and closings, essential for efficient engine operation.

- Fuel Injection System: Responsible for delivering the correct amount of fuel to the combustion chamber, significantly affecting engine efficiency.

Importance of Each Component

Understanding the significance of each part can aid in diagnosing issues and performing maintenance. A malfunctioning crankshaft can lead to severe engine damage, while improper fuel delivery can hinder performance. Regular checks on components such as valves and pistons can prevent larger problems down the line.

In conclusion, a solid understanding of engine components not only enhances knowledge but also equips individuals with the tools to maintain and troubleshoot engines effectively.

Diagnostic Tools for Troubleshooting

Effective troubleshooting requires the right set of diagnostic instruments to identify and resolve issues efficiently. Utilizing appropriate tools can significantly enhance the accuracy of the diagnostic process, ensuring that underlying problems are addressed promptly.

One essential category of diagnostic tools includes multimeters, which measure voltage, current, and resistance. These devices are invaluable for checking electrical systems and identifying faults in wiring or components. Another vital instrument is the oscilloscope, which provides visual representations of electrical signals, helping technicians diagnose complex issues in real time.

Additionally, scan tools are critical for interfacing with onboard diagnostic systems. They can retrieve error codes and provide detailed information about system performance, enabling a more targeted approach to repairs. Furthermore, pressure testers are useful for evaluating fluid systems, ensuring that leaks or pressure drops can be swiftly detected.

In summary, a comprehensive toolkit that includes multimeters, oscilloscopes, scan tools, and pressure testers is essential for effective troubleshooting. These instruments not only facilitate quicker diagnostics but also contribute to more accurate repairs, ultimately improving the overall reliability of the machinery.

Fuel System Maintenance Guidelines

Proper upkeep of the fuel delivery system is essential for ensuring optimal performance and longevity of the engine. Regular attention to this system can prevent costly repairs and enhance fuel efficiency. By following specific maintenance practices, operators can help maintain peak functionality and reliability.

Regular Inspections

Conducting periodic checks of the fuel components is crucial. Look for signs of leaks, corrosion, or wear. Inspect fuel lines for cracks and ensure that all connections are secure. Pay attention to the fuel filter; replacing it as per the manufacturer’s recommendations will help keep contaminants from entering the engine.

Fuel Quality Management

Maintaining high-quality fuel is vital for the system’s performance. Use fresh, clean fuel and avoid sources that may contain impurities. Consider adding a fuel stabilizer if the vehicle will be idle for extended periods. This can prevent the degradation of fuel, ensuring optimal combustion and reducing the risk of engine knock.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual conducting the work but also safeguard the equipment and surrounding environment. Adopting a systematic approach to safety can significantly reduce the risk associated with mechanical servicing.

Essential Safety Measures

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure the work area is clean and free of hazards, such as spills or clutter.

- Always disconnect the power source before beginning any servicing tasks.

- Use tools and equipment that are in good condition and suitable for the task at hand.

Emergency Preparedness

- Familiarize yourself with the location of emergency exits and first aid kits.

- Have a fire extinguisher accessible and know how to use it.

- Maintain clear communication with team members regarding safety protocols and emergency procedures.

By prioritizing these safety measures, individuals can create a secure environment conducive to effective maintenance work. Following these guidelines will help mitigate risks and enhance overall safety during mechanical tasks.

Parts Replacement: Best Practices

Effective component replacement is crucial for maintaining the performance and longevity of any machinery. Understanding the best practices in this area ensures that repairs are conducted smoothly and efficiently, minimizing downtime and maximizing reliability. This section outlines essential strategies for successful part swaps.

Choosing the Right Components

Selecting high-quality replacements is fundamental. Always opt for original equipment manufacturer (OEM) parts or trusted aftermarket options. Compatibility with your specific machine model is vital, as it ensures optimal functionality. Researching reviews and consulting with professionals can also provide insights into the best choices available.

Preparation and Procedure

Before initiating the replacement process, ensure the work area is clean and organized. Gather all necessary tools and parts to avoid interruptions. Documenting the disassembly process can be beneficial for reassembly, particularly for complex components. Follow a systematic approach, taking care to adhere to safety protocols to protect both yourself and the equipment.