Maintaining your high-performance 65cc motorcycle is essential for ensuring optimal performance and longevity. This guide aims to provide detailed insights into the necessary procedures and practices that keep your machine in peak condition.

Understanding the inner workings of your bike will not only enhance your riding experience but also empower you to address potential issues before they escalate. From routine checks to specific adjustments, each aspect plays a crucial role in the overall functionality of your vehicle.

Whether you are a seasoned rider or a newcomer, the following sections will offer valuable information and techniques that cater to all skill levels. Embrace the art of motorcycle care and enhance your riding adventures with confidence.

Overview of KTM 65 SX

The KTM 65 SX is a compact and agile machine designed for young riders looking to enhance their skills on the track. It offers an impressive blend of performance and handling, making it suitable for both novice and intermediate levels. The lightweight design and powerful engine create an exhilarating experience, allowing riders to navigate various terrains with ease.

Equipped with advanced suspension components, this model ensures optimal comfort and stability during rides. The innovative engineering behind the bike allows for precise maneuverability, which is crucial for developing confidence in younger enthusiasts. Safety features have also been incorporated, prioritizing the well-being of the rider as they explore their passion for motorsports.

Overall, this machine stands out as a reliable option for those eager to progress in their riding journey. Its performance, combined with user-friendly controls, fosters a seamless transition from beginner to more experienced rider, making it a favorite among young adventurers.

Common Issues and Symptoms

When dealing with performance issues in small off-road motorcycles, several recurring problems may arise. Recognizing these symptoms early can prevent more serious complications and ensure optimal functionality.

Engine Performance Problems

One of the most common signs of trouble is a decrease in power or difficulty in starting the engine. These symptoms can indicate issues with the fuel system, spark plug, or exhaust.

| Symptoms | Possible Causes |

|---|---|

| Poor acceleration | Clogged air filter, fuel starvation |

| Engine stalling | Faulty spark plug, carburetor issues |

| Difficulty starting | Weak battery, ignition problems |

Suspension and Handling Issues

Another area to monitor is the suspension system, as it significantly affects handling and rider comfort. Signs of malfunction may include excessive bouncing or instability during rides.

| Symptoms | Possible Causes |

|---|---|

| Unstable handling | Worn-out shocks, improper tire pressure |

| Excessive bouncing | Damaged springs, fluid leaks |

| Noisy suspension | Lack of lubrication, worn components |

Tools Needed for Repairs

When maintaining and servicing your vehicle, having the right tools is essential for ensuring effective and safe operations. A well-equipped toolkit not only simplifies the process but also enhances the overall experience. This section outlines the essential equipment required for various tasks.

Essential Equipment List

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Wrenches | Used for turning nuts and bolts of various sizes. |

| Phillips and Flathead Screwdrivers | Essential for various types of screws in assemblies. |

| Pliers | Useful for gripping and manipulating components. |

| Cleaning Supplies | For maintaining the cleanliness of the components. |

Safety Gear

In addition to tools, having the appropriate safety gear is crucial. Gloves, goggles, and masks help protect against hazards that may arise during the process. Prioritizing safety ensures a more enjoyable and worry-free experience while working on your vehicle.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your two-wheeler. Regular upkeep is essential for enhancing reliability and preventing potential issues. Below are systematic steps to follow for effective maintenance.

| Task | Frequency | Notes |

|---|---|---|

| Check engine oil | Every ride | Ensure proper level and quality. |

| Inspect air filter | Every month | Clean or replace as necessary. |

| Examine brakes | Every month | Check pads and fluid levels. |

| Lubricate chain | Every 300 km | Use suitable chain lubricant. |

| Inspect tires | Every ride | Check for wear and correct pressure. |

By adhering to these guidelines, you can significantly enhance the performance and durability of your machine. Regular attention to these aspects will prevent unexpected breakdowns and ensure a smoother ride.

Engine Troubleshooting Techniques

Identifying and resolving issues in a motor’s operation can significantly enhance its performance and longevity. Employing effective troubleshooting methods is essential for diagnosing common problems and implementing solutions to restore optimal functionality.

Here are some fundamental techniques to consider:

- Visual Inspection: Start by examining the engine for any visible signs of damage or wear. Look for oil leaks, loose connections, or broken components.

- Listen for Unusual Noises: Pay attention to any strange sounds while the engine is running. Knocking, grinding, or excessive vibrations may indicate underlying issues.

- Check Fluid Levels: Ensure that all fluids, including oil and coolant, are at appropriate levels. Low fluid levels can lead to overheating or inadequate lubrication.

- Examine Spark Plug Condition: Inspect the spark plugs for signs of wear or fouling. A damaged spark plug can lead to misfires and poor performance.

Utilizing these techniques can help in diagnosing and addressing engine problems effectively, leading to smoother operation and extended service life.

Transmission and Clutch Repair

This section delves into the intricacies of the power transfer system, focusing on the mechanisms that ensure seamless gear shifting and effective engagement of the powertrain. Proper maintenance and timely adjustments are crucial for optimal performance, longevity, and reliability of the components involved.

Understanding the Components

The transmission system consists of various gears and shafts that work in tandem to provide the desired speed and torque. The clutch mechanism plays a vital role in connecting and disconnecting the engine’s power to the wheels, allowing for smooth transitions during operation. Regular inspection and servicing of these parts are essential to prevent premature wear and malfunction.

Maintenance Procedures

Regular upkeep involves checking fluid levels, inspecting for leaks, and ensuring all components are properly aligned. It’s important to replace worn-out parts promptly and follow manufacturer recommendations for lubrication and adjustments. This practice not only enhances performance but also extends the lifespan of the entire system.

| Component | Maintenance Task | Frequency |

|---|---|---|

| Gears | Inspect for wear and damage | Every 20 hours |

| Clutch Plates | Check thickness and replace if necessary | Every 30 hours |

| Fluid Levels | Check and top up | Every 10 hours |

Suspension System Adjustments

The performance of a vehicle’s suspension system is crucial for achieving optimal handling and ride comfort. Properly adjusting the components can enhance stability, reduce fatigue, and improve overall control. This section focuses on the key adjustments that can be made to ensure the suspension functions effectively under various conditions.

Understanding the Components

A well-tuned suspension consists of several elements, including forks and shock absorbers. Each component plays a vital role in absorbing impacts and maintaining contact with the ground. Understanding how these parts interact allows for better tuning to suit individual riding styles and terrain types.

Adjustment Techniques

To achieve the desired setup, it is essential to familiarize oneself with the available adjustment options. Compression settings control how quickly the suspension absorbs bumps, while rebound settings dictate how quickly it returns to its original position. Experimenting with these settings can lead to significant improvements in ride quality and handling.

Regular checks and adjustments ensure that the system remains responsive and reliable, allowing for a safer and more enjoyable riding experience.

Brake System Maintenance Tips

Ensuring the optimal performance of your braking components is crucial for safety and efficiency. Regular upkeep not only enhances responsiveness but also extends the lifespan of the system. Here are essential practices to consider for maintaining braking integrity.

Regular Inspection

Conducting frequent checks on the braking system is vital. Look for wear and tear on pads and discs, as well as fluid levels. A visual assessment can reveal signs of damage or contamination that require immediate attention. Pay close attention to any unusual noises during operation, as these can indicate underlying issues.

Fluid Replacement

Keeping the hydraulic fluid fresh is essential for effective braking performance. Old or contaminated fluid can lead to reduced braking power and system failure. Follow the manufacturer’s guidelines on fluid replacement intervals to ensure optimal functionality. Regularly bleeding the brakes helps eliminate air bubbles that can compromise performance.

Electrical System Diagnostics

Understanding the intricacies of the electrical framework in your vehicle is crucial for optimal performance. This section delves into methods for assessing and troubleshooting the electronic components that play a vital role in functionality.

Initial Assessment involves inspecting wiring, connectors, and components for signs of wear or damage. Start by visually examining the harness for fraying or exposed wires. Ensure that all connections are secure and free from corrosion, as these factors can significantly affect the system’s reliability.

Voltage Testing is an essential step in diagnosing electrical issues. Utilize a multimeter to measure voltage at various points within the system. Compare your findings with the manufacturer’s specifications to identify discrepancies. A low voltage reading may indicate a failing battery or poor connections.

Component Testing should be performed to evaluate the functionality of individual parts. This can include checking switches, relays, and sensors. By isolating each element, you can determine if they operate within the expected parameters, allowing for targeted repairs and replacements.

By employing these diagnostic strategies, you can effectively pinpoint and resolve electrical issues, ensuring your vehicle remains in peak condition.

Cleaning and Lubrication Procedures

Maintaining the performance and longevity of your vehicle involves systematic cleaning and appropriate lubrication. These essential tasks ensure that various components function smoothly and reduce wear over time. Proper attention to these procedures not only enhances efficiency but also contributes to the overall safety of the ride.

Cleaning involves removing dirt, debris, and contaminants from crucial areas. This helps prevent build-up that can lead to mechanical issues. Here are the key steps to follow:

- Initial Inspection: Before starting, visually inspect all parts for any signs of damage or excessive wear.

- Surface Cleaning: Use a soft brush or cloth to wipe down surfaces. For stubborn grime, a mild cleaning solution can be applied.

- Component Cleaning: Pay special attention to moving parts, such as chains and gears, ensuring they are free from dirt.

Once cleaning is completed, lubrication plays a vital role in maintaining the functionality of various elements. Proper application of lubricant minimizes friction and protects against corrosion. Follow these steps for effective lubrication:

- Choosing the Right Lubricant: Select a high-quality product suitable for the specific components you are treating.

- Application: Apply lubricant evenly to all moving parts, ensuring thorough coverage without over-saturation.

- Regular Maintenance: Schedule periodic checks and reapply lubricant as needed to keep everything operating optimally.

By adhering to these cleaning and lubrication protocols, you can significantly extend the life of your vehicle and enhance its performance on every ride.

Replacement Parts and Upgrades

When maintaining and enhancing your off-road motorcycle, selecting the right components is crucial for optimal performance and longevity. This section will explore various options for improving functionality and reliability through thoughtful part replacements and upgrades.

Choosing high-quality alternatives can significantly impact your riding experience. Consider the following areas for enhancement:

- Engine Components: Upgrading pistons, cylinders, and gaskets can lead to improved power output and efficiency.

- Suspension: Enhanced forks and shock absorbers provide better handling and stability on rugged terrains.

- Braking System: High-performance brake pads and rotors increase stopping power and safety.

- Exhaust System: A more efficient exhaust can improve engine performance and reduce weight.

- Wheels and Tires: Upgrading to lightweight wheels and specialized tires can enhance grip and maneuverability.

Before making any modifications, it’s essential to consult with knowledgeable sources to ensure compatibility and effectiveness of the new components. Investing in quality parts can lead to a significant enhancement in your riding experience, making every adventure more enjoyable.

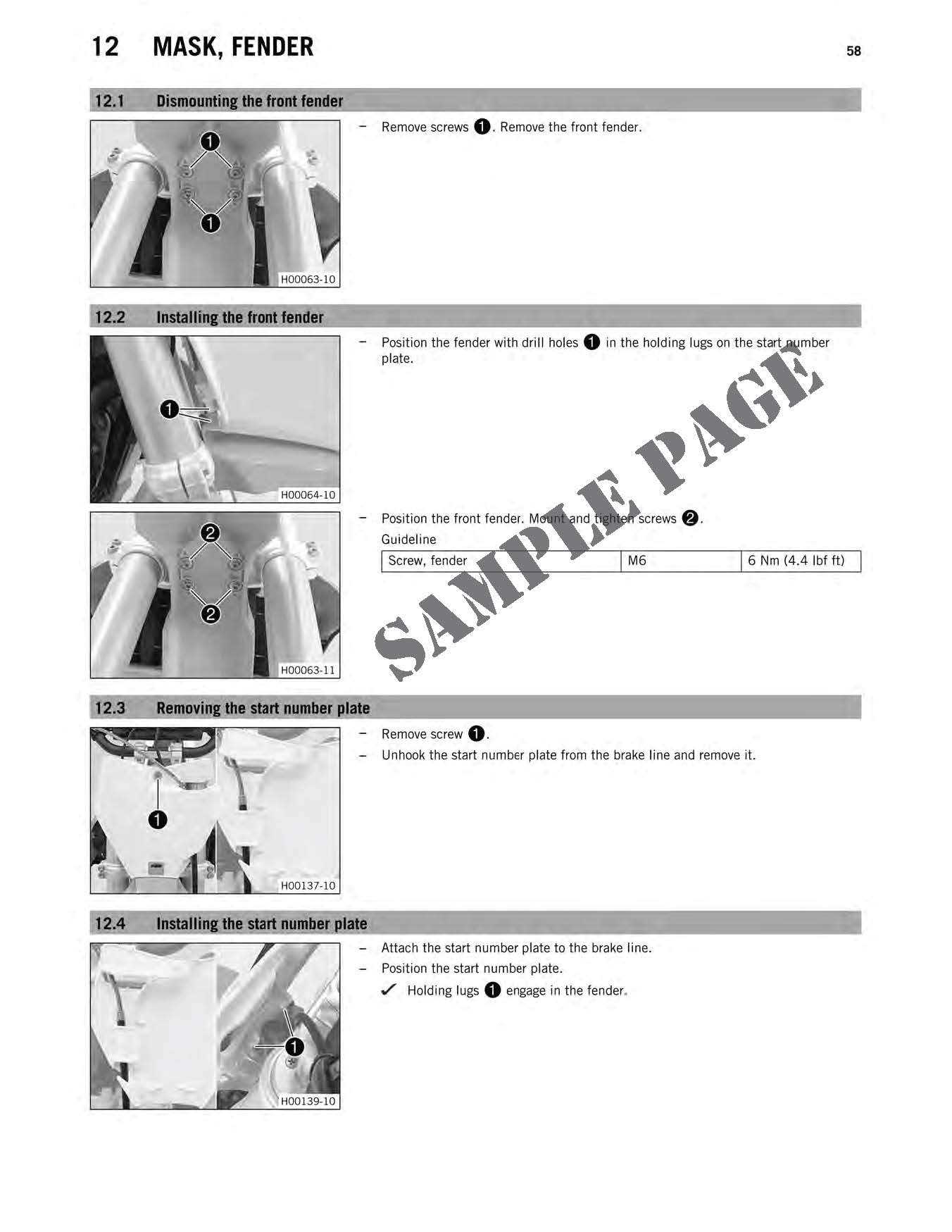

Final Assembly and Testing

The concluding phase of the assembly process is crucial for ensuring that all components function harmoniously. This stage involves carefully putting together all parts while adhering to manufacturer specifications. Proper alignment and secure fastening are essential to achieve optimal performance.

Once the assembly is complete, it’s vital to conduct a thorough examination to confirm that everything is correctly positioned and operating as intended. Start with a visual inspection, checking for any loose connections or misaligned components. Following this, a series of tests should be performed to assess functionality and reliability.

During testing, focus on key aspects such as engine performance, suspension responsiveness, and braking efficiency. Make adjustments as necessary to enhance overall performance. Document any findings to ensure that future maintenance can be effectively managed.