Maintaining a chainsaw is essential for ensuring its longevity and optimal performance. A thorough understanding of the essential components and their functions can greatly enhance the user experience. Whether you’re a novice or an experienced operator, having a resource that outlines troubleshooting and upkeep can be invaluable.

From routine checks to intricate repairs, this guide will cover various aspects of care, equipping you with the knowledge to tackle common issues. By familiarizing yourself with the intricacies of your tool, you can avoid potential pitfalls and ensure smooth operation.

Additionally, understanding the significance of each part will enable you to make informed decisions about repairs and replacements. A well-maintained device not only improves efficiency but also enhances safety during use, making it crucial for any user to grasp these concepts.

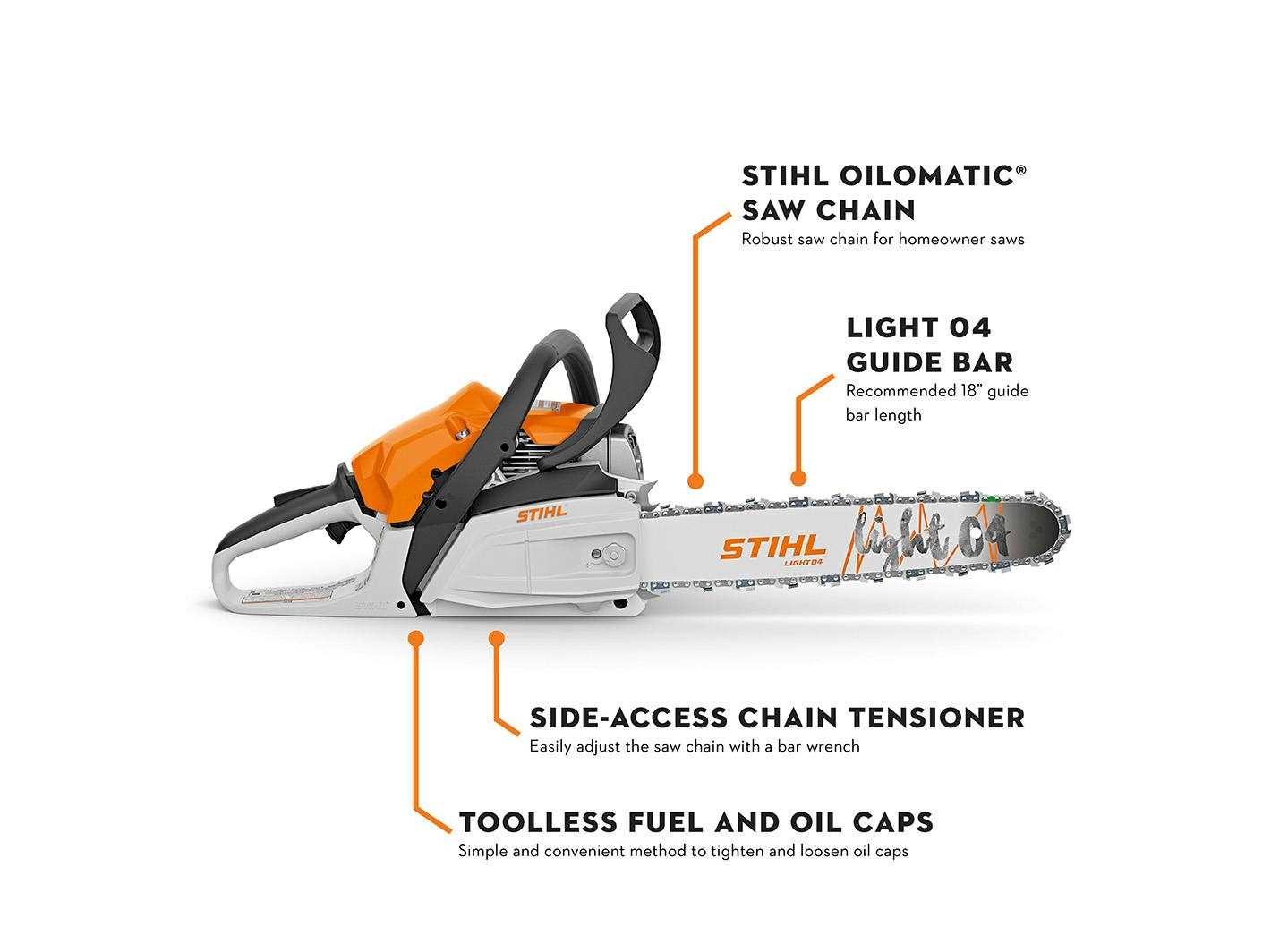

Stihl MS 180 Overview

This section provides a comprehensive examination of a popular outdoor power tool designed for various cutting tasks. Its robust design and efficient performance make it a favored choice among both professionals and enthusiasts. Understanding its features and capabilities is essential for maximizing its use.

Key Features

- Lightweight and compact design for easy maneuverability

- Powerful engine for efficient cutting performance

- Easy-to-use controls for user-friendly operation

- Durable construction for longevity in demanding conditions

Applications

- Tree trimming and pruning

- Firewood cutting

- General landscaping tasks

- Clearing brush and small trees

With its blend of power and versatility, this tool serves as an essential asset for outdoor projects, offering reliable performance across a range of applications.

Common Issues and Troubleshooting

This section addresses frequent complications encountered with certain outdoor power tools and provides solutions to resolve them effectively. Understanding these common challenges can enhance the user experience and prolong the lifespan of the equipment.

Below are some typical problems and their troubleshooting steps:

- Engine Won’t Start:

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for wear or damage.

- Verify that the on/off switch is in the correct position.

- Loss of Power:

- Examine the air filter for clogs or dirt.

- Ensure the carburetor is clean and functioning properly.

- Check for fuel line blockages.

- Excessive Vibration:

- Inspect for loose screws or components.

- Examine the cutting attachment for damage.

- Ensure proper assembly of all parts.

- Overheating:

- Check for proper ventilation around the engine.

- Ensure the cooling fins are clean and unobstructed.

- Verify oil levels and quality.

By identifying and addressing these common issues, users can ensure optimal performance and longevity of their equipment.

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right equipment is crucial. The appropriate instruments not only facilitate the task but also ensure safety and efficiency throughout the process. Familiarity with these essential tools can greatly enhance the overall experience of servicing your device.

Basic Hand Tools

Among the fundamental instruments required for maintenance are various hand tools. A selection of screwdrivers, wrenches, and pliers forms the backbone of any toolkit. These items allow for the adjustment and removal of components, ensuring that each part can be accessed with ease.

Specialized Equipment

In addition to standard tools, certain specialized equipment can significantly aid in troubleshooting and repairs. A spark plug wrench is essential for addressing ignition issues, while a compression tester helps evaluate engine performance. Having these specific tools on hand can make a considerable difference when tackling more complex problems.

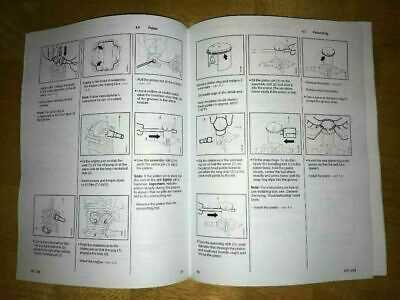

Step-by-Step Maintenance Guide

Proper upkeep of your equipment is essential for ensuring its longevity and optimal performance. This guide provides a comprehensive approach to routine care, helping users maintain efficiency and prevent common issues. By following these steps, you can keep your machinery in excellent working condition and enhance its overall functionality.

Essential Tools and Supplies

Before starting maintenance, gather the necessary tools and supplies. Typical items include a suitable wrench set, a screwdriver, and a cleaning cloth. Ensure you have adequate lubricants and replacement parts, such as filters and spark plugs, to facilitate the process.

Maintenance Steps

Begin by cleaning the exterior to remove debris and dirt, which can hinder performance. Check and replace the air filter to maintain proper airflow. Regularly inspect and sharpen the cutting blade, as a sharp edge improves efficiency. Lastly, ensure that all moving parts are adequately lubricated to minimize friction and wear.

Engine Specifications and Features

This section delves into the essential characteristics and capabilities of the power unit, highlighting its performance metrics and design elements. Understanding these specifications is crucial for maximizing efficiency and ensuring optimal functionality.

Power Output: The engine delivers an impressive output, facilitating robust operation for various tasks. Its design enhances torque delivery, ensuring effective performance even under heavy loads.

Cylinder Configuration: Featuring a precise arrangement, the cylinder design optimizes combustion efficiency. This configuration contributes to reduced emissions while maintaining powerful performance.

Displacement: The volume of the engine’s cylinders plays a significant role in determining overall power. The carefully calculated displacement supports enhanced acceleration and responsiveness.

Fuel System: Equipped with a sophisticated fuel delivery system, the engine ensures consistent performance. This system aids in achieving an ideal air-fuel mixture, which is vital for efficiency and power output.

Cooling Mechanism: The effective cooling system prevents overheating, allowing for prolonged operation. This feature is crucial for maintaining reliability during extended use.

In summary, the specifications and features of the engine are designed to provide high performance, efficiency, and durability, making it a versatile choice for a range of applications.

Fuel and Oil Requirements

Proper fuel and lubrication are essential for the optimal performance and longevity of your equipment. Selecting the right mixtures ensures efficient operation and helps prevent damage. Understanding the specifications for both fuel and oil is crucial for maintaining peak functionality.

For fuel, a high-quality mixture of gasoline and oil is recommended. Typically, a ratio of 50:1 is common, meaning one part oil to fifty parts gasoline. This blend ensures adequate lubrication during operation. Always opt for unleaded fuel to minimize carbon buildup and enhance engine efficiency.

As for lubrication, it is vital to use the appropriate type of oil specifically designed for two-stroke engines. Using the correct oil type helps in achieving a smooth operation while reducing wear and tear on internal components. Regularly check oil levels and refill as needed to prevent overheating and maintain optimal performance.

Chain and Bar Maintenance Tips

Proper upkeep of the cutting components is crucial for optimal performance and longevity. Regular attention to these elements ensures efficient operation and prevents wear and tear that can lead to more significant issues.

1. Regular Lubrication: Always ensure that the cutting chain is adequately lubricated. This reduces friction and heat, which can cause damage over time. Use high-quality oil designed for this purpose.

2. Tension Adjustment: Frequently check the tension of the chain. A properly adjusted chain minimizes the risk of derailment and ensures a smooth cutting experience. If the chain is too loose, it may come off; if too tight, it can cause excessive wear.

3. Cleaning: After each use, clean the bar and chain to remove debris and sawdust. This prevents clogging and ensures that lubrication reaches all necessary parts.

4. Sharpening: Keep the chain sharp for effective cutting. Dull blades can cause the engine to work harder and lead to premature wear. Regularly inspect and sharpen the teeth as needed.

5. Inspect for Damage: Periodically examine the bar and chain for signs of wear or damage. Look for cracks, bends, or excessive wear on the teeth, and replace any damaged components promptly to maintain safety and efficiency.

Electrical System Diagnostics

Understanding the functionality of the electrical components within your equipment is essential for effective troubleshooting and maintenance. This segment focuses on evaluating the various elements that contribute to the electrical performance, ensuring optimal operation and longevity of the device.

Identifying Issues begins with a thorough examination of the wiring and connections. Look for signs of wear, corrosion, or loose fittings that may disrupt the flow of electricity. Regular inspections can help pinpoint potential problems before they escalate.

Testing Components involves using appropriate tools to assess voltage levels and continuity. Multimeters and test lights are invaluable in determining whether components such as switches, relays, and ignition systems are functioning as intended. Proper diagnostics not only aids in resolving current issues but also in preventing future failures.

By implementing systematic diagnostics, you can enhance the reliability of your equipment and ensure it operates smoothly, saving both time and resources in the long run.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance work is paramount for both personal well-being and the longevity of the equipment. Proper precautions can prevent accidents and damage, leading to a more efficient workflow. This section highlights essential measures to take before, during, and after any servicing tasks.

Preparing the Work Area

Before starting any task, it is crucial to create a safe and organized environment. Ensure that the workspace is clean, well-lit, and free from distractions. Remove any unnecessary tools and materials that may obstruct movement. Additionally, wearing appropriate protective gear, such as gloves and goggles, significantly reduces the risk of injury.

Using Tools Safely

When handling equipment, it is vital to use tools correctly to prevent accidents. Always select the right tool for the job, and inspect it for any damage before use. Keep hands dry and avoid loose clothing that could become entangled. Following the manufacturer’s guidelines for usage can enhance safety and effectiveness.

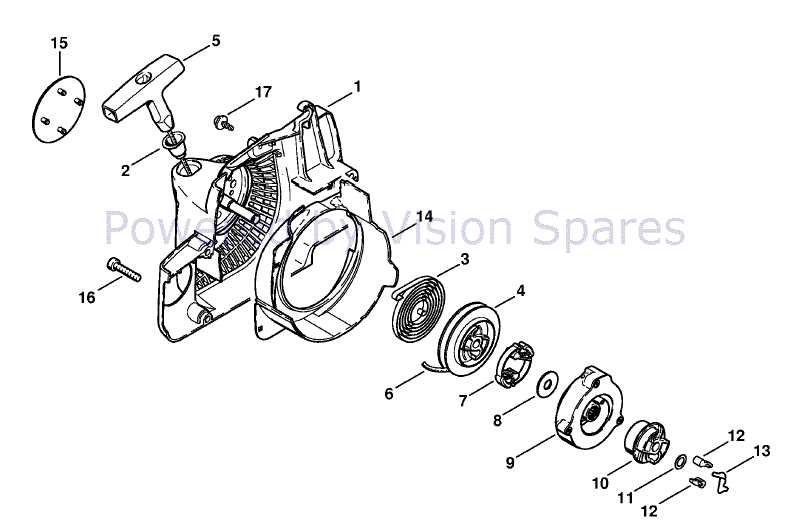

Parts Replacement and Upgrades

Maintaining optimal performance in your equipment often requires timely substitution of components and enhancements. This section outlines essential practices for ensuring your machine operates efficiently and remains up to date with the latest advancements.

Identifying Worn Components

Recognizing when parts have reached the end of their lifespan is crucial. Regular inspections can help spot signs of wear, such as cracks, excessive play, or corrosion. Replacing these elements promptly can prevent further damage and maintain overall functionality.

Upgrading for Enhanced Performance

Incorporating upgraded components can significantly enhance your machine’s capabilities. Consider improved blades or advanced filters to increase efficiency and prolong the lifespan of your equipment. Research compatible upgrades that provide the best balance between performance and durability.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and troubleshooting for various models of chain saws. Whether you are a novice or an experienced user, these answers can help clarify essential aspects of operation and care.

| Question | Answer |

|---|---|

| How do I start my chainsaw? | Ensure the fuel tank is filled, engage the chain brake, and pull the starter cord gently until resistance is felt before pulling firmly. |

| What should I do if the saw won’t start? | Check the fuel mixture, spark plug, and ensure the choke is in the correct position. |

| How often should I sharpen the chain? | Sharpen the chain after every five hours of use or when cutting becomes more difficult. |

| What type of oil should I use? | Use high-quality bar and chain oil to ensure smooth operation and extend the life of the components. |

| How can I prevent kickback? | Maintain a proper grip and stance, and ensure the guide bar is properly maintained to minimize the risk of kickback. |