Maintaining household equipment is essential for ensuring their longevity and optimal performance. Understanding common issues that arise with various appliances can help homeowners address problems effectively. This section provides insights into diagnosing and resolving malfunctions that may occur in your laundry machines.

Whether you’re dealing with unusual noises, ineffective drying, or electronic glitches, knowing the basics can empower you to take action. Familiarity with your machine’s components and functionality can significantly simplify the troubleshooting process. With the right information at your fingertips, you’ll be equipped to tackle most challenges that may arise.

This resource is designed to guide you through various solutions and preventative measures, helping you keep your equipment running smoothly. Armed with practical knowledge, you can save time and potentially reduce repair costs, allowing you to focus on what truly matters.

Understanding Common Dryer Issues

Many household appliances experience common hiccups over time, especially those involving regular heating and mechanical movement. Identifying these symptoms early can help prevent bigger problems and ensure efficient operation. Below, we’ll explore some frequent concerns, detailing their possible causes and straightforward solutions.

- No Heat or Low Temperature: One of the most typical challenges involves a lack of warmth. This may be due to worn components responsible for heating or issues with sensors that control temperature. Inspecting these areas can often reveal simple fixes or identify parts that need replacement.

- Extended Drying Time: If cycles are taking longer than usual, airflow might be restricted. Blockages in filters, vents, or ducts reduce circulation, causing inefficient drying. Regular cleaning of these areas can restore performance and prevent overheating.

- Unusual Noises: Strange sounds often indicate that internal parts, such as belts or rollers, are experiencing wear. Addressing these noises early by inspecting and replacing affected parts can avoid further mechanical issues.

- Drum Not Spinning: When the drum fails to rotate, the source may be related to drive belts or motor components. Ensuring these parts are properly aligned and intact can often resolve the issue without complex repairs.

By keeping an eye out for these common signs, you can maintain smooth operation and address minor concerns before they develop into significant problems.

Step-by-Step Troubleshooting Guide

When facing issues with your appliance, a systematic approach can help pinpoint the problem quickly and accurately. This guide offers an easy-to-follow process, ensuring each essential aspect is thoroughly checked to restore your unit’s optimal functionality.

1. Check Power and Connections

- Confirm the machine is plugged in securely. Inspect the outlet and plug for visible damage.

- Reset any tripped circuit breakers or replace blown fuses that may be affecting operation.

- Examine any accessible wiring connections to ensure they are secure and free of wear.

2. Inspect Key Components

- Heating Element: If the device isn’t warming as expected, the heating unit may need replacement. Test continuity with a multimeter to confirm functionality.

- Thermostats: Several temperature regulators monitor internal heat levels. If one is defective, the appliance may not function properly. Each should be tested individually.

- Thermal Fuse: Check this safety component, as it will stop operations if temperatures exceed safe levels. If blown, replace it before further testing.

3. Verify Control Settings

- Double-check the selected cycle settings. Ensure that the cycle matches your intended outcome and that all buttons or dials are working properly.

- Look for error codes on the control panel. Many modern models display codes that indicate specific issues.

4. Address Common Operational Problems

- Unusual Noises: If strange sounds occur, investigate for loose objects or worn bearings in the drum are

Tools Needed for Dryer Repair

When restoring a household appliance to working order, having the right set of tools is essential. With a few key items on hand, troubleshooting and replacing components becomes much easier and safer. Here is a list of commonly used tools to handle most maintenance tasks efficiently.

- Screwdriver Set: Both flathead and Phillips screwdrivers are usually necessary to remove panels and access internal parts.

- Multimeter: Useful for checking electrical continuity and ensuring circuits are operating correctly.

- Socket Wrench Set: Needed for loosening and tightening nuts and bolts securely, particularly in hard-to-reach areas.

- Needle-Nose Pliers: Perfect for gripping, bending, or twisting small parts or wires.

- Putty Knife: Often used to release clips and access certain sections without causing scratches or damage.

- Work Gloves: To protect hands from sharp edges, hot parts, and other hazards during maintenance.

- Vacuum Cleaner or Dust Brush: For cleaning out lint and debris, ensuring airflow and performance remain optimal.

With these tools, maintenance and minor fixes become straightforward, allowing you to restore appliance functionality and prolong its lifespan.

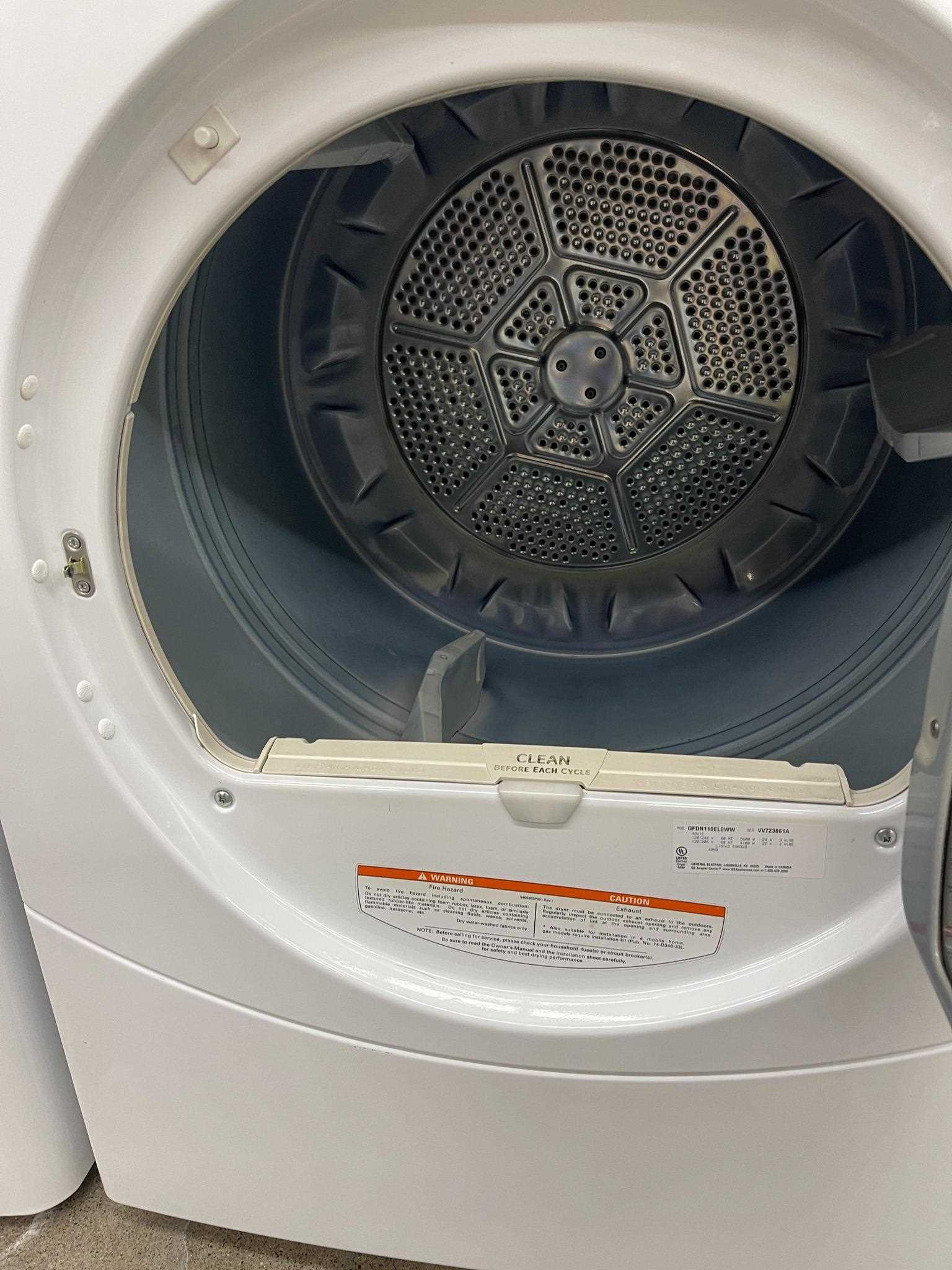

Key Components of GE Dryers

The main parts of these appliances work together to ensure effective drying, energy efficiency, and ease of use. Each component contributes to achieving optimal performance, maintaining balanced operation, and prolonging the life of the unit.

- Heating Element: This part is essential for creating the necessary warmth that removes moisture from clothes.

- Thermostats: These sensors monitor internal temperature levels, helping to keep heat within safe and efficient limits.

- Blower Fan: This fan circulates warm air throughout the chamber, ensuring even drying.

- Drum: The rotating drum tumbles the clothes, promoting balanced heat distribution for uniform results.

- Lint Filter: This filter captures fibers and debris, maintaining airflow and reducing potential fire hazards.

- Drive Belt: This belt connects the motor to the drum, allowing smooth rotation during the cycle.

- Control Panel: The interface enables users to select specific drying cycles and adjust settings as needed.

Understanding these key parts provides insights into how the appliance functions and helps identify potential areas to check if issues arise.

How to Replace a Heating Element

Replacing a heating element can restore warmth to your appliance, helping it to perform efficiently once more. This part may require attention over time, as it naturally wears down, affecting the overall function. Below are the steps for safely installing a new one, with a focus on ensuring safety and accuracy.

- Unplug the machine and ensure it’s disconnected from any power source to prevent accidental shocks.

- Locate the heating component, usually found at the back or bottom section. For most models, you’ll need to remove a panel by loosening screws.

- Detach any wires connected to the heating part, making note of their original positions to simplify reassembly.

- Remove the element by loosening its holding screws. Carefully take it out of its slot.

- Place the new element in the same position, securing it with screws. Reconnect the wires as noted earlier.

- Reattach the panel and ensure everything is tightened properly.

- Plug the machine back in and test it to confirm that the new heating element functions correctly.

By following these steps, you can ensure that the device is back to operating at its best, providing consistent results without the need for professional assistance.

Fixing a Faulty Door Switch

A malfunctioning door mechanism can disrupt the operation of your appliance, preventing it from starting or running efficiently. Understanding how to address this issue is crucial for restoring functionality. This section will guide you through the necessary steps to troubleshoot and resolve problems associated with the door actuator.

Before diving into the repair process, it is important to ensure safety measures are in place. Disconnecting the power supply is essential to prevent any electrical hazards during inspection and maintenance. After ensuring safety, follow the steps outlined below to diagnose and fix the door switch issue.

Step Description 1 Check the door latch for any visible signs of damage or misalignment. 2 Test the switch with a multimeter to determine if it is functioning properly. 3 If defective, remove the faulty switch and replace it with a new component. 4 Reassemble the door and ensure it closes securely. 5 Reconnect the power supply and perform a functionality test to ensure the appliance operates correctly. Addressing issues with the door mechanism can significantly improve the efficiency and reliability of your unit. Regular maintenance and prompt repairs can help avoid more extensive problems in the future.

Cleaning the Lint Filter Effectively

Maintaining optimal performance of your appliance requires regular upkeep, especially when it comes to the removal of lint buildup. This process not only enhances efficiency but also minimizes fire hazards associated with accumulated debris. A clean filter ensures that air circulates freely, allowing garments to dry thoroughly and quickly.

Steps for Proper Maintenance

To ensure that your lint trap remains in excellent condition, follow these straightforward steps:

Step Action 1 Remove the filter from its compartment carefully. 2 Use your hands or a soft brush to wipe away loose lint. 3 Rinse the filter under warm water to remove stubborn debris. 4 Allow the filter to air dry completely before reinserting it. 5 Regularly check for any signs of wear and replace if necessary. Tips for Enhanced Efficiency

In addition to regular cleaning, consider the following tips to boost the functionality of your device:

- Clean the filter after every use to prevent buildup.

- Avoid overloading the compartment to ensure proper airflow.

- Inspect the surrounding area for lint accumulation and clean it as needed.

Identifying Electrical Problems

Recognizing issues within the power system of an appliance is crucial for effective troubleshooting. Various symptoms may indicate underlying faults that affect the functionality and safety of the unit. By observing the behavior of the machine and performing specific checks, users can pinpoint electrical complications that require attention.

Common signs of trouble include unusual noises, failure to start, or erratic operation. Additionally, burnt smells or scorch marks around the power cord can suggest severe hazards. To diagnose these problems, one can begin by ensuring that the unit is correctly plugged in and that the circuit breaker has not tripped. Using a multimeter to test voltage levels can also help identify if the appliance is receiving the proper current.

It is essential to assess the condition of fuses and wiring, as these components are often the source of power-related issues. Loose connections or frayed wires can lead to intermittent power loss, compromising performance. Regular inspections and prompt intervention can prevent minor faults from escalating into major failures.

Maintaining Your GE Dryer

Regular upkeep of your appliance is essential for optimal performance and longevity. By following a few simple steps, you can ensure that your unit operates efficiently, reducing the risk of unexpected breakdowns. This proactive approach not only enhances functionality but also promotes safety and energy conservation.

Routine Cleaning

Cleaning various components of your machine is vital. Accumulated lint and debris can hinder efficiency and pose a fire hazard. Focus on the following areas:

Component Cleaning Frequency Tips Lint Filter After Every Use Remove and clean with soap and water. Exhaust Vent Every 6 Months Detach and vacuum to remove buildup. Drum Interior Monthly Wipe down with a damp cloth and mild detergent. Periodic Checks

Conducting regular inspections can prevent minor issues from escalating. Look for signs of wear and ensure all connections are secure. Pay attention to unusual sounds during operation, as these can indicate underlying problems.

When to Call a Professional

Addressing issues with your home appliance can often be managed independently; however, there are circumstances where seeking assistance from a qualified technician becomes essential. Understanding when to involve an expert is crucial for both safety and efficiency.

If you encounter persistent malfunctions despite troubleshooting efforts, it may be time to reach out for help. Strange noises, inconsistent performance, or signs of excessive wear can indicate underlying problems that require specialized knowledge to diagnose and resolve.

Furthermore, if you notice burning odors or see smoke, stop using the device immediately. These warning signs suggest a potentially dangerous situation that necessitates professional intervention. Always prioritize your safety and the integrity of your equipment by consulting with an experienced technician when you’re uncertain about the next steps.