In the realm of aviation and recreational vehicles, understanding the intricacies of engine upkeep is crucial for ensuring optimal performance and longevity. This segment delves into the essential techniques and best practices for maintaining a specific type of engine commonly used in light aircraft and other applications. Through a systematic approach, enthusiasts and professionals alike can enhance their knowledge and skills, ultimately leading to safer and more reliable operation.

Effective maintenance involves not only routine checks but also a thorough understanding of various components and their functions. By familiarizing oneself with the inner workings of the engine, operators can identify potential issues before they escalate into serious problems. This guide aims to provide detailed insights into troubleshooting, servicing, and component replacement, empowering users to take proactive steps in engine care.

Whether you are a seasoned expert or a novice, having access to a well-structured resource can make all the difference. This documentation emphasizes practical advice, step-by-step instructions, and safety precautions that are vital for anyone involved in the upkeep of their machinery. By following these guidelines, one can ensure that their engine operates smoothly and efficiently, leading to a more enjoyable experience in the skies or on the ground.

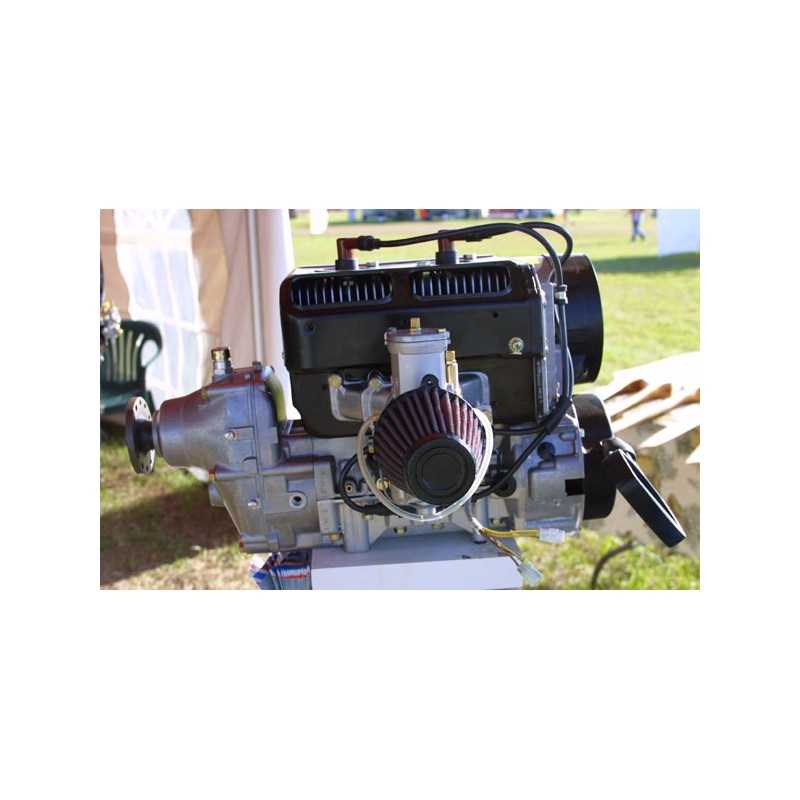

Understanding the Rotax 447 Engine

This section delves into the intricacies of a specific lightweight powerplant commonly used in various recreational aircraft. It highlights the design features, operational principles, and performance characteristics that make it a favored choice among enthusiasts and builders alike.

Key Features of the Engine

This power unit is renowned for its efficient design and reliable performance. It typically incorporates a two-stroke configuration, allowing for a compact structure with a favorable power-to-weight ratio. The integration of advanced cooling systems ensures optimal temperature management, which is crucial for maintaining engine integrity during extended flights.

Operational Principles

The functionality of this engine is based on a straightforward yet effective mechanism. Air and fuel are mixed and drawn into the combustion chamber, where they ignite to produce power. This process not only drives the propeller but also contributes to the engine’s overall efficiency and responsiveness, making it ideal for varied flight conditions.

Common Issues with Rotax 447

Understanding the frequent challenges faced by users of this specific engine type can significantly enhance performance and longevity. Various factors contribute to operational difficulties, ranging from mechanical malfunctions to maintenance oversights. Identifying these common problems is crucial for ensuring optimal functionality.

One prevalent issue involves overheating, which can occur due to inadequate cooling or blockages in the cooling system. Regular inspections of coolant levels and flow are essential to prevent this problem. Additionally, improper fuel mixtures can lead to performance degradation, affecting efficiency and power output.

Another concern is ignition failure, often stemming from worn spark plugs or faulty ignition components. Regular checks and timely replacements can mitigate this risk, ensuring reliable starting and operation. Furthermore, wear and tear on seals and gaskets can lead to leaks, impacting both performance and safety.

Lastly, vibrations during operation may indicate misalignment or imbalance within the engine assembly. Addressing these vibrations promptly can prevent further damage and enhance the overall user experience. By being aware of these common issues and their symptoms, users can take proactive measures to maintain their equipment effectively.

Essential Tools for Repairing Rotax 447

Having the right equipment is crucial for maintaining and fixing engines effectively. Proper tools not only ensure efficiency but also enhance the quality of work, reducing the risk of damage during the process. Below is a list of indispensable instruments that every technician should consider for optimal engine service.

- Wrench Set: A variety of wrenches is necessary for loosening and tightening bolts and nuts. Ensure to have both standard and metric sizes.

- Screwdriver Set: Flathead and Phillips screwdrivers in various sizes are essential for accessing different components.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing over-tightening and potential damage.

- Multimeter: Useful for diagnosing electrical issues, a multimeter helps measure voltage, current, and resistance.

- Fuel Pressure Gauge: Monitoring fuel pressure is key for ensuring optimal performance; this gauge helps identify any fuel delivery issues.

- Compression Tester: Checking the compression in cylinders can provide insight into engine health and performance.

- Cleaning Supplies: Brushes, solvents, and rags are necessary for maintaining cleanliness during work, which is vital for preventing debris-related problems.

- Diagnostic Software: For modern engines, having access to software that interfaces with the engine’s onboard computer can facilitate troubleshooting and performance tuning.

Investing in quality tools will not only streamline the process but also ensure that the work performed is thorough and effective. Proper maintenance and timely repairs can greatly extend the lifespan of the engine.

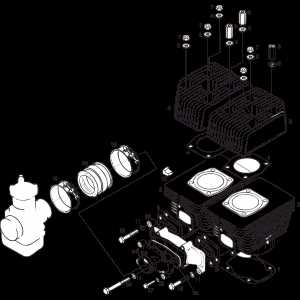

Step-by-Step Disassembly Process

This section outlines a systematic approach to carefully disassemble the engine, ensuring that all components are removed in a safe and organized manner. Following these steps will help prevent damage to parts and facilitate a smoother reassembly process.

Before beginning, ensure you have all necessary tools at hand and a clean workspace to keep track of removed components. Each step is crucial for maintaining the integrity of the engine and ensuring that no pieces are lost.

| Step | Description |

|---|---|

| 1 | Disconnect the battery to prevent any electrical issues during disassembly. |

| 2 | Remove external components such as the air intake and exhaust system for easier access. |

| 3 | Detach the fuel lines, ensuring to collect any residual fuel safely. |

| 4 | Unscrew and remove the outer casing, taking care not to strip any bolts. |

| 5 | Carefully extract the internal components, noting their order and orientation. |

| 6 | Organize all parts in labeled containers to avoid confusion during reassembly. |

By following these steps meticulously, you will ensure a thorough disassembly process that will contribute to the effective maintenance and longevity of the engine.

Inspecting Engine Components

Regular examination of engine parts is crucial for maintaining optimal performance and longevity. Thorough inspections can identify potential issues before they escalate into more serious problems, ensuring the reliability of the machinery. Each component plays a vital role, and understanding how to evaluate their condition is essential for any operator.

Start by checking the overall appearance of the engine assembly. Look for signs of wear, such as cracks, corrosion, or discoloration. Ensure that all fasteners are secure and free from damage. A loose or damaged bolt can lead to significant operational failures.

Pay special attention to the fuel system, including lines and filters. Inspect for leaks and blockages, as these can severely impact performance. The intake and exhaust systems should also be evaluated for any obstructions or signs of degradation.

The ignition components require careful scrutiny as well. Ensure that spark plugs are clean and properly gapped. Worn or fouled plugs can hinder ignition and reduce efficiency. Additionally, check the ignition coil and wiring for any signs of wear or damage.

Finally, review the lubrication system. Inspect oil levels and quality, looking for any contaminants that may indicate internal issues. Ensure that the oil pump and lines are functioning correctly, as proper lubrication is vital for reducing friction and wear on moving parts.

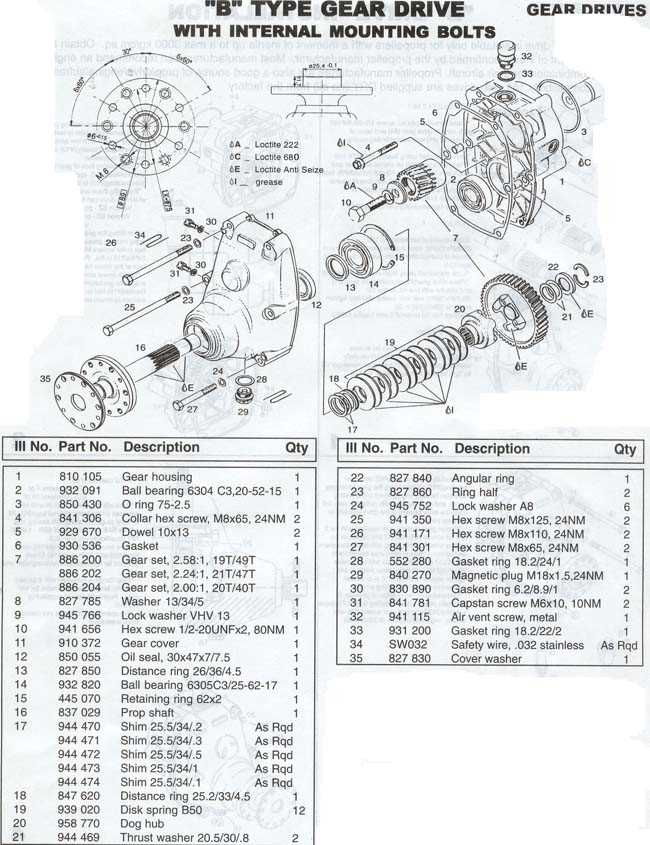

Reassembly Techniques for Rotax 447

Reassembling an engine requires precision and attention to detail to ensure optimal performance. This process involves systematically putting together components that have been disassembled for maintenance or repair. Proper techniques during reassembly are crucial for the longevity and reliability of the engine.

Begin by thoroughly cleaning all parts to remove any debris or contaminants. Use appropriate solvents and tools to avoid damage. Organize components in a logical manner, making it easier to reference the order of assembly. It’s beneficial to consult any documentation or guidelines available for specific assembly instructions and torque specifications.

When reassembling, apply lubrication to moving parts to reduce friction and wear. Ensure that all gaskets and seals are in good condition and properly positioned to prevent leaks. Take care to align components accurately; misalignment can lead to mechanical failures. Gradually tighten bolts to the recommended torque settings in a crisscross pattern to evenly distribute pressure.

After completing the assembly, perform a thorough inspection to confirm that all parts are secure and correctly installed. Finally, run a series of tests to check for any issues before returning the engine to operational status. By following these techniques, you can achieve a reliable and efficient assembly process.

Lubrication and Maintenance Guidelines

Proper upkeep and adequate lubrication are essential for ensuring the longevity and optimal performance of your engine. Regular attention to these aspects not only enhances efficiency but also minimizes the risk of unexpected failures. Following systematic procedures will lead to smoother operations and increased reliability over time.

Essential Lubrication Practices

Always use high-quality oil that meets the manufacturer’s specifications. Regularly check oil levels and replenish as necessary to prevent wear. It’s crucial to adhere to the recommended intervals for oil changes, ensuring that any contaminants are removed and the internal components remain protected.

Routine Maintenance Steps

Conduct periodic inspections of all moving parts, ensuring they are clean and free from debris. Replace any worn-out seals or gaskets promptly to maintain proper function. Keeping a detailed log of all maintenance activities can help track the condition of the engine and inform future servicing decisions.

Common Mistakes to Avoid

When working on aviation engines, avoiding common pitfalls can significantly enhance performance and longevity. Many enthusiasts and technicians may overlook crucial steps or make assumptions that lead to complications down the line. Awareness of these frequent errors is essential for ensuring successful outcomes.

| Mistake | Description | Consequence |

|---|---|---|

| Neglecting Regular Maintenance | Skipping scheduled inspections or routine servicing. | Increased risk of failures and reduced efficiency. |

| Using Incorrect Tools | Employing inappropriate instruments for tasks. | Potential for damage to components and inaccurate adjustments. |

| Over-tightening Fasteners | Applying excessive torque to screws and bolts. | Stripped threads and compromised integrity of parts. |

| Ignoring Manufacturer Guidelines | Disregarding specific instructions and recommendations. | Increased likelihood of improper assembly and operational issues. |

| Inadequate Cleaning | Failing to properly clean components before reassembly. | Contamination leading to wear and decreased performance. |

Testing the Engine After Repairs

After any maintenance work on an aircraft powerplant, it is crucial to thoroughly assess its functionality and performance. This phase ensures that all modifications or replacements have been executed correctly and that the unit operates as intended. A systematic approach to testing helps identify any potential issues that could affect safety and reliability.

Initially, a visual inspection should be conducted to check for any signs of leaks, loose connections, or irregularities in the assembly. Following this, it’s advisable to conduct a ground run, allowing the engine to reach operating temperature while monitoring various parameters such as oil pressure and temperature. This step provides an opportunity to listen for unusual noises and observe the overall behavior of the engine.

Subsequently, performance tests can be performed to evaluate the power output and efficiency. It is essential to compare the results against manufacturer specifications to ensure optimal operation. Furthermore, logging data during these tests can aid in diagnosing any unforeseen issues that may arise post-maintenance.

Finally, once the engine has been deemed to perform satisfactorily, it is recommended to carry out a series of flight tests under controlled conditions. This real-world evaluation will further confirm that the powerplant is functioning correctly and safely in its intended environment.

Resources for Rotax 447 Parts

Finding reliable components for your engine can significantly enhance its performance and longevity. Numerous suppliers and platforms provide essential parts, ensuring you have access to quality materials for maintenance and upgrades. Whether you are looking for specific components or general supplies, a variety of resources are available to cater to your needs.

Online Suppliers

Several online retailers specialize in aviation parts, offering a wide range of items for your engine. These platforms often provide detailed descriptions and customer reviews, helping you make informed choices.

| Supplier Name | Website | Contact Information |

|---|---|---|

| Aero Parts Online | aeropartsonline.com | [email protected] |

| Engine Components Direct | enginecomponentsdirect.com | [email protected] |

| Aircraft Supply Store | aircraftsupplystore.com | [email protected] |

Local Distributors

In addition to online options, local distributors can provide personalized service and immediate access to parts. Establishing a relationship with a nearby supplier can be advantageous for urgent needs or specific advice related to your engine.

Upgrading Your Rotax 447 Engine

Enhancing the performance of your engine can significantly improve your flying experience. Whether you’re aiming for increased power, better fuel efficiency, or improved reliability, there are several modifications and upgrades you can consider. Understanding the options available will allow you to make informed decisions tailored to your specific needs.

One of the most effective ways to boost performance is by upgrading the exhaust system. A high-performance exhaust can reduce back pressure, allowing the engine to breathe more freely and produce greater power. Additionally, consider using lightweight materials to decrease overall weight, which can enhance agility.

Another vital area for improvement is the ignition system. Upgrading to a modern ignition module can provide better spark timing and energy, resulting in smoother operation and improved combustion efficiency. This change can lead to noticeable enhancements in throttle response and overall performance.

Don’t overlook the importance of tuning. A well-tuned engine maximizes efficiency and power output. Regularly adjusting the carburetor settings based on altitude and temperature can ensure optimal performance. Consulting a specialist can also provide insights into the best tuning practices for your specific setup.

Finally, consider enhancing the cooling system. An efficient cooling setup will prevent overheating, which can be detrimental to engine health. Upgrading radiators or adding additional cooling fins can help maintain optimal operating temperatures during extended flights.

By focusing on these key areas, you can transform your engine into a high-performing powerhouse, enhancing your overall flying experience.

Best Practices for Long-Term Care

Maintaining the longevity and performance of machinery requires diligent attention and proactive measures. Implementing effective strategies can significantly extend the life of your equipment, ensuring optimal functioning and reducing the need for extensive repairs.

- Regular Maintenance: Establish a consistent schedule for inspections and routine checks. This helps identify potential issues before they escalate.

- Quality Lubrication: Use the recommended lubricants and fluids to minimize friction and wear on moving parts.

- Cleanliness: Keep components free from debris and contaminants. Regular cleaning prevents buildup that can lead to inefficiencies.

- Temperature Control: Monitor operating temperatures closely. Excess heat can cause damage over time, so ensure proper cooling mechanisms are in place.

- Documentation: Maintain a detailed log of all maintenance activities. This record can be invaluable for troubleshooting and understanding wear patterns.

By following these best practices, you can enhance the reliability and durability of your equipment, ensuring it remains in top condition for years to come.