In the world of aquatic transportation, ensuring optimal performance of propulsion systems is crucial for a seamless experience on the water. This section focuses on essential practices for maintaining and diagnosing issues related to these vital components. Understanding the intricacies involved can significantly enhance both the longevity and efficiency of your equipment.

Whether you’re a seasoned enthusiast or a newcomer, familiarizing yourself with standard procedures and troubleshooting techniques can make all the difference. This guide aims to provide clear insights and practical advice, empowering users to tackle common challenges and perform necessary upkeep with confidence.

By following the outlined steps and recommendations, you will gain a deeper understanding of how to keep your propulsion system in peak condition. Emphasizing proactive maintenance not only prevents unexpected failures but also enhances overall safety and enjoyment during your aquatic adventures.

This section aims to explore the essential concepts related to the propulsion systems commonly found in watercraft. Understanding the fundamental components and their functionalities is crucial for effective troubleshooting and maintenance.

In this guide, we will delve into various aspects that contribute to the overall performance and longevity of these systems. Familiarity with parts such as the power source, propulsion mechanism, and control elements can greatly enhance your ability to manage issues that may arise.

| Component | Description |

|---|---|

| Power Source | The engine type that provides the necessary energy for propulsion. |

| Propulsion Mechanism | Components that convert engine power into movement. |

| Control Elements | Systems that allow the operator to manage speed and direction. |

Common Issues in Boat Motors

Understanding typical complications in watercraft propulsion systems is essential for effective troubleshooting and maintenance. Many users encounter similar challenges that can affect performance, efficiency, and overall reliability.

Fuel System Problems

One of the most frequent concerns arises from the fuel system. Clogged filters, contaminated fuel, or improper fuel mixtures can lead to stalling or reduced power. Regular inspection and cleaning can help mitigate these issues.

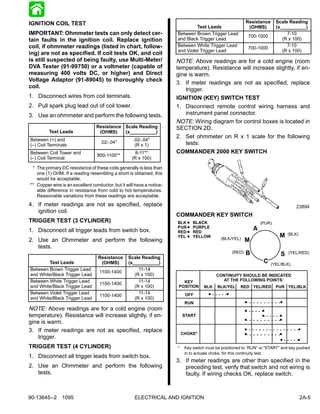

Electrical System Failures

Another prevalent issue involves the electrical components. Faulty wiring, corroded connections, or dead batteries often result in starting difficulties or erratic behavior. Ensuring proper connections and routine checks can enhance system reliability.

Essential Tools for Repairs

When it comes to maintaining and fixing aquatic engines, having the right set of instruments is crucial. A well-equipped toolkit can significantly enhance the efficiency of the process, ensuring that any necessary adjustments or replacements are made smoothly and effectively. Below, we highlight the key instruments that are essential for tackling various tasks involved in engine maintenance.

Basic Hand Tools

Every technician should have a reliable collection of hand tools to perform essential tasks. These items facilitate the disassembly and assembly of components with ease. Common hand tools include wrenches, pliers, and screwdrivers, which allow for precise manipulation of parts.

Diagnostic Equipment

In addition to hand tools, having access to diagnostic devices can provide valuable insights into engine performance. These tools help in identifying issues quickly, enabling prompt action. Whether it’s a multimeter for electrical checks or compression testers for assessing cylinder function, the right diagnostic equipment is vital for thorough inspections.

| Tool Type | Description |

|---|---|

| Wrenches | Used for tightening or loosening bolts and nuts. |

| Pliers | Essential for gripping and manipulating small components. |

| Screwdrivers | Ideal for assembling and disassembling various fixtures. |

| Multimeter | Helps diagnose electrical issues by measuring voltage and resistance. |

| Compression Tester | Assesses the engine’s cylinder pressure for performance evaluation. |

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues with aquatic propulsion systems. Following a systematic method can help identify the root cause of performance problems and facilitate effective solutions.

Initial Assessment

- Check the fuel levels to ensure adequate supply.

- Examine the ignition system for any signs of malfunction.

- Inspect the cooling system to prevent overheating.

- Look for visible leaks or unusual sounds during operation.

Common Issues and Solutions

- Engine Fails to Start:

- Verify the battery charge and connections.

- Inspect the starter motor functionality.

- Check for any fuel blockages in the lines.

- Overheating:

- Ensure the water intake is clear of debris.

- Examine the thermostat for proper operation.

- Assess the water pump for efficiency.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your aquatic propulsion system requires consistent care and attention. Proper maintenance practices not only enhance performance but also prevent costly repairs in the future.

Regular Inspections

Conduct routine assessments to identify any signs of wear or damage. Check essential components such as seals, gaskets, and hoses. Early detection of issues can save time and resources.

Optimal Fluid Levels

Maintain appropriate levels of lubricants and coolants to ensure smooth operation. Fluids play a crucial role in reducing friction and preventing overheating, contributing to overall efficiency.

By implementing these practices, you can significantly enhance the reliability and functionality of your system.

Replacing Essential Parts

Maintaining optimal performance often requires the timely replacement of crucial components within the engine system. This process ensures that the equipment operates efficiently and safely, minimizing the risk of breakdowns during usage.

Identifying Key Components is the first step in this undertaking. Commonly replaced elements include seals, gaskets, and filters, which can wear out over time due to regular use and environmental factors. Recognizing the signs of wear is essential for effective maintenance.

Once the components have been identified, the next stage involves removal and installation. Proper tools and techniques should be employed to ensure that replacements fit correctly. Always consult relevant guidelines to avoid damaging surrounding parts during this process.

Finally, after installing new components, it is crucial to test the system to verify that everything functions as intended. This step helps to confirm that the replacement has been successful and that the equipment is ready for operation. Regular checks and maintenance will prolong the lifespan of the machinery and enhance its overall performance.

Adjusting Motor Settings Properly

Properly configuring the settings of your engine is essential for achieving optimal performance and efficiency. This process ensures that all components work harmoniously, contributing to a smoother operation and prolonged lifespan.

Understanding Key Adjustments

Familiarizing yourself with the fundamental adjustments can significantly enhance performance. These include fine-tuning the throttle response, optimizing fuel-air mixtures, and calibrating ignition timing. Each of these elements plays a critical role in how effectively the engine operates.

Steps for Effective Configuration

Begin by consulting the specifications for your particular unit. Carefully assess the current settings and make incremental changes while monitoring performance. Documenting each adjustment will help in identifying the most effective configurations. Remember to allow the engine to reach operating temperature before making significant changes, as this can affect performance outcomes.

Winterizing Your Engine

Preparing your engine for the colder months is essential to ensure its longevity and reliable performance. Proper winterization helps prevent damage caused by freezing temperatures and allows for a smooth start when the season changes.

Steps to Prepare Your Engine

- Drain all fluids to remove any water that could freeze and expand.

- Flush the cooling system with fresh water to clear out any contaminants.

- Change the oil and replace the oil filter to keep the internal components lubricated.

- Examine the fuel system, adding a fuel stabilizer to prevent degradation.

- Disconnect the battery to prevent drainage during storage.

Final Checks Before Storage

- Inspect the exterior for any signs of wear or damage.

- Cover the engine with a protective tarp to shield it from dust and moisture.

- Store the engine in a dry, temperature-controlled environment if possible.

Taking these steps will help ensure that your engine remains in excellent condition throughout the winter, ready for action when the warm weather returns.

Recognizing Signs of Wear

Identifying indicators of deterioration is crucial for maintaining the longevity of any aquatic machinery. Regular observation can help users detect issues before they escalate into more significant problems. Understanding these signs ensures safe and efficient operation.

Common Symptoms to Watch For

There are several noticeable symptoms that can signal wear and tear. Users should remain vigilant and consider the following:

| Indicator | Description |

|---|---|

| Unusual Noises | Any unfamiliar sounds during operation may indicate internal issues. |

| Vibration | Excessive shaking can suggest misalignment or worn components. |

| Leaking Fluids | Fluid leaks often point to failing seals or gaskets. |

| Reduced Performance | A noticeable drop in power or efficiency can signal significant wear. |

Proactive Measures

To mitigate the risks associated with wear, regular inspections and maintenance are essential. Users should familiarize themselves with their equipment and consult professionals when necessary to address any signs of deterioration promptly.

Testing Performance After Repairs

After completing maintenance tasks on your aquatic propulsion system, it’s essential to evaluate its functionality to ensure optimal operation. This assessment helps identify any lingering issues and confirms that the adjustments made have yielded the desired improvements.

Pre-Testing Preparations

Before initiating the performance assessment, verify that all components are securely installed and properly calibrated. Check fluid levels, connections, and any external factors that may affect performance. Conducting a thorough visual inspection can prevent complications during testing.

Conducting the Performance Test

Once preparations are complete, proceed to the testing phase. Engage the system and monitor its response at various throttle positions. Listen for unusual sounds and observe for any irregular vibrations. Take note of speed and acceleration to gauge improvements compared to previous benchmarks.

Documenting Results: Keeping a record of performance metrics is crucial for future reference. This information will assist in tracking the effectiveness of repairs and inform any necessary adjustments moving forward.

Resources for Further Assistance

When facing challenges with your aquatic engine, it’s essential to have access to reliable resources that can provide guidance and support. A variety of platforms and materials are available to help you navigate any issues that may arise.

Online Forums: Engaging with communities dedicated to marine equipment can offer valuable insights and shared experiences. Members often share tips, troubleshooting techniques, and solutions to common problems.

Instructional Videos: Many enthusiasts and experts create visual content that walks you through specific processes related to maintenance and troubleshooting. These step-by-step guides can enhance your understanding and improve your hands-on skills.

Local Workshops: Participating in workshops or classes organized by local experts can provide practical knowledge and hands-on experience. These sessions often cover a range of topics, from basic upkeep to more advanced techniques.

Manufacturer Resources: While direct manuals may not be available, many manufacturers offer customer service lines and online support that can address specific queries and provide tailored advice.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial for both personal safety and effective outcomes. Proper precautions help prevent accidents and injuries, fostering a smoother workflow.

Before starting any maintenance, it’s important to gather all necessary tools and equipment in a designated workspace. This minimizes distractions and enhances focus on the task at hand.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and appropriate clothing to protect against harmful substances and potential injuries. |

| Ensure Ventilation | Work in a well-ventilated area to avoid inhaling toxic fumes from fuels or chemicals. |

| Disconnect Power Sources | Before beginning any work, ensure that all power sources are disconnected to prevent accidental starts. |

| Keep Area Organized | Maintain a clean workspace to reduce the risk of tripping hazards and misplacing tools. |

| Follow Manufacturer Guidelines | Adhere to safety instructions provided by the equipment’s manufacturer to ensure proper handling and maintenance. |

By implementing these safety measures, individuals can significantly reduce risks and create a more efficient maintenance experience.