In the world of agriculture, maintaining machinery is crucial for ensuring optimal performance and longevity. This guide serves as an essential resource for operators and enthusiasts alike, providing valuable insights into the upkeep of specific tractor models that are widely utilized in various farming operations. Understanding the intricacies of your equipment can lead to enhanced efficiency and reduced downtime.

Familiarity with operational systems and troubleshooting techniques empowers users to tackle common issues independently. This knowledge not only saves time but also minimizes costs associated with professional repairs. By investing in a thorough understanding of machinery mechanics, one can ensure that every component functions harmoniously.

Equipped with detailed information about routine maintenance practices, users can develop a proactive approach to care for their equipment. This includes everything from basic inspections to more complex adjustments, fostering a culture of diligence and attention to detail that pays off in the long run. Engaging with this guide will enhance your ability to keep your agricultural assets in peak condition.

Overview of Specifications

This section provides a detailed examination of the key specifications of a particular agricultural machine designed for efficiency and durability. Understanding these specifications is crucial for anyone involved in its maintenance and operation, as they directly impact performance and usability.

Key specifications include engine details, dimensions, and performance metrics, which collectively define the machine’s capabilities. Below are some of the essential attributes:

- Engine Type: The machinery is equipped with a powerful diesel engine, known for its reliability and fuel efficiency.

- Horsepower: The engine delivers a significant amount of horsepower, making it suitable for various farming tasks.

- Transmission: A multi-speed transmission system allows for smooth gear shifts and better control over speed and torque.

- Dimensions: The compact design ensures easy maneuverability in tight spaces while providing ample power.

- Weight: The overall weight contributes to stability during operation, especially in uneven terrains.

Additionally, the machine’s hydraulic system enhances its versatility, enabling it to operate various attachments and implements effectively. Overall, these specifications highlight the robust nature and operational capacity of the equipment, making it a valuable asset in agricultural operations.

Common Issues with Ford 3930

This section explores frequent challenges encountered with a specific agricultural machine. Understanding these problems can help owners maintain optimal performance and prevent unexpected breakdowns. Addressing these issues promptly can enhance the longevity and reliability of the equipment.

One prevalent concern involves the engine not starting or exhibiting difficulty in ignition. This issue may stem from a drained battery, faulty starter, or issues within the fuel system. Regular checks of these components can mitigate such troubles.

Another common problem is overheating, often caused by coolant leaks or a malfunctioning radiator. It is crucial to monitor coolant levels and ensure the cooling system is functioning correctly to avoid severe engine damage.

Hydraulic system failures can also arise, leading to reduced efficiency in operation. Inspecting hydraulic fluids and connections regularly can prevent these issues from escalating and ensure smooth functionality.

Wear and tear on the transmission is yet another concern. Regular maintenance and timely fluid changes are essential to keep the transmission in good working order and avoid costly repairs.

Lastly, electrical system malfunctions can disrupt various functions of the machinery. Checking wiring, fuses, and connections can help identify potential problems early and maintain electrical reliability.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal can significantly impact the efficiency and effectiveness of the work. A well-equipped toolkit not only streamlines the process but also enhances safety and precision during various operations.

Here is a list of indispensable tools that every technician should consider:

- Wrenches: A variety of wrenches, including adjustable, socket, and torque, are crucial for loosening and tightening bolts and nuts.

- Screwdrivers: A set of both flat-head and Phillips screwdrivers will help tackle different types of screws found in machinery.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, twisting, and cutting wires or small components.

- Impact Driver: This tool is essential for driving screws and loosening stubborn fasteners with minimal effort.

- Diagnostic Tools: Electronic diagnostic devices can help identify issues quickly and accurately, saving time and effort.

- Jack Stands: These provide safe support for lifting equipment, ensuring stability while you work underneath.

- Measuring Tools: Accurate measurements are vital; thus, having a tape measure and caliper is essential for precise work.

Incorporating these tools into your toolkit will enhance your ability to perform tasks efficiently and safely, leading to successful outcomes in your maintenance endeavors.

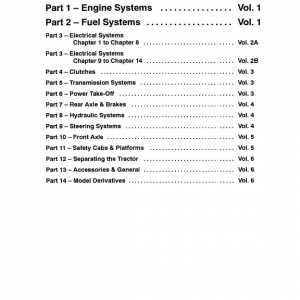

Step-by-Step Maintenance Procedures

Regular upkeep of your agricultural machinery is essential for optimal performance and longevity. Following systematic procedures ensures that all components function efficiently, reducing the risk of unexpected failures. This guide outlines straightforward steps to help you maintain your equipment effectively.

| Procedure | Description | Frequency |

|---|---|---|

| Fluid Checks | Inspect and top up engine oil, hydraulic fluid, and coolant levels. | Every 50 hours |

| Filter Replacement | Replace oil, fuel, and air filters to ensure clean operation. | Every 200 hours |

| Tire Inspection | Check tire pressure and tread wear; rotate if necessary. | Monthly |

| Greasing | Lubricate all grease points to prevent wear and tear. | Every 100 hours |

| Belt and Hose Check | Examine belts and hoses for cracks or wear, replacing as needed. | Every 500 hours |

By adhering to these guidelines, you can significantly enhance the reliability and efficiency of your machinery, ensuring it remains in peak condition for years to come.

Engine Troubleshooting Techniques

Diagnosing issues within an engine requires a systematic approach to identify the root cause of the malfunction. By utilizing various methods, one can effectively pinpoint problems and implement appropriate solutions.

Here are some essential techniques to consider:

- Visual Inspection: Begin with a thorough visual check for any obvious signs of wear or damage. Look for leaks, cracks, and loose connections.

- Listen for Unusual Noises: Pay attention to any strange sounds that may indicate internal problems, such as knocking or grinding.

- Check Fluid Levels: Ensure that all fluids, including oil and coolant, are at the correct levels and free of contaminants.

- Use Diagnostic Tools: Employ OBD-II scanners or pressure gauges to gather data on engine performance and identify error codes.

- Test Electrical Components: Inspect batteries, wiring, and sensors to ensure they are functioning correctly and delivering adequate power.

By following these methods, one can systematically approach engine issues, facilitating a more efficient troubleshooting process and ensuring optimal performance.

Hydraulic System Maintenance Tips

Maintaining the hydraulic system is crucial for ensuring optimal performance and longevity of your machinery. Regular upkeep not only enhances efficiency but also minimizes the risk of costly breakdowns. Implementing a few essential practices can greatly improve the reliability and functionality of these systems.

Here are some valuable tips to keep your hydraulic system in excellent condition:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Level Check | Weekly | Ensure the hydraulic fluid is at the recommended level to prevent air from entering the system. |

| Filter Inspection | Monthly | Examine filters for debris and replace them if they are clogged to maintain fluid cleanliness. |

| Leak Detection | Every Use | Regularly inspect hoses and connections for leaks, which can lead to fluid loss and reduced performance. |

| Fluid Replacement | Annually | Change the hydraulic fluid according to the manufacturer’s recommendations to ensure optimal performance. |

| System Bleeding | As Needed | Purge air from the hydraulic system to maintain efficiency and responsiveness. |

By following these guidelines, you can ensure that your hydraulic system operates smoothly and effectively, prolonging its lifespan and enhancing overall performance.

Transmission Care and Repair

Maintaining and fixing the transmission system is crucial for ensuring optimal performance and longevity of your machinery. Regular attention to this component can prevent more extensive issues and improve efficiency. Proper care involves routine checks, timely servicing, and addressing any signs of wear and tear promptly.

Routine Maintenance

Regular inspections should include checking fluid levels, examining for leaks, and ensuring that all connections are secure. It is advisable to change the transmission fluid at recommended intervals, as old fluid can lose its effectiveness and lead to overheating or inadequate lubrication. Additionally, replacing filters helps maintain cleanliness and efficiency within the system.

Signs of Trouble

Be vigilant for warning signs that may indicate a malfunctioning transmission. Unusual noises, slipping gears, or delayed shifting can suggest underlying problems. If any of these symptoms arise, it is essential to conduct a thorough evaluation to diagnose the issue. Prompt intervention can prevent further damage and costly repairs.

Electrical System Diagnostics Explained

The evaluation of electrical systems is crucial for ensuring optimal functionality and reliability in machinery. Understanding how to diagnose issues within these systems can save time and prevent costly repairs. This section delves into the various components and methods involved in troubleshooting electrical circuits.

Key components to consider during diagnostics include:

- Batteries

- Wiring harnesses

- Connectors

- Relays and switches

- Sensors and actuators

To effectively diagnose electrical problems, follow these systematic steps:

- Visual Inspection: Examine all wiring and connections for signs of damage, corrosion, or loose fittings.

- Check Battery Voltage: Use a multimeter to ensure the battery is functioning correctly and supplying adequate voltage.

- Test Continuity: Verify that circuits are complete by checking for continuity with a multimeter.

- Inspect Ground Connections: Ensure all ground connections are secure and free of corrosion.

- Analyze Component Functionality: Test individual components to confirm they are working as intended.

By adhering to these principles and utilizing appropriate diagnostic tools, one can effectively identify and rectify electrical issues, leading to improved performance and longevity of the equipment.

Parts Replacement: A Quick Guide

Replacing components in machinery is a crucial task that ensures optimal performance and longevity. Understanding the process and having the right information at hand can simplify this task significantly. This guide provides an overview of essential steps and considerations when dealing with part substitution.

Before proceeding with the replacement, it’s important to identify the specific component that needs attention. Gather all necessary tools and materials to ensure a smooth workflow. Below is a summary of common parts and their typical replacement procedures.

| Component | Symptoms of Failure | Replacement Steps |

|---|---|---|

| Oil Filter | Decreased efficiency, engine noise | 1. Turn off the engine. 2. Locate and remove the old filter. 3. Install the new filter securely. |

| Fuel Injector | Engine misfiring, poor fuel economy | 1. Disconnect the fuel lines. 2. Remove the old injector. 3. Install the new injector and reconnect lines. |

| Belt | Squeaking noises, visible wear | 1. Release tension on the belt. 2. Remove the old belt. 3. Install the new belt and adjust tension. |

Following these guidelines can facilitate a straightforward replacement process. Always refer to specific instructions related to the machinery for best results and safety practices.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Following specific guidelines can create a secure environment and ensure the well-being of everyone involved. Awareness of potential hazards and adherence to recommended practices can significantly reduce risks during the process.

Essential Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots.

- Ensure that the workspace is well-ventilated to avoid inhalation of harmful fumes.

- Disconnect the power source before beginning any disassembly or adjustment.

- Keep tools organized and within reach to prevent unnecessary movement or distractions.

Handling Equipment Safely

- Use lifting equipment for heavy components to prevent strain or injury.

- Be aware of pinch points and moving parts while working.

- Regularly inspect tools for wear and damage before use.

- Maintain a clean and clutter-free workspace to minimize tripping hazards.