The intricate dance of gear shifting is essential for optimal vehicle performance, ensuring a smooth transition between power and motion. When these crucial components falter, it can lead to frustrating driving experiences and potential damage to the overall system. Addressing issues related to these mechanisms is vital for maintaining efficiency and longevity.

Understanding the nuances of these engagement systems allows enthusiasts and technicians alike to tackle common challenges with confidence. Whether it’s wear and tear from regular use or unforeseen damage, recognizing the symptoms of malfunction can pave the way for effective solutions. A proactive approach not only enhances vehicle performance but also enriches the driver’s connection to their machine.

In this guide, we will delve into the fundamental techniques and insights necessary for revitalizing these critical components. By exploring the underlying mechanics and practical methods, we aim to empower readers to undertake this important maintenance task with skill and assurance. Join us as we navigate the essential steps toward restoring the harmony of your vehicle’s gear engagement.

Understanding Manual Transmission Basics

This section delves into the fundamental concepts behind vehicle gear shifting systems, emphasizing their essential role in enhancing driving experience and performance. Knowing how these systems operate is crucial for effective engagement and smooth transitions between gear ratios.

Key components involved in these systems include:

- Gear sets: These determine the vehicle’s speed and torque output.

- Clutch mechanisms: These allow for the engagement and disengagement of gears.

- Shifter assembly: This facilitates the driver’s selection of desired gear ratios.

Understanding how these elements interact is vital for troubleshooting and maintenance. Here are some important aspects to consider:

- Operation: The driver manually selects gears, which engages the appropriate gear set.

- Role of the Clutch: The clutch allows for smooth gear changes by disconnecting the engine from the wheels.

- Importance of Synchronization: Proper timing is essential to avoid gear grinding and ensure seamless shifts.

By grasping these basics, one can appreciate the intricacies of gear shifting systems and their impact on overall vehicle functionality.

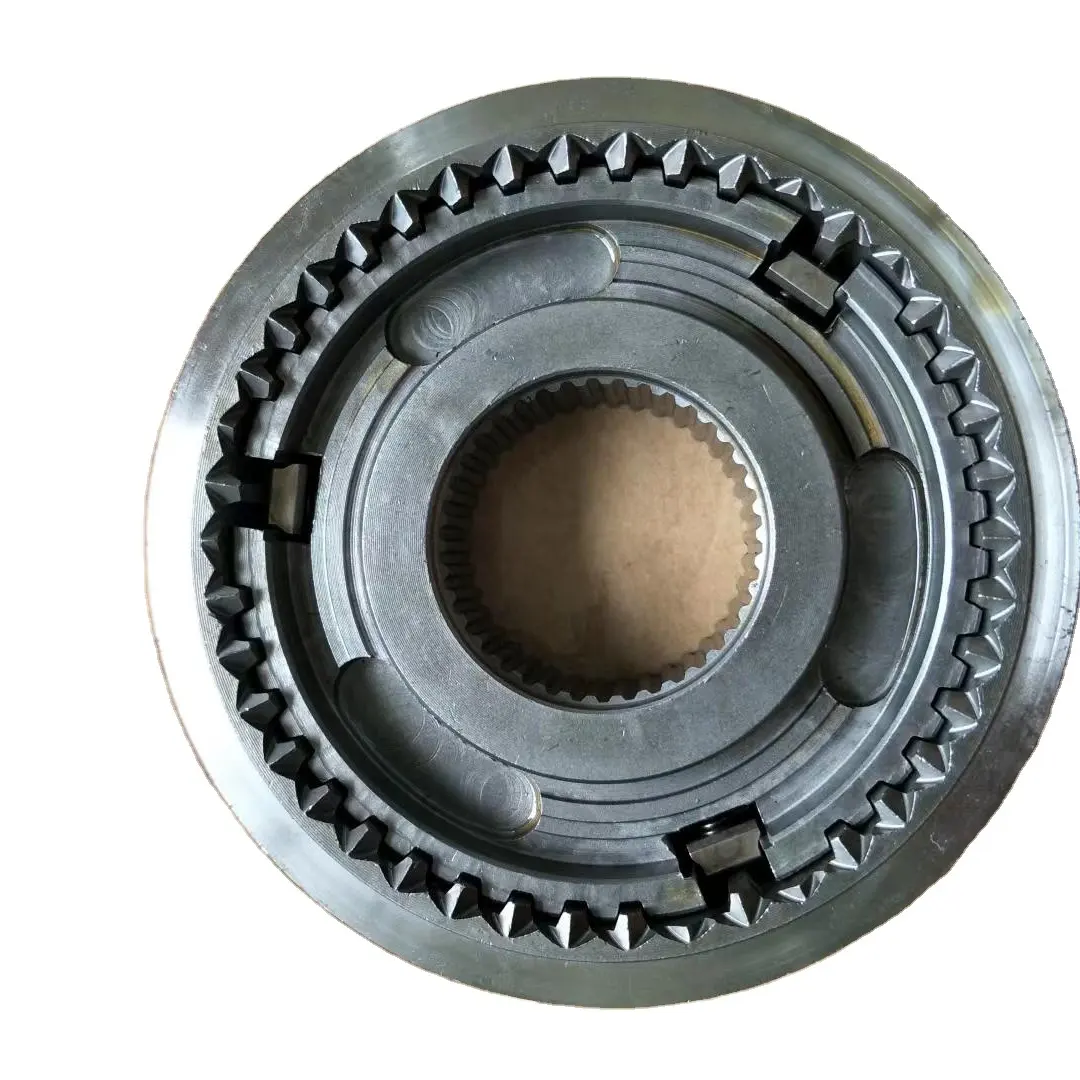

Common Issues with Synchronizers

In the realm of gear engagement mechanisms, several prevalent problems can arise that hinder their efficiency and functionality. These issues often lead to difficulties in shifting gears smoothly, resulting in a frustrating driving experience. Understanding these common challenges can help in their diagnosis and resolution.

Wear and Tear

Over time, components can suffer from wear, diminishing their ability to engage properly. This degradation can manifest in various ways, affecting overall performance.

Misalignment

Improper alignment of parts can lead to significant issues, causing gears to clash or not engage fully. Ensuring correct alignment is crucial for smooth operation.

| Issue | Description | Symptoms |

|---|---|---|

| Wear | Gradual erosion of surfaces due to friction. | Difficulty shifting, grinding noise. |

| Misalignment | Improper positioning of components. | Gears not engaging, unusual noises. |

| Contamination | Presence of debris or fluid leaks affecting operation. | Erratic shifting, increased resistance. |

Tools Required for Synchronizer Repair

When undertaking the intricate task of restoring shifting components, having the right equipment is essential for success. The proper tools not only facilitate the process but also ensure that each part is handled with care and precision, ultimately leading to a more effective overhaul.

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Snap Ring Pliers | Essential for removing and installing retaining rings. |

| Pullers | Helps in extracting components without damage. |

| Calipers | Used for precise measurements of components. |

| Cleaning Supplies | Necessary for maintaining a clean work environment and components. |

| Lubricants | Important for ensuring smooth operation of moving parts. |

Equipped with these essential instruments, the process of restoring gear engagement systems becomes more manageable and efficient, allowing for a thorough and effective overhaul.

Step-by-Step Repair Process

This section outlines the comprehensive method for restoring the critical components that facilitate smooth gear shifting. Each step is designed to ensure efficiency and effectiveness, leading to optimal performance once completed.

| Step | Description |

|---|---|

| 1 | Begin by disassembling the relevant parts carefully to avoid damage. |

| 2 | Inspect the components for wear and tear, identifying any that need attention. |

| 3 | Clean all parts thoroughly to remove debris and old lubricant. |

| 4 | Replace worn components with new or refurbished ones, ensuring a proper fit. |

| 5 | Reassemble the unit carefully, double-checking each connection and alignment. |

| 6 | Test the functionality after reassembly to confirm smooth operation. |

Diagnosing Synchronizer Problems

Identifying issues within a shifting mechanism is crucial for ensuring optimal vehicle performance. Several symptoms may indicate malfunctioning components, requiring careful observation and systematic troubleshooting. By understanding the common signs of trouble, one can effectively address the underlying causes and restore functionality.

Common Symptoms of Malfunction

Drivers often report difficulties in engaging gears, unusual noises during shifting, or a grinding sensation when transitioning between gears. These issues may arise from wear and tear, misalignment, or insufficient lubrication. It is essential to listen for these auditory clues and monitor the feel of the gear lever to pinpoint potential problems.

Diagnostic Steps

To accurately diagnose the issue, begin with a visual inspection of the related components. Look for signs of wear, damage, or contamination. Next, perform a functional test by attempting to shift through the gears while observing any irregularities. Finally, consider checking fluid levels and quality, as improper lubrication can significantly impact the mechanism’s performance.

Rebuilding vs. Replacing Synchronizers

When facing issues with gear engagement mechanisms, two primary options often arise: refurbishment and outright replacement. Each approach has its own advantages and disadvantages, making it essential to understand the nuances before making a decision.

Refurbishment typically involves disassembling the component, replacing worn parts, and reassembling it to restore functionality. This process can be cost-effective and allows for the use of original materials, which might maintain the integrity of the overall system. However, it may not always address underlying issues that could arise in the future.

On the other hand, replacement means sourcing a new or refurbished component to install. This option often ensures enhanced performance and reliability since new parts are less likely to have hidden defects. Nevertheless, it can be more expensive and may require additional adjustments during installation.

- Refurbishment Pros:

- Cost-effective solution

- Retains original materials

- Can provide extended lifespan if done correctly

- Refurbishment Cons:

- May not resolve all underlying issues

- Requires skilled labor for effective execution

- Replacement Pros:

- Improved reliability with new parts

- Less risk of future failures

- Often comes with a warranty

- Replacement Cons:

- Higher cost compared to refurbishment

- Possible compatibility issues with existing components

Ultimately, the choice between refurbishing and replacing comes down to factors such as budget, expected longevity, and the specific condition of the gear engagement mechanism. Assessing these elements carefully can lead to a more informed and satisfactory decision.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s shifting components requires attentive care and regular maintenance. By adopting certain practices, you can significantly extend their lifespan and enhance overall performance.

1. Regular Fluid Checks: Periodically inspect and replace the fluid used in the shifting system. Clean and high-quality fluids help in reducing wear and provide smoother operation.

2. Driving Habits: Adopt gentle driving techniques. Avoid sudden accelerations and hard shifts, as these can create unnecessary stress on the components.

3. Proper Warm-Up: Allow the engine and shifting system to warm up before aggressive driving. This practice helps in achieving optimal operating temperatures and improves efficiency.

4. Use of Quality Parts: When replacement is necessary, opt for high-quality components. Subpar parts can lead to quicker deterioration and may compromise performance.

5. Periodic Inspections: Conduct routine checks to identify any signs of wear or damage early. Addressing minor issues before they escalate can save time and resources in the long run.

6. Avoid Overloading: Do not exceed the recommended load capacity of your vehicle. Excess weight can put additional strain on the shifting components, leading to premature failure.

7. Professional Servicing: Schedule regular inspections and maintenance with a qualified technician. Professional assessments can catch potential issues that might be overlooked during routine checks.

Implementing these strategies will contribute to the longevity of your vehicle’s shifting elements, ensuring a smoother and more reliable driving experience.

Signs of Synchronizer Wear

Recognizing the early indicators of wear in key components is essential for maintaining optimal performance in vehicles. Over time, specific symptoms may arise that suggest the internal mechanisms are not functioning as they should. These signs can lead to more significant issues if left unaddressed, ultimately affecting driving experience and safety.

Common Symptoms

Drivers often report difficulty when shifting gears, which can manifest as grinding noises or resistance during the process. Additionally, experiencing unexpected popping out of gear can indicate that the internal parts are losing their effectiveness. Unusual sounds during gear changes, such as clashing or whining, may also point towards wear and tear.

Visual and Physical Indicators

Inspection of the affected components may reveal visible signs of damage, such as scoring or excessive wear patterns. Furthermore, if there is an observable fluid leak or discoloration of the lubricant, it may suggest that seals or other related parts are compromised. Addressing these visual cues promptly can prevent more severe complications down the line.

Impact of Improper Shifting Techniques

Shifting gears incorrectly can lead to significant issues within the vehicle’s operating system. When drivers fail to execute gear changes smoothly, it can result in increased wear and tear on components, affecting overall performance and longevity. Understanding the repercussions of poor techniques is crucial for maintaining the efficiency of the drive system.

Wear on Components: Inadequate shifting can cause excessive friction between moving parts. This friction not only accelerates wear but can also lead to premature failures, requiring costly interventions.

Driving Experience: A lack of finesse during gear transitions can result in a jarring experience. Passengers may find the ride uncomfortable, detracting from the overall enjoyment of the journey.

Fuel Efficiency: Inefficient gear changes can disrupt the engine’s optimal performance, leading to increased fuel consumption. This not only impacts the wallet but also contributes to higher emissions.

Potential for Damage: Continually shifting improperly can cause damage to vital elements of the vehicle. Over time, this damage can escalate, leading to more serious mechanical failures that may require extensive service.

In conclusion, mastering the art of smooth gear changes is essential for both the performance and longevity of a vehicle. By employing proper techniques, drivers can mitigate the risks associated with improper shifting and ensure a more enjoyable and efficient driving experience.

Cost Considerations for Repairs

When addressing issues within vehicle gear mechanisms, understanding the financial aspects is crucial. Costs can vary significantly based on several factors, from the complexity of the task to the type of components involved. It’s essential to analyze these elements to make informed decisions regarding maintenance and upgrades.

Factors Influencing Costs

- Parts Quality: The choice between OEM and aftermarket components can greatly affect expenses.

- Labor Rates: Prices can differ based on location and the expertise of the technician performing the work.

- Vehicle Make and Model: Some vehicles require specialized parts, which can drive up costs.

- Extent of Damage: Minor adjustments may be more economical than complete overhauls.

Estimating Total Expenses

It’s advisable to seek multiple estimates before proceeding. Here are steps to better assess overall costs:

- Research average labor rates in your area.

- Compare prices of parts from different suppliers.

- Consult professionals for a detailed diagnosis of the issue.

- Consider potential future maintenance needs to avoid additional costs down the line.

By taking these factors into account, vehicle owners can better navigate the financial landscape of gear mechanism issues and ensure their investments are well-placed.