Understanding the intricacies of marine propulsion systems is essential for any enthusiast. Proper maintenance ensures optimal performance, longevity, and safety during aquatic adventures. This section will delve into various aspects of upkeep, highlighting common challenges and their solutions.

Regular inspections are crucial for identifying potential issues before they escalate. Familiarizing yourself with the components will empower you to perform basic evaluations and recognize when professional assistance is necessary. Knowledge of routine checks not only enhances the reliability of your vessel but also provides peace of mind.

When complications arise, knowing how to address them is vital. This guide will explore various techniques and strategies to tackle typical problems encountered with these propulsion systems. By following the outlined procedures, you can effectively maintain functionality and enjoy seamless excursions on the water.

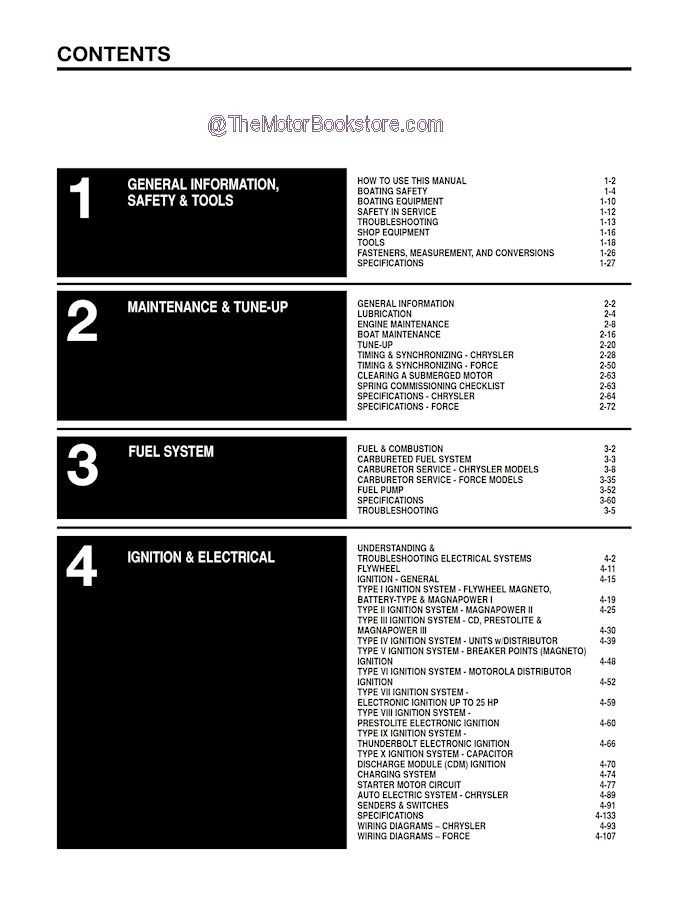

Common Issues with Outboard Engines

When it comes to marine propulsion systems, various challenges can arise that hinder performance and reliability. Understanding these typical problems can significantly aid in maintaining optimal functionality. This section highlights some prevalent complications that users may encounter while operating their watercraft.

Fuel-Related Challenges

One of the most frequent issues involves fuel delivery. Problems such as contaminated fuel or clogged lines can lead to poor engine performance or failure to start. Ensuring that the fuel system is clean and that high-quality fuel is used is essential for smooth operation. Regular maintenance can help prevent these complications from becoming significant obstacles.

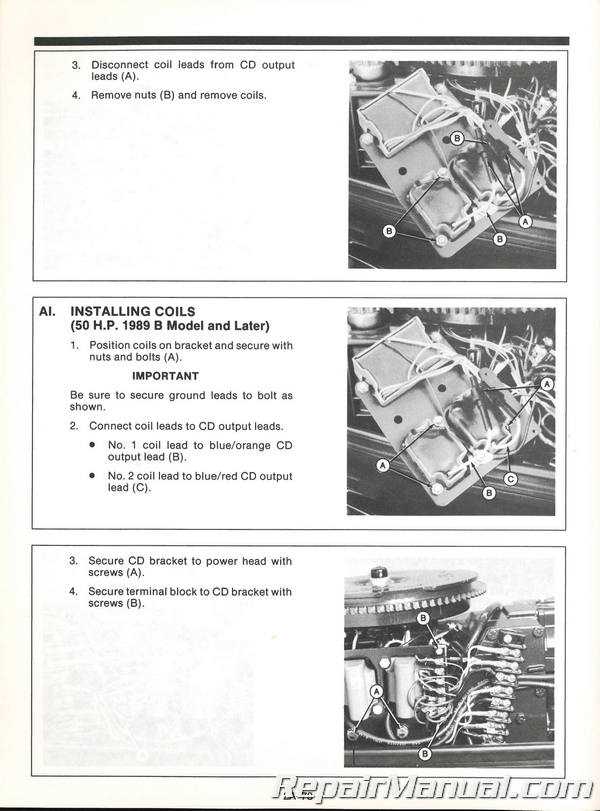

Electrical System Failures

Another common area of concern is the electrical system. Faulty wiring, dead batteries, or malfunctioning ignition components can cause erratic behavior or complete shutdowns. Periodic inspections of electrical connections and components can help identify potential failures early, allowing for timely repairs and reducing the risk of being stranded on the water.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and servicing of aquatic engines. Proper tools not only streamline the process but also ensure that tasks are completed safely and efficiently. This section outlines the fundamental instruments that every technician should have on hand.

Basic Hand Tools

Wrenches, screwdrivers, and pliers are the backbone of any technician’s toolkit. These items are essential for loosening and tightening various components. A variety of sizes is recommended to accommodate different fittings.

Specialized Equipment

In addition to basic tools, some specialized instruments can greatly enhance repair capabilities. Compression testers and digital multimeters are invaluable for diagnosing issues and ensuring optimal performance. Having these tools available can make troubleshooting more efficient and accurate.

Step-by-Step Maintenance Guide

This section offers a comprehensive approach to ensuring the longevity and optimal performance of your watercraft engine. By following these systematic procedures, you can enhance the efficiency and reliability of your vessel. Regular upkeep is essential for preventing unexpected breakdowns and ensuring a smooth sailing experience.

Regular Inspection Procedures

Conducting frequent assessments is crucial to identify potential issues early. Here are some key areas to focus on:

| Component | Inspection Frequency | Notes |

|---|---|---|

| Fuel System | Every trip | Check for leaks and ensure fuel quality. |

| Cooling System | Weekly | Examine hoses and connections for wear. |

| Electrical Connections | Monthly | Ensure all connections are secure and free of corrosion. |

Seasonal Maintenance Checklist

At the beginning of each season, follow this checklist to prepare your engine:

| Task | Details |

|---|---|

| Change Oil | Replace with high-quality oil recommended for your engine type. |

| Replace Filters | Install new fuel and oil filters to maintain efficiency. |

| Inspect Propeller | Check for damage or debris that may affect performance. |

Diagnosing Engine Performance Problems

Identifying issues with engine efficiency is crucial for maintaining optimal performance. Various symptoms may indicate underlying problems, ranging from unusual noises to poor acceleration. Understanding these signs can help in pinpointing the root causes and implementing appropriate solutions.

Start by observing any irregularities in operation, such as difficulty starting or stalling during use. These issues might stem from fuel delivery problems, ignition failures, or issues with the air intake system. Listening closely for abnormal sounds can also provide valuable insights, as knocking or excessive vibration often signals mechanical wear or imbalance.

Next, checking the fuel quality and ensuring that the correct type of fuel is being used can significantly affect performance. Contaminated or stale fuel may lead to combustion issues, resulting in sluggish operation or reduced power output. It’s essential to inspect fuel lines and filters for blockages or leaks that could hinder proper fuel flow.

Additionally, examining the electrical components, including the battery, spark plugs, and wiring, is vital. Weak batteries or faulty connections can lead to starting problems or erratic engine behavior. Regular maintenance and timely replacement of worn-out components are key to ensuring reliable performance.

Finally, performing a comprehensive diagnostic check using specialized tools can reveal deeper issues that may not be immediately apparent. This process involves analyzing engine codes and performance metrics to detect any anomalies. By systematically assessing each aspect of the engine, one can effectively address performance-related concerns and restore functionality.

Fuel System Troubleshooting Tips

Diagnosing issues within the fuel delivery system is crucial for ensuring optimal performance and reliability. Understanding the common signs of fuel-related problems can help in identifying and resolving issues swiftly. This section outlines essential troubleshooting strategies to aid in maintaining a well-functioning fuel system.

Identifying Fuel Flow Issues

Start by examining the fuel lines for any signs of cracks, blockages, or leaks. Inspecting connections and filters is vital, as contaminants can hinder fuel flow. If the engine struggles to start or runs erratically, there may be an obstruction within the delivery pathway.

Checking Fuel Quality

Evaluate the quality of the fuel being used. Stale or contaminated fuel can lead to poor combustion and performance. Regularly replacing old fuel and using additives can help maintain system integrity. Additionally, ensuring proper storage conditions for fuel can prevent degradation and prolong system health.

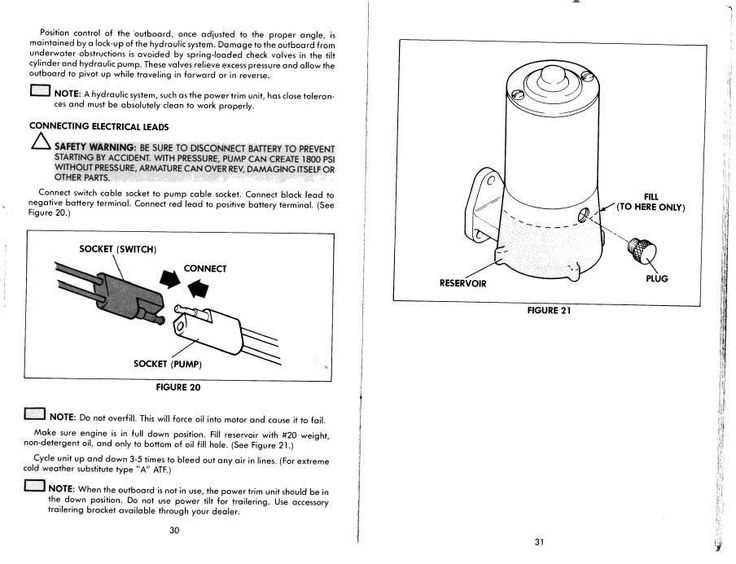

Electrical System Inspection Procedures

This section outlines the essential steps for evaluating the electrical components of your vessel’s propulsion system. Regular inspection is crucial for ensuring reliable performance and safety while operating. A thorough examination can help identify potential issues before they lead to more significant problems, enhancing the longevity and functionality of the equipment.

Initial Assessment

Begin the evaluation by checking the visual condition of wiring and connections. Look for signs of wear, corrosion, or damage that could compromise performance. Ensuring that all connections are tight and secure is vital to maintaining efficient operation.

Testing Components

After the initial visual assessment, proceed with testing key components. Utilize a multimeter to measure voltage and resistance at various points in the electrical circuit. This will help confirm that all parts are functioning within their specified ranges.

| Component | Normal Voltage Range | Resistance Value |

|---|---|---|

| Battery | 12.4 – 12.6 V | N/A |

| Starter Relay | 12.0 – 13.0 V | 0.2 – 0.5 Ohms |

| Ignition Coil | 12.0 – 14.5 V | 3 – 5 Ohms |

Conclude the inspection by verifying the functionality of any switches and circuit breakers. Ensure they operate smoothly and reset properly. Proper maintenance of the electrical system is essential for safe navigation and efficient performance.

Cooling System Repair Techniques

The efficiency and longevity of a marine propulsion unit significantly depend on its thermal management. Proper maintenance of the cooling system is crucial for optimal performance and to prevent overheating. Various approaches can be employed to troubleshoot and enhance this vital component.

Regular Inspection: Conducting routine checks of the cooling components is essential. Look for signs of wear, corrosion, or blockages. Pay special attention to hoses, pumps, and thermostats, as these parts are critical in ensuring a steady flow of coolant.

Cleaning and Flushing: Accumulation of debris and mineral deposits can impede the cooling process. Periodically flushing the system with fresh water or a suitable cleaning solution helps remove contaminants. This practice not only restores functionality but also prevents future issues.

Seal and Gasket Replacement: Over time, seals and gaskets may degrade, leading to leaks and decreased efficiency. Replacing these components ensures that the system maintains proper pressure and coolant levels, which are vital for effective cooling.

Thermostat Testing: The thermostat regulates the temperature of the coolant. Testing its operation can reveal if it is functioning correctly. A faulty thermostat can cause overheating or inefficient cooling, necessitating its replacement.

Pump Maintenance: The water pump is integral to circulating coolant. Inspecting and servicing the pump regularly, including checking impeller condition and housing integrity, can prevent cooling failures and enhance performance.

Propeller and Drive System Checks

Ensuring the functionality of the propulsion components is crucial for optimal performance and safety. Regular assessments of these parts can help prevent malfunctions and enhance efficiency. This section outlines essential steps to examine the propeller and drive system effectively.

Visual Inspection

Begin by conducting a thorough visual inspection of the propeller and associated drive system. Look for signs of wear, damage, or corrosion that could affect performance. Pay close attention to the blades and shaft, ensuring they are free from any debris or obstructions.

Performance Evaluation

Next, evaluate the operational efficiency of the propulsion system. This involves checking for unusual vibrations or noises during use, which may indicate underlying issues. Monitoring the response during acceleration and deceleration can also provide insight into the health of these components.

| Component | Check Frequency | Common Issues |

|---|---|---|

| Propeller Blades | Every Use | Chips, Dents, Corrosion |

| Shaft | Monthly | Wear, Misalignment |

| Gearbox | Seasonal | Leaks, Overheating |

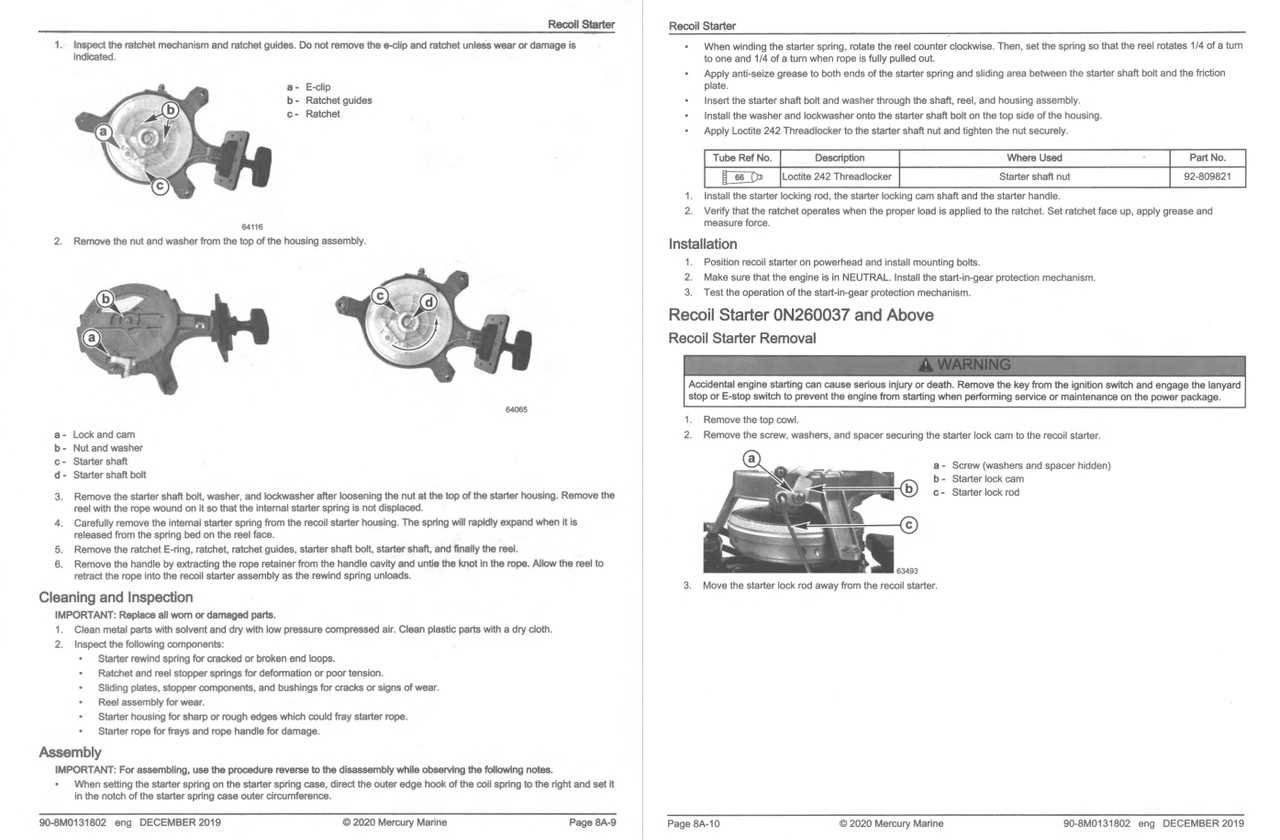

Common Parts Replacement Procedures

Maintaining the functionality of your aquatic propulsion system often requires replacing various components. Understanding the typical procedures involved can enhance your efficiency and ensure smooth operation.

-

Identify the Component:

Begin by determining which part needs replacement. Common items include the propeller, fuel filter, and spark plugs.

-

Gather Necessary Tools:

Ensure you have the appropriate tools at hand, such as wrenches, pliers, and screwdrivers, to facilitate the replacement process.

-

Remove the Old Part:

Carefully detach the worn or damaged component by following the specified steps to avoid causing further issues.

-

Install the New Component:

Position the new part correctly, ensuring it fits snugly and aligns with other related elements.

-

Test the System:

After installation, conduct a thorough test to confirm that the new part is functioning as intended.

By following these basic guidelines, you can effectively manage the upkeep of essential components, ultimately extending the lifespan of your equipment.

Preventive Maintenance for Longevity

Regular upkeep is essential to ensure equipment remains functional over time, reducing unexpected issues and improving overall performance. By taking consistent care of various components, users can extend the lifespan of their machines and maintain optimal efficiency during each use.

Routine Cleaning and Lubrication

Consistent cleaning of critical parts removes debris that can lead to wear and tear. Additionally, applying the right type of lubricant to moving sections reduces friction and helps components work smoothly. Here are some key steps:

- Wipe down surfaces to remove dirt and salt residue after every use.

- Apply lubricant to joints, pivots, and other moving parts at regular intervals.

- Check seals and connections for any signs of wear and address issues promptly.

Inspection and Replacement of Parts

Inspecting parts regularly allows for early detection of any wear or damage, preventing larger issues down the road. Following a checklist can be helpful for systematic inspections:

- Examine belts, hoses, and cables for cracks or fraying, replacing as needed.

- Check bolts and fasteners to ensure all are tightened correctly.

- Test electrical connections and replace any corroded components to avoid power issues.

By following these preventive measures, users can help ensure that

Resources for Further Assistance

When seeking guidance on maintaining and troubleshooting your equipment, a range of specialized resources can provide additional insights. These materials can help improve your understanding of both routine upkeep and complex issues, making it easier to keep your device in optimal condition. Below are some valuable sources to consider, covering various types of support and detailed advice.

Online Communities and Forums

Engaging with online communities dedicated to marine equipment and watercraft maintenance can be immensely helpful. Forums offer discussions where users share personal experiences, advice, and solutions to common problems. Many members are enthusiasts or experts who willingly provide detailed answers, making forums an excellent place to troubleshoot specific concerns.

Official Service Providers

Consulting certified service providers or professional technicians can often be the most reliable way to address complex mechanical issues. Many service centers offer consultation services or technical support that can guide you through various issues. In addition, official websites of these service centers often have resources such as guides, video tutorials, and contact details for one-on-one assistance.

Additional Learning Resources: Various online libraries, technical support sites, and instructional videos can also provide a wealth of information. These resources are designed to cater to a range of expertise levels, from beginners to advanced users, helping you deepen your knowledge of maintenance practices and troubleshooting techniques.