In the realm of automotive care, having access to detailed information is crucial for ensuring the longevity and performance of your vehicle. This resource serves as a beacon for enthusiasts and everyday drivers alike, offering insights into effective troubleshooting, routine upkeep, and essential repairs. With the right knowledge at hand, one can tackle a variety of challenges that may arise over time.

Whether you’re dealing with minor adjustments or more significant issues, understanding the inner workings of your automobile is paramount. This guide is designed to empower you with step-by-step instructions, diagrams, and practical tips that can make even the most daunting tasks manageable. By equipping yourself with this invaluable information, you’ll be well-prepared to maintain your vehicle in optimal condition.

From engine diagnostics to electrical systems, each section provides clear explanations and actionable advice. Embracing the responsibility of car maintenance not only enhances your driving experience but also saves time and money in the long run. Dive into this comprehensive resource and take charge of your vehicle’s health with confidence.

Vehicle Overview

This section provides a comprehensive look at a popular compact sedan known for its reliability and efficiency. This model stands out in the automotive market due to its practical features, comfortable interior, and impressive fuel economy, making it a preferred choice for many drivers.

Key Features

- Efficient engine performance

- Spacious interior with ample legroom

- User-friendly technology and infotainment system

- Strong safety ratings

- Affordable maintenance costs

Performance and Handling

This vehicle is equipped with a range of engines that deliver a balanced mix of power and fuel efficiency. Its handling is responsive, making it easy to maneuver in various driving conditions. The suspension system provides a smooth ride, enhancing overall comfort for both drivers and passengers.

Essential Tools for Repairs

When it comes to maintaining and fixing vehicles, having the right equipment is crucial for achieving effective results. A well-equipped toolkit can significantly simplify the process and ensure that tasks are completed efficiently and safely. Below is a guide to the fundamental instruments every automotive enthusiast should have at their disposal.

Basic Hand Tools

- Wrenches: An assortment of both metric and standard sizes is necessary for loosening and tightening bolts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will cover most fastening needs.

- Pliers: Needle-nose and slip-joint pliers are essential for gripping and manipulating components.

- Socket Set: A comprehensive socket set allows for easier access to fasteners in tight spaces.

Specialized Equipment

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications.

- Jack and Jack Stands: Essential for lifting the vehicle safely while working underneath.

- Diagnostic Scanner: A vital device for identifying issues through error codes from the vehicle’s computer.

- Oil Filter Wrench: Designed specifically for removing and installing oil filters with ease.

Having these essential tools on hand will greatly enhance your ability to perform various tasks, ensuring that your vehicle remains in optimal condition for years to come.

Common Issues with 2005 Corolla

Many vehicle owners encounter similar challenges as their cars age. Identifying and understanding these prevalent problems can assist in maintaining performance and ensuring safety. Below are some frequent concerns associated with this particular model.

Engine Performance

- Rough idling

- Loss of power during acceleration

- Excessive oil consumption

- Check engine light frequently illuminating

Transmission Troubles

- Slipping gears

- Delayed shifting

- Unusual noises while changing gears

- Fluid leaks

Addressing these issues promptly can help avoid more extensive repairs and keep the vehicle running smoothly.

Step-by-Step Maintenance Procedures

This section outlines essential tasks for keeping your vehicle in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of your automobile. Follow these straightforward procedures to ensure your ride remains reliable and safe on the road.

1. Oil Change

Changing the oil is crucial for engine health. Follow these steps:

- Gather necessary tools: oil filter wrench, socket set, and oil catch pan.

- Warm up the engine to thin the oil, then turn it off.

- Lift the vehicle using a jack and secure it with jack stands.

- Remove the drain plug and let the old oil drain completely.

- Replace the oil filter and reinstall the drain plug.

- Pour in new oil using a funnel, checking the level with the dipstick.

- Start the engine and let it run for a few minutes, checking for leaks.

2. Tire Rotation

Regularly rotating tires ensures even wear and extends their life. Follow these steps:

- Check tire pressure and inflate if necessary.

- Loosen the lug nuts on all wheels while the vehicle is on the ground.

- Lift the vehicle with a jack and secure with jack stands.

- Remove the wheels and switch their positions according to the pattern (e.g., front to back, side to side).

- Reattach the wheels and tighten the lug nuts in a crisscross pattern.

- Lower the vehicle and check the tire pressure once again.

Engine Troubleshooting Guide

This section provides essential insights for diagnosing and resolving common issues that may arise within the powertrain. Understanding the symptoms and potential causes can significantly aid in restoring optimal performance.

Symptoms of Engine Problems

Recognizing the signs of engine trouble is crucial. Typical indicators include unusual noises, decreased power, rough idling, and the illumination of warning lights on the dashboard. Each symptom can point to different underlying issues that require careful analysis.

Common Issues and Solutions

One frequent problem is poor fuel efficiency, which may stem from factors such as a clogged air filter or fuel injector issues. Regular maintenance of these components can enhance performance. Another common concern is overheating, often caused by low coolant levels or a malfunctioning thermostat. Addressing these areas promptly can prevent severe damage.

Diagnostic Techniques

Employing diagnostic tools, such as OBD-II scanners, can provide valuable insights into engine performance. These devices read trouble codes that help identify specific problems. Additionally, conducting visual inspections of belts, hoses, and connections can reveal leaks or wear that necessitate attention.

When to Seek Professional Help

If basic troubleshooting does not resolve the issue, it may be time to consult a qualified technician. Complex problems, such as internal engine failures, often require specialized knowledge and equipment for proper diagnosis and repair.

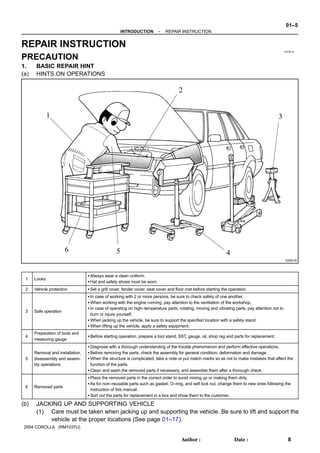

Electrical System Diagnostics

The electrical system of a vehicle plays a crucial role in its overall functionality, influencing everything from ignition to various comfort features. Proper diagnostics are essential for identifying issues that can affect performance and safety. This section will guide you through the processes and tools necessary for troubleshooting electrical problems effectively.

Common Electrical Issues

Vehicles often encounter several recurring electrical challenges. These may include malfunctioning lights, battery drainage, or issues with the starter. Understanding the symptoms of these problems is the first step in diagnosing them. For example, flickering headlights may indicate a failing alternator, while a slow-cranking engine could suggest a weak battery.

Diagnostic Tools and Techniques

Utilizing the right tools is vital for effective troubleshooting. A multimeter is essential for checking voltage, current, and resistance in various components. In addition, an OBD-II scanner can provide valuable insights by reading diagnostic trouble codes (DTCs) that the onboard computer generates. These tools allow you to pinpoint issues accurately, ensuring that repairs can be made efficiently and effectively.

Suspension and Steering Repairs

This section provides essential guidance on maintaining and restoring the components that ensure smooth handling and stability in your vehicle. Proper attention to these systems enhances safety and driving comfort, addressing common issues that may arise over time.

Suspension System Maintenance

The suspension system plays a crucial role in absorbing shocks and providing a comfortable ride. Regular inspection of components such as shocks, struts, and springs is vital. Look for signs of wear, such as leaking fluid or unusual noises when driving over bumps. Replacing worn parts promptly can prevent further damage and enhance vehicle performance.

Steering System Care

Maintaining the steering mechanism is essential for precise control. Check for any play in the steering wheel and listen for strange sounds when turning. If steering feels loose or unresponsive, it may indicate issues with the rack and pinion or other related components. Fluid levels should also be monitored, ensuring that they are at optimal levels to maintain smooth operation.

Braking System Maintenance Tips

Maintaining the braking system is crucial for ensuring safe and efficient vehicle operation. Regular checks and timely interventions can prevent costly repairs and enhance the longevity of braking components. Here are some essential tips to help you keep your braking system in optimal condition.

First, routinely inspect brake pads and rotors for wear. If you notice any thinning or uneven surfaces, consider replacing them to avoid diminished performance. Additionally, listen for unusual sounds such as squeaking or grinding, which may indicate that maintenance is needed.

Next, check the brake fluid level and quality regularly. Low fluid levels can lead to decreased braking efficiency, while contaminated fluid can harm components. If the fluid appears dark or murky, it’s advisable to flush and replace it.

Ensure that brake lines and hoses are free from leaks or cracks. Any signs of deterioration should prompt immediate attention, as compromised lines can lead to brake failure.

Finally, pay attention to the overall feel of the brake pedal. If it feels spongy or unresponsive, it may indicate air in the brake lines or other issues that require professional evaluation. Consistent monitoring of these aspects will help maintain a reliable braking system.

Transmission Fluid Change Instructions

Changing the transmission fluid is an essential maintenance task that helps ensure optimal performance and longevity of the vehicle’s transmission system. Regularly replacing the fluid prevents contamination and degradation, which can lead to costly repairs and decreased efficiency.

Tools and Materials Required:

- New transmission fluid (check specifications)

- Fluid pump or funnel

- Wrench set

- Drain pan

- Rags or shop towels

Step-by-Step Instructions:

1. Prepare the Vehicle: Ensure the vehicle is parked on a level surface. Engage the parking brake for safety. Allow the engine to cool if it has been running.

2. Locate the Transmission Pan: Identify the transmission pan underneath the vehicle. Refer to the owner’s guide for specific details if necessary.

3. Drain the Old Fluid: Place a drain pan under the transmission pan. Carefully remove the drain plug using the appropriate wrench, allowing the old fluid to completely drain into the pan.

4. Replace the Filter: If applicable, remove the old transmission filter and install a new one according to the manufacturer’s guidelines.

5. Reinstall the Drain Plug: Once the fluid has drained, securely reinstall the drain plug, ensuring it is tightened to the recommended torque specifications.

6. Add New Fluid: Using a fluid pump or funnel, add the new transmission fluid through the dipstick tube or designated fill port until it reaches the correct level as indicated on the dipstick.

7. Check Fluid Level: Start the engine and allow it to reach operating temperature. With the engine running, shift through all gears and return to park. Check the fluid level again and add more fluid if necessary.

Final Checks: After the process, inspect for any leaks around the drain plug and filter area. Dispose of the old fluid and filter responsibly, following local regulations.

Cooling System Checkup Steps

Maintaining an efficient cooling system is crucial for ensuring optimal engine performance and longevity. Regular inspection and maintenance can prevent overheating and costly repairs. This section outlines essential steps to effectively check and maintain the cooling system.

Step-by-Step Inspection

The following steps should be undertaken to ensure the cooling system is functioning properly:

| Step | Description |

|---|---|

| 1 | Check Coolant Level: Inspect the coolant reservoir to ensure it is filled to the recommended level. Add the appropriate type of coolant if necessary. |

| 2 | Inspect Hoses: Examine all hoses for any signs of cracks, leaks, or wear. Replace any damaged hoses to prevent fluid loss. |

| 3 | Examine Radiator: Look for any debris or blockages on the radiator. Clean the exterior to ensure proper airflow and check for leaks. |

| 4 | Test Thermostat: Ensure the thermostat is functioning correctly by checking if the engine reaches the appropriate operating temperature. |

| 5 | Check Water Pump: Listen for unusual noises from the water pump and check for leaks around the pump area. |

| 6 | Inspect Belts: Examine all belts for signs of wear or fraying. Replace any belts that are damaged to ensure proper operation of the cooling system. |

Final Checks and Maintenance

After completing the inspection, it is important to monitor the cooling system regularly. Schedule a thorough maintenance check at least once a year, or more frequently if the vehicle is often used in extreme conditions. Keeping a log of maintenance activities can also help track the performance of the cooling system over time.

Interior Components Repair Guide

This section provides essential insights into maintaining and fixing various parts within the cabin of your vehicle. Understanding the layout and function of each component is crucial for ensuring a comfortable and safe driving experience. Whether you are addressing minor issues or performing routine maintenance, a comprehensive knowledge of interior elements can enhance the longevity and performance of your automobile.

Common Interior Issues

Several problems may arise within the cabin that can affect functionality and comfort. Below is a table summarizing typical issues and their potential solutions:

| Issue | Symptoms | Suggested Solution |

|---|---|---|

| Loose Dashboard | Rattling noise, visible gaps | Tighten screws and reattach panels |

| Worn Upholstery | Tears, fading, stains | Patch or replace fabric; use cleaners |

| Malfunctioning Controls | Unresponsive buttons or knobs | Inspect wiring; replace defective components |

| Faulty Air Conditioning | Poor airflow, unusual noises | Check refrigerant levels; clean filters |

Maintenance Tips

Regular upkeep is essential for the longevity of interior components. Ensure to clean surfaces frequently and address any issues promptly to avoid further damage. Familiarizing yourself with the basic tools and techniques will empower you to manage repairs effectively, enhancing the overall driving experience.

Safety Precautions During Repairs

When undertaking maintenance or fixes on a vehicle, ensuring personal safety and protecting the surrounding environment is paramount. Proper precautions can significantly reduce the risk of accidents, injuries, or damage to components. Adhering to established safety protocols is essential for anyone engaging in such activities.

Essential Gear

Wearing appropriate protective equipment is crucial. This includes gloves to shield hands from sharp objects and chemicals, as well as safety goggles to protect eyes from debris. Additionally, employing steel-toed boots can prevent injuries from heavy parts or tools falling. A well-fitting work apron can also offer protection and convenience by keeping tools easily accessible.

Work Environment

Ensuring a clean and organized workspace cannot be overstated. Removing clutter minimizes the risk of tripping or losing tools. Adequate lighting is essential for spotting potential hazards and clearly seeing what you are working on. If possible, using a well-ventilated area helps dissipate any harmful fumes or dust generated during the process.