This section serves as an essential resource for individuals seeking to enhance their understanding of automotive care and troubleshooting techniques. It aims to provide practical insights and methods to address common issues encountered with a specific type of vehicle.

Through detailed explanations and user-friendly guidance, readers will be equipped with the knowledge necessary to tackle various maintenance tasks effectively. Whether it involves routine checks or more complex repairs, this guide will assist in navigating the intricacies of vehicle upkeep.

By following the outlined procedures and recommendations, vehicle owners can ensure optimal performance and longevity of their automobiles. This resource emphasizes the importance of proactive measures and informed decision-making in maintaining one’s vehicle in peak condition.

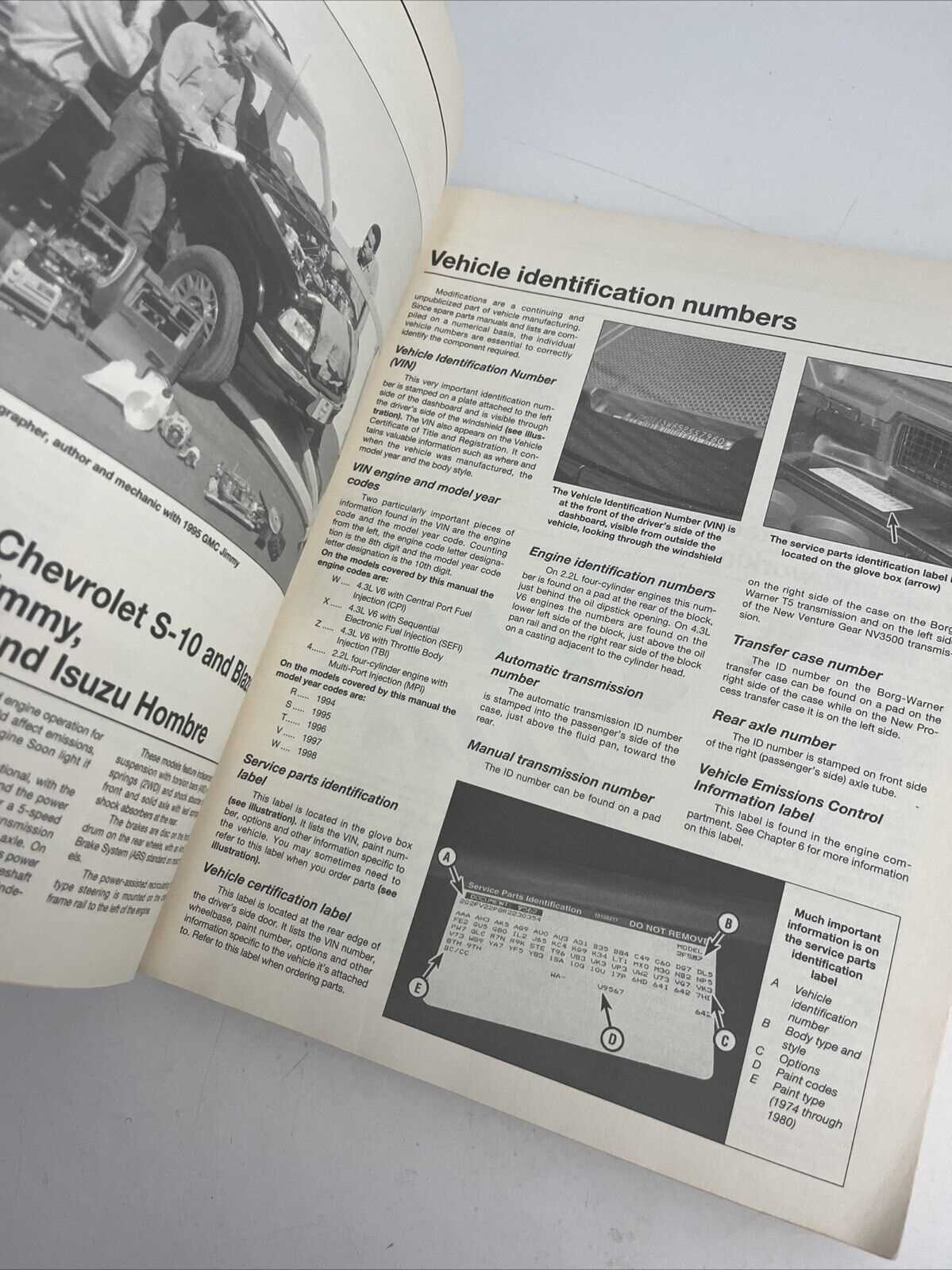

1994 GMC Sonoma Repair Manual

This section provides essential guidance for maintaining and troubleshooting a specific vehicle model. It covers various aspects of upkeep, helping owners ensure optimal performance and longevity. Detailed instructions and tips aim to facilitate effective management of common issues that may arise during use.

General Maintenance Tips

Regular upkeep is crucial for ensuring the vehicle runs smoothly. Routine checks on fluid levels, tire pressure, and battery condition can prevent minor problems from escalating. Additionally, following a scheduled service plan contributes to overall reliability.

Troubleshooting Common Issues

Identifying and resolving typical complications is essential for maintaining functionality. Common signs such as unusual noises or performance issues can often indicate the need for inspection. Understanding the potential causes of these symptoms aids in timely interventions, ultimately preserving the vehicle’s efficiency.

Understanding Common Issues in Older Models

As vehicles age, they often develop recurring issues that can affect performance and reliability. Understanding these common challenges can help owners maintain their vehicles effectively and anticipate potential repairs.

- Electrical System Problems: Older vehicles may experience wiring wear and tear, leading to issues such as flickering lights, faulty switches, and inconsistent sensor readings. Inspecting and replacing worn wiring can mitigate these problems.

- Cooling System Failures: Aging components like radiators, hoses, and thermostats can become less efficient, leading to overheating. Regular checks of coolant levels and replacing older parts can help prevent serious engine damage.

- Suspension Wear: Over time, components like shock absorbers, springs, and bushings may wear out, resulting in a less comfortable ride and reduced handling. Routine suspension inspections and timely part replacements improve both safety and ride quality.

- Brake System Degradation: Brake pads, rotors, and lines can deteriorate, reducing stopping power and increasing the risk of failure. Frequent inspection and replacement of these parts as needed can ensure reliable braking performance.

- Transmission Concerns: With time, transmission fluid can degrade, and parts may start to slip or struggle to engage. Regular fluid changes and inspections help extend transmission life and prevent sudden issues.

By understanding and addressing these typical concerns, owners of older vehicles can maintain safety and prolong the lifespan of their automobiles.

Essential Tools for DIY Repairs

For successful vehicle maintenance, having a reliable set of basic tools is crucial. These tools enable efficiency, precision, and safety in each task, making the difference between a smooth process and a challenging repair.

- Socket Set: Essential for removing and tightening bolts and nuts, a high-quality socket set offers the flexibility needed for various sizes and types of fasteners.

- Wrenches: Open-end, box-end, and adjustable wrenches are all useful for accessing tight spots and ensuring a secure grip on bolts of different sizes.

- Torque Wrench: This tool is vital for applying the correct force on bolts, helping avoid under or over-tightening and ensuring parts are securely fastened.

- Screwdrivers: Both flathead and Phillips screwdrivers are frequently needed for interior and exterior components, making them a staple for adjustments and part replacements.

- Pliers and Wire Cutters: Useful for gripping, bending, and cutting wires, these tools are essential for electrical work and tight spaces.

- Jack and Jack Stands: To safely lift the vehicle, a sturdy jack paired with reliable jack stands is necessary for any work under the chassis.

- Multimeter: For diagnosing electrical issues, a multimeter provides accurate readings of voltage, current, and resistance, aiding in effective troubleshooting.

- Work Light: Good visibility is key, and a portable work light ensures clear vision, even in dark engine areas or low-light conditions.

Equipping yourself with these essential tools prepares you for various repair tasks, making DIY maintenance more efficient, safer, and ultimately more rewarding.

Maintenance Tips for Engine Longevity

Regular engine maintenance is crucial to ensure smooth performance and extend the lifespan of your vehicle’s engine. Simple preventive steps can go a long way in keeping the engine running efficiently while reducing the risk of costly repairs over time.

- Oil and Filter Changes: Replace engine oil and filters as recommended to maintain proper lubrication and remove contaminants that can harm engine components.

- Coolant Check: Regularly inspect coolant levels and quality to prevent overheating. Proper cooling is essential to avoid engine wear and maintain optimal temperature.

- Air Filter Maintenance: A clean air filter allows efficient air intake, which enhances fuel combustion and minimizes strain on the engine. Replace it as per the maintenance schedule or sooner if needed.

- Spark Plug Inspection: Worn spark plugs can lead to poor engine performance and increased fuel consumption. Regularly check and replace them to ensure proper ignition and efficient operation.

- Battery Health: Inspect battery terminals for corrosion and ensure a secure connection. A stable power supply supports all engine functions, contributing to its overall longevity.

- Fuel System Care: Periodic fuel system cleaning prevents clogging in injectors and lines, promoting smooth fuel delivery and optimal engine performance.

By following these routine maintenance steps, you help protect the engine from unnecessary wear and improve its durability, keeping your vehicle reliable and efficient on the road.

Electrical System Troubleshooting Guide

The electrical system is integral to the vehicle’s functionality, ensuring that various components operate effectively. When issues arise within this system, they can lead to a range of malfunctions, from dimmed lights to ignition difficulties. Identifying and resolving these problems requires a structured approach to ensure each part of the system is thoroughly evaluated and restored to proper working order.

Start by examining the battery and its connections, as corrosion or loose terminals often lead to issues with power distribution. Use a multimeter to confirm the battery’s voltage, as low or unstable readings could indicate the need for a replacement or additional inspection.

Once the battery has been assessed, check the fuses and relays in the vehicle’s fuse box. Blown fuses are common culprits in power disruptions to individual components. Replace any damaged fuses with new ones of the correct amperage to restore functionality. Additionally, inspect the relays, as these control the flow of electricity to various parts of the vehicle.

Following fuse inspection, move on to the wiring harness. Look for visible signs of wear, fraying, or damage. Worn wires can cause short circuits or power loss. If any damaged wires are found, they should be repaired or replaced immediately to maintain consistent power flow across the system.

Finally, evaluate the alternator and starter motor, as these are crucial to maintaining the battery charge and initiating the engine. Test the alternator’s output using a multimeter to verify it is providing the necessary voltage. If issues are detected, the alternator or starter may need to be repaired or replaced.

By systematically inspecting each element of the electrical system, issues can be isolated and addressed, leading to more reliable vehicle performance and reduced downtime.

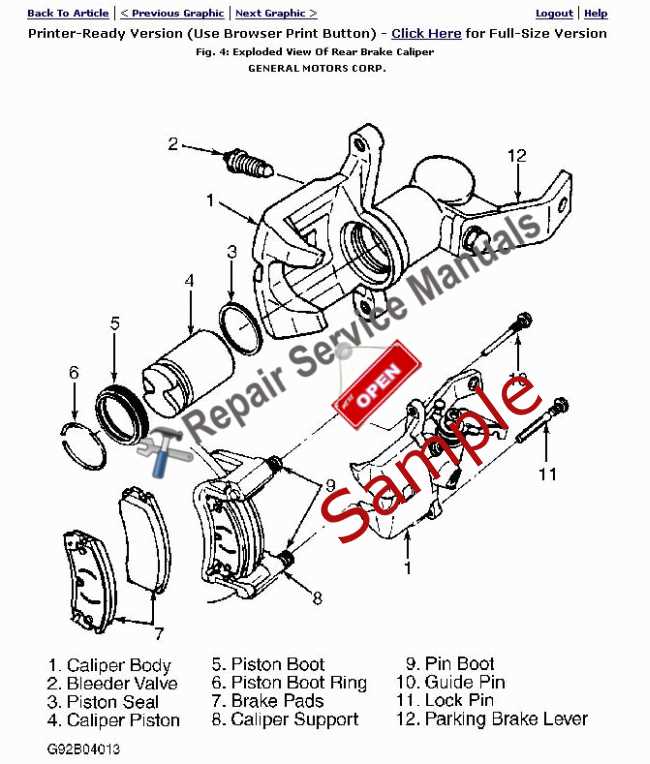

Brake System Inspection and Repair

The functionality of the braking mechanism is essential for vehicle safety and performance. Regular examination and maintenance of this system can prevent potential hazards and ensure reliable operation. This section outlines the steps necessary to evaluate and address common issues related to the braking system.

Initial Inspection Steps

Begin by visually examining the brake components, including the pads, rotors, and fluid levels. Look for signs of wear, such as uneven surfaces or corrosion. Checking for fluid leaks is also crucial, as any loss of hydraulic fluid can compromise braking efficiency. Ensure that all connections are secure and that the brake lines are intact.

Addressing Common Issues

Should any abnormalities be detected during the inspection, immediate action is required. Replacing worn brake pads or resurfacing rotors can significantly enhance performance. In cases of fluid leaks, it is vital to replace damaged hoses or seals promptly. Regular upkeep and timely repairs will contribute to the overall safety and longevity of the vehicle.

Improving Fuel Efficiency and Performance

Enhancing the economy and functionality of a vehicle involves a combination of maintenance practices and driving habits. By focusing on key areas, one can achieve better mileage and overall responsiveness, leading to a more satisfying driving experience.

Regular maintenance is essential. Checking tire pressure frequently ensures optimal contact with the road, reducing drag and improving fuel consumption. Additionally, keeping the engine well-tuned, including changing filters and fluids, contributes to more efficient operation.

Adopting mindful driving habits can also make a significant difference. Avoiding rapid acceleration and excessive idling helps conserve fuel, while maintaining a steady speed on the highway optimizes efficiency. Furthermore, reducing excess weight by clearing out unnecessary items can enhance both performance and fuel economy.

Lastly, considering fuel quality can impact efficiency. Using higher-grade fuel or additives designed to clean the fuel system can promote better combustion and improve overall performance. By implementing these strategies, drivers can enjoy a smoother ride and lower fuel costs.

Transmission Care and Problem Solving

Ensuring the longevity and optimal performance of a vehicle’s transmission system requires regular maintenance and attention to detail. Proper care involves understanding the signs of potential issues and addressing them promptly to prevent further complications. This section provides valuable insights into maintaining a smooth-operating transmission and troubleshooting common problems that may arise.

Maintenance Tips for Optimal Performance

Routine checks and timely servicing are essential to keep the transmission functioning efficiently. Regularly inspecting the fluid level and condition is crucial, as low or contaminated fluid can lead to serious damage. Additionally, adhering to recommended service intervals for fluid changes and filter replacements contributes to the overall health of the transmission system. Ensuring that the cooling system operates effectively also plays a significant role in maintaining optimal temperatures and preventing overheating.

Common Issues and Solutions

Several symptoms may indicate underlying transmission problems. Unusual noises, slipping gears, or delayed engagement can signal the need for immediate inspection. In such cases, conducting a thorough diagnostic check is advisable. Often, simple adjustments or fluid replacements can resolve these issues. However, if problems persist, consulting a professional mechanic for a comprehensive evaluation may be necessary to avoid more extensive repairs.

Cooling System Maintenance Essentials

Regular upkeep of the cooling system is crucial for ensuring optimal engine performance and longevity. This system is responsible for regulating the engine’s temperature, preventing overheating, and maintaining the overall efficiency of the vehicle. Proper maintenance not only extends the life of the engine but also enhances fuel efficiency and reduces emissions.

Here are some key practices to consider for effective cooling system maintenance:

- Regular Fluid Checks: Routinely inspect the coolant level and condition. Low or contaminated coolant can lead to system failure.

- System Flushing: Periodically flush the cooling system to remove rust, debris, and old coolant, ensuring efficient heat exchange.

- Inspect Hoses and Connections: Examine hoses for cracks, leaks, or signs of wear. Ensure that all connections are secure to prevent fluid loss.

- Check the Thermostat: Test the thermostat to ensure it opens and closes at the correct temperatures, facilitating proper coolant circulation.

- Examine the Radiator: Inspect the radiator for any signs of damage or blockage, which can impair the system’s ability to dissipate heat.

- Monitor Temperature Gauge: Keep an eye on the temperature gauge during operation. Sudden changes may indicate an issue with the cooling system.

Implementing these essential maintenance practices will help ensure that the cooling system operates effectively, preventing potential engine issues and maintaining overall vehicle performance.

Suspension and Steering Adjustments

Proper alignment and calibration of the suspension and steering systems are essential for optimal vehicle performance and safety. Regular adjustments ensure that components function harmoniously, resulting in improved handling, stability, and tire longevity. This section outlines key aspects to consider when fine-tuning these systems.

Key Components for Adjustment

- Shock Absorbers: Check for wear and tear, as well as proper fluid levels.

- Alignment: Ensure that the wheels are aligned to the manufacturer’s specifications to prevent uneven tire wear.

- Ball Joints: Inspect for play and replace if necessary to maintain steering accuracy.

- Control Arms: Adjust to guarantee the correct positioning of the wheels relative to the body.

Adjustment Procedure

- Start by lifting the vehicle and securely placing it on jack stands.

- Inspect all components for damage or excessive wear.

- Use a laser alignment tool to measure the wheel angles and adjust as needed.

- Check the torque settings on all fasteners according to specifications.

- Lower the vehicle and take it for a test drive to ensure smooth handling.

Replacing Worn Interior Components

Maintaining the comfort and aesthetics of a vehicle’s interior is essential for an enjoyable driving experience. Over time, various elements within the cabin may become worn or damaged, necessitating replacement to restore both functionality and appearance. This section will outline the process and considerations involved in replacing these components.

Identifying Worn Parts

Before proceeding with replacements, it is crucial to identify which components require attention. Common interior parts that may show signs of wear include:

- Upholstery

- Floor mats

- Dashboards

- Door panels

- Steering wheel covers

Replacement Process

The following steps can guide you through the replacement of worn interior components:

- Gather necessary tools, such as screwdrivers, pliers, and replacement parts.

- Remove the damaged component carefully, ensuring not to damage surrounding areas.

- Clean the area where the new component will be installed.

- Install the new part, securing it in place according to manufacturer specifications.

- Test the new component to ensure it functions correctly and fits properly.