In the world of outdoor utility vehicles, understanding the intricacies of their upkeep is essential for optimal performance and longevity. This section delves into the critical aspects of maintaining these robust machines, ensuring they remain reliable companions for various tasks, from farming to recreational activities.

Whether you’re an experienced operator or a newcomer, having access to detailed information on servicing, diagnostics, and component functionality is invaluable. The knowledge shared here empowers users to tackle common issues, perform essential adjustments, and enhance the overall efficiency of their vehicles.

Through a blend of practical advice and technical insights, this guide aims to equip readers with the tools needed to navigate maintenance challenges confidently. By fostering a deeper understanding of the mechanisms involved, operators can ensure that their vehicles are always ready to meet the demands of the job at hand.

Kawasaki Mule Overview

This section provides a comprehensive introduction to a versatile utility vehicle designed for a variety of tasks. Renowned for its ruggedness and reliability, this machine is favored in both recreational and professional settings. It effectively combines functionality with ease of use, making it an ideal choice for individuals seeking efficiency in outdoor activities.

The vehicle is equipped with features that enhance performance, including a robust engine, durable chassis, and ample cargo space. These elements allow for smooth operation across diverse terrains, whether on a farm, construction site, or during leisurely adventures. Its user-friendly design ensures that operators of all skill levels can navigate and utilize the vehicle with confidence.

In addition to its practical applications, this vehicle also emphasizes safety and comfort. Ergonomic seating and intuitive controls create a pleasant driving experience, while safety measures provide peace of mind during operation. Overall, this utility vehicle stands out as a reliable companion for anyone in need of a powerful and adaptable solution for various tasks.

Importance of a Repair Manual

Having a comprehensive guide for maintenance and troubleshooting is essential for any vehicle owner. It provides a wealth of information that helps ensure the longevity and optimal performance of the equipment. Such resources are invaluable for both novice and experienced users, as they outline the necessary steps for proper care and address common issues effectively.

Moreover, these guides serve as a reference point for understanding the intricate systems within the machinery. By following the outlined procedures, users can identify problems early, which can save time and money in the long run. The documentation often includes diagrams, parts lists, and step-by-step instructions that simplify complex tasks.

| Benefits | Description |

|---|---|

| Enhanced Longevity | Regular maintenance leads to a longer lifespan for your equipment. |

| Cost Savings | Early detection of issues reduces the need for costly repairs. |

| Improved Safety | Proper upkeep minimizes the risk of accidents or malfunctions. |

| Increased Knowledge | Users gain a better understanding of their equipment’s functionality. |

Ultimately, a well-structured guide is a key tool for anyone looking to maintain their equipment effectively. It not only facilitates routine upkeep but also empowers users to tackle challenges confidently, leading to better overall performance and reliability.

Common Issues with Kawasaki Mule

In the world of utility vehicles, certain challenges tend to arise that can hinder performance and reliability. Understanding these frequent problems is crucial for maintaining optimal function and ensuring a smooth driving experience. Below are some prevalent concerns that users may encounter.

Engine Performance Troubles

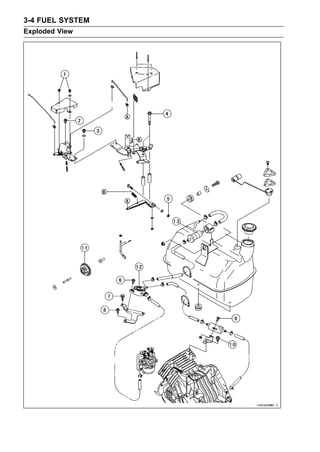

One of the most common issues involves the engine, which may exhibit symptoms such as stalling or difficulty starting. Factors contributing to these problems can include fuel system malfunctions, electrical component failures, or even air filter blockages. Regular inspection and maintenance are essential to prevent such complications and keep the engine running smoothly.

Transmission and Drivetrain Concerns

Another frequent area of concern pertains to the transmission and drivetrain. Users might notice unusual noises or slipping when shifting gears. These issues can stem from low fluid levels, worn components, or improper alignment. Addressing these matters promptly can help avoid more severe damage and ensure reliable operation.

Tools Needed for Repairs

When it comes to maintaining and fixing your utility vehicle, having the right equipment is essential for efficiency and safety. Proper tools not only expedite the process but also ensure that tasks are completed effectively. Below is a guide to the essential instruments that will aid you in various maintenance activities.

Basic Hand Tools: A set of hand tools is fundamental for any maintenance job. This includes wrenches, screwdrivers, pliers, and sockets. These items are necessary for loosening or tightening bolts and screws, making adjustments, and performing routine checks.

Power Tools: For more demanding tasks, power tools such as drills and impact wrenches can significantly reduce the effort and time required. These tools are ideal for handling larger components and can make difficult jobs more manageable.

Diagnostic Equipment: Investing in diagnostic tools is crucial for troubleshooting issues effectively. These devices help identify problems quickly, allowing for a more targeted approach to fixing them.

Safety Gear: Never overlook the importance of safety equipment. Gloves, goggles, and masks protect you while working and are essential for any maintenance task. Always prioritize safety to prevent injuries.

Having these tools at your disposal will prepare you for a wide range of tasks, ensuring your vehicle remains in optimal condition for any challenge ahead.

Step-by-Step Repair Guide

This section provides a detailed approach to addressing common issues that may arise with your utility vehicle. Following a systematic process can help you effectively troubleshoot and resolve problems, ensuring your machine remains in optimal condition.

1. Identify the Issue: Begin by observing any unusual behaviors or symptoms. Note any specific sounds, performance drops, or warning indicators that may provide clues to the underlying problem.

2. Gather Tools and Supplies: Before diving into the task, collect all necessary equipment and materials. This may include wrenches, screwdrivers, replacement parts, and lubricants to streamline the process.

3. Consult Resources: Refer to guides and documentation relevant to your vehicle model. These resources often contain valuable information regarding specifications and common troubleshooting steps.

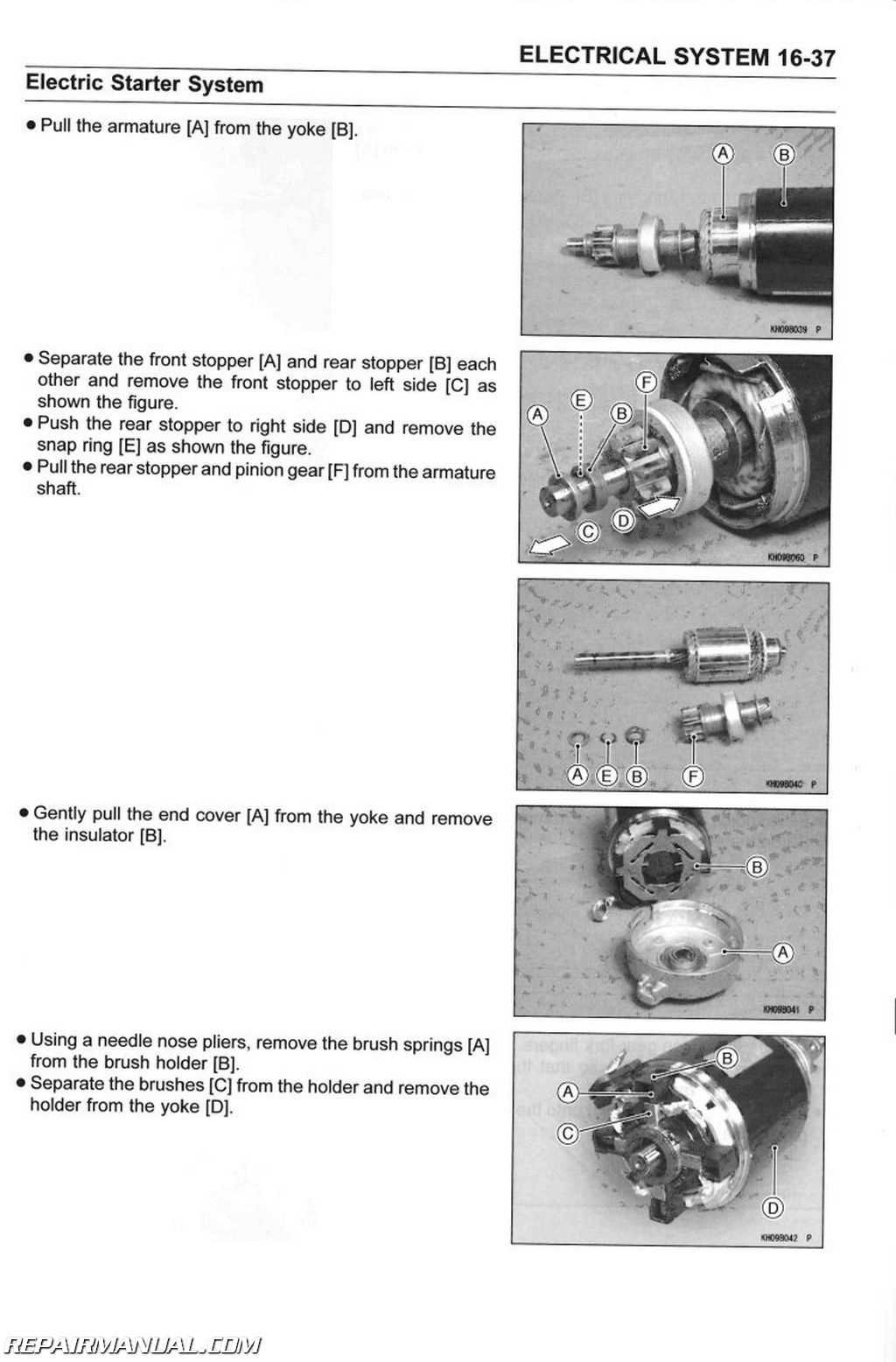

4. Disassemble with Care: If the problem requires accessing internal components, carefully disassemble the necessary parts. Keep track of screws and components to ensure a smooth reassembly.

5. Inspect Components: Examine each part for wear, damage, or blockage. Look for signs of corrosion, cracks, or other issues that could contribute to malfunction.

6. Replace or Repair: Based on your inspection, decide whether to replace damaged components or perform necessary repairs. Follow guidelines to ensure correct installation and functionality.

7. Reassemble the Vehicle: Once repairs are complete, carefully reassemble all components. Double-check that everything is secured and in the proper position.

8. Test the System: After reassembly, conduct a thorough test to ensure that the vehicle operates correctly. Pay attention to any lingering issues and address them as needed.

9. Maintain Regular Checks: Establish a routine for regular maintenance checks. This will help identify potential problems before they escalate, keeping your vehicle running smoothly.

By following these steps, you can effectively troubleshoot and address a range of issues, ensuring longevity and reliability in your vehicle’s performance.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your utility vehicle involves regular care and attention. By following a systematic approach to upkeep, you can enhance performance, minimize repairs, and enjoy a smoother ride for years to come.

Regular Inspections

Frequent checks can help identify potential issues before they escalate. Here are some key areas to focus on:

- Check tire pressure and tread wear.

- Inspect brakes for wear and functionality.

- Examine belts and hoses for signs of cracking or fraying.

- Ensure all lights and indicators are working properly.

Fluid Maintenance

Proper fluid levels are crucial for the efficient operation of your vehicle. Follow these guidelines:

- Regularly check and change the engine oil according to the manufacturer’s recommendations.

- Monitor coolant levels and top up as necessary.

- Inspect the transmission fluid and replace it when it becomes dirty or discolored.

- Keep an eye on brake fluid and hydraulic fluid levels.

By incorporating these maintenance practices, you can significantly improve the durability and performance of your utility vehicle.

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of your utility vehicle is crucial for maintaining optimal performance. This section aims to guide you through common problems, providing systematic approaches to identify and rectify faults. A thorough understanding of the components and their interactions can significantly enhance troubleshooting efficiency.

Common Electrical Issues

Several typical problems may arise, including battery failures, faulty wiring, or malfunctioning switches. A weak or dead battery often leads to starting difficulties. Inspecting connections for corrosion or looseness is essential. Additionally, intermittent power loss can signal wiring issues that may require a detailed examination of harnesses and connectors.

Troubleshooting Steps

Start by checking the battery voltage and ensuring all terminals are secure. Use a multimeter to test the continuity of circuits, identifying any breaks or shorts. Follow the wiring diagram to trace connections, confirming that each component operates as intended. Document any anomalies, as this will help in both immediate repairs and future reference.

Engine Performance Enhancements

Improving the output and efficiency of an engine can significantly elevate the overall experience and functionality of a vehicle. By implementing specific modifications and upgrades, enthusiasts can enhance power delivery, responsiveness, and fuel efficiency, leading to a more dynamic performance on various terrains.

Here are several strategies to boost engine performance:

- Upgrade the Air Intake System: Improving airflow into the engine can increase combustion efficiency. Consider installing a high-performance air filter or a complete cold air intake system.

- Exhaust Modifications: Enhancing the exhaust system reduces back pressure, allowing for better engine breathing. Options include aftermarket headers or a cat-back exhaust system.

- Engine Tuning: Adjusting the engine’s electronic control unit (ECU) can optimize fuel maps and ignition timing for improved performance. Custom tuning is often the best route.

- Forced Induction: Adding a supercharger or turbocharger can significantly increase horsepower by forcing more air into the engine, enabling more fuel to be burned.

- Fuel System Enhancements: Upgrading fuel injectors and pumps ensures that the engine receives adequate fuel supply under increased demand.

- Weight Reduction: While not a direct engine modification, reducing overall vehicle weight can enhance performance by improving power-to-weight ratio.

Implementing these enhancements requires careful consideration and, in some cases, professional assistance. Always ensure that modifications align with local regulations and maintenance guidelines for optimal performance and reliability.

Safety Precautions During Repairs

When performing maintenance tasks on any vehicle, ensuring a safe working environment is paramount. Proper precautions help to mitigate risks and protect both the individual and the machinery involved. Understanding and implementing safety measures can prevent accidents and enhance the overall efficiency of the work process.

Personal Protective Equipment (PPE) is essential for anyone involved in maintenance activities. Always wear appropriate gear such as gloves, goggles, and steel-toed boots. This equipment acts as a barrier against potential injuries from sharp objects, chemicals, or falling debris.

Furthermore, ensure that the workspace is clean and well-organized. Clutter can lead to accidents, so it is advisable to keep tools and materials neatly stored and easily accessible. Additionally, always work in a well-ventilated area, especially when using chemicals or working with fuels, to avoid inhaling harmful fumes.

Before starting any task, disconnecting the battery is a critical step. This simple action can prevent electrical shocks and unintended vehicle movements. Similarly, use wheel chocks to secure the vehicle in place, ensuring it does not roll during maintenance.

Finally, always consult the relevant documentation for guidance on specific procedures and safety warnings. Staying informed and adhering to recommended practices will significantly reduce the likelihood of incidents during maintenance activities.

When to Seek Professional Help

Understanding when to enlist the expertise of a qualified technician can be crucial in maintaining the functionality of your utility vehicle. While many issues can be addressed by enthusiasts, some problems require specialized knowledge and tools that only professionals possess.

Consider reaching out for assistance if you encounter persistent mechanical issues that do not resolve after basic troubleshooting. Unusual noises, such as grinding or knocking sounds, can indicate serious underlying problems that need immediate attention. Additionally, if you notice significant leaks or fluid loss, it’s essential to consult an expert to prevent further damage.

Furthermore, when electrical systems fail, such as lights not functioning or ignition problems, professional help may be necessary. These situations often involve intricate wiring and components that can be challenging to diagnose without the proper experience. Lastly, if you’re unsure about how to proceed with any repair or maintenance task, it’s better to seek guidance rather than risk making the situation worse.