In the world of automotive engineering, understanding the intricacies of vehicle systems is crucial for achieving optimal performance and longevity. This section delves into the essential aspects of maintenance and troubleshooting for a specific class of robust vehicles designed for heavy loads and demanding conditions. Whether you’re a seasoned technician or a dedicated enthusiast, grasping the nuances of your vehicle’s mechanics can significantly enhance its reliability.

The following information provides a thorough exploration of various components and systems, aiming to equip readers with the knowledge necessary for effective upkeep. From engine functionality to electrical systems, every detail matters when it comes to ensuring seamless operation. This guide serves as a valuable resource, empowering owners to tackle challenges and perform necessary tasks with confidence.

By familiarizing yourself with the recommended practices and diagnostic techniques, you can not only address issues as they arise but also proactively maintain your vehicle’s performance. This approach fosters a deeper connection with your machinery, enhancing both safety and efficiency on the road.

Overview of the 2006 Dodge Ram 2500 Diesel

This section provides a comprehensive look at a robust heavy-duty vehicle known for its durability and performance. The model is designed to handle a variety of tasks, making it a popular choice among those needing a reliable workhorse. Its powerful engine and sturdy build contribute to its reputation in both commercial and recreational sectors.

Key Features

Highlighting the essential attributes of this vehicle, the following table summarizes its most notable specifications:

| Feature | Specification |

|---|---|

| Engine Type | Turbocharged Inline-6 |

| Horsepower | 325 hp |

| Towing Capacity | Up to 17,000 lbs |

| Transmission | 6-speed automatic |

| Payload Capacity | 3,000 lbs |

Performance and Capabilities

This vehicle excels in various conditions, combining efficiency with strength. It is particularly favored for its capability to manage heavy loads and navigate rugged terrain, making it an excellent choice for both work and leisure activities.

Common Issues in Diesel Trucks

Heavy-duty vehicles equipped with compression ignition engines often face a range of challenges due to their complex systems and demanding operational conditions. Understanding these common problems can help owners and mechanics anticipate issues and maintain optimal performance.

- Fuel System Problems: Contaminated fuel, clogged filters, and malfunctioning injectors can lead to poor engine performance and efficiency.

- Starting Difficulties: Issues with the battery, starter motor, or glow plugs can prevent the engine from starting, especially in cold weather.

- Overheating: Insufficient coolant levels, a faulty thermostat, or a malfunctioning water pump can cause the engine to overheat, potentially leading to severe damage.

- Exhaust Emissions: Increased emissions may indicate issues with the exhaust system or the need for maintenance on components like the catalytic converter or EGR system.

- Transmission Issues: Hard shifting, slipping, or delayed engagement can point to problems within the transmission, requiring thorough inspection.

Regular maintenance and prompt attention to these common issues can significantly enhance the longevity and reliability of heavy-duty vehicles.

Tools Required for Effective Repairs

Ensuring a successful maintenance process involves having the right instruments at your disposal. Properly equipped individuals can tackle various tasks with confidence and precision, minimizing the risk of errors. This section outlines essential tools that are indispensable for achieving effective results during maintenance activities.

Essential Hand Tools

- Wrenches: A range of sizes is necessary for different fasteners.

- Sockets and Ratchets: Ideal for loosening and tightening bolts quickly.

- Screwdrivers: Both flat and Phillips-head versions should be included.

- Pliers: Useful for gripping, twisting, and cutting wires or other materials.

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

Power Tools and Equipment

- Impact Wrench: Provides high torque output, perfect for stubborn bolts.

- Drill: Essential for creating holes or driving screws efficiently.

- Diagnostic Scanner: Helps in identifying issues by reading error codes.

- Work Light: Ensures visibility in dimly lit areas during tasks.

Understanding the Engine Components

The intricate machinery of an automotive powertrain comprises several key elements that work harmoniously to ensure optimal performance. Each part plays a vital role in the overall functionality, influencing everything from fuel efficiency to power output. A comprehensive understanding of these components is essential for effective diagnostics and maintenance.

Key Components of the Engine

At the heart of any engine lies the cylinder block, which houses the cylinders where combustion occurs. Surrounding this structure are the pistons, which move up and down to convert thermal energy into mechanical power. This movement is crucial for driving the vehicle forward.

The Role of the Fuel System

The fuel injection system is another critical element, responsible for delivering the precise amount of fuel to the combustion chamber. This ensures efficient burning, optimizing power generation while minimizing emissions. A well-functioning fuel system is essential for maintaining engine health and performance.

Maintenance Tips for Longevity

Ensuring the durability and reliability of your vehicle requires consistent attention and care. By following a few essential practices, you can extend its lifespan and maintain optimal performance.

- Regularly check and change the engine oil to keep the components lubricated and functioning smoothly.

- Inspect the air filter periodically; a clean filter allows for better airflow and enhances engine efficiency.

- Monitor tire pressure and tread depth to ensure proper traction and handling, as well as to improve fuel economy.

- Examine brake components frequently to prevent wear and ensure safe stopping capabilities.

- Flush and replace coolant as recommended to prevent overheating and protect the engine from corrosion.

In addition to routine checks, it’s crucial to stay aware of any unusual sounds or changes in performance. Addressing issues early can prevent more significant problems down the road.

- Keep the battery terminals clean and connections tight to avoid electrical issues.

- Ensure that belts and hoses are in good condition; replace them at the first sign of wear or cracking.

- Regularly wash the exterior and undercarriage to remove dirt and salt, which can lead to corrosion.

Following these maintenance strategies will not only enhance the longevity of your vehicle but also provide peace of mind during your journeys.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues with your vehicle. By following a systematic method, you can identify and resolve problems effectively, ensuring optimal performance and longevity of your machinery.

Start by gathering all necessary tools and materials. This preparation phase is crucial for a smooth troubleshooting experience. Familiarize yourself with the vehicle’s components and systems to facilitate the process.

Next, observe any unusual symptoms. Take detailed notes on performance irregularities, noises, or warning indicators. This information will help pinpoint the source of the issue.

Proceed with a visual inspection of accessible parts. Look for obvious signs of wear, leaks, or damage. Pay close attention to hoses, connections, and electrical components, as these are common areas for faults.

After visual assessment, perform basic diagnostic tests. Check fluid levels, battery health, and fuse integrity. These preliminary checks can often uncover simple issues that are easily resolved.

If the problem persists, delve deeper into specific systems, using specialized tools as necessary. Consult technical resources to understand the intricacies of each component, allowing for targeted troubleshooting.

Finally, once the fault is identified, proceed with repairs or replacements as required. Document your findings and the steps taken, which will be beneficial for future reference and maintenance.

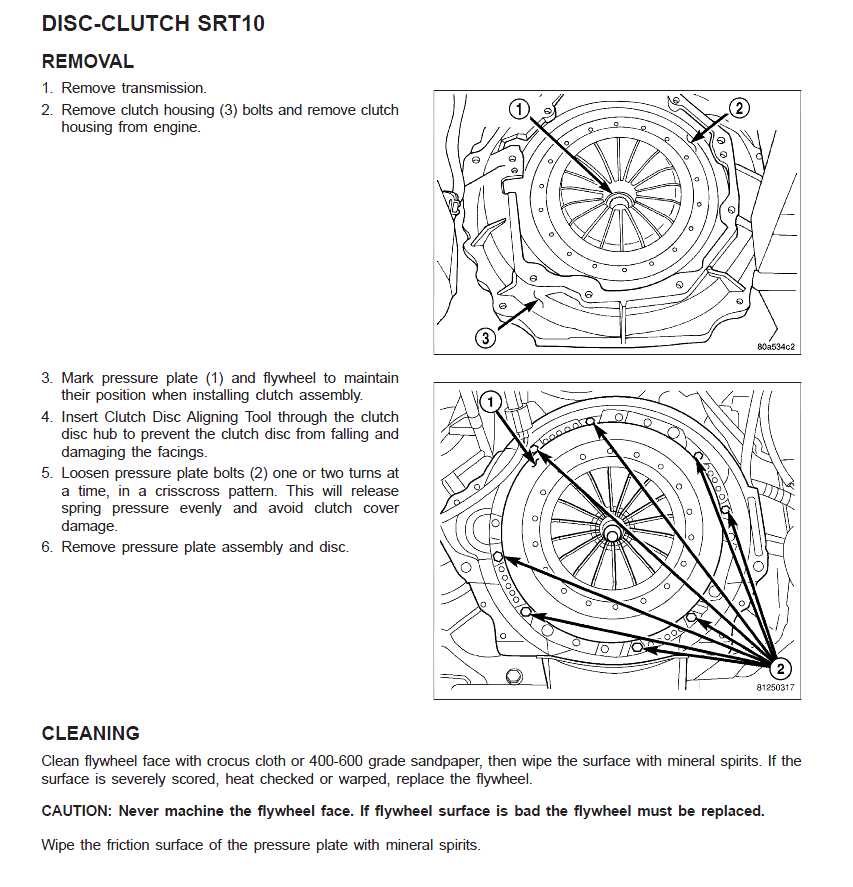

Transmission Repair Techniques Explained

Understanding the intricacies of transmission systems is crucial for maintaining vehicle performance. This section delves into effective methods for addressing common issues encountered within these vital components. From diagnosing faults to executing repairs, mastering these techniques can significantly enhance the longevity and efficiency of the drivetrain.

Common Issues and Diagnostic Approaches

Identifying problems early can prevent more extensive damage. Mechanics often begin by examining fluid levels and condition, as transmission fluid plays a critical role in functionality. Discoloration or a burnt smell may indicate contamination or overheating. Additionally, conducting electronic diagnostics can reveal error codes related to shifting irregularities, helping to pinpoint specific failures.

Repair Techniques and Best Practices

Once issues are diagnosed, various repair strategies can be employed. For minor leaks, replacing seals or gaskets may suffice. In more severe cases, a complete overhaul might be necessary, involving disassembly of the transmission to replace worn components. It’s essential to use high-quality parts to ensure durability. Regular maintenance practices, such as fluid changes and filter replacements, can also prevent future problems and prolong the system’s life.

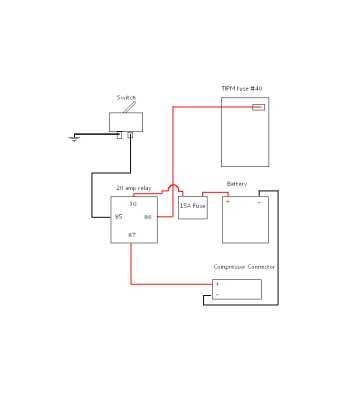

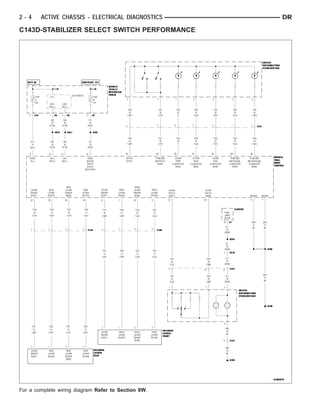

Electrical System Diagnostics and Fixes

This section focuses on the essential processes involved in troubleshooting and repairing electrical systems within heavy-duty vehicles. Understanding these procedures is crucial for ensuring the reliability and safety of the vehicle’s operation.

Proper diagnostics can help identify issues such as faulty wiring, malfunctioning components, and poor connections. A systematic approach allows for efficient resolution of these problems, minimizing downtime and maintaining performance.

| Common Issues | Symptoms | Recommended Fixes |

|---|---|---|

| Dead Battery | No start, dim lights | Replace battery, check charging system |

| Faulty Alternator | Warning light on, battery not charging | Test alternator output, replace if necessary |

| Blown Fuses | Inoperative accessories | Inspect and replace fuses, check for short circuits |

| Poor Ground Connections | Intermittent electrical issues | Clean and secure ground connections |

| Corroded Terminals | Starting problems, electrical shorts | Clean or replace corroded terminals |

By following these guidelines and utilizing the recommended diagnostic techniques, you can effectively address electrical problems and enhance the performance and longevity of the vehicle.

Brake System Maintenance and Repair

Ensuring the optimal performance of the braking mechanism is crucial for safety and vehicle longevity. Regular attention to this system helps prevent potential issues and enhances driving confidence. This section outlines essential practices and considerations for maintaining and fixing the braking components.

Here are some key aspects to focus on during maintenance:

- Inspection: Regularly check the condition of brake pads, rotors, and fluid levels.

- Fluid Replacement: Change the brake fluid periodically to prevent moisture contamination and maintain effectiveness.

- Pad and Rotor Condition: Inspect for wear and replace pads and rotors as necessary to ensure effective stopping power.

When issues arise, consider the following troubleshooting steps:

- Unusual Noises: Listen for squeaking or grinding sounds, which may indicate worn components.

- Pulsation: Feel for vibrations when applying brakes, suggesting potential rotor issues.

- Brake Warning Light: Pay attention to dashboard indicators that may signal a problem.

Addressing these aspects will contribute to a reliable braking system and enhance overall driving safety.

Suspension and Steering Adjustments

The proper calibration of the suspension and steering systems is crucial for optimal vehicle performance. Adjustments in these areas can enhance ride comfort, improve handling, and extend the lifespan of components. This section explores the key adjustments necessary for achieving a well-balanced and responsive driving experience.

Suspension Adjustments play a vital role in maintaining stability and comfort while driving. Ensuring the correct alignment of components, such as shock absorbers and springs, is essential. This involves checking the ride height and making necessary changes to ensure that the vehicle sits level. Additionally, proper damping settings must be verified to optimize the vehicle’s response to road conditions.

Steering Alignment is equally important for safe operation. An accurate alignment helps prevent uneven tire wear and ensures that the vehicle tracks straight. Regularly inspecting and adjusting the toe, camber, and caster angles can prevent handling issues and improve overall responsiveness. Moreover, checking the condition of the steering components, such as tie rods and bushings, is essential to maintain proper function and safety.

Cooling System Maintenance Procedures

Regular upkeep of the cooling mechanism is essential for optimal engine performance and longevity. Proper maintenance helps prevent overheating and ensures that the cooling components function efficiently, reducing the risk of serious damage.

Routine Checks

- Inspect the coolant level regularly to ensure it is within the recommended range.

- Check for leaks around hoses, connections, and the radiator.

- Examine the condition of the coolant; it should be clear and free of debris.

Coolant Replacement

- Drain the old coolant from the system.

- Flush the system to remove any contaminants or buildup.

- Refill with the appropriate coolant mixture, following manufacturer specifications.

- Run the engine to circulate the new coolant and check for leaks.

Fuel System Troubleshooting Strategies

Diagnosing issues within the fuel system is essential for maintaining optimal performance and reliability. A systematic approach is required to identify the root causes of malfunctions. This section outlines effective strategies to troubleshoot common fuel-related problems, ensuring that the system functions as intended.

Common Symptoms and Initial Checks

Identifying symptoms can lead to a more efficient diagnostic process. Here are typical indicators of fuel system issues and the initial checks to perform:

| Symptom | Initial Check |

|---|---|

| Engine stalling or hard starting | Inspect fuel levels and pump operation |

| Loss of power during acceleration | Check for clogged filters or lines |

| Unusual engine noise | Examine fuel injectors for leaks |

| Excessive exhaust smoke | Assess for fuel quality and contamination |

Advanced Diagnostic Techniques

If initial checks do not reveal the issue, more advanced techniques may be necessary. Utilizing diagnostic tools can help pinpoint problems with greater accuracy. Consider the following methods:

- Fuel pressure testing to ensure the system maintains proper pressure levels.

- Using a scan tool to retrieve fault codes that may indicate electronic control issues.

- Visual inspection of hoses and connections for wear or damage that could affect fuel delivery.

Body and Interior Repair Essentials

Ensuring the integrity and aesthetics of a vehicle’s exterior and interior is crucial for both functionality and appearance. This section focuses on fundamental practices and considerations for maintaining and restoring these areas, emphasizing a thorough approach to each task.

Key aspects to consider include:

- Assessing Damage: Regular inspections can identify issues early. Look for signs of wear, rust, or impact.

- Tools and Materials: Equip yourself with appropriate tools such as hammers, pliers, and cleaning supplies, alongside materials like paint, sealants, and upholstery fabric.

- Surface Preparation: Proper cleaning and sanding are vital for effective adhesion of paints and coatings.

- Techniques: Familiarize yourself with methods such as welding, panel replacement, and upholstery repair to ensure a comprehensive skill set.

Maintenance tips for keeping the interior in top shape include:

- Cleaning: Regularly vacuum and wipe surfaces to prevent dirt buildup.

- Conditioning: Use appropriate cleaners and conditioners for leather and fabric to maintain their quality.

- Repairing: Address small tears or stains promptly to prevent further damage.

By following these essentials, you can enhance the longevity and aesthetic appeal of your vehicle’s body and interior, ensuring a pleasant experience for both driver and passengers.