Ensuring optimal performance and longevity of your off-road vehicle requires a thorough understanding of its components and systems. This resource aims to provide invaluable insights for enthusiasts and mechanics alike, highlighting essential techniques and best practices for upkeep. From routine inspections to complex repairs, mastering these skills will enhance your riding experience and safety.

Familiarity with the intricate workings of your machine is key to identifying potential issues before they escalate. Whether you are dealing with engine performance, suspension adjustments, or brake maintenance, having a structured approach is crucial. This guide serves as a comprehensive reference, offering step-by-step procedures and expert tips to tackle various challenges.

Moreover, knowledge of maintenance schedules and troubleshooting strategies empowers riders to make informed decisions. Understanding how to diagnose problems efficiently can save time and resources, ensuring your vehicle remains in peak condition. Equip yourself with the right tools and techniques to navigate the complexities of your off-road companion.

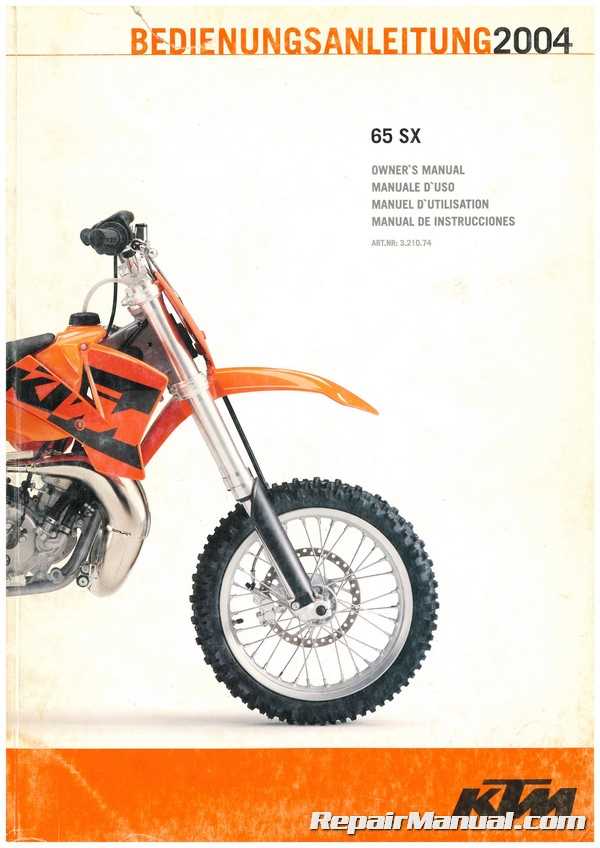

KTM 65 SX Overview

The 65 SX is a compact and powerful machine designed for young riders looking to hone their skills in motocross. Engineered for performance, it combines agility and responsiveness, making it an ideal choice for those entering the world of competitive racing. This model stands out with its lightweight frame and high-revving engine, allowing for quick acceleration and nimble handling on various terrains.

Featuring advanced suspension components, this bike provides excellent stability and control, ensuring that riders can tackle challenging tracks with confidence. Its design emphasizes safety and comfort, allowing younger enthusiasts to enjoy their riding experience while developing their technique. Overall, this motorcycle is a perfect blend of innovation and practicality, setting the stage for the next generation of motocross champions.

Key Features of 2004 Model

This section highlights the distinctive characteristics of the motocross bike designed for younger riders, focusing on performance, durability, and user-friendliness. These attributes make it an exceptional choice for those starting their journey in competitive racing.

Performance and Handling

- Lightweight chassis for improved maneuverability

- Powerful engine delivering exceptional acceleration

- Responsive suspension system for tackling rough terrain

- Optimized gearing ratios for enhanced speed control

Design and Comfort

- Ergonomic seat for better rider posture

- Adjustable handlebars to accommodate different riding styles

- Durable frame designed to withstand impacts and stresses

- Aesthetic graphics appealing to younger enthusiasts

Common Issues and Solutions

When it comes to maintaining high-performance off-road vehicles, owners often encounter a range of challenges. Identifying these problems early and knowing how to address them can ensure longevity and optimal performance. This section highlights prevalent issues along with effective solutions to keep your machine running smoothly.

Frequent Challenges

- Engine Performance Issues

- Transmission Problems

- Electrical System Failures

- Suspension Irregularities

Effective Solutions

- Engine Performance Issues: Regularly check the air filter and spark plug for clogs or wear. Cleaning or replacing them can significantly improve engine efficiency.

- Transmission Problems: Inspect the clutch and transmission fluid levels. Changing the fluid and adjusting the clutch can resolve many shifting difficulties.

- Electrical System Failures: Ensure all connections are tight and free from corrosion. Replacing faulty wires or connectors can restore functionality.

- Suspension Irregularities: Check for leaks in the suspension components and adjust or replace springs as necessary to ensure a smooth ride.

Maintenance Tips for Longevity

Ensuring the durability of your machine requires a thoughtful approach to upkeep and care. Regular attention to key components can significantly enhance performance and extend the life of your vehicle. Here are essential strategies to maintain your equipment effectively.

- Regular Cleaning: Keep the exterior and interior free from dirt and debris. Use appropriate cleaners to avoid damaging sensitive parts.

- Fluid Checks: Regularly inspect and replace fluids such as oil, coolant, and fuel to ensure optimal operation.

- Chain Maintenance: Lubricate and adjust the chain tension frequently to prevent wear and tear.

In addition to these basic practices, consider the following detailed recommendations:

- Inspect Tires: Regularly check tire pressure and tread depth to maintain proper traction and handling.

- Brake System Care: Monitor brake pads and fluid levels. Replace components as needed to ensure safety.

- Electrical Components: Check wiring and connections to prevent electrical failures. Replace worn-out parts promptly.

- Periodic Professional Servicing: Schedule routine inspections with a qualified technician to address any underlying issues.

By implementing these maintenance practices, you can significantly enhance the performance and longevity of your machine, ensuring a more enjoyable riding experience for years to come.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance task. A well-stocked toolkit not only enhances efficiency but also ensures that tasks are completed safely and effectively. Understanding the various tools needed for different jobs will empower enthusiasts to tackle issues with confidence and precision.

Basic Hand Tools

Every technician should possess a selection of fundamental hand tools. Items such as wrenches, screwdrivers, and pliers form the backbone of any toolkit. These tools allow for a wide range of adjustments and fixes, making them indispensable for minor tweaks and regular upkeep.

Specialized Equipment

In addition to basic tools, having specialized equipment can significantly aid in more complex tasks. Items like torque wrenches, feeler gauges, and diagnostic tools can provide the necessary precision and insights required for intricate repairs. Investing in high-quality specialized tools will lead to better results and longer-lasting performance.

Step-by-Step Repair Guide

This section offers a comprehensive approach to addressing common issues encountered in your two-wheeled machine. By following the outlined procedures, you can effectively restore performance and ensure longevity, enhancing your riding experience.

Initial Inspection

Begin with a thorough examination of the vehicle. Check for visible signs of wear, such as leaks, unusual noises, or loose components. Identifying problems early can prevent more extensive damage down the line. Ensure that all fluids are at the proper levels and that tires are adequately inflated.

Basic Maintenance Steps

Start with routine upkeep tasks like cleaning the air filter and inspecting the spark plug. Replace any worn parts to maintain efficiency. Pay close attention to the chain; it should be properly lubricated and tensioned. Regularly checking and adjusting these elements can significantly improve your machine’s reliability.

Engine Troubleshooting Techniques

Troubleshooting engine issues requires a systematic approach to identify and resolve problems effectively. Understanding the common symptoms and employing logical methods can lead to successful diagnosis and repair. Below are key techniques that can help you analyze engine performance issues.

Common Symptoms to Identify

- Unusual noises during operation

- Difficulty starting the engine

- Excessive smoke or unusual exhaust color

- Poor acceleration or power loss

- Overheating

Step-by-Step Troubleshooting Process

- Visual Inspection: Check for leaks, damaged components, or loose connections.

- Check Fuel Supply: Ensure there is adequate fuel and that the fuel system is functioning properly.

- Inspect Electrical Components: Test the battery, ignition system, and wiring for faults.

- Perform Compression Test: Measure cylinder compression to assess engine health.

- Evaluate Cooling System: Ensure the cooling system is working effectively to prevent overheating.

- Consult Documentation: Reference guides or manuals for specific troubleshooting steps related to particular issues.

By following these techniques, you can effectively pinpoint and address engine problems, ensuring optimal performance and longevity of the machine.

Suspension Adjustments Explained

Suspension settings play a crucial role in optimizing a motorcycle’s performance and handling. By fine-tuning these components, riders can enhance stability, comfort, and overall ride quality. Understanding how to make these adjustments can significantly impact your riding experience, especially in varying terrains and conditions.

Here are key aspects to consider when adjusting suspension:

- Compression: This setting controls how quickly the suspension compresses under load. Adjusting compression affects the bike’s ability to absorb bumps and impacts.

- Rebound: This setting dictates how quickly the suspension returns to its original position after compression. Proper rebound adjustment helps maintain tire contact with the ground.

- Preload: This setting determines the initial tension on the suspension springs. Adjusting preload affects ride height and the bike’s response to different rider weights.

To achieve optimal performance, consider the following steps:

- Identify the type of riding you will be doing, such as motocross or trail riding.

- Start with the manufacturer’s recommended settings as a baseline.

- Make incremental adjustments to each setting and test ride to evaluate changes.

- Keep notes on each adjustment for future reference.

By understanding and implementing these suspension adjustments, riders can tailor their machines to better handle specific riding conditions and personal preferences, ultimately enhancing both safety and enjoyment on the track or trail.

Electrical System Diagnostics

Diagnosing issues within the electrical framework of a vehicle is essential for ensuring optimal performance and reliability. A systematic approach helps in identifying faults and facilitating timely repairs, ultimately enhancing the overall functionality.

When assessing the electrical components, consider the following steps:

- Visual Inspection: Examine all wiring and connections for signs of wear, corrosion, or damage.

- Check Battery Condition: Ensure the battery is fully charged and terminals are clean and secure.

- Test Fuses: Inspect all fuses for continuity and replace any that are blown.

- Examine Switches and Relays: Ensure all switches operate smoothly and relays click when engaged.

- Use a Multimeter: Measure voltage at various points in the circuit to confirm proper operation.

By following these diagnostic steps, you can effectively pinpoint electrical issues and address them before they escalate, ensuring a seamless experience on the track or trail.

Replacing Worn Parts Effectively

Maintaining optimal performance in any machine involves the timely substitution of components that have experienced wear. This process not only enhances efficiency but also prolongs the lifespan of the entire system. Identifying the right moments for replacement, along with selecting appropriate replacements, is crucial for achieving the best results.

Start by thoroughly inspecting the parts for signs of damage or fatigue. Look for cracks, excessive play, or discoloration, which may indicate a need for replacement. Keeping a log of maintenance activities can help track the lifespan of various components, making it easier to anticipate when they will require attention.

Once you identify worn parts, sourcing high-quality replacements is vital. Always consider OEM or reputable aftermarket options that ensure compatibility and reliability. When installing new components, follow proper techniques and torque specifications to avoid future issues. This attention to detail will not only enhance performance but also contribute to the overall safety and reliability of the machine.

Finally, don’t forget to regularly review and update your maintenance practices. Continuous education about best practices and advancements in technology can significantly improve your ability to manage part replacements effectively. Emphasizing proactive maintenance will lead to a more reliable and efficient operation over time.

Performance Upgrades for Improvement

Enhancing the capabilities of your off-road machine can lead to a significantly more thrilling and efficient riding experience. By focusing on key components and modifications, riders can unlock the full potential of their vehicle, resulting in improved speed, handling, and overall performance.

- Exhaust System: Upgrading to a high-performance exhaust can reduce weight and increase horsepower by improving exhaust flow.

- Air Filter: A high-flow air filter allows for better airflow to the engine, enhancing combustion efficiency and throttle response.

- Jetting Adjustments: Fine-tuning the carburetor settings can optimize fuel delivery, leading to improved acceleration and power output.

- Suspension Tuning: Adjusting the suspension settings or upgrading components can provide better stability and comfort over rough terrain.

- Gearing Changes: Altering the sprocket sizes can improve acceleration or top speed, depending on riding preferences and conditions.

Each of these enhancements can contribute to a more dynamic and enjoyable riding experience. Riders should assess their needs and choose upgrades that align with their goals, ensuring a tailored approach to performance improvement.

Safety Considerations During Repairs

When undertaking maintenance tasks on your off-road vehicle, prioritizing safety is essential. Proper precautions can prevent accidents and ensure a smooth process. Whether you are a novice or experienced enthusiast, adhering to safety guidelines is critical for protecting both yourself and your machine.

Essential Safety Gear

Wearing the appropriate safety equipment is crucial. Below are the recommended items:

- Helmet: Protects your head from impacts.

- Gloves: Safeguard your hands from sharp edges and chemicals.

- Goggles: Shield your eyes from debris and dust.

- Steel-toed boots: Provide foot protection from heavy objects.

- Long sleeves and pants: Minimize skin exposure to oils and sharp components.

Workspace Organization

A well-organized workspace can significantly reduce risks. Consider the following tips:

- Ensure adequate lighting to clearly see your work area.

- Keep tools and parts neatly arranged to avoid tripping hazards.

- Use a sturdy surface to work on, preventing items from falling.

- Clear away clutter that could obstruct your movement.

- Maintain a fire extinguisher nearby in case of emergencies.

By following these safety considerations, you can create a secure environment that fosters efficient work while minimizing potential hazards.