Maintaining machinery is crucial for ensuring its longevity and optimal performance. A thorough understanding of operational nuances and potential issues can greatly enhance the efficiency of any equipment. This section delves into essential insights, offering valuable guidance for troubleshooting and upkeep.

For operators and technicians alike, having access to detailed resources is indispensable. These materials provide step-by-step instructions, enabling users to address common challenges and implement preventative measures. By fostering a proactive approach to maintenance, one can minimize downtime and extend the lifespan of the equipment.

In this guide, we explore various techniques and practices tailored for effective maintenance routines. Emphasis is placed on practical advice, illustrating how to navigate through repairs and adjustments with confidence. Equip yourself with the knowledge necessary to keep your machinery running smoothly and efficiently.

Understanding the New Holland LS170

This section provides insights into a versatile piece of equipment widely used in various industries. With its robust design and efficient functionality, this machine plays a crucial role in tasks that require power and agility. Understanding its features and capabilities can enhance user experience and operational efficiency.

Key Features

- Powerful engine for optimal performance

- Compact size allowing for maneuverability in tight spaces

- Intuitive controls for ease of operation

- Durable construction suitable for rugged environments

Common Applications

- Landscaping and site preparation

- Construction projects requiring lifting and moving materials

- Agricultural tasks like soil preparation and crop maintenance

- Snow removal in winter conditions

Understanding these aspects can greatly assist operators in maximizing the effectiveness and longevity of this equipment.

Common Issues and Symptoms

Understanding the frequent problems that machinery can encounter is essential for effective troubleshooting. By recognizing specific signs, operators can take timely actions to mitigate further complications. Below are some typical issues and their corresponding symptoms to watch for.

Hydraulic System Problems

- Inconsistent or weak lift capacity

- Slow or unresponsive hydraulic movements

- Fluid leaks around hoses and connections

Engine Performance Issues

- Difficulty starting the engine

- Unusual noises or vibrations during operation

- Decreased power output or stalling

By identifying these symptoms early, operators can ensure their equipment remains in optimal working condition.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and fixing machinery effectively. This section outlines the fundamental tools that every technician should have on hand to ensure that tasks can be completed efficiently and safely. A well-equipped workspace not only facilitates smooth operations but also enhances the overall quality of work performed.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts of various sizes. |

| Wrenches | Essential for gripping and turning fasteners in tight spaces. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Multimeter | Used for electrical testing, measuring voltage, current, and resistance. |

| Hydraulic Jack | Facilitates lifting heavy components safely and efficiently. |

| Screwdriver Set | Essential for driving screws and performing various assembly tasks. |

| Pliers | Useful for gripping, bending, and cutting wires and other materials. |

Equipping your workspace with these essential items will not only save time but also prevent potential damage and accidents during the maintenance process. Proper tools allow for precise work and can make all the difference in achieving satisfactory outcomes.

Step-by-Step Maintenance Guide

Regular upkeep of your machinery is essential for optimal performance and longevity. This section provides a structured approach to maintaining your equipment, ensuring that it runs efficiently and reliably. By following these guidelines, you can prevent common issues and enhance the lifespan of your machinery.

Daily Inspections

Conducting daily checks is crucial. Begin by inspecting fluid levels, including oil, coolant, and hydraulic fluids. Look for any signs of leaks or unusual wear. Additionally, ensure that all safety features are functioning correctly, and examine the tires for proper inflation and tread wear.

Scheduled Maintenance Tasks

Establish a routine for scheduled maintenance tasks, such as changing the oil and filters, greasing fittings, and checking battery connections. Adhering to a set schedule not only improves performance but also helps in identifying potential problems early. Keep a detailed log of all maintenance activities to track progress and facilitate future repairs.

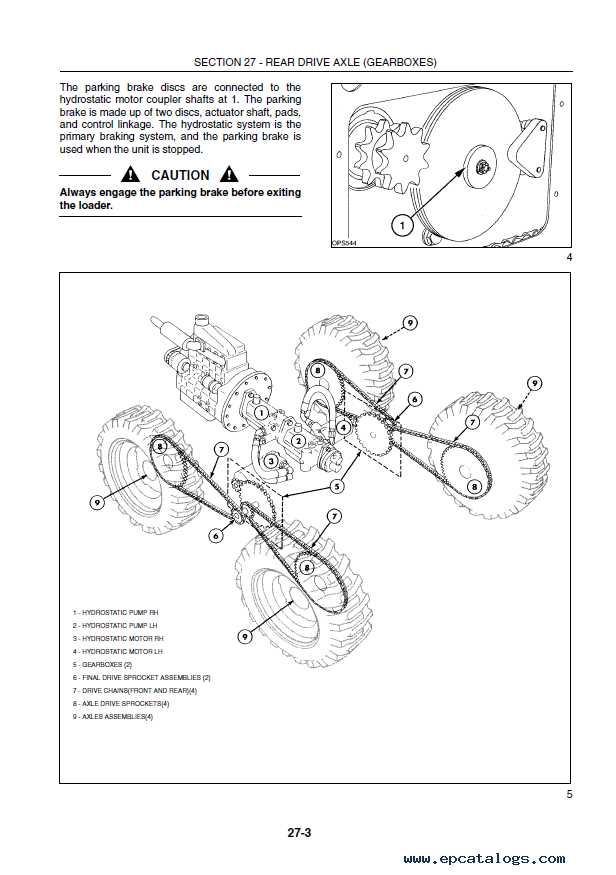

Hydraulic System Troubleshooting

Understanding the functionality and potential issues of hydraulic systems is crucial for effective maintenance and operation. A hydraulic system relies on fluid dynamics to transmit power, making it vital to identify and rectify problems promptly to ensure optimal performance.

Common Issues and Symptoms

- Insufficient power or slow operation of attachments

- Unusual noises during operation

- Fluid leaks around hoses and connections

- Overheating of the hydraulic fluid

- Contamination of the hydraulic fluid

Troubleshooting Steps

- Check fluid levels and top up if necessary.

- Inspect hoses and fittings for signs of wear or damage.

- Examine filters for clogs or contamination.

- Listen for abnormal sounds indicating pump or valve issues.

- Monitor temperature to prevent overheating; replace fluid if degraded.

By systematically following these steps, operators can effectively diagnose and address issues within hydraulic systems, ensuring continued reliability and performance.

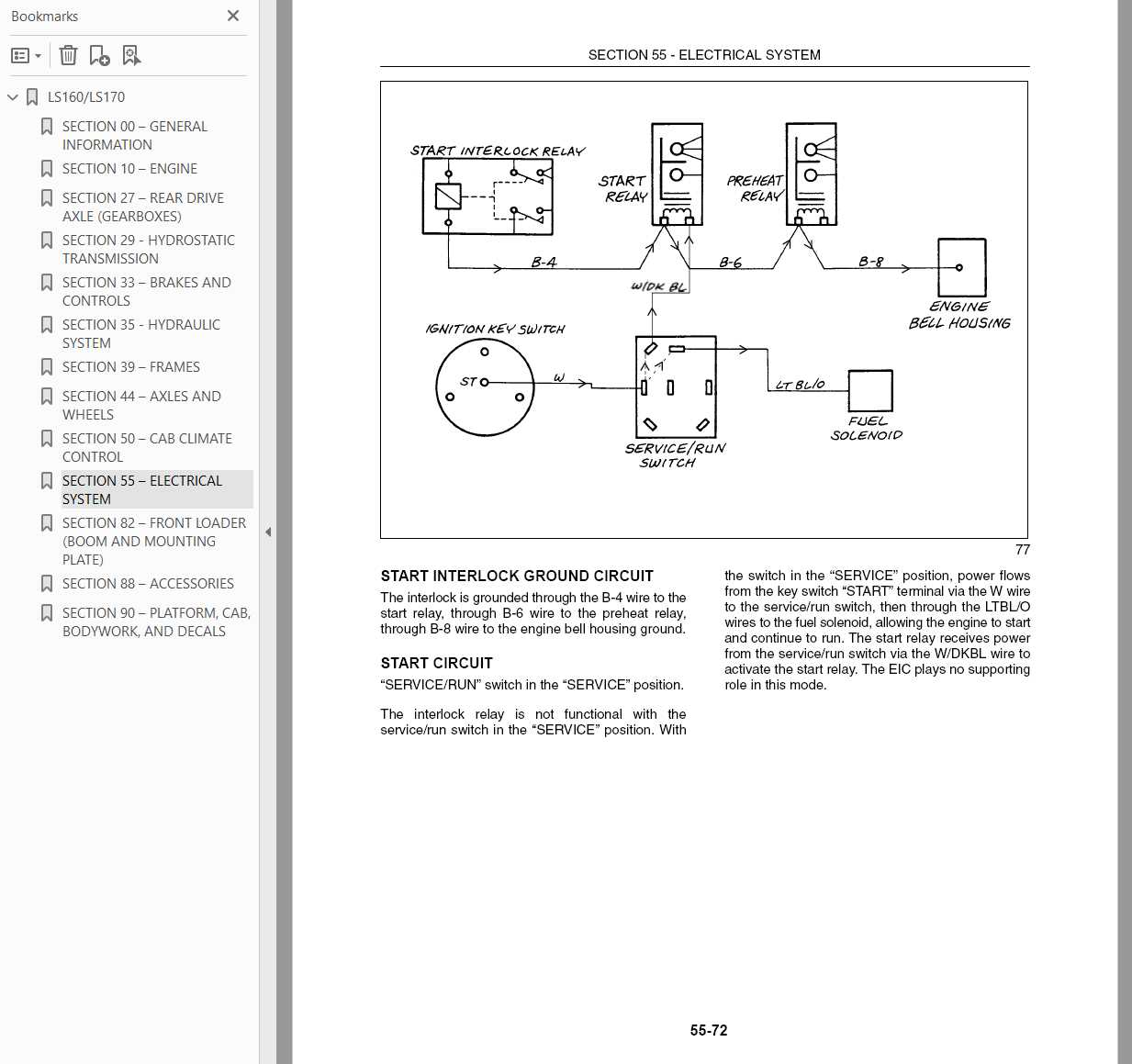

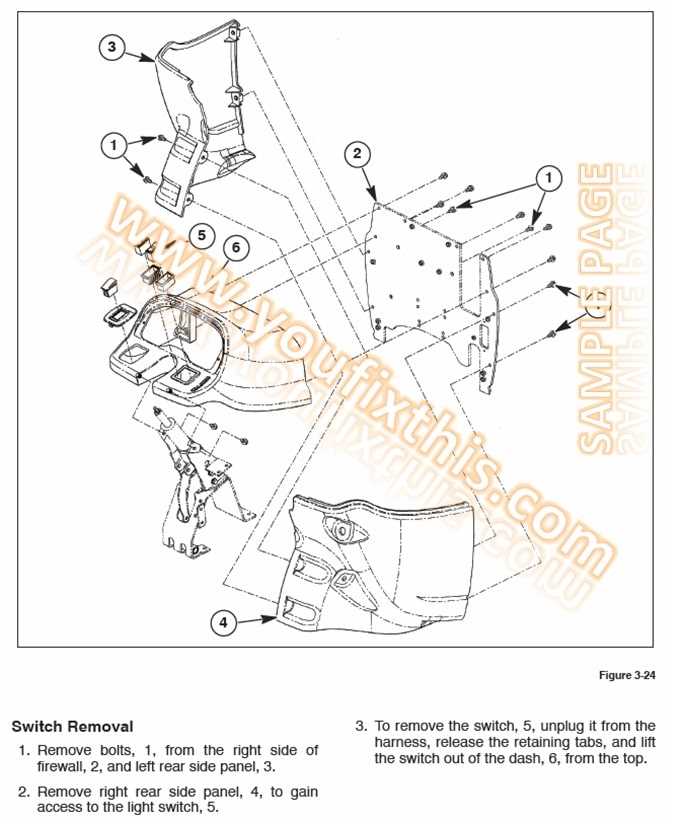

Electrical Components Overview

This section provides insight into the various electrical systems that are essential for the efficient operation of heavy machinery. Understanding these components is crucial for effective maintenance and troubleshooting.

Key Electrical Components

- Batteries: Store electrical energy to start the engine and power accessories.

- Alternators: Generate electricity to recharge batteries and power the electrical system while the engine runs.

- Wiring Harnesses: Network of wires that connect electrical components, allowing for the transmission of power and signals.

- Sensors: Monitor various parameters such as temperature, pressure, and speed, providing feedback to the control systems.

- Relays: Act as switches that control larger currents, enabling the operation of various systems without manual intervention.

- Fuses: Protect electrical circuits from overload by breaking the circuit when excessive current flows.

Maintenance Tips

- Regularly inspect wiring for signs of wear or damage.

- Ensure battery connections are clean and tight to prevent starting issues.

- Check fuses periodically to ensure they are functional.

- Monitor sensor performance and replace any faulty components.

- Keep electrical connections dry and free from corrosion.

Maintaining these components is vital for ensuring the machinery operates smoothly and efficiently, preventing costly breakdowns and enhancing overall performance.

Engine Performance Problems

Engine performance issues can significantly impact the efficiency and functionality of your equipment. Identifying these problems early is crucial to ensure smooth operation and prevent further damage. Common symptoms include reduced power, unusual noises, or difficulties in starting.

One of the primary factors contributing to engine inefficiency is fuel quality. Contaminated or substandard fuel can lead to poor combustion, resulting in a noticeable drop in performance. Regularly checking and replacing the fuel filter can help mitigate these issues.

Air intake is another critical element that affects engine performance. A clogged air filter can restrict airflow, leading to a lean fuel mixture and causing the engine to struggle under load. Ensuring that the air intake system is clean and free from obstructions is essential for optimal performance.

Additionally, ignition system malfunctions can cause misfires, leading to uneven power delivery. Inspecting spark plugs and ignition components regularly will help maintain smooth operation and prevent potential breakdowns.

Lastly, regular maintenance and timely diagnostics are key in addressing these performance problems. Keeping an eye on engine parameters can help you identify issues before they escalate, ensuring your equipment runs efficiently for years to come.

Replacing the Fuel Filter

Maintaining optimal engine performance requires regular attention to the fuel system, including the timely replacement of the fuel filter. This essential component plays a critical role in ensuring that impurities do not enter the engine, thereby promoting efficiency and longevity.

Before starting the process, ensure that you have the necessary tools and a replacement filter ready. It’s advisable to consult your vehicle’s specifications for the correct filter type. Begin by safely disconnecting the battery to prevent any electrical issues during the procedure.

Next, locate the fuel filter, which is typically situated along the fuel line. Carefully detach the filter from its mounting, taking care to catch any spilled fuel. Install the new filter in the same orientation as the old one, ensuring a snug fit to avoid leaks. Once secured, reconnect the fuel lines and battery.

Finally, start the engine and check for any signs of leakage around the newly installed filter. This simple yet vital maintenance step can significantly enhance your engine’s performance and reliability.

Importance of Regular Lubrication

Proper maintenance is crucial for the longevity and efficiency of machinery. One of the fundamental aspects of this maintenance is the consistent application of lubricants. Regular lubrication not only enhances performance but also prevents wear and tear, leading to a more reliable operation.

Here are several key reasons why consistent lubrication is essential:

- Reduces Friction: Lubrication creates a protective barrier between moving parts, minimizing friction and preventing overheating.

- Prevents Corrosion: Lubricants help protect components from moisture and contaminants that can lead to rust and degradation.

- Extends Lifespan: Regularly lubricated machinery tends to last longer, reducing the need for costly replacements.

- Improves Efficiency: Well-lubricated systems operate more smoothly, enhancing overall productivity.

- Minimizes Downtime: Effective lubrication helps avoid unexpected breakdowns, allowing for continuous operation.

In conclusion, prioritizing regular lubrication is vital for maintaining the performance and reliability of equipment. Adopting a consistent lubrication schedule can yield significant long-term benefits. It is an investment in the efficiency and durability of your machinery.

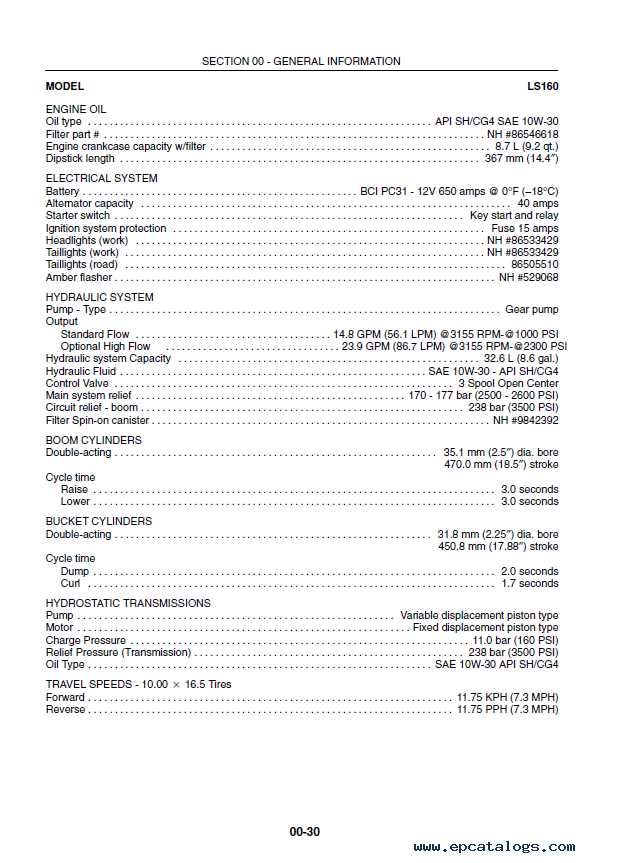

Transmission Maintenance Tips

Proper upkeep of your equipment’s transmission is essential for ensuring optimal performance and longevity. Regular attention to this critical component can prevent costly breakdowns and enhance overall efficiency. Below are some key strategies to help you maintain your transmission effectively.

1. Regular Fluid Checks: Monitor the transmission fluid levels consistently. Low fluid can lead to overheating and increased wear. Ensure the fluid is clean and at the appropriate level, and replace it according to the manufacturer’s recommendations.

2. Cleanliness is Key: Keep the transmission area clean and free from debris. Dirt and grime can hinder performance and lead to mechanical issues. Regularly inspect and clean any surrounding components to avoid contamination.

3. Inspect for Leaks: Regularly check for any signs of leakage. Fluid leaks can indicate serious issues that require immediate attention. Addressing leaks promptly can prevent further damage and ensure your system operates smoothly.

4. Monitor Operating Temperature: Keep an eye on the temperature gauge. Excessive heat can damage the transmission. If you notice unusually high temperatures, investigate potential causes and address them immediately.

5. Follow Scheduled Maintenance: Adhere to the maintenance schedule outlined in your owner’s documentation. Routine inspections and service can catch problems early and extend the life of your transmission.

6. Use Quality Parts: When replacements are necessary, always opt for high-quality components. Using substandard parts can compromise performance and lead to premature failure.

7. Drive with Care: Be mindful of how you operate your equipment. Avoid sudden starts and stops, and ensure smooth shifting to reduce strain on the transmission.

By implementing these maintenance tips, you can significantly enhance the reliability and functionality of your transmission, ensuring it performs efficiently for years to come.

Safety Precautions During Repairs

Ensuring a safe working environment is paramount when conducting maintenance or servicing tasks. Adhering to proper safety measures not only protects the individual performing the work but also minimizes risks to others in the vicinity. Awareness and preparation are key components in maintaining safety throughout the process.

Here are essential precautions to consider:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Keep the workspace clean and organized to prevent accidents.

- Ensure proper ventilation if working in enclosed spaces to avoid inhaling harmful fumes.

- Disconnect the power source before beginning any task to prevent accidental starts.

Additionally, follow these guidelines:

- Read all safety warnings and instructions related to the machinery being serviced.

- Utilize tools and equipment designed for the specific tasks at hand.

- Maintain a first aid kit nearby and be familiar with emergency procedures.

- Work with a partner when handling heavy components to reduce the risk of injury.

By implementing these safety measures, individuals can significantly reduce the likelihood of accidents and create a more secure environment during maintenance activities.

Parts Sourcing and Compatibility

When maintaining heavy machinery, ensuring that components are sourced correctly is essential for optimal performance. Compatibility of parts directly impacts the efficiency and longevity of the equipment. Therefore, understanding where to find reliable components and how to verify their suitability is crucial for operators and technicians alike.

Several options exist for acquiring parts, ranging from original equipment manufacturers (OEM) to aftermarket suppliers. Each option presents distinct advantages and considerations that must be weighed based on individual needs and circumstances.

| Source Type | Advantages | Considerations |

|---|---|---|

| OEM Parts | Guaranteed compatibility, high quality | Typically more expensive, longer delivery times |

| Aftermarket Parts | Cost-effective, often readily available | Variable quality, compatibility concerns |

| Used Parts | Lower cost, sustainable option | Uncertain condition, limited warranty |

To ensure the chosen components will function effectively, it’s advisable to cross-reference part numbers and specifications. Additionally, consulting with experienced professionals or utilizing online forums can provide valuable insights into best practices for sourcing parts that meet the required standards.

User Reviews and Repair Experiences

This section explores insights and feedback from users who have dealt with maintenance and troubleshooting tasks for their equipment. Their experiences can provide valuable information on common issues and effective solutions, making it easier for others facing similar challenges.

Common Issues Reported

- Hydraulic system malfunctions

- Engine starting difficulties

- Electrical component failures

- Wear and tear on critical parts

Helpful Tips from Users

- Regularly check fluid levels to prevent overheating.

- Keep connections clean and free of corrosion for better performance.

- Refer to community forums for shared experiences and solutions.

- Invest in quality replacement parts for longevity.

Sharing experiences not only fosters a community of support but also enhances knowledge about effective practices and preventive measures. Users are encouraged to document their findings and contribute to this ongoing dialogue.