When it comes to ensuring optimal performance of marine propulsion systems, having access to comprehensive resources is essential. These guides provide valuable insights and detailed instructions that empower users to effectively troubleshoot and enhance the longevity of their equipment. Whether you’re a seasoned enthusiast or a novice, knowing where to find reliable information can make a significant difference.

Within these informative documents, you’ll discover a wealth of knowledge covering various aspects of operation and upkeep. From basic troubleshooting tips to more advanced techniques, the content is designed to cater to a wide range of skill levels. By familiarizing yourself with these resources, you can take proactive steps in maintaining your vessel and avoiding costly repairs.

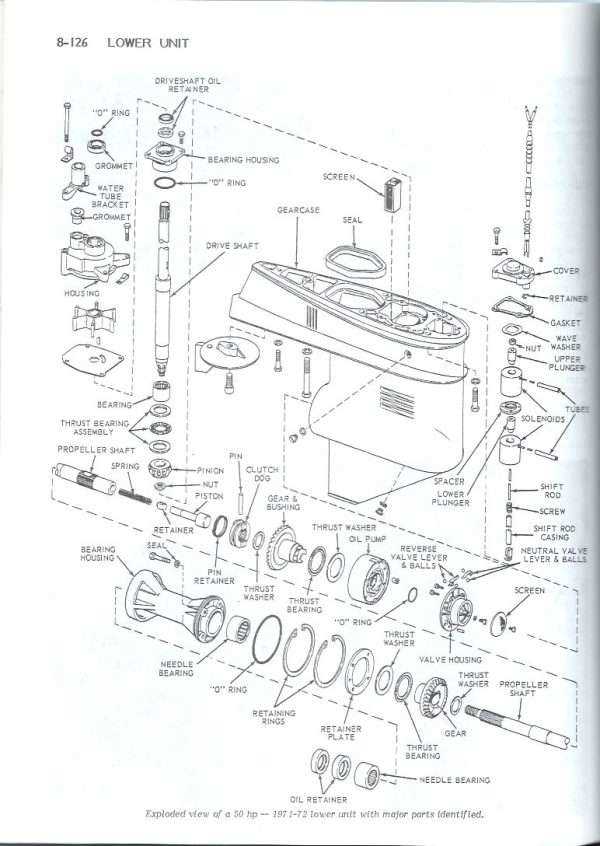

In addition to addressing common issues, these guides often include specifications and diagrams that facilitate a deeper understanding of the machinery. This information not only aids in resolving current problems but also enhances your ability to perform routine checks and preventive maintenance. Armed with the right tools and knowledge, you can ensure your marine engine remains in peak condition for years to come.

Understanding Johnson Evinrude Engines

Exploring the intricacies of outboard motor systems provides valuable insights into their operation and maintenance. These marine engines are designed for optimal performance on the water, combining engineering excellence with user-friendly features. A comprehensive understanding of these power units is essential for enthusiasts and professionals alike.

Key Features of Outboard Motors

- Design: Modern outboard motors are built for efficiency, often featuring lightweight materials and compact designs.

- Performance: These engines offer reliable power and speed, tailored for various boating activities.

- Fuel Efficiency: Advanced technologies enhance fuel economy, minimizing costs for boaters.

Common Issues and Maintenance Tips

- Regular Inspections: Periodically check fuel lines, connections, and overall engine condition.

- Winterization: Properly prepare the motor for off-season storage to prevent damage.

- Use Quality Parts: When replacing components, opt for high-quality alternatives to ensure longevity and reliability.

By grasping the fundamental characteristics and care practices, users can enhance the lifespan and performance of their marine propulsion systems, ensuring enjoyable and trouble-free outings on the water.

Common Issues with Johnson Evinrude Models

Many boat enthusiasts encounter various challenges when using specific outboard motor brands. Understanding these common problems can significantly enhance the maintenance and performance of your watercraft. Here, we explore typical issues that users may face, along with their potential solutions.

| Issue | Description | Solution |

|---|---|---|

| Starting Difficulties | Engines may struggle to start, often due to fuel delivery or electrical problems. | Check fuel lines, filters, and battery connections. Ensure proper priming of the system. |

| Overheating | Engines can overheat due to inadequate cooling or blockages in the cooling system. | Inspect the water intake, clean any debris, and ensure the thermostat is functioning. |

| Stalling | Unexpected stalling can occur during operation, often linked to fuel quality or engine settings. | Use high-quality fuel and verify the carburetor or fuel injector settings are correct. |

| Rough Idling | Engines may idle unevenly, which can indicate issues with the ignition or fuel mixture. | Check spark plugs and adjust the fuel mixture as necessary to achieve smooth operation. |

| Excessive Smoke | Heavy smoke emissions can signal over-oiling or a malfunctioning fuel system. | Reduce oil levels and ensure the fuel system is calibrated correctly for optimal performance. |

Tools Needed for Effective Repairs

Having the right instruments at your disposal is crucial for achieving optimal outcomes in maintenance tasks. Whether you’re addressing issues in marine engines or other mechanical systems, utilizing appropriate tools can significantly enhance your efficiency and precision. This section outlines essential equipment that will aid you in successfully completing various tasks.

Essential Hand Tools

Basic hand tools form the foundation of any mechanical work. These items are versatile and can tackle a variety of tasks, making them indispensable in any toolkit.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To drive screws of various types and sizes. |

| Pliers | For gripping, twisting, and cutting wires or small parts. |

| Socket Set | To work with fasteners in tight spaces. |

Power Tools for Efficiency

Incorporating power tools can greatly reduce the time and effort required for more demanding tasks. These devices can handle heavier workloads and provide increased precision.

| Tool | Purpose |

|---|---|

| Drill | For creating holes and driving fasteners quickly. |

| Angle Grinder | To cut, grind, or polish materials. |

| Impact Wrench | For delivering high torque output to fasteners. |

| Multimeter | To measure electrical values and diagnose issues. |

Step-by-Step Maintenance Guide

Proper upkeep of your outboard motor is essential for optimal performance and longevity. This section provides a comprehensive approach to ensure your engine runs smoothly and efficiently. Following these detailed steps will help prevent common issues and extend the life of your equipment.

| Step | Description |

|---|---|

| 1 | Check and replace the fuel filter to ensure clean fuel reaches the engine. |

| 2 | Inspect the spark plugs; clean or replace them if necessary to maintain ignition quality. |

| 3 | Examine the propeller for any signs of damage or wear, ensuring it is secure and functioning properly. |

| 4 | Flush the cooling system with fresh water to remove salt and debris, preventing overheating. |

| 5 | Check the oil level and quality; change it if it appears dirty or low to keep the engine lubricated. |

| 6 | Inspect hoses and connections for leaks or cracks, replacing any damaged parts to maintain integrity. |

| 7 | Store the engine properly during off-seasons, ensuring all components are protected from corrosion. |

Following this systematic approach not only enhances performance but also ensures that your motor remains reliable for years to come.

How to Diagnose Engine Problems

Identifying issues within a motor requires a systematic approach that encompasses observation, testing, and analysis. By understanding the symptoms and utilizing appropriate diagnostic techniques, one can effectively pinpoint the root causes of malfunctioning components.

The first step in the diagnostic process is to gather information on the performance of the engine. This includes noting any unusual sounds, vibrations, or changes in operation. Keeping a detailed record of these observations is crucial for further analysis.

| Symptom | Possible Cause | Next Steps |

|---|---|---|

| Engine won’t start | Faulty ignition or fuel delivery issue | Check battery, spark plugs, and fuel lines |

| Overheating | Insufficient cooling or blocked passages | Inspect cooling system and flush if necessary |

| Excessive smoke | Oil leakage or incorrect fuel mixture | Examine oil levels and adjust fuel ratio |

| Poor acceleration | Clogged filters or malfunctioning throttle | Clean filters and check throttle response |

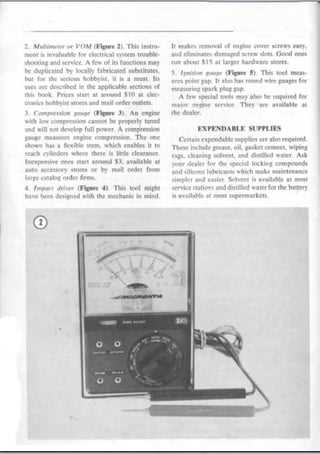

Once the symptoms are noted, conducting tests on the engine’s systems is essential. Utilizing tools like multimeters and pressure gauges can provide valuable data for further investigation. Comparing these results against manufacturer specifications aids in confirming suspected issues.

After identifying potential problems, it’s important to address them methodically. Prioritize repairs based on severity and impact on performance. Keeping the maintenance history in mind can also help in making informed decisions about the necessary actions to restore optimal functionality.

Essential Safety Precautions During Repairs

When working on marine engines, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks associated with maintenance tasks. Here are some key precautions to consider:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and a mask.

- Ensure your workspace is well-ventilated to avoid inhaling harmful fumes.

- Disconnect the power supply before beginning any work to prevent electrical shocks.

- Keep a fire extinguisher nearby, especially when dealing with flammable substances.

- Use tools that are in good condition and appropriate for the task at hand.

In addition to these basic precautions, consider the following steps to enhance safety:

- Always read and understand the equipment’s guidelines before starting.

- Work with a partner when performing complex tasks to ensure assistance is available in case of emergencies.

- Keep the work area organized to minimize hazards from clutter and misplaced tools.

- Regularly inspect and maintain safety equipment to ensure it is functional.

- Report any unsafe conditions or practices to the appropriate personnel immediately.

By implementing these essential safety measures, you can create a secure environment that allows for efficient and effective maintenance of marine engines.

Replacing Spark Plugs: A Quick Guide

Changing the spark plugs is an essential maintenance task that can significantly improve engine performance. This process ensures that your machine runs smoothly and efficiently. Follow these steps for a hassle-free replacement.

- Gather Necessary Tools:

- New spark plugs

- Socket wrench

- Gap gauge

- Anti-seize compound (optional)

- Prepare the Engine:

Ensure the engine is cool before starting. Disconnect the battery to avoid any electrical issues.

- Remove Old Spark Plugs:

Using the socket wrench, carefully unscrew the old spark plugs. Take note of their condition as this can indicate engine issues.

- Check Gap on New Plugs:

Use the gap gauge to ensure the new spark plugs are set to the correct specifications. Adjust if necessary.

- Install New Spark Plugs:

Apply a small amount of anti-seize compound to the threads (if desired). Screw in the new plugs by hand, then tighten them with the wrench, ensuring not to over-tighten.

- Reconnect Battery:

Once the new plugs are securely in place, reconnect the battery and start the engine to ensure everything is functioning properly.

Regularly checking and replacing spark plugs can lead to better fuel efficiency and smoother operation. Keep an eye on your engine’s performance for optimal results.

Fuel System Troubleshooting Techniques

Diagnosing issues within the fuel delivery system is crucial for optimal engine performance. Proper assessment can prevent further complications and ensure the longevity of the machinery. This section outlines various strategies to identify and resolve common fuel system problems.

Common Symptoms and Their Causes

- Engine Stalling: Possible fuel blockage or inadequate fuel pressure.

- Poor Acceleration: Could indicate a clogged fuel filter or malfunctioning pump.

- Excessive Fuel Consumption: May result from a leaking injector or incorrect fuel mixture.

Troubleshooting Steps

- Check the fuel level in the tank to ensure there is sufficient fuel.

- Inspect fuel lines for cracks, leaks, or kinks that may restrict flow.

- Examine the fuel filter for clogs and replace if necessary.

- Test the fuel pump operation to ensure it is delivering the correct pressure.

- Verify the condition of injectors for proper spray patterns and functionality.

By following these techniques, one can effectively identify and address issues within the fuel delivery system, leading to improved engine efficiency and performance.

Understanding the Cooling System Components

The cooling system in marine engines plays a crucial role in maintaining optimal operating temperatures, ensuring longevity and efficiency. This intricate assembly comprises several key elements, each contributing to effective temperature regulation. Understanding how these components interact is essential for proper maintenance and troubleshooting.

At the heart of the system is the water pump, which circulates water through the engine. This component draws in water from the surrounding environment and pushes it into the engine’s cooling passages. The flow of water helps dissipate heat generated during operation, preventing overheating.

Another vital element is the thermostat, which regulates the temperature by controlling the flow of coolant. It opens and closes in response to the engine’s temperature, ensuring that the engine warms up quickly while preventing excessive heat build-up.

The heat exchanger is another significant component, allowing for effective heat transfer between the coolant and the surrounding water. This device helps to maintain the desired temperature by transferring excess heat away from the engine.

Finally, hoses and connections are crucial for transporting the coolant throughout the system. These components must be inspected regularly for leaks and wear, as they are essential for maintaining a closed loop of circulation.

By familiarizing oneself with these elements, operators can better appreciate the complexities of the cooling system and the importance of regular checks to ensure optimal performance.

Electrical System Checks and Fixes

Ensuring the reliability of the electrical system is crucial for optimal performance. This section provides a comprehensive overview of diagnostic procedures and corrective actions to enhance the efficiency of your engine’s electrical components.

Begin with a systematic approach to identifying potential issues. Regular checks can prevent minor faults from escalating into significant problems.

- Examine the battery condition, checking for signs of corrosion and ensuring proper charge levels.

- Inspect all wiring for wear, fraying, or loose connections that may impede electrical flow.

- Test the ignition system components, including coils and spark plugs, for proper functionality.

Once you have conducted the initial assessments, focus on specific areas that commonly require attention:

-

Battery Maintenance:

- Clean terminals and ensure tight connections.

- Verify voltage with a multimeter; it should read between 12.4V and 12.7V when fully charged.

-

Wiring Inspection:

- Look for any signs of short circuits or breaks in the insulation.

- Ensure all connectors are secure and free of moisture.

-

Ignition Testing:

- Use an ohmmeter to test the resistance of the ignition coil.

- Check spark plug gaps and replace worn plugs as needed.

By diligently following these checks and fixes, you can maintain the integrity of your electrical system, ensuring smooth operation and reliability for all your marine adventures.

Upgrading Parts for Enhanced Performance

Improving the functionality of your watercraft can significantly elevate your overall experience. By focusing on specific components, you can achieve greater efficiency, speed, and reliability. Upgrading key parts not only enhances performance but also prolongs the lifespan of your vessel.

Key components to consider for enhancement include the fuel system, ignition, and propeller. Each of these elements plays a crucial role in the overall operation, and optimizing them can lead to impressive gains.

For instance, investing in a high-performance fuel injector can result in better fuel atomization, leading to increased power output and improved fuel efficiency. Similarly, a modern ignition system can enhance firing consistency, contributing to smoother acceleration and reduced emissions.

Finally, selecting the right propeller tailored to your specific needs can maximize thrust and minimize drag, ultimately providing a more responsive and enjoyable ride. Delve into these upgrades to unlock the ultimate potential of your craft.

Finding Replacement Parts for Your Engine

Maintaining optimal performance of your outboard motor requires access to high-quality components. Identifying and acquiring suitable replacements can significantly enhance the longevity and efficiency of your engine.

To effectively locate the necessary parts, consider the following strategies:

- Authorized Dealers: Start by checking with official distributors who specialize in marine equipment. They often carry a comprehensive selection of parts that meet manufacturer specifications.

- Online Retailers: Explore reputable e-commerce platforms that focus on marine supplies. Many of these sites offer extensive inventories and customer reviews to guide your purchase.

- Local Marine Shops: Visit nearby stores that cater to boating enthusiasts. They can provide valuable insights and may have the parts you need readily available.

- Forums and Community Groups: Engage with online communities dedicated to boating. Members often share resources and recommendations for sourcing hard-to-find components.

When searching for parts, ensure you have accurate information about your engine model and specifications. This diligence will help you avoid compatibility issues and ensure a smooth installation process.

Lastly, consider exploring options for refurbished or aftermarket components. These alternatives can often provide substantial savings while still maintaining quality performance.