For those who value the longevity and efficiency of their equipment, understanding the core principles of upkeep is crucial. A well-kept machine not only extends its operational life but also guarantees consistent performance. Ensuring every component is in optimal condition can save time, effort, and money in the long run.

Effective servicing of a garden tractor requires familiarity with its intricate systems and knowledge of specific troubleshooting methods. Whether it’s addressing common issues or performing regular maintenance tasks, having the right strategies at your disposal can make all the difference. Regular checks and timely adjustments are essential to avoid more significant problems.

This comprehensive guide will provide clear instructions and key insights into the essential steps for enhancing the durability and reliability of your equipment. By following these techniques, you can ensure that your machine remains in top-notch condition, ready to tackle any task efficiently.

Guidance for Maintaining and Restoring Lawn Equipment

Keeping garden machinery in top condition requires understanding essential aspects of maintenance and troubleshooting. With regular use, these types of equipment may face wear and tear, leading to reduced performance or mechanical issues. This section provides an overview of fundamental principles and techniques to help users ensure their machines remain efficient and functional.

Routine Inspections play a critical role in preventing unexpected breakdowns. By consistently checking crucial components like belts, filters, and blades, users can identify potential issues early on. Additionally, attention to proper lubrication of moving parts helps minimize friction, which is a major factor in the deterioration of the machine.

Another essential part of upkeep involves keeping the engine and other key systems clean and free of debris. Grass clippings and dirt accumulation can negatively impact performance, causing overheating or other complications. By periodically clearing out these elements, users can maintain optimal efficiency and extend the life of their equipment.

Addressing common problems as soon as they arise is crucial. For instance, if a noticeable decrease in performance occurs, it might indicate that the carburetor needs cleaning or that the air filter requires replacement. Similarly, unusual vibrations could signify issues with the cutting mechanism

Identifying Common Issues in GT5000

Maintaining a riding mower involves understanding the recurring problems that might hinder its optimal performance. Recognizing these typical malfunctions allows for timely interventions, minimizing disruptions and ensuring consistent operation.

Engine Performance Challenges

One of the frequent difficulties is linked to engine functionality. Issues such as poor starting, stalling, or loss of power often stem from fuel system irregularities or spark plug wear. Regular inspections of these components can help prevent more serious breakdowns.

Transmission and Steering Concerns

Another common challenge lies in the transmission and steering systems. Symptoms like difficulty shifting gears or hard-to-control steering might indicate worn-out belts or misaligned mechanisms. Addressing these faults promptly not only restores smooth operation but also prolongs the lifespan of the equipment.

Step-by-Step Troubleshooting Guide

This section provides a clear and structured approach to identifying and resolving common issues. By following these steps, you can efficiently diagnose problems and apply effective solutions to restore functionality.

Initial Inspection

Begin with a visual examination of all key components to identify visible damage or loose connections. Pay close attention to the condition of cables, connections, and mechanical parts.

- Check all electrical connections for corrosion or looseness.

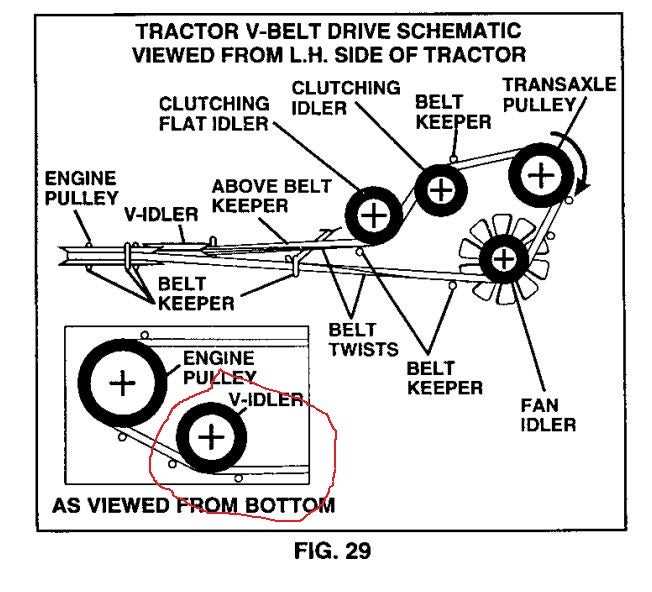

- Inspect belts, pulleys, and moving parts for signs of wear or misalignment.

- Verify that all safety switches are functioning correctly and are properly engaged.

Operational Testing

If no visible issues were found, proceed with testing the system to pinpoint the cause of the problem. Use the following steps to systematically diagnose any malfunctions.

- Start the engine and listen for unusual noises that could indicate mechanical issues.

- Test all control levers to ensure they respond smoothly and do not stick or jam.

- Check for fluid leaks or unusual vibrations during operation.

If an issue is identified during these steps, refer to specific component guides for detailed solutions and part replacements.

Maintenance Tips for Longevity

Regular upkeep and attention to detail are key to extending the lifespan of any machinery. By following a few essential practices, owners can prevent common issues, reduce wear, and maintain optimal performance over time.

- Keep It Clean: Ensure all components are free from dirt, dust, and debris. A thorough cleaning after each use helps prevent build-up that can cause malfunctions.

- Lubricate Moving Parts: Apply appropriate lubricants to all essential joints and connections. This minimizes friction and reduces the risk of premature wear.

- Inspect and Replace Worn Parts: Regularly check for signs of wear, such as cracks or loose connections. Prompt replacement of worn-out parts can avoid costly breakdowns.

- Check Fluid Levels: Maintaining adequate fluid levels is crucial for smooth operation. Monitor and refill necessary fluids periodically to prevent overheating and damage.

- Store Properly: Keep machinery in a dry, sheltered location when not in use. Proper storage protects it from moisture and other environmental factors that may cause corrosion or damage.

By following these straightforward maintenance practices, you can significantly increase the longevity and efficiency of your equipment.

Understanding the Engine Mechanics

The core of any reliable garden vehicle lies in its engine system. The intricacies of its components and the way they work together determine both performance and durability. A clear comprehension of these mechanisms is essential for maintaining efficiency and preventing common mechanical issues.

Key Components and Their Roles

At the heart of the system is the combustion unit, which functions as the powerhouse. This section includes the cylinder, piston, and spark plug, working in sync to convert fuel into motion. Supporting elements like the cooling system and oil circulation ensure that the engine maintains a stable temperature and reduces friction between moving parts. Proper lubrication is vital to prevent wear and extend the lifespan of each component.

Common Engine Challenges

Despite their robust design, these engines can encounter issues over time. Problems such as overheating, reduced fuel efficiency, and irregular sounds often signal underlying complications. Understanding these signs and knowing the causes, such as a clogged air filter or a misaligned timing belt, can help in identifying solutions swiftly. Timely inspections and maintenance checks play a critical role in avoiding significant malfunctions.

Essential Tools for Repairs

To effectively maintain and restore machinery, having the right instruments at your disposal is crucial. These tools not only facilitate the process but also ensure that tasks are executed efficiently and safely. Whether you are a seasoned technician or a novice enthusiast, familiarizing yourself with the necessary equipment will enhance your ability to tackle various challenges.

Basic Hand Tools

Every repair toolkit should include a set of fundamental hand tools. Wrenches, screwdrivers, and pliers are essential for performing a range of tasks, from loosening bolts to securing components. These tools come in various sizes and types, allowing for versatility in addressing different machinery requirements.

Power Tools for Efficiency

Incorporating power tools into your maintenance activities can significantly boost efficiency. Drills, grinders, and saws allow for quicker and more precise work compared to manual methods. Selecting the appropriate power tools based on the specific demands of each project will streamline your workflow and enhance productivity.

Hydraulic System Diagnostics

The hydraulic system is a crucial component that requires careful monitoring and evaluation to ensure optimal performance. Identifying issues within this system is essential for maintaining operational efficiency and preventing further damage. Through systematic assessment and testing, various factors contributing to hydraulic malfunction can be uncovered.

To initiate diagnostics, start by inspecting the hydraulic fluid levels, as low fluid can lead to inadequate pressure and functionality. Next, examine the condition of hoses and connections for any signs of leaks or wear. Testing the hydraulic pump’s performance is also vital, as it should generate the required pressure to operate the system effectively. Additionally, the functioning of valves and actuators should be assessed to ensure they respond accurately to input controls.

Utilizing specialized diagnostic tools can greatly aid in identifying hidden issues. Pressure gauges, flow meters, and hydraulic testers can provide critical insights into system performance. Regular diagnostics not only extend the life of the hydraulic system but also enhance the overall efficiency of the equipment.

Electrical System Overview and Fixes

The electrical system of a lawn tractor plays a crucial role in its overall performance and functionality. Understanding the components involved and their interconnections is essential for diagnosing issues and implementing effective solutions. This section will explore common electrical components, potential problems, and suggested remedies.

Key components of the electrical system include the battery, ignition switch, wiring harness, and various electrical connections. Each part must function correctly to ensure reliable operation. Over time, wear and tear, corrosion, or loose connections can lead to malfunctioning systems.

| Component | Common Issues | Possible Fixes |

|---|---|---|

| Battery | Weak charge, corrosion | Clean terminals, replace if necessary |

| Ignition Switch | Failure to start, intermittent power | Test continuity, replace if defective |

| Wiring Harness | Frayed wires, loose connections | Inspect and repair or replace damaged sections |

| Fuses | Blown fuses, poor connectivity | Replace blown fuses, check for underlying issues |

Regular maintenance of the electrical system can prevent many issues. Ensure all connections are tight and clean, and inspect components for signs of damage. By addressing problems early, you can enhance the longevity and reliability of your equipment.

How to Replace Worn-Out Parts

Maintaining the efficiency of your machinery often involves replacing components that have degraded over time. Identifying these parts and understanding the process of substitution can significantly enhance performance and prolong the lifespan of the equipment. This section outlines essential steps and considerations for effectively exchanging outdated elements.

Identifying Worn Components

The first step in the replacement process is to recognize which parts require attention. Common indicators of wear include unusual noises, decreased functionality, and visible damage. Regular inspections can help pinpoint these issues early, preventing further complications.

Replacement Procedure

Once the worn components are identified, follow these steps for replacement:

| Step | Action |

|---|---|

| 1 | Gather the necessary tools and new parts. |

| 2 | Ensure the machinery is turned off and disconnected from power. |

| 3 | Remove the old parts carefully, taking note of their installation for reference. |

| 4 | Install the new components, ensuring a secure fit. |

| 5 | Test the machinery to confirm proper operation. |

By adhering to these steps, you can ensure that your machinery operates smoothly and efficiently, minimizing downtime and enhancing productivity.

Tire and Wheel Alignment Advice

Proper alignment of tires and wheels is crucial for optimal vehicle performance. Ensuring that these components are correctly adjusted can enhance driving safety, improve fuel efficiency, and extend the lifespan of your tires. This section offers practical tips to maintain and achieve the correct alignment.

Signs of Misalignment

- Uneven tire wear patterns

- Vehicle pulling to one side while driving

- Steering wheel off-center when driving straight

- Vibration in the steering wheel

Alignment Maintenance Tips

- Regularly inspect tire pressure and adjust as needed.

- Check for visible signs of damage on tires and suspension components.

- Have your alignment checked after any significant impact or if you notice any misalignment symptoms.

- Follow the manufacturer’s guidelines for routine maintenance and alignments.

Safety Precautions during Repairs

Ensuring a safe environment while conducting maintenance activities is crucial for both the individual and the equipment involved. Proper precautions not only prevent accidents but also enhance the efficiency of the work process. Adopting a safety-first mindset can significantly reduce risks and foster a secure workspace.

Essential Safety Measures

Before commencing any maintenance task, it is important to be aware of the necessary safety measures. These steps should be followed to minimize hazards:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use gloves, goggles, and masks to shield against potential injuries and exposure to harmful substances. |

| Disconnect Power Sources | Always ensure that the equipment is unplugged or the battery is removed to prevent accidental starts. |

| Maintain a Clean Workspace | Keep the area tidy to avoid tripping hazards and ensure easy access to tools and equipment. |

| Read Instructions Carefully | Familiarize yourself with the guidelines and specifications before proceeding with the task. |

Emergency Preparedness

Being prepared for emergencies is a vital aspect of safe maintenance practices. Knowing how to react in case of an accident can save lives and prevent further damage. Ensure that first aid supplies are readily available and that all individuals involved are aware of emergency procedures.

Optimizing Performance Post-Repair

Ensuring optimal functionality after maintenance is crucial for extending the lifespan of your equipment. By following specific guidelines and practices, users can enhance efficiency, reduce wear, and maintain overall performance. This section will cover essential steps to ensure your machinery operates at its best after servicing.

Routine Maintenance Practices

Establishing a consistent maintenance routine is vital for ongoing performance. Regular inspections and servicing help identify potential issues before they escalate. Key practices include:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Use high-quality oil to reduce friction. |

| Filter Replacement | Every season | Ensure clean filters for better airflow. |

| Tire Inspection | Monthly | Check for proper inflation and tread wear. |

Performance Enhancements

In addition to routine tasks, consider implementing performance upgrades. Upgrading components can lead to significant improvements in efficiency. Options may include:

- Installing a more efficient air filter

- Upgrading the fuel system

- Enhancing the exhaust system for better airflow