In any laboratory setting, the functionality of precision instruments is crucial for achieving accurate results. This section focuses on the essential practices for maintaining and troubleshooting advanced spinning devices commonly used in various scientific applications. Proper understanding and execution of these procedures ensure optimal performance and longevity of the equipment.

With the complexity of modern instruments, users may encounter a range of operational challenges over time. Addressing these issues effectively requires a comprehensive approach, encompassing both preventative measures and corrective actions. This guide aims to provide clear instructions and insights for users to navigate common malfunctions and restore the device to its full operational capacity.

By familiarizing yourself with the key components and functions of your spinning apparatus, you can significantly reduce downtime and enhance your laboratory’s efficiency. Engaging with the outlined procedures will empower users to take informed actions, ultimately leading to more reliable outcomes in their experiments.

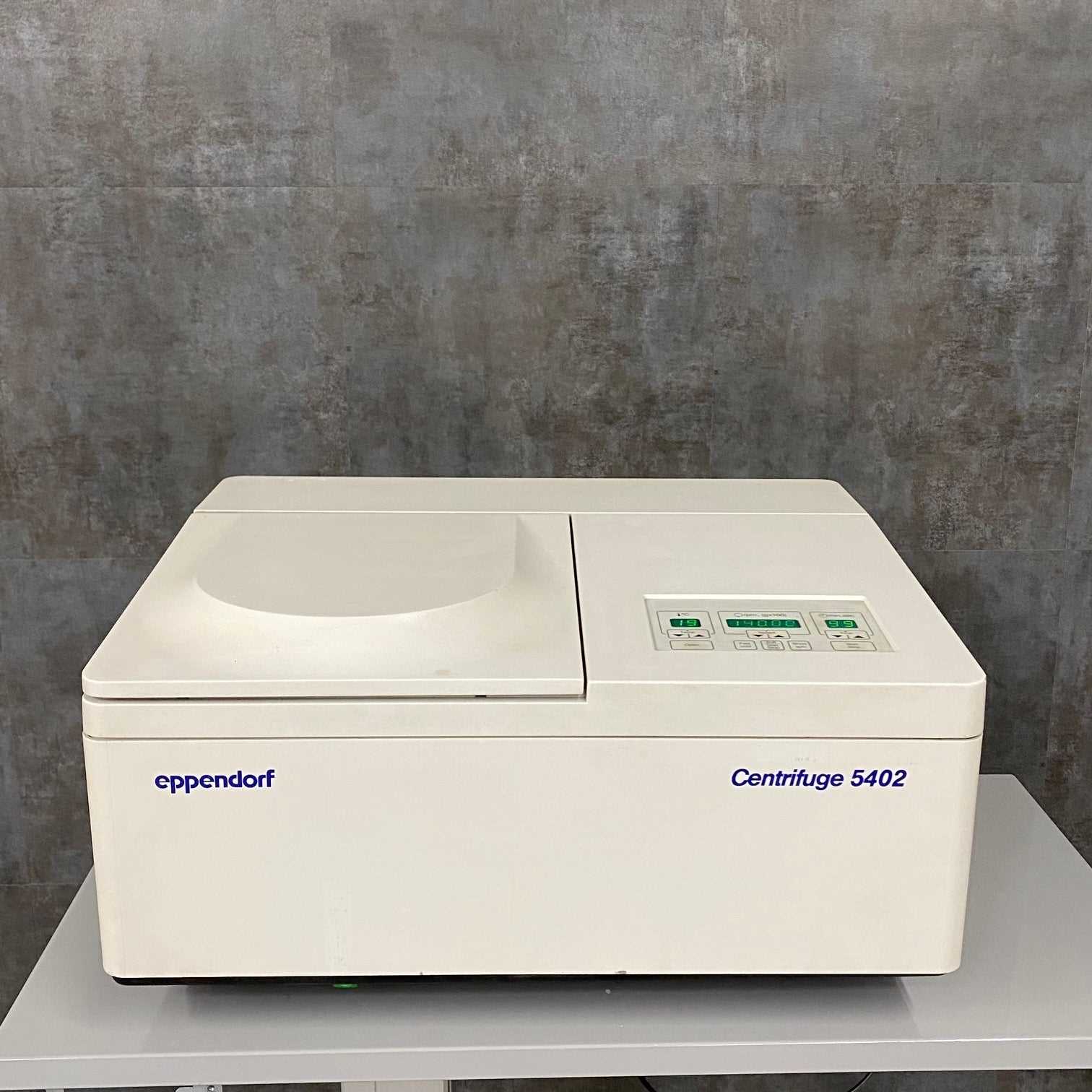

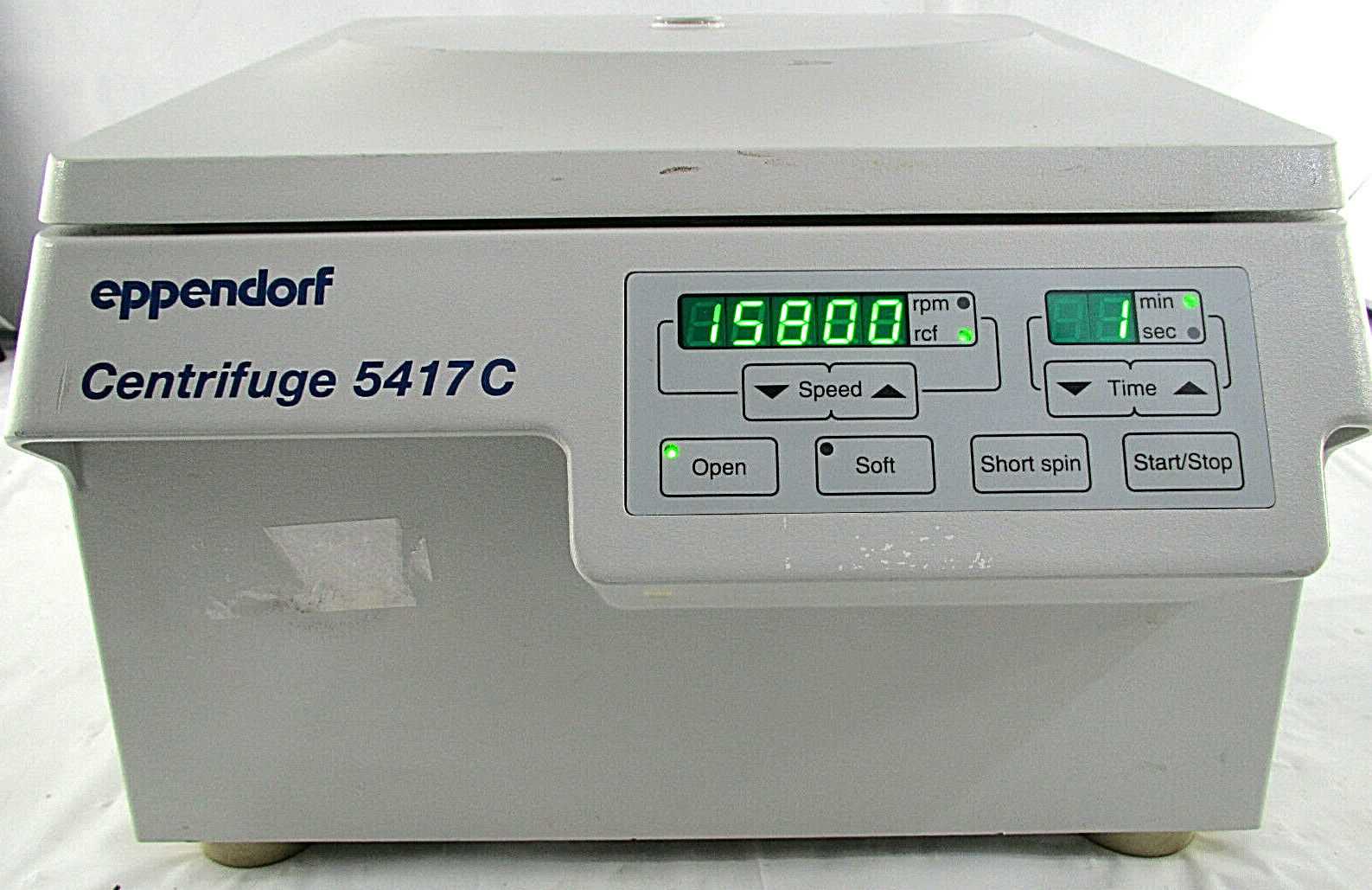

Overview of Eppendorf 5417R Model

This section provides a comprehensive look at a highly regarded laboratory device designed for efficient separation processes. Known for its compact design and user-friendly interface, this model is favored in many research and clinical settings for its reliability and precision.

The unit is equipped with advanced features that facilitate a variety of applications, including the ability to handle various sample types. Its versatility makes it suitable for both routine tasks and specialized protocols. Additionally, the device is engineered to maintain optimal performance while ensuring safety during operation.

In terms of maintenance, understanding the essential components and functionality is crucial for effective troubleshooting. Users can benefit from familiarizing themselves with its key features, which enhance both efficiency and accuracy in experimental procedures.

Overall, this model exemplifies innovation in laboratory technology, providing researchers with the tools needed to achieve precise results in their work.

Common Issues and Troubleshooting Steps

This section aims to address frequent challenges encountered with laboratory spinning devices and provide practical solutions. Understanding these common problems can significantly enhance operational efficiency and prolong the lifespan of the equipment.

Below are some typical issues along with corresponding troubleshooting steps:

| Issue | Troubleshooting Steps |

|---|---|

| Device fails to start |

|

| Unusual noise during operation |

|

| Inconsistent speed |

|

| Leaking from the rotor |

|

By following these steps, users can effectively troubleshoot and resolve common issues, ensuring that the equipment continues to function optimally.

Essential Tools for Repairs

Successful maintenance of laboratory equipment relies heavily on having the right set of instruments. A well-equipped workspace enhances efficiency and ensures that technicians can address issues swiftly and accurately. This section highlights the fundamental implements needed for effective servicing.

Basic Instrumentation

At the core of any service toolkit are the essential instruments that allow for precise diagnostics and adjustments. These tools facilitate disassembly, inspection, and reassembly of complex systems, ensuring optimal functionality.

| Tool | Purpose |

|---|---|

| Screwdrivers | For loosening and tightening screws during disassembly. |

| Wrenches | To adjust bolts and nuts securely. |

| Multimeter | For testing electrical components and ensuring proper voltage levels. |

| Pliers | To grip, twist, or cut wires and small parts. |

| Cleaning Solutions | For maintaining the integrity of components and removing contaminants. |

Advanced Tools

In addition to basic tools, some tasks may require specialized equipment that enhances precision and effectiveness. These advanced instruments can address specific challenges that arise during servicing.

| Tool | Purpose |

|---|---|

| Torque Wrench | To apply a specific torque to bolts, preventing over-tightening. |

| Oscilloscope | For analyzing electrical signals and diagnosing issues in circuits. |

| Heat Gun | To soften adhesives or heat shrink tubing. |

| Calibration Equipment | To ensure measurements and settings are accurate. |

Disassembling the Centrifuge Safely

When attempting to take apart any laboratory equipment, following safety protocols is essential to avoid injuries and damage. Proper techniques not only ensure personal safety but also help maintain the integrity of the device for future use.

Preparation Steps

- Ensure that the device is powered off and unplugged from the electrical source.

- Gather necessary tools such as screwdrivers, pliers, and safety goggles.

- Wear appropriate personal protective equipment, including gloves and lab coats.

- Read through the manufacturer’s guidelines if available, to familiarize yourself with the assembly and components.

Disassembly Process

- Carefully remove any external components, such as lids or covers, using the appropriate tools.

- Locate and unscrew the fasteners securing the internal sections.

- Gently lift out the internal parts, taking care not to force any components that may be stuck.

- Keep all removed pieces organized, labeling them if necessary for easier reassembly.

- Check for any signs of wear or damage as you disassemble, noting any areas that may require attention.

Following these guidelines will help ensure a safe and efficient disassembly process, preparing the equipment for maintenance or repair as needed.

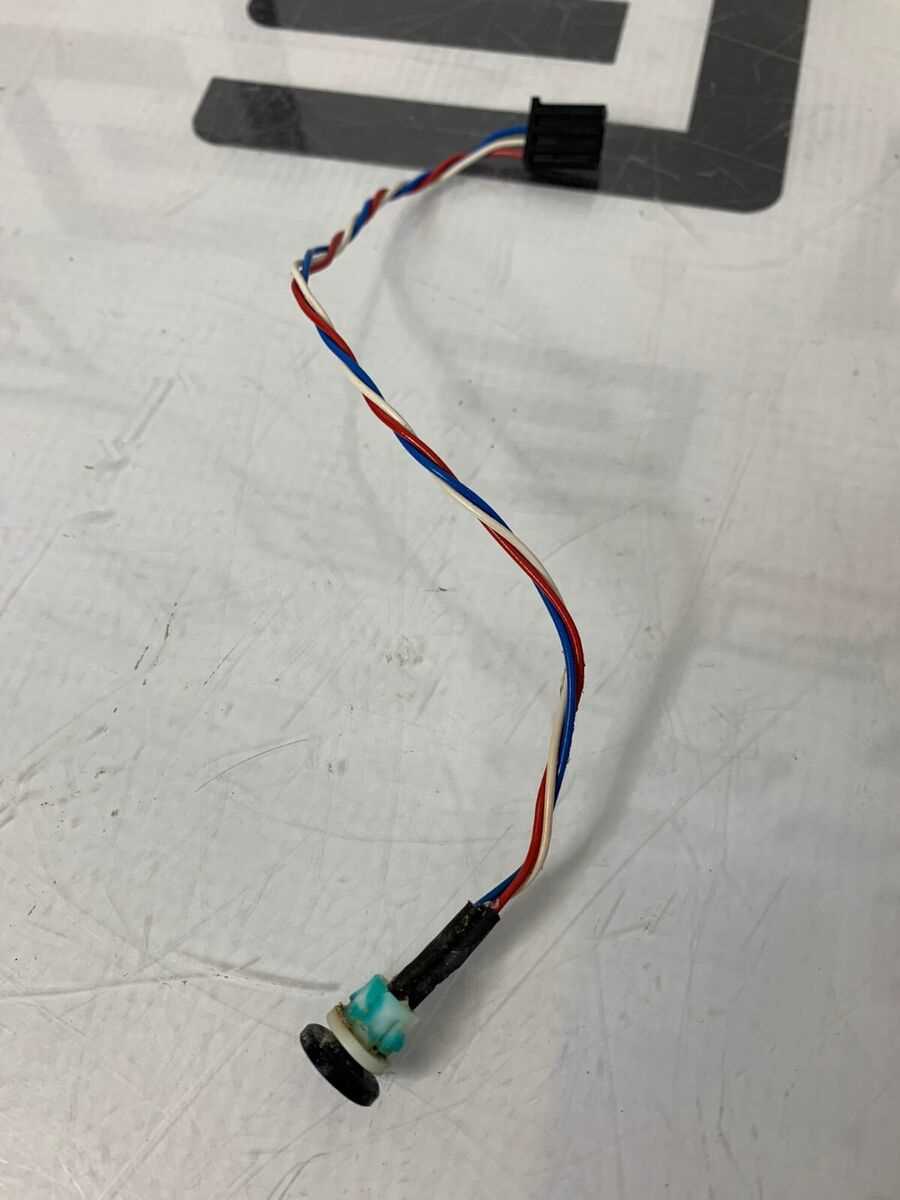

Replacing Worn-Out Parts

Over time, components in laboratory equipment can experience wear and tear, leading to decreased performance and potential malfunctions. Identifying and replacing these degraded elements is crucial for maintaining optimal functionality and ensuring reliable results in your experiments.

First, assess the condition of each part regularly. Look for signs of wear, such as cracks, discoloration, or unusual noises during operation. Components like rotors, seals, and drive belts are particularly susceptible to deterioration. Promptly addressing these issues can prevent further damage and costly repairs down the line.

When it comes to replacement, always use parts that meet the manufacturer’s specifications. This ensures compatibility and reliability. Additionally, consult your equipment documentation for guidance on proper installation techniques to avoid any mishaps. Following these steps will help maintain the integrity and efficiency of your apparatus.

Calibrating the Device After Repairs

Ensuring accurate performance following maintenance is crucial for any laboratory apparatus. Calibration involves adjusting the system to guarantee it operates within specified parameters. This process is vital to restore the precision required for successful experiments and analyses.

Start by collecting the necessary calibration tools and reference materials. It is essential to consult the device specifications to understand the required settings and tolerances. After preparing the equipment, follow the prescribed steps to adjust the readings accurately, ensuring that all adjustments align with the manufacturer’s recommendations.

Once adjustments are made, conduct a series of tests to verify the device’s performance. Monitoring results during this phase will help identify any discrepancies that may need further attention. Regular checks and recalibration are advisable to maintain optimal functionality over time.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring that laboratory equipment remains functional and reliable over time. Regular attention can prevent breakdowns and extend the life of your apparatus, contributing to efficient workflow and consistent results.

- Regular Cleaning: Keep the exterior and interior components free from dust and contaminants. Use appropriate cleaning agents recommended by the manufacturer.

- Routine Inspections: Periodically check for signs of wear or damage. Look for loose connections, frayed wires, or any irregularities in performance.

- Calibrate Frequently: Ensure that all settings and parameters are accurately calibrated according to specifications. This practice enhances precision in your experiments.

- Store Properly: When not in use, store the unit in a dry, stable environment away from extreme temperatures and humidity to prevent corrosion or malfunction.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and procedures provided by the equipment maker for optimal performance.

By implementing these best practices, users can significantly improve the lifespan and functionality of their equipment, ensuring it remains an invaluable tool in their research endeavors.

Understanding the User Manual

The user guide serves as a crucial resource for operating and maintaining laboratory equipment effectively. It offers insights into the functionality, components, and troubleshooting processes essential for ensuring optimal performance.

Within this guide, users can find detailed information about the device’s features and operational protocols. Familiarizing oneself with this documentation can significantly enhance efficiency and safety in the laboratory setting.

| Section | Description |

|---|---|

| Introduction | Overview of the device and its intended applications. |

| Setup Instructions | Step-by-step guidelines for proper installation and initial setup. |

| Operating Procedures | Detailed instructions for utilizing the equipment effectively. |

| Troubleshooting | Common issues and solutions to ensure smooth operation. |

| Maintenance | Recommended practices for routine upkeep and care. |

By consulting this essential resource, users can ensure that they are utilizing the equipment to its fullest potential while adhering to safety standards and best practices.

Frequently Asked Questions

This section aims to address common inquiries related to troubleshooting and maintenance of laboratory spinning devices. Here, users can find solutions to frequently encountered issues, ensuring optimal performance and longevity of their equipment.

Common Issues and Solutions

| Issue | Solution |

|---|---|

| Device does not power on | Check the power supply and ensure the unit is properly plugged in. Inspect the fuse for any damage. |

| Excessive noise during operation | Examine the rotor for any debris and ensure it is correctly seated. Lubricate moving parts if necessary. |

| Error message displayed | Refer to the troubleshooting guide for error codes. Reset the device and try again. |

Maintenance Tips

Regular maintenance is essential to prevent breakdowns and enhance efficiency. It is advisable to routinely clean the interior and exterior surfaces and conduct periodic inspections of the rotor and other components.

When to Seek Professional Help

Recognizing when to turn to an expert is crucial for maintaining the functionality of your laboratory equipment. There are instances when self-service may not suffice, and outside assistance is necessary to prevent further damage and ensure accurate results.

Consider consulting a specialist if you encounter persistent issues that don’t resolve with basic troubleshooting steps. Signs of serious malfunction or irregular performance can indicate underlying problems that require professional attention.

| Signs Indicating Professional Help is Needed | Description |

|---|---|

| Unusual Noises | Strange sounds during operation may signal mechanical failure. |

| Inconsistent Results | Irregular outcomes can suggest calibration issues or component malfunction. |

| Visible Damage | Cracks, leaks, or wear may compromise functionality and safety. |

| Frequent Errors | Repeated error messages can indicate a more complex issue that needs professional diagnosis. |

Engaging a qualified technician can save time and resources, ensuring that your equipment operates at its best. Prioritize safety and reliability by seeking expert intervention when necessary.