Understanding how to troubleshoot and maintain home appliances is essential for every household. This section provides valuable insights into the various aspects of appliance functionality and common issues that may arise. Being equipped with knowledge on how to address these challenges can save time and money while ensuring that your equipment operates efficiently.

From basic operational principles to advanced troubleshooting techniques, this guide aims to empower users with practical skills. Recognizing signs of malfunction and knowing how to respond appropriately can enhance the lifespan of your equipment. Whether dealing with minor glitches or more significant concerns, having a solid foundation in appliance care is crucial.

Additionally, this resource emphasizes the importance of regular upkeep and preventive measures. Simple routines can significantly reduce the likelihood of unexpected breakdowns. By familiarizing yourself with the essential maintenance tasks, you can enjoy a smoother and more reliable experience with your household devices.

Error codes are essential indicators that help users diagnose issues within their appliances. These codes are designed to provide a clear understanding of specific malfunctions, allowing for more efficient troubleshooting. Recognizing what each code signifies can save time and potentially prevent further complications.

Typically, the error codes are displayed on the control panel or through a series of blinking lights. Here’s a brief overview of common codes and their meanings:

- E1: Indicates a problem with the temperature sensor.

- E2: Suggests a blockage in the venting system.

- E3: Reflects issues with the drum movement.

- E4: Points to an electrical malfunction.

It’s important to consult the specific guidelines provided by the manufacturer for detailed descriptions and solutions. Understanding these codes will empower users to take appropriate actions and maintain their appliances effectively.

Tools Needed for Repairs

When addressing issues with your appliance, having the right tools at hand is essential for a smooth and efficient process. A well-equipped toolbox not only facilitates troubleshooting but also ensures that each task can be completed with precision. Below are some common instruments that are typically required for effective maintenance and service.

Essential Tools

| Tool | Purpose |

|---|---|

| Screwdriver Set | To loosen or tighten screws for access to internal components. |

| Wrench Set | For securing and adjusting bolts and nuts during assembly or disassembly. |

| Multimeter | To measure electrical parameters and diagnose issues effectively. |

| Pliers | Useful for gripping, twisting, and cutting wires or small components. |

| Vacuum Cleaner | For cleaning lint and debris from the machine’s interior and surrounding area. |

Additional Supplies

In addition to the basic tools, consider keeping a stock of replacement parts and supplies, such as fuses, belts, and connectors, to facilitate quicker resolutions. This preparation can significantly reduce downtime and enhance the overall effectiveness of your maintenance efforts.

Cleaning the Lint Filter Properly

Maintaining optimal performance in your appliance is crucial for ensuring efficiency and longevity. One essential aspect of this maintenance is the proper cleaning of the filter designed to capture debris. This task not only enhances airflow but also minimizes the risk of potential hazards.

Step 1: Begin by removing the filter from its designated compartment. Gently pull it out, being careful not to exert excessive force that could damage the component.

Step 2: Use your fingers to remove any visible lint. For thoroughness, consider using a soft brush or a vacuum attachment to dislodge stubborn particles.

Step 3: After clearing the filter, rinse it under warm water to remove any residual particles. Ensure it dries completely before reinserting it into the appliance.

Tip: Regularly checking and cleaning this component can significantly enhance the efficiency of your appliance and reduce energy consumption. Aim to perform this task after every use or at least once a week for optimal results.

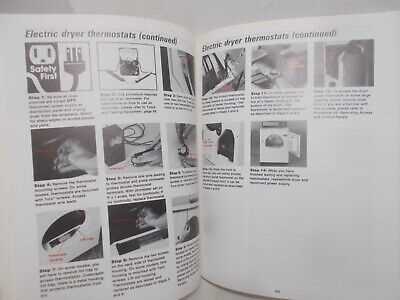

Replacing a Faulty Drum Belt

Over time, components in your appliance can wear out, causing issues in functionality. One common problem is a damaged or broken belt that plays a crucial role in the operation of the system. This section will guide you through the process of replacing this essential part, ensuring that your unit operates smoothly again.

Identifying the Problem

Before attempting to replace the belt, it’s important to diagnose the issue correctly. Signs of a faulty belt may include unusual noises, clothes not tumbling, or a burning smell. If you notice any of these indicators, it’s time to investigate further and consider a replacement.

Steps for Replacement

Start by disconnecting the unit from its power source for safety. Next, remove the front panel or access door to reach the drum area. Carefully take out the old belt by unhooking it from the motor pulley and drum. Then, position the new belt around the drum and thread it through the motor pulley, ensuring it is aligned properly. Finally, reassemble the panel and reconnect the power supply.

By following these steps, you can restore functionality to your appliance and ensure it operates efficiently for years to come.

Troubleshooting Heating Problems

When faced with insufficient warmth during the drying cycle, it’s essential to identify the underlying causes that may be affecting the performance of your appliance. Various factors can contribute to heating issues, from electrical components to airflow restrictions. Understanding these elements can help pinpoint the source of the problem and guide you toward an effective solution.

Check the Power Supply: Ensure that the appliance is receiving adequate power. Inspect the outlet and circuit breaker to confirm that there are no interruptions in the electrical flow. A malfunctioning outlet or a tripped breaker can significantly hinder the heating element’s operation.

Inspect the Heating Element: The heating element is crucial for generating warmth. If it’s defective or damaged, the unit may struggle to reach optimal temperatures. Use a multimeter to test the heating element for continuity, replacing it if necessary.

Examine the Thermostat: The thermostat regulates the temperature inside the appliance. A faulty thermostat may cause the unit to overheat or fail to heat altogether. Check its functionality and replace it if it does not respond correctly.

Assess Airflow: Proper airflow is vital for effective drying. Blocked vents or lint buildup can restrict airflow, leading to overheating or insufficient drying. Clean the lint filter regularly and ensure that exhaust ducts are free from obstructions to promote optimal performance.

By systematically addressing these common areas of concern, you can effectively troubleshoot and resolve heating challenges, restoring your appliance’s efficiency.

Checking Electrical Connections

Ensuring that all electrical links are secure is crucial for the proper functioning of any appliance. Loose or damaged connections can lead to malfunctions or even hazardous situations. A thorough examination of these links is necessary to maintain safety and efficiency.

Start by unplugging the unit from the power source to avoid any risk of electric shock. Inspect the power cord for signs of wear or damage, such as fraying or exposed wires. Pay close attention to the connectors at both ends of the cord; they should be free of corrosion and tightly attached.

Next, examine the outlet where the appliance is plugged in. Look for any discoloration or burnt marks, which could indicate a poor connection. If you notice any abnormalities, consider consulting a qualified electrician for further assessment.

Additionally, inspect the internal connections within the appliance. Accessing the back panel may require a screwdriver, so ensure you have the right tools on hand. Once open, check for any loose screws or terminals that might need tightening. Ensure all wires are securely attached and free from damage.

Finally, after all connections have been verified and secured, reassemble any panels and plug the appliance back into the outlet. Monitor its performance closely during the first few uses to confirm that the issue has been resolved.

Maintaining the Moisture Sensor

Ensuring the optimal performance of moisture detection systems is crucial for enhancing drying efficiency and prolonging the lifespan of the appliance. Regular upkeep not only improves functionality but also minimizes energy consumption. Here are key aspects to consider for effective maintenance.

- Regular Cleaning: Dust and lint can accumulate on the sensor, impacting its accuracy. Clean the sensor gently with a soft cloth or a vacuum brush.

- Check for Obstructions: Ensure that there are no items obstructing the sensor’s pathway. This can include small objects or lint buildup that may interfere with its operation.

- Inspect Connections: Examine the wiring and connections leading to the sensor. Loose or damaged wires can affect the sensor’s performance.

- Test Functionality: Periodically test the sensor’s performance by running a drying cycle with a load of clothes and checking if the appliance operates efficiently.

- Calibration: If the sensor appears to be malfunctioning, consult the guidelines for recalibrating the sensor to restore its effectiveness.

By following these maintenance tips, users can ensure that the moisture detection system operates smoothly, leading to optimal drying results and improved energy efficiency.

Inspecting and Replacing Fuses

Ensuring the proper functioning of your appliance involves regular checks and timely replacements of essential components. Fuses play a crucial role in protecting the device from electrical surges and potential damage. Identifying when these components fail is vital to maintaining performance and safety.

Identifying Fuse Issues

Start by examining the unit for signs of malfunction. If the device does not power on or frequently shuts off, it may indicate a blown fuse. Visual inspections can reveal discoloration or burn marks around the fuse area, suggesting that it has been compromised. Always ensure the appliance is disconnected from the power source before conducting any assessments.

Replacing the Fuses

To replace a faulty fuse, locate the fuse holder, which is often accessible from the back or side of the device. Carefully remove the old fuse by gently pulling it out. Insert a new fuse of the same type and rating to ensure compatibility. Securely close the fuse holder and reconnect the appliance to the power supply. After replacing the fuse, monitor the device during operation to confirm that the issue has been resolved.

Steps for Cleaning the Vent System

Maintaining the efficiency of your appliance involves ensuring that the airflow remains unobstructed. A clean vent system not only enhances performance but also reduces safety risks associated with lint buildup.

Begin by disconnecting the unit from the power source to ensure safety during the cleaning process. This step is crucial to prevent any accidents or electrical hazards.

Remove the vent duct from the back of the appliance. This allows for thorough access to the ducting and prevents any debris from being pushed further into the system.

Use a vacuum cleaner with a hose attachment to remove lint and debris from both the duct and the vent opening. Ensure you reach deep into the vent to eliminate any accumulated particles that could impede airflow.

Check the exterior vent for blockages. Ensure that the outside vent flap opens freely when the appliance is in use. If it appears stuck or clogged, clear any obstructions to maintain proper ventilation.

Reattach the duct securely to the unit after cleaning. Double-check that all connections are tight to prevent air leaks. Finally, plug the appliance back into the power source and run a test cycle to ensure everything is functioning correctly.

Adjusting the Drum Roller Alignment

Ensuring proper alignment of the drum rollers is essential for the efficient functioning of your appliance. Misalignment can lead to excessive noise, uneven wear, and potentially cause further damage. This section outlines the steps to check and adjust the positioning of the rollers to maintain optimal performance.

Follow these steps to achieve correct roller alignment:

- Unplug the unit and remove the front panel to access the drum assembly.

- Inspect the drum rollers for any signs of wear or damage.

- Check the alignment by manually rotating the drum. It should move freely without obstruction.

- If misalignment is detected, adjust the roller positioning as follows:

- Loosen the mounting screws on the roller brackets.

- Gently reposition the rollers until they are aligned correctly.

- Tighten the screws securely to hold the rollers in place.

Regular maintenance of the drum roller alignment will enhance the lifespan of your device and improve its overall efficiency.

When to Call a Professional

There are moments when it becomes necessary to seek assistance from a qualified technician. While many issues can be addressed with basic troubleshooting and maintenance, some situations demand expertise beyond typical homeowner capabilities. Recognizing these instances can save time and prevent further complications.

Identifying Complex Problems

If you encounter persistent issues that do not resolve after following standard procedures, it is advisable to consult a professional. Symptoms such as unusual noises, inconsistent performance, or failure to function altogether may indicate underlying problems that require specialized knowledge and tools.

Safety Concerns

Safety should always be a priority. If you notice any signs of electrical hazards, such as burning smells, sparking, or frayed wiring, it is crucial to refrain from attempting repairs on your own. In such cases, contacting a skilled technician immediately is essential to ensure safe and effective resolution.