In the world of modern kitchen devices, effective troubleshooting and upkeep are essential for ensuring longevity and optimal performance. This section aims to provide essential insights into maintaining high-quality refrigeration units, addressing common issues that may arise over time. A well-functioning appliance not only enhances convenience but also contributes to energy efficiency.

Regular attention to these machines can prevent minor inconveniences from escalating into significant problems. By familiarizing oneself with key components and potential malfunctions, users can save time and resources. Whether dealing with temperature fluctuations, unusual noises, or operational inefficiencies, knowing the right steps to take can make all the difference.

This guide will cover various aspects of device upkeep, empowering users with the knowledge needed to handle common challenges. From simple diagnostic checks to understanding more intricate components, gaining familiarity with one’s appliance can lead to a smoother, more enjoyable experience in the kitchen.

Understanding Samsung RF18HFENBSR Features

This section explores the key characteristics and functionalities of a modern refrigeration unit designed to enhance user experience and food preservation. These innovative features not only improve efficiency but also add convenience to daily life.

- Spacious Storage: Ample interior space allows for efficient organization of groceries, accommodating various sizes and shapes.

- Energy Efficiency: Engineered to consume less energy, contributing to lower utility bills while being environmentally friendly.

- Advanced Cooling Technology: Maintains optimal temperature and humidity levels, ensuring freshness for longer periods.

- Smart Features: Integration with smart home systems enables remote monitoring and control, enhancing convenience.

- Flexible Shelving: Adjustable shelves provide versatility in storage arrangements, making it easy to fit larger items.

These elements collectively contribute to a user-friendly appliance that meets contemporary needs and preferences.

Common Issues with Refrigerators

Refrigerators are essential appliances in every household, but they can encounter various problems over time. Understanding these common issues can help users troubleshoot effectively and maintain their units in optimal condition.

Frequent Problems

- Temperature Fluctuations: Inconsistent cooling can lead to spoiled food and beverages.

- Noisy Operation: Unusual sounds, such as rattling or buzzing, often indicate underlying mechanical issues.

- Inefficient Energy Use: Higher electricity bills may result from a malfunctioning appliance, requiring attention to energy consumption.

- Water Leaks: Puddles or excessive moisture can signal drainage problems or issues with seals.

- Frost Buildup: Excessive ice formation can hinder airflow and cooling efficiency.

Troubleshooting Tips

- Check the temperature settings to ensure they are correctly adjusted.

- Inspect door seals for damage and clean them regularly to maintain an airtight closure.

- Clear any obstructions around the appliance to ensure proper airflow.

- Unplug the unit for a few minutes to reset the system in case of electronic glitches.

- Regularly clean the condenser coils to improve energy efficiency.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing common issues encountered in household refrigeration units. By following a systematic methodology, you can effectively diagnose problems, apply solutions, and restore functionality to the appliance.

Step 1: Preparation

Begin by gathering the necessary tools and safety equipment. Ensure that you have a multimeter, screwdrivers, and any replacement parts on hand. Unplug the unit to avoid electrical hazards during the process.

Step 2: Diagnosis

Identify the specific symptoms presented by the unit. Listen for unusual noises, check for cooling issues, and observe any error codes displayed. This initial assessment is crucial for determining the underlying problem.

Step 3: Disassembly

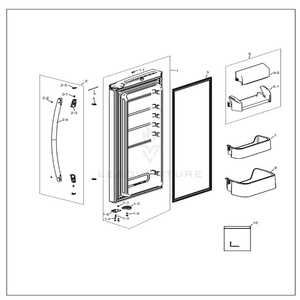

Carefully remove the relevant panels or covers to gain access to internal components. Take note of the arrangement of screws and parts for easier reassembly later. Keep all hardware organized to prevent misplacement.

Step 4: Component Inspection

Examine critical components such as the compressor, condenser coils, and fans for signs of wear or damage. Use a multimeter to test electrical connections and continuity in circuit boards. Replace any faulty parts as necessary.

Step 5: Cleaning

While the unit is disassembled, take the opportunity to clean dust and debris from coils and fans. Proper airflow is essential for optimal performance and longevity of the appliance.

Step 6: Reassembly

Carefully reassemble the unit, ensuring all components are securely in place. Refer to your notes or photographs taken during disassembly to avoid errors.

Step 7: Testing

Plug the unit back in and observe its operation. Monitor for any unusual sounds or issues. Verify that the appliance is cooling properly and that all features function as intended.

Step 8: Final Checks

After successful testing, perform a final inspection to ensure that everything is in order. Clean up the work area and dispose of any old parts responsibly. Your unit should now be fully operational and efficient.

Essential Tools for Refrigerator Repair

When tackling issues with cooling appliances, having the right instruments can make all the difference. A well-equipped toolkit not only enhances efficiency but also ensures safety while addressing various challenges. Understanding which tools are crucial for maintenance and troubleshooting can empower individuals to handle minor fixes effectively.

Basic Hand Tools: A reliable set of hand tools is fundamental. This includes screwdrivers of various sizes, pliers, and wrenches. These instruments are essential for accessing internal components and securing loose parts.

Multimeter: A multimeter is an invaluable device for diagnosing electrical problems. It allows users to measure voltage, current, and resistance, helping to identify faulty connections or malfunctioning components.

Vacuum Cleaner: Keeping the condenser coils clean is vital for optimal performance. A vacuum cleaner, particularly with a brush attachment, is useful for removing dust and debris that can hinder efficiency.

Refrigerant Scale: For those dealing with refrigerant issues, a refrigerant scale is necessary. It helps in accurately measuring the amount of refrigerant being added or removed, ensuring the system operates within specified limits.

Thermometer: A good thermometer is crucial for monitoring temperatures in both the fridge and freezer compartments. This tool helps verify if the appliance is maintaining the appropriate temperature levels.

Incorporating these essential tools into your toolkit will prepare you for effectively managing a variety of issues that may arise with your cooling appliance. With the right equipment, tackling even complex problems becomes a more approachable task.

Maintenance Tips for Longevity

Ensuring the durability of your appliance requires consistent care and attention. By implementing a few straightforward practices, you can significantly extend its lifespan and maintain optimal performance. Here are some essential tips to help you achieve this goal.

Regular Cleaning: Keeping the interior and exterior clean is crucial. Wipe down surfaces with a mild detergent and ensure that spills are cleaned promptly. Pay special attention to door seals and gaskets, as they can accumulate dirt and impede efficiency.

Check Temperature Settings: Verify that the temperature is set correctly. Ideal settings typically range around 37°F (3°C) for the refrigerator and 0°F (-18°C) for the freezer. Proper temperatures help prevent food spoilage and reduce energy consumption.

Inspect Coils: Dust and debris can accumulate on the condenser coils, leading to overheating. Regularly inspect and clean these coils to maintain efficient operation. A vacuum or brush can be used to remove any buildup.

Monitor Door Seals: Ensure that the door seals are in good condition. Damaged or worn seals can lead to air leaks, resulting in temperature fluctuations. If necessary, replace seals to maintain efficiency.

Defrost When Necessary: If your appliance is not frost-free, regular defrosting is essential. Excessive frost buildup can reduce efficiency and storage capacity. Follow guidelines for safe defrosting to avoid damage.

Avoid Overloading: Overfilling shelves can obstruct airflow, leading to uneven temperatures. Organize items to promote good air circulation and ensure that the appliance operates effectively.

By following these maintenance tips, you can help ensure that your appliance remains reliable and efficient for years to come.

How to Diagnose Cooling Problems

Identifying issues with refrigeration units requires a systematic approach. Understanding the signs of inadequate cooling can help in pinpointing the root cause and implementing effective solutions. This section provides insights into common indicators and troubleshooting techniques to assist in assessing performance issues.

Common Signs of Insufficient Cooling

Several symptoms can indicate that a cooling appliance is not functioning correctly. Look for excessive frost buildup inside the unit, unusual noises, or inconsistent temperatures. Additionally, check for water pooling at the base or the back of the appliance, which may suggest drainage problems. Monitoring these signs closely can provide valuable clues for further investigation.

Troubleshooting Steps

Start by examining the thermostat settings to ensure they are correctly adjusted. Next, inspect the door seals for any gaps or damage that could lead to temperature fluctuations. Clean the condenser coils, as dust and debris can significantly hinder performance. If problems persist, consider evaluating the compressor and evaporator fan for proper operation. Each step plays a crucial role in diagnosing and resolving cooling challenges.

Replacing Key Components Safely

Ensuring the safe replacement of essential parts in home appliances is crucial for maintaining functionality and preventing damage. Understanding the proper procedures and precautions can lead to effective repairs while minimizing risks. This section will guide you through the essential steps to follow during the component replacement process.

Preparation and Safety Measures

Before beginning any work, it’s vital to disconnect the appliance from its power source. This simple step can prevent electrical shocks and injuries. Gather all necessary tools and replacement parts beforehand to streamline the process. Additionally, wearing protective gear such as gloves and safety goggles is recommended to safeguard against any debris or sharp edges.

Step-by-Step Component Replacement

Start by carefully removing the outer casing or access panels, ensuring that no screws are lost. When detaching components, take note of their arrangement to facilitate reassembly. It’s advisable to label wires and connectors to avoid confusion later. After installing the new part, double-check all connections and secure everything back in place before restoring power. Testing the appliance afterward will confirm that the new component is functioning correctly.

In conclusion, adhering to these guidelines not only enhances the safety of the process but also ensures a successful outcome, allowing your appliance to operate at its best.

Understanding Electrical Schematics

Electrical schematics are crucial diagrams that represent the connections and functions of various components within a system. These visual representations help technicians and engineers comprehend how electrical systems operate, making troubleshooting and design modifications more efficient. A well-constructed schematic offers a clear overview of the circuit’s layout and the relationship between its elements.

Key Elements of Electrical Schematics

When analyzing electrical diagrams, it’s important to familiarize yourself with the essential components typically found within them:

- Symbols: Each element in a circuit is represented by a specific symbol, allowing for quick identification.

- Connections: Lines indicate how components are linked, showing the flow of electricity through the system.

- Labels: Components often have labels or numbers that provide additional information, such as specifications or functions.

Reading and Interpreting Schematics

To effectively read electrical diagrams, follow these steps:

- Identify the Symbols: Learn the common symbols used in electrical schematics to understand what each component represents.

- Trace the Connections: Follow the lines to see how components are interconnected, which can help diagnose potential issues.

- Refer to the Legend: Many schematics include a legend that explains the symbols and their meanings for clarification.

By mastering the interpretation of electrical diagrams, individuals can enhance their problem-solving skills and improve their overall understanding of complex systems.

Identifying Refrigerant Leaks

Detecting leaks in a cooling system is crucial for maintaining efficiency and performance. A refrigerant leak not only compromises the functionality of the unit but can also lead to environmental issues. Recognizing the signs of a leak early can help prevent further complications and costly repairs.

Common Signs of Refrigerant Leaks

Several indicators can signal a refrigerant leak. One of the most noticeable signs is a significant drop in cooling performance. If the appliance struggles to maintain the desired temperature, it may be a result of insufficient refrigerant levels. Additionally, users may observe unusual ice buildup on the coils or lines, which can also suggest a leak. Other symptoms include hissing or bubbling noises, indicating escaping gas, and an increase in energy bills due to the system working harder to achieve cooling.

Testing for Leaks

To confirm a leak, several methods can be employed. A common approach is the use of a soapy water solution, which can reveal leaks when bubbles form at the site of an escape. For more accurate detection, electronic leak detectors are available, designed specifically for refrigerants. These devices can quickly identify even the smallest leaks, providing a reliable assessment of the system’s integrity.

Preventative Measures to Avoid Repairs

Taking proactive steps can significantly extend the lifespan of your appliance and reduce the need for maintenance. By incorporating simple routines and best practices into your daily use, you can minimize wear and tear, ensuring that your unit operates efficiently for years to come.

Regularly cleaning and maintaining the exterior and interior components is essential. Dust and debris can accumulate, affecting performance. Ensure that seals and gaskets are clean and in good condition to prevent energy loss and maintain optimal temperature control.

Monitor temperature settings to avoid excessive strain on the system. Keeping the appliance within recommended temperature ranges not only enhances efficiency but also reduces the risk of overworking the compressor and other vital parts.

Periodic inspection of the power supply and cord integrity is crucial. Avoid overloading electrical outlets and use surge protectors to safeguard against power surges that can damage internal components.

Lastly, consider seasonal checks to assess the appliance’s performance. Early detection of potential issues can save time and resources, allowing you to address minor concerns before they escalate into major problems.

Consumer Feedback and Common Complaints

This section explores the insights and experiences shared by users regarding their household appliance, highlighting both positive feedback and recurring issues. Understanding consumer sentiment can provide valuable context for potential buyers and help current owners navigate challenges.

Positive Experiences

Many users appreciate the appliance’s modern design and energy efficiency. Customers often note its spacious interior and innovative features that enhance usability. The convenience of adjustable shelving and temperature controls has received particular praise, making it easier for users to organize their food and maintain optimal freshness.

Recurring Issues

Despite the favorable feedback, some consumers have reported common problems that warrant attention. A frequent complaint revolves around the noise level, with certain models producing sounds that can be disruptive. Additionally, users have mentioned issues with ice maker functionality, including slow production rates and occasional jams. These concerns highlight areas where improvements could enhance overall user satisfaction.

When to Call a Professional Technician

Knowing when to seek help from an expert is crucial for maintaining the longevity and functionality of your appliance. While some issues can be resolved with basic troubleshooting, others require specialized knowledge and tools. Here are some indicators that it might be time to contact a skilled technician.

- Persistent Problems: If a malfunction continues despite your attempts to fix it, it may indicate a more serious underlying issue.

- Unusual Noises: Sounds such as banging, hissing, or grinding can signal mechanical problems that need professional attention.

- Leaking Fluids: Any signs of leakage can pose safety hazards and should be addressed immediately by a qualified individual.

- Inconsistent Performance: If your unit is not operating at its expected efficiency, this may require expert evaluation.

- Electrical Issues: Problems related to wiring or power supply should be handled by professionals to avoid risks of electrocution or fire.

- Warning Lights: Activation of warning indicators on your device typically suggests the need for specialized service.

When in doubt, opting for professional assistance can save time, money, and potential damage. Don’t hesitate to reach out for expert help when faced with these challenges.