Ensuring the smooth operation of a vehicle’s power transfer system is crucial for optimal performance. This section delves into the intricacies of maintaining a specific type of automotive mechanism, focusing on common issues, troubleshooting techniques, and essential maintenance practices. A well-functioning system enhances not only the driving experience but also the longevity of the vehicle.

Understanding the Mechanism is the first step toward effective upkeep. Familiarizing oneself with the components and their functions allows for better diagnosis of potential problems. Knowledge about typical wear and tear can significantly aid in early detection, thus preventing more severe damage down the line.

Step-by-step procedures for addressing common challenges will be outlined, equipping enthusiasts and professionals alike with the necessary skills. Whether dealing with fluid changes or intricate part replacements, having a structured approach simplifies the process and increases efficiency.

Lastly, regular assessments and adherence to recommended service intervals can make a significant difference in maintaining optimal functionality. By prioritizing consistent care, drivers can enjoy a seamless experience while navigating the roads.

Understanding the AL4 Gearbox

This section aims to provide a comprehensive overview of a specific automatic transmission system widely used in various vehicles. It focuses on the key components, functionality, and the typical issues that may arise during its operation. Gaining insight into this system will enhance your understanding of how it contributes to the overall performance and reliability of the vehicle.

Key Components

The automatic transmission consists of several crucial parts that work together to ensure smooth gear shifting and optimal power delivery. The following table outlines the primary elements and their functions:

| Component | Function |

|---|---|

| Torque Converter | Transfers power from the engine to the transmission and allows for fluid coupling. |

| Planetary Gear Set | Provides different gear ratios to enable smooth acceleration and deceleration. |

| Hydraulic System | Controls the flow of fluid to engage and disengage gears automatically. |

| Control Module | Monitors driving conditions and optimizes shifting patterns for efficiency. |

Common Issues

While this transmission system is generally reliable, certain problems can arise over time. Understanding these issues can aid in early detection and maintenance. Common concerns include slipping gears, delayed engagement, and fluid leaks. Regular checks and timely interventions can significantly enhance longevity and performance.

Common Issues with AL4 Gearboxes

Understanding the typical challenges encountered in automatic transmission systems can help owners identify and address problems early. These complications can lead to decreased performance, unusual noises, and ultimately, operational failures if not managed properly.

Shifting Problems

One of the most prevalent issues involves difficulties in transitioning between gears. Drivers may experience hesitation, slipping, or abrupt changes, often linked to hydraulic pressure or electronic control failures. Regular diagnostic checks are essential to pinpoint the underlying cause.

Fluid Leaks

Fluid leaks can significantly impact functionality and longevity. Signs of leakage may include fluid spots under the vehicle or a noticeable drop in fluid levels. Addressing these leaks promptly is crucial to avoid extensive damage and costly repairs.

Symptoms of a Failing AL4

Identifying the warning signs of an underperforming transmission system is crucial for ensuring the longevity and functionality of your vehicle. Early detection of issues can prevent costly repairs and enhance driving safety. Below are common indicators that your automatic shifting mechanism may be experiencing difficulties.

Unusual Noises

One of the first signs of trouble is the emergence of strange sounds during operation. This may include grinding, whining, or clunking noises when shifting between gears. These sounds often signal internal wear or damage, necessitating immediate attention.

Shifting Delays or Irregularities

If you notice hesitation when accelerating or rough transitions between gears, it can indicate a malfunction. Smooth shifting is essential for optimal performance, and any disruption can lead to further complications. Additionally, unexpected gear changes or being stuck in one gear can also be symptoms of a failing system.

Recognizing these signs early on can help maintain your vehicle’s performance and avoid more severe issues in the future.

Tools Needed for Repair

When undertaking a complex task involving mechanical components, having the right equipment is essential for ensuring efficiency and effectiveness. Proper tools not only facilitate the disassembly and assembly processes but also enhance safety and accuracy during the work.

Key instruments typically required include wrenches of various sizes for loosening and tightening fasteners, screwdrivers for precision adjustments, and pliers for gripping and manipulating small parts. A torque wrench is crucial for applying the correct amount of force, while a diagnostic tool may be needed for electronic systems. Additionally, protective gear such as gloves and goggles is important to ensure personal safety while working.

Organizing your workspace with a clean, well-lit area will aid in the process, allowing for easier access to tools and components. Investing in quality instruments will yield better results and prolong the lifespan of the equipment being serviced.

Step-by-Step Disassembly Guide

This section provides a detailed procedure for taking apart a complex transmission system. Following these steps will ensure that each component is accessed carefully and safely, allowing for efficient maintenance or replacement of parts as needed.

Preparation for Disassembly

Before starting the process, gather all necessary tools and equipment. Ensure that the workspace is clean and organized to prevent any loss of small components. It is crucial to have a suitable area for laying out parts in the order they are removed, which will aid in reassembly.

Disassembly Steps

Begin by disconnecting all electrical connections and hydraulic lines. Use a wrench to remove bolts securing the outer casing. Gently tap around the edges to loosen any stubborn parts. Once the outer shell is removed, take out the internal assemblies systematically, noting their arrangement. Documenting each step with photographs can be helpful for reference during reassembly.

As you proceed, inspect each piece for wear and damage. Keep all removed components in labeled containers to maintain order. By adhering to these guidelines, you will facilitate a smoother disassembly process, ultimately leading to successful maintenance or upgrades.

Inspecting Internal Components

Evaluating the internal parts of a transmission system is crucial for ensuring optimal performance and longevity. This process involves a thorough examination of various elements that contribute to the overall functionality. Proper inspection can help identify wear, damage, or any irregularities that may affect operation.

When inspecting internal components, consider the following key areas:

- Gears: Check for signs of wear, pitting, or cracking. Ensure that the teeth engage smoothly without any resistance.

- Bearings: Inspect for excessive play or noise. Replace any that show signs of degradation.

- Shafts: Look for bending or scoring. Ensure that they rotate freely without obstruction.

- Seals: Examine for leaks or damage. Proper sealing is essential to maintain fluid integrity.

- Clutch Components: Assess the condition of friction materials and check for proper engagement and disengagement.

Utilizing appropriate tools and techniques during the inspection can enhance accuracy. Following a systematic approach will help in documenting findings and determining necessary actions for maintenance or replacement.

Regular checks can prevent minor issues from escalating into major problems, ensuring a reliable and efficient operation of the entire system.

Common Repair Techniques Explained

Understanding the typical methods used in transmission maintenance is essential for achieving optimal performance and longevity. This section delves into various approaches that professionals employ to troubleshoot and resolve issues effectively.

Fluid Replacement is a fundamental technique, as the condition of the lubricant directly affects functionality. Regularly changing the fluid helps remove contaminants and ensures that components operate smoothly.

Sealing and Gasket Replacement is another critical method. Over time, seals and gaskets can wear out, leading to leaks that compromise efficiency. Replacing these elements can prevent further damage and maintain system integrity.

Component Inspection plays a vital role in identifying wear or failure. Technicians often conduct thorough examinations of parts like clutches and bands to determine their condition, enabling informed decisions about necessary interventions.

Calibration and Adjustment ensure that all components function harmoniously. Misalignment or incorrect settings can lead to performance issues, making this step crucial for restoring optimal operation.

Each of these methods, when applied appropriately, contributes significantly to maintaining the functionality and reliability of the system. Understanding these techniques can empower owners to make informed decisions regarding maintenance and troubleshooting.

Fluid Replacement Procedures

Ensuring the optimal performance of your transmission system requires regular maintenance, particularly concerning fluid changes. This process is crucial for preventing wear and tear, promoting efficient operation, and extending the lifespan of the components involved. The following guidelines outline the necessary steps to effectively replace the fluid.

-

Preparation:

- Gather the necessary tools, including a fluid pump, containers for old fluid, and the recommended replacement fluid.

- Ensure the vehicle is parked on a level surface and the engine is turned off.

- Consult the vehicle’s specifications for the correct fluid type and capacity.

-

Draining Old Fluid:

- Locate the drain plug on the transmission housing.

- Position the container under the drain plug and remove the plug to allow the fluid to flow out completely.

- Once drained, replace the drain plug securely.

-

Refilling with New Fluid:

- Identify the fill port on the transmission system.

- Using the fluid pump, introduce the new fluid until the appropriate level is reached.

- Monitor the fluid level using the dipstick (if applicable) to ensure accuracy.

-

Final Checks:

- Start the engine and let it idle for a few minutes to circulate the new fluid.

- Check for leaks around the drain and fill ports.

- Re-check the fluid level and add more if necessary.

Following these procedures will help maintain the integrity and efficiency of your transmission system, contributing to a smoother driving experience.

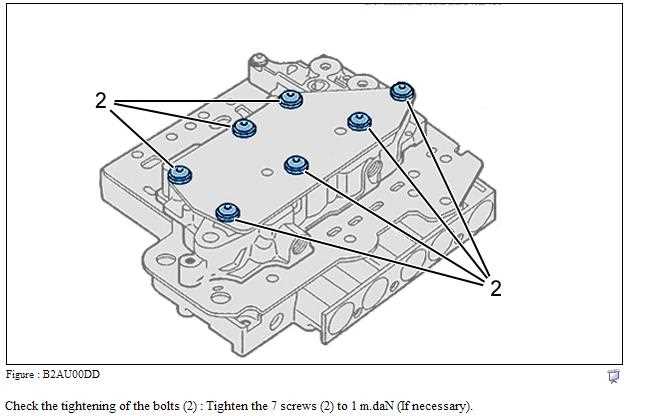

Reassembling the AL4 Gearbox

The process of putting together the transmission unit requires careful attention to detail and precision. This phase is critical to ensure optimal performance and longevity of the system. Proper alignment of components and adherence to specified torque settings are essential for achieving a seamless operation.

Preparation Steps

Before starting the reassembly, gather all necessary tools and components. Make sure the work area is clean and organized to avoid losing any small parts. Inspect all items for wear and replace any damaged components as needed.

Reassembly Procedure

Follow these steps to successfully reassemble the transmission:

| Step | Description |

|---|---|

| 1 | Align the housing halves and ensure all sealing surfaces are clean. |

| 2 | Install the input shaft, ensuring it engages correctly with the planetary gears. |

| 3 | Position the clutch pack and verify proper placement of springs and friction plates. |

| 4 | Carefully insert the output shaft, aligning it with the previous components. |

| 5 | Secure the assembly with the specified fasteners, adhering to the recommended torque values. |

Once all steps are completed, perform a thorough inspection to ensure everything is properly seated and aligned before proceeding to the next phase.

Testing After Repairs

Once maintenance work has been completed on the transmission system, it is crucial to conduct a series of evaluations to ensure optimal functionality. These assessments help identify any potential issues that may arise post-service, ensuring that the vehicle operates smoothly and efficiently.

Initial Functionality Check

The first step involves a basic functionality test. Start the engine and engage the transmission through various driving modes. Listen for any unusual sounds and monitor the response during gear changes. Pay attention to any hesitation or slippage, as these could indicate underlying problems that need addressing.

Road Test Evaluation

Following the initial checks, a comprehensive road test is essential. This allows for the observation of the system under real driving conditions. Assess performance at different speeds and under various loads. Ensure that shifting is seamless and that the vehicle responds as expected during acceleration and deceleration. If any irregularities are detected, further investigation may be necessary.

Ultimately, thorough testing after servicing is vital to guarantee reliability and safety. By following these steps, one can ensure that the transmission system is functioning correctly and ready for everyday use.

Preventative Maintenance Tips

Regular upkeep is essential to ensure the longevity and efficient operation of complex mechanical systems. By adopting proactive measures, you can significantly reduce the likelihood of unexpected failures and costly repairs. This section provides valuable strategies to help maintain optimal performance and reliability over time.

Regular Fluid Checks

Monitoring and maintaining fluid levels is crucial for smooth functioning. Ensure that fluids are changed at recommended intervals to prevent contamination and degradation. This includes transmission fluid, which plays a vital role in lubrication and cooling. Keeping an eye on fluid quality can also indicate underlying issues that may need attention.

Inspection of Components

Periodic inspection of all relevant components helps identify wear and tear before they lead to serious problems. Pay special attention to seals, gaskets, and connectors, as these parts are often prone to failure over time. Early detection of potential issues allows for timely interventions, which can save both time and resources in the long run.

When to Seek Professional Help

Understanding the right moment to engage a specialist can significantly impact the longevity and performance of your vehicle’s transmission system. While many issues may appear manageable, certain signs and symptoms indicate that professional intervention is necessary to prevent further complications.

Signs Indicating Professional Intervention

- Persistent unusual noises during operation, such as grinding or clunking.

- Fluid leaks beneath the vehicle, especially if the fluid is dark or has a burnt smell.

- Unresponsive shifting or difficulty engaging gears.

- Warning lights on the dashboard indicating transmission-related problems.

- Frequent overheating, leading to performance issues.

Benefits of Seeking Expert Assistance

- Accurate diagnostics that identify the root cause of the issue.

- Access to specialized tools and equipment necessary for complex repairs.

- Expertise in the latest technologies and methods for transmission maintenance.

- Warranty protection on repairs and parts.

- Peace of mind knowing the work is performed by trained professionals.