As the cold season approaches, the reliability of your outdoor machinery becomes paramount. Ensuring that your essential tools are in peak condition not only enhances their performance but also prolongs their lifespan. This section aims to provide invaluable insights into the intricacies of maintaining these powerful machines.

Understanding the components and mechanisms of your winter equipment is crucial for effective upkeep. Each unit has its unique features that require specific attention and care. By familiarizing yourself with these aspects, you can tackle common issues and prevent more significant problems from arising.

This guide offers detailed instructions, troubleshooting tips, and maintenance best practices to help you achieve optimal functionality. Whether you’re a seasoned user or a novice, the information here will equip you with the knowledge needed to keep your machinery running smoothly throughout the winter months.

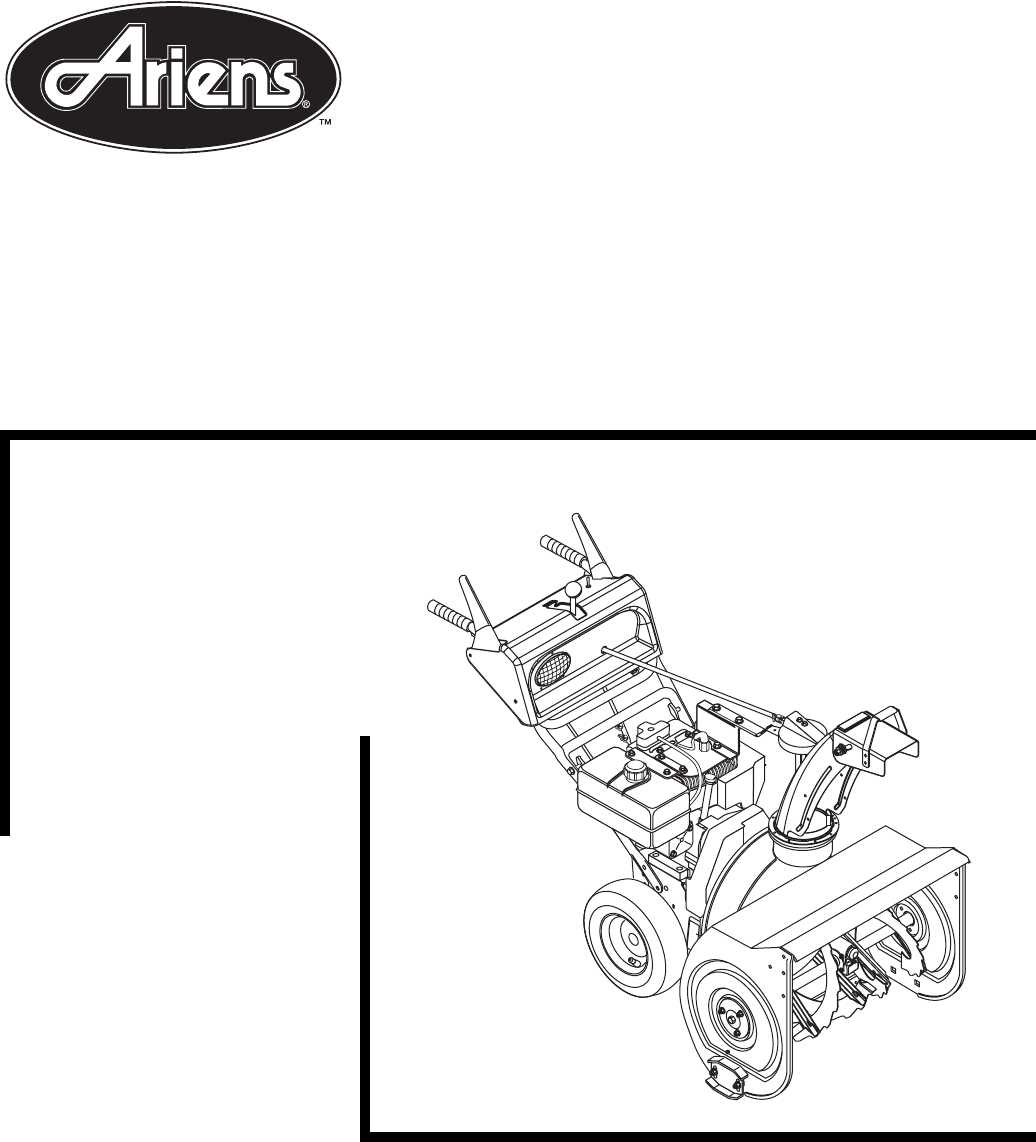

Ariens 824 Snowblower Overview

This section provides a comprehensive look at a robust machine designed for effective snow removal in various conditions. Engineered to handle heavy snowfall, this model combines power and efficiency, making it a reliable choice for homeowners and professionals alike. Its user-friendly features enhance operation, ensuring that users can navigate winter weather with ease.

Key Features

One of the standout attributes of this model is its powerful engine, which delivers impressive performance across different terrains. The enhanced clearing width allows for quick and efficient snow displacement, while adjustable speed settings provide versatility for varying snow conditions. Additionally, the inclusion of heated hand grips ensures comfort during prolonged use.

Maintenance Tips

To ensure optimal performance and longevity, regular maintenance is essential. This includes routine checks on the belts, blades, and fuel system. Cleaning the auger and discharge chute after each use helps prevent clogging, while an annual tune-up can keep the machine running smoothly. Following these simple practices will enhance durability and effectiveness in tackling winter challenges.

Common Issues with Ariens 824

When operating a powerful outdoor tool designed for winter tasks, users may encounter several typical challenges that can affect performance. Understanding these common problems can help owners troubleshoot effectively and maintain optimal functionality throughout the season.

Starting Difficulties

One of the most frequently reported concerns involves issues with ignition. Often, this can stem from a drained battery, stale fuel, or a clogged fuel line. Regular maintenance, including checking the spark plug and ensuring the fuel is fresh, can significantly alleviate these problems.

Uneven Snow Discharge

Another prevalent issue is the inconsistent expulsion of snow. This can be caused by a buildup of ice or snow within the discharge chute, dull blades, or even improper engine speed settings. Cleaning the chute and inspecting the blades for wear are crucial steps in ensuring efficient operation.

By addressing these common concerns, users can enhance the reliability and longevity of their outdoor equipment during the winter months.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues related to winter equipment. Following a systematic method can help ensure that each problem is addressed thoroughly, leading to optimal performance during the colder months.

Preparation Before You Start

Before diving into the process, it’s essential to gather all necessary tools and materials. This will facilitate a smoother workflow and prevent interruptions.

- Wrench set

- Screwdriver set

- Oil and fuel

- Safety goggles and gloves

- Cleaning cloths

Steps to Follow

- Inspect the Equipment: Begin with a visual examination to identify any obvious signs of wear or damage.

- Check Fluid Levels: Ensure that oil and fuel levels are adequate for operation.

- Examine the Belts: Look for any fraying or signs of wear on belts, and replace if necessary.

- Clean the Components: Remove any debris or snow buildup to maintain efficiency.

- Test the Ignition: Verify that the starting mechanism functions properly and replace any faulty parts.

- Adjust Settings: Make necessary adjustments to ensure the equipment is set up for optimal performance.

- Final Inspection: Conduct a thorough check before putting the equipment back to use.

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right set of tools is crucial. These instruments not only facilitate the process but also ensure that tasks are performed safely and efficiently. From basic hand tools to specialized equipment, each plays a vital role in achieving optimal performance.

Wrenches are fundamental for loosening and tightening various bolts and nuts. A comprehensive set that includes both metric and imperial sizes will allow you to tackle most fasteners with ease. Additionally, screwdrivers in different sizes and types–such as flathead and Phillips–are essential for working with screws found in various components.

Another indispensable item is a socket set. This versatile tool allows for better torque and accessibility in tight spaces, making it easier to work on intricate parts. For more complex tasks, a torque wrench ensures that connections are made with the correct tightness, preventing damage to components.

Don’t forget about pliers and cutters, which are useful for gripping, twisting, and cutting wires and other materials. A good quality multimeter is also invaluable for diagnosing electrical issues, providing insights into voltage, current, and resistance.

Lastly, having a well-organized toolbox or workstation can significantly enhance your efficiency. Keeping everything in its designated place saves time and helps prevent the frustration of searching for misplaced items. Armed with these essential instruments, you’ll be well-prepared to address any challenges that arise during maintenance tasks.

Maintaining Your Snowblower

Proper upkeep of your winter machine is essential for optimal performance and longevity. Regular care not only ensures efficient operation during snowy conditions but also prevents costly issues down the line.

Here are key maintenance practices to keep in mind:

- Clean the Equipment: After each use, remove any snow and debris to prevent rust and damage.

- Check the Oil: Regularly inspect the oil level and quality, replacing it as needed to maintain engine health.

- Inspect the Belts: Examine belts for wear and tear, replacing them if they show signs of fraying or damage.

- Sharpen the Blades: Keeping blades sharp is crucial for efficient snow removal; sharpen or replace them as necessary.

- Inspect the Fuel System: Ensure the fuel lines and filter are clean and free of clogs to avoid performance issues.

By adhering to these maintenance steps, you can enhance the reliability of your winter equipment and ensure it is ready for action when you need it most.

Parts Replacement and Compatibility

Ensuring the optimal functionality of your equipment often requires timely substitutions of various components. Understanding how to identify compatible parts is essential for maintaining efficiency and performance. This section aims to guide you through the process of selecting the right replacements, emphasizing the significance of compatibility in achieving long-lasting results.

Identifying Compatible Components

When it comes to sourcing new parts, it’s crucial to reference model specifications and manufacturer recommendations. Each unit may have unique identifiers that dictate which replacements will fit seamlessly. Utilizing part numbers and cross-referencing with trusted suppliers can streamline your search, ensuring that you acquire high-quality replacements tailored to your specific machinery.

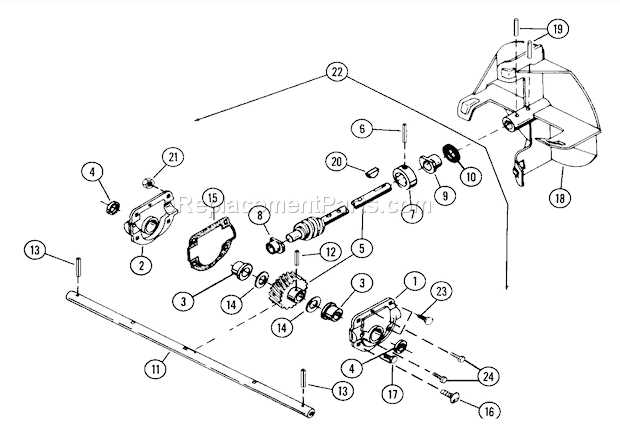

Installation Considerations

Proper installation of replacement components is vital for their performance. Before beginning the process, it’s advisable to review guidelines and best practices. Pay attention to any special tools or techniques that may be required. Ensuring a secure fit not only enhances operational efficiency but also prolongs the lifespan of the entire unit.

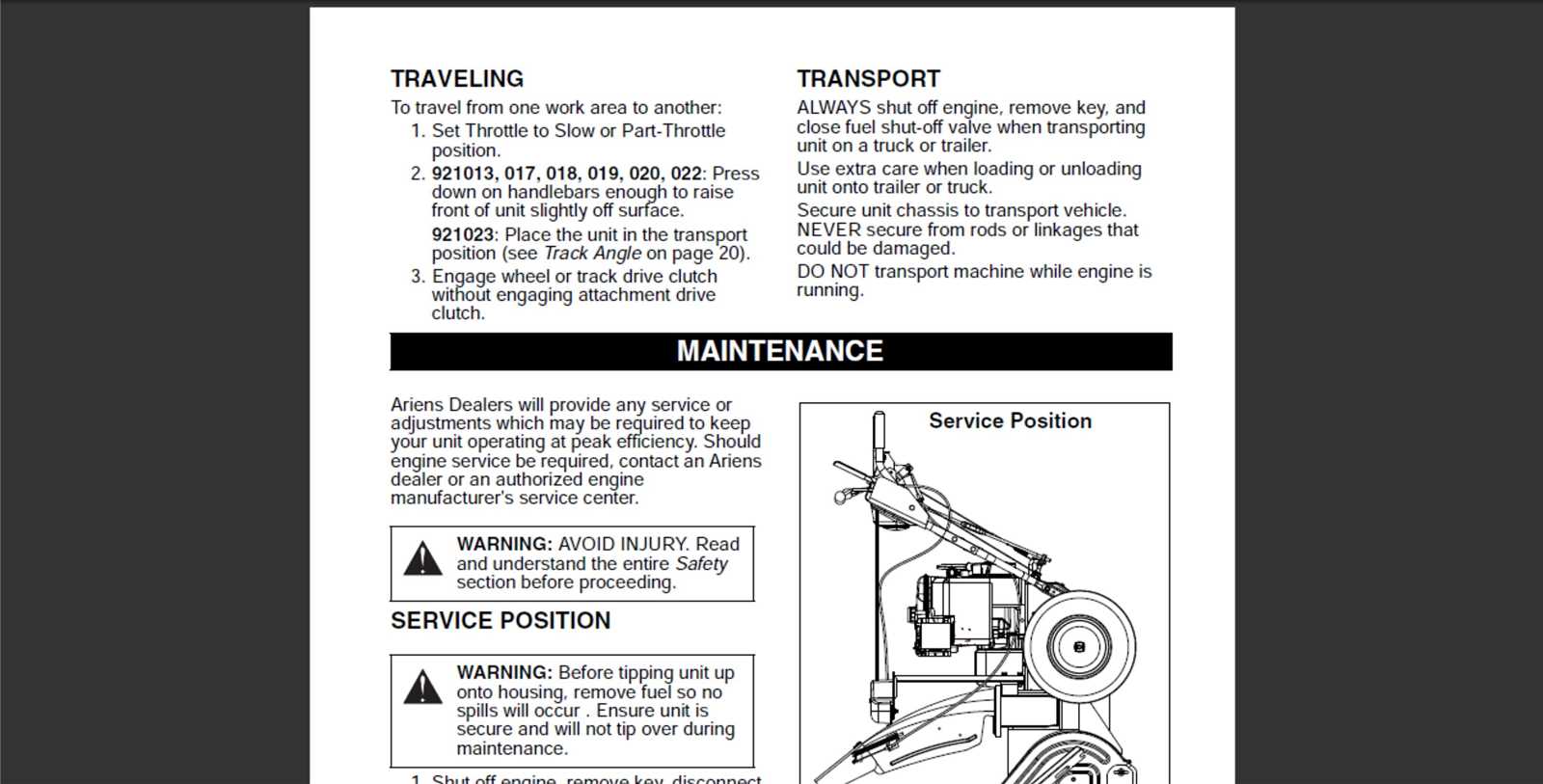

Safety Tips During Repair

Ensuring your well-being while working on machinery is paramount. Understanding the potential hazards and taking necessary precautions can significantly reduce the risk of injury. This section provides essential guidelines to follow for a safe and effective experience while maintaining your equipment.

Wear Protective Gear: Always don appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. This helps shield you from sharp objects, moving parts, and hazardous materials.

Work in a Well-Ventilated Area: Adequate airflow is crucial, especially when dealing with fuels or chemicals. Ensure your workspace is free from fumes to avoid respiratory issues.

Disconnect Power Sources: Before beginning any task, always ensure the machine is completely powered down and disconnected from its energy source. This reduces the likelihood of accidental starts during maintenance.

Keep Tools Organized: Maintain a tidy workspace by keeping tools and components organized. This minimizes the chance of accidents caused by clutter and makes it easier to locate what you need.

Follow Manufacturer Guidelines: Refer to the provided instructions specific to your equipment. Adhering to recommended practices ensures that you perform tasks correctly and safely.

Ask for Help: If you encounter difficulties or feel uncertain about any process, don’t hesitate to seek assistance. It’s always better to consult someone more experienced than to risk making a mistake.

Troubleshooting Engine Problems

Engine issues can manifest in various ways, often leading to performance degradation or complete failure to operate. Identifying the root cause of these malfunctions is essential for effective resolution. This section will guide you through common symptoms and potential solutions to ensure optimal functionality of your machine.

Starting Difficulties: If the engine fails to start, check the fuel supply first. Ensure that there is sufficient fuel and that it is not stale. Additionally, inspect the spark plug for wear or damage, as a faulty spark plug can prevent ignition.

Rough Idling: If the engine runs unevenly or stalls frequently, it may indicate issues with the air filter or carburetor. A clogged air filter restricts airflow, while a dirty carburetor can disrupt the fuel-air mixture. Cleaning or replacing these components can often rectify the problem.

Overheating: Excessive heat can lead to engine damage. Verify that the cooling fins are clean and unobstructed. Ensure that the oil level is adequate and that the oil is not contaminated, as this can hinder proper lubrication and cooling.

Unusual Noises: If you hear knocking or grinding sounds, it may suggest internal damage or wear. Check for loose parts or a malfunctioning component. Immediate inspection is crucial to prevent further damage.

By systematically addressing these common engine problems, you can restore performance and extend the lifespan of your equipment. Regular maintenance and prompt attention to issues will significantly enhance reliability and efficiency.

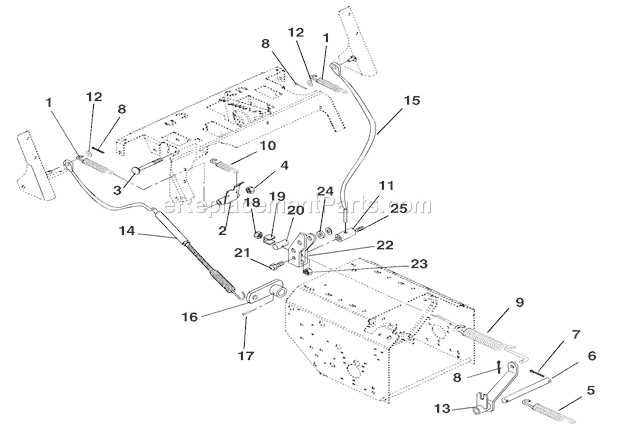

Adjusting the Chassis and Blades

Maintaining optimal performance of your equipment involves precise adjustments to both the frame and the cutting components. Proper alignment and calibration are essential for enhancing efficiency and ensuring a smooth operation, especially during challenging conditions. This section will guide you through the necessary steps to achieve the desired setup.

Frame Alignment

The chassis plays a crucial role in stability and functionality. Regular inspection and adjustment are vital to prevent wear and tear, ensuring that all parts function harmoniously. Follow these steps for effective alignment:

| Step | Action |

|---|---|

| 1 | Check for any visible misalignment or damage to the frame. |

| 2 | Loosen the mounting bolts that secure the frame. |

| 3 | Adjust the chassis until it is level and centered. |

| 4 | Tighten the bolts securely to maintain the new position. |

Blade Adjustment

Properly setting the cutting edges is essential for achieving effective snow clearing. Incorrect positioning can lead to inefficient operation and increased strain on the machinery. Follow these guidelines for blade adjustment:

| Step | Action |

|---|---|

| 1 | Inspect the blades for wear and damage before making adjustments. |

| 2 | Loosen the blade mounting bolts to allow for repositioning. |

| 3 | Align the blades so they are parallel to the ground and evenly spaced. |

| 4 | Tighten the bolts securely to ensure stability during operation. |

Winter Preparation Checklist

As the colder months approach, ensuring that your outdoor equipment is ready for the challenges ahead is essential. This checklist serves as a comprehensive guide to help you prepare effectively for the winter season, ensuring optimal performance and safety.

1. Inspect Equipment: Thoroughly examine your machinery for any signs of wear or damage. Check belts, cables, and any moving parts for functionality.

2. Change Fluids: Replace the oil and other necessary fluids to ensure smooth operation. Fresh oil helps maintain engine health and efficiency.

3. Fuel System Maintenance: Use fresh fuel and consider adding a stabilizer to prevent issues caused by old gasoline. This will keep the fuel system clean and efficient.

4. Check Spark Plug: Inspect and, if necessary, replace the spark plug to ensure easy starts and optimal combustion during operation.

5. Clear Debris: Remove any debris from around the machine, including leaves, dirt, or other obstructions that could impede performance.

6. Test Run: After all checks and maintenance, perform a test run to verify everything is functioning correctly. Pay attention to any unusual sounds or behavior.

7. Prepare for Emergencies: Keep a supply of essential items on hand, such as fuel, oil, and tools. Being prepared for unexpected situations can save time and stress.

By following this checklist, you can ensure that your outdoor equipment is ready to handle the winter weather, providing reliability and peace of mind throughout the season.