This section aims to provide essential insights into the upkeep of agricultural machinery, focusing on effective techniques and strategies. Proper maintenance is crucial for ensuring optimal performance, longevity, and reliability of equipment used in farming operations.

Understanding the various components and systems of your machinery can significantly enhance troubleshooting and repair processes. By familiarizing yourself with specific features, operators can proactively address potential issues before they escalate, saving both time and resources.

In this guide, you will find valuable information that covers a range of topics, from routine inspections to in-depth procedures for more complex challenges. Whether you are a seasoned professional or a novice in the field, this resource will equip you with the knowledge needed to maintain your equipment efficiently and effectively.

Massey Ferguson 275 Overview

This section provides a comprehensive introduction to a popular agricultural machine, renowned for its robust design and reliable performance. It is a vital asset for farmers seeking efficiency in their operations, combining advanced engineering with user-friendly features.

Key Features

The model boasts a powerful engine and a well-balanced chassis, ensuring optimal traction and stability on various terrains. With a focus on durability, it is designed to withstand demanding tasks, making it suitable for both small farms and larger agricultural enterprises.

Usage and Applications

This machinery is particularly effective in various farming activities, including tilling, planting, and harvesting. Its versatility allows operators to tackle a wide range of tasks efficiently, enhancing productivity and reducing operational downtime.

In summary, this agricultural unit represents a blend of innovation and practicality, making it a valuable choice for those in the farming sector.

Common Issues with the 275 Model

The following section outlines frequent challenges encountered with this particular agricultural machine. Understanding these common problems can assist operators in maintaining optimal performance and extending the lifespan of their equipment.

Engine Performance Problems

One of the prevalent concerns involves the engine’s efficiency. Symptoms such as difficulty starting, unusual noises, or inconsistent power output may indicate underlying issues. Regular checks of fuel quality, air filters, and spark plugs are essential to ensure smooth operation.

Hydraulic System Failures

The hydraulic system is vital for various functionalities, and complications here can lead to significant operational delays. Common signs include sluggish response times or complete failure of hydraulic components. It is crucial to inspect fluid levels and check for leaks in hoses and connections to prevent extensive damage.

Addressing these issues promptly can help maintain the functionality of the machine and reduce downtime, ensuring that agricultural tasks are completed efficiently.

Essential Tools for Repairs

When it comes to maintaining and fixing agricultural machinery, having the right set of instruments is crucial for ensuring efficiency and effectiveness. A well-equipped toolkit not only streamlines the process but also enhances safety and precision during work. Below are some fundamental implements every technician should consider having on hand.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for driving screws and performing adjustments. |

| Pliers | Useful for gripping, twisting, and cutting wires or fasteners. |

| Jack | Necessary for lifting heavy components for easier access. |

| Diagnostic Tools | Helps in identifying and troubleshooting issues effectively. |

Step-by-Step Maintenance Guide

Proper upkeep of your agricultural machinery is essential for optimal performance and longevity. This guide outlines a systematic approach to ensure your equipment remains in peak condition. By following these steps, you can prevent potential issues and enhance the efficiency of your operations.

1. Regular Inspection: Begin with a thorough examination of the entire unit. Check for any signs of wear or damage, particularly in critical components such as the engine and transmission.

2. Fluid Levels: Ensure that all fluids are at the recommended levels. This includes oil, coolant, and hydraulic fluids. Replace or top off as necessary to maintain proper function.

3. Filter Replacement: Regularly change air and oil filters to prevent contaminants from affecting the machinery’s performance. This simple step can significantly extend the lifespan of your equipment.

4. Battery Maintenance: Inspect the battery connections for corrosion and ensure the terminals are clean. A well-maintained battery is crucial for reliable starting and operation.

5. Tire Care: Check the tire pressure and tread condition. Properly inflated tires improve traction and fuel efficiency, while good tread ensures safety during operation.

6. Cleaning: Keep the exterior and undercarriage free from dirt and debris. Regular cleaning helps prevent rust and extends the life of various components.

7. Documentation: Maintain a log of all maintenance activities performed. This will help track the history of the machinery and assist in future maintenance planning.

By adhering to this guide, you can ensure your agricultural equipment operates smoothly, minimizing downtime and maximizing productivity.

Hydraulic System Troubleshooting Tips

Effective troubleshooting of hydraulic systems is crucial for ensuring optimal performance and longevity. Understanding common issues and their symptoms can help in quickly identifying and rectifying problems, thereby minimizing downtime.

Here are some common issues to look out for:

- Fluid Leaks: Check for any visible leaks around hoses, fittings, and connections. Inspect seals and gaskets for wear.

- Inadequate Pressure: Monitor pressure gauges. Low pressure may indicate pump failure or a blockage in the system.

- Unusual Noises: Listen for grinding or whining sounds, which could suggest air in the system or mechanical issues within the pump.

- Slow Operation: If actuators are slow to respond, it might indicate low fluid levels or a malfunctioning pump.

To effectively troubleshoot, follow these steps:

- Inspect the hydraulic fluid levels and top up if necessary.

- Examine all connections and hoses for signs of damage or wear.

- Test the hydraulic pump to ensure it is functioning correctly.

- Check filters for clogs and clean or replace as needed.

By systematically addressing these areas, you can efficiently resolve hydraulic system issues and maintain peak performance.

Engine Performance Enhancements

Improving the output and efficiency of an engine can significantly enhance overall machine performance. This section explores various strategies and modifications that can lead to noticeable gains in power and efficiency. By focusing on key areas, operators can optimize their equipment for better productivity and reliability.

Key Modifications

- Air Intake Systems: Upgrading air intake components can improve airflow, resulting in enhanced combustion efficiency.

- Exhaust Systems: A well-designed exhaust system reduces back pressure, allowing for better engine breathing and increased horsepower.

- Fuel Delivery: Enhancing fuel injectors and pumps ensures a more precise fuel-air mixture, improving performance and efficiency.

Regular Maintenance

- Ensure timely oil changes to maintain lubrication and reduce wear.

- Check and replace air and fuel filters to keep systems clean and functioning optimally.

- Inspect spark plugs and ignition systems for consistent performance.

Implementing these enhancements not only boosts performance but also extends the lifespan of the engine. Regular assessment and upgrades can lead to significant operational advantages.

Electrical System Diagnostics

Diagnosing the electrical framework of agricultural machinery is crucial for ensuring optimal functionality and preventing potential failures. This process involves a systematic approach to identify issues within the wiring, components, and circuits that affect performance. Understanding how to effectively analyze these systems can significantly enhance operational efficiency.

Common Issues and Symptoms

Operators may encounter various challenges, such as malfunctioning lights, starting difficulties, or erratic behavior of electronic components. Recognizing these symptoms is the first step in the diagnostic process. It is essential to examine each element of the electrical layout, from switches to connectors, to pinpoint the source of the problem.

Diagnostic Tools and Techniques

Utilizing the appropriate diagnostic instruments, such as multimeters and circuit testers, can facilitate a thorough evaluation of the electrical components. Regular testing and inspections of connections and fuses help maintain system integrity and prevent minor issues from escalating into major repairs. Implementing a methodical approach ensures that every aspect of the electrical network is scrutinized effectively.

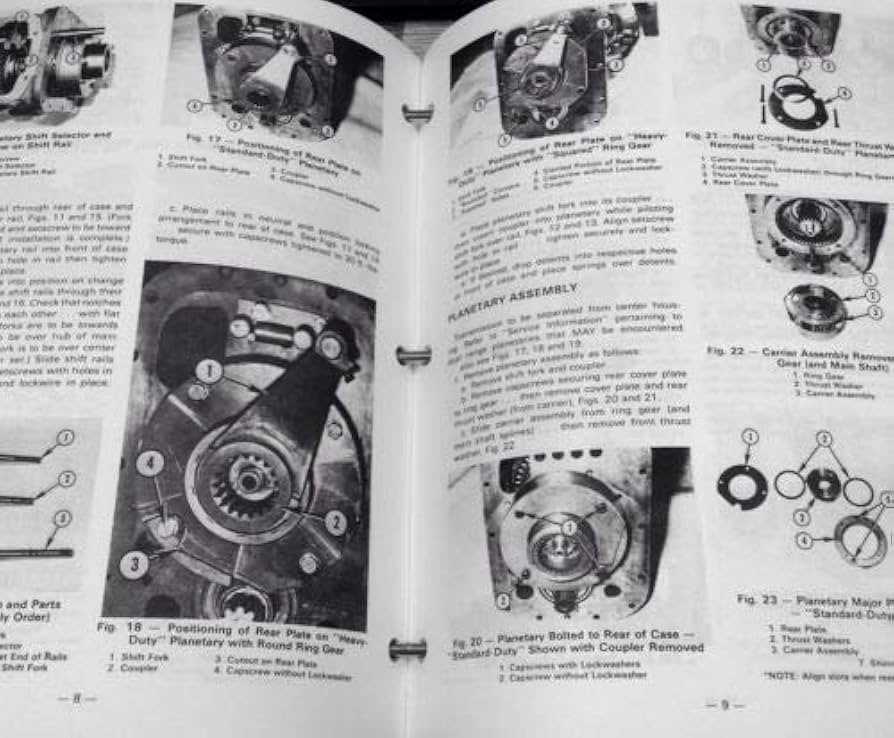

Transmission Repair Procedures

This section outlines essential methods for addressing issues related to the gear shifting mechanism in agricultural machinery. Understanding these processes is crucial for maintaining operational efficiency and ensuring the longevity of the equipment.

Initial Diagnosis

The first step involves assessing the transmission for any signs of wear or malfunction. Look for unusual noises, difficulty in shifting gears, or fluid leaks. A thorough examination will help identify whether the issue lies within the gears, bearings, or hydraulic system.

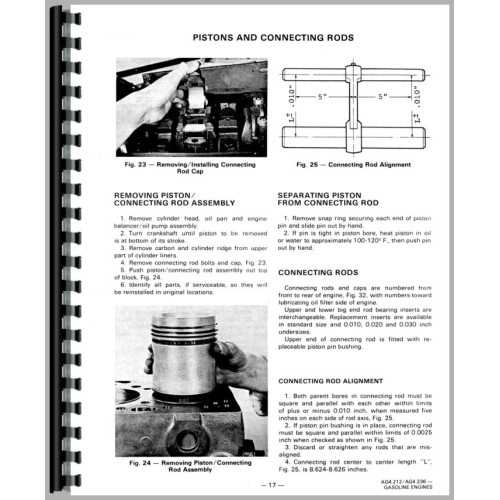

Disassembly and Inspection

Once a problem has been identified, proceed to disassemble the transmission unit. Carefully remove components in the correct sequence to avoid damage. Inspect each part for signs of wear, such as pitting on gears or excessive play in bearings. Replace any damaged components with high-quality replacements to ensure reliable performance.

After reassembly, perform a series of tests to confirm that the transmission operates smoothly and efficiently. Regular maintenance checks will prolong the life of the transmission system.

Preventative Care Practices

Implementing regular maintenance routines is essential for ensuring the longevity and efficiency of machinery. These practices help in identifying potential issues before they escalate, ultimately saving time and resources. A proactive approach can enhance performance and reduce the likelihood of unexpected breakdowns.

Routine Inspections

Conducting frequent checks on equipment components is vital. This includes examining fluids, filters, and belts for signs of wear and tear. Regular assessments can reveal minor problems that, if left unchecked, may lead to major repairs. Keeping a log of these inspections can aid in tracking maintenance needs over time.

Lubrication and Cleaning

Proper lubrication of moving parts minimizes friction and wear, enhancing overall functionality. Additionally, maintaining cleanliness around the machine prevents dirt accumulation, which can lead to mechanical issues. Establishing a consistent cleaning schedule will contribute to the smooth operation and durability of the equipment.

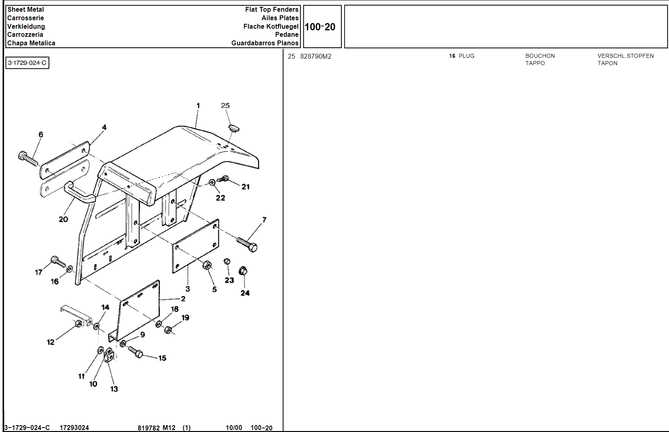

Parts Replacement and Upgrades

Maintaining optimal performance of agricultural machinery involves regular updates and the timely substitution of components. This process not only enhances efficiency but also extends the lifespan of the equipment. Understanding the significance of both parts replacement and upgrades is crucial for achieving superior operational results.

When considering replacements, it is essential to evaluate the quality and compatibility of the new components. Utilizing original or high-quality aftermarket parts can prevent future issues and ensure that the machinery operates smoothly. Regular inspections can help identify worn-out components before they lead to significant malfunctions.

Upgrades offer an opportunity to enhance functionality and efficiency. Implementing modern technologies can significantly improve performance, reduce fuel consumption, and increase productivity. Upgrading components such as the transmission system or the hydraulic components can lead to a notable increase in overall effectiveness.

In conclusion, proactive management of parts replacement and upgrades is vital for the sustained performance of agricultural machinery. By investing in quality components and considering upgrades, operators can ensure that their equipment remains reliable and efficient in the long term.

Owner Testimonials and Experiences

This section aims to share insights and feedback from users who have had hands-on experience with their machinery. Personal stories and reflections can provide valuable perspectives on the reliability and performance of these essential tools in agricultural settings.

John D., a long-time user, expresses his satisfaction: “This equipment has been a game changer for my farm. Its efficiency and power have significantly reduced my workload.”

Sarah K. highlights the importance of maintenance: “Regular upkeep is key. I’ve found that following the recommended guidelines ensures that my machine runs smoothly for years.”

Mike R. shares his initial concerns: “I was hesitant at first due to past experiences, but the performance has exceeded my expectations. It has become a reliable partner in my daily tasks.”

User experiences like these underscore the value of understanding operational nuances and the importance of care in prolonging the life of vital agricultural equipment.

Resources for Further Assistance

When tackling mechanical issues or maintenance tasks, having access to reliable resources can significantly enhance the repair process. Numerous avenues exist to obtain valuable information, support, and guidance for troubleshooting and restoring equipment.

Online Platforms

- Forums and Community Groups: Engaging with online communities can provide insights from fellow enthusiasts and experts who share similar experiences.

- Manufacturer Websites: Many manufacturers offer digital resources, including technical specifications, instructional videos, and FAQs that can be invaluable.

- YouTube Channels: A variety of channels dedicated to machinery repairs offer visual guides that can clarify complex procedures.

Printed Resources

- Books and Guides: Look for comprehensive literature covering machinery maintenance and repair techniques.

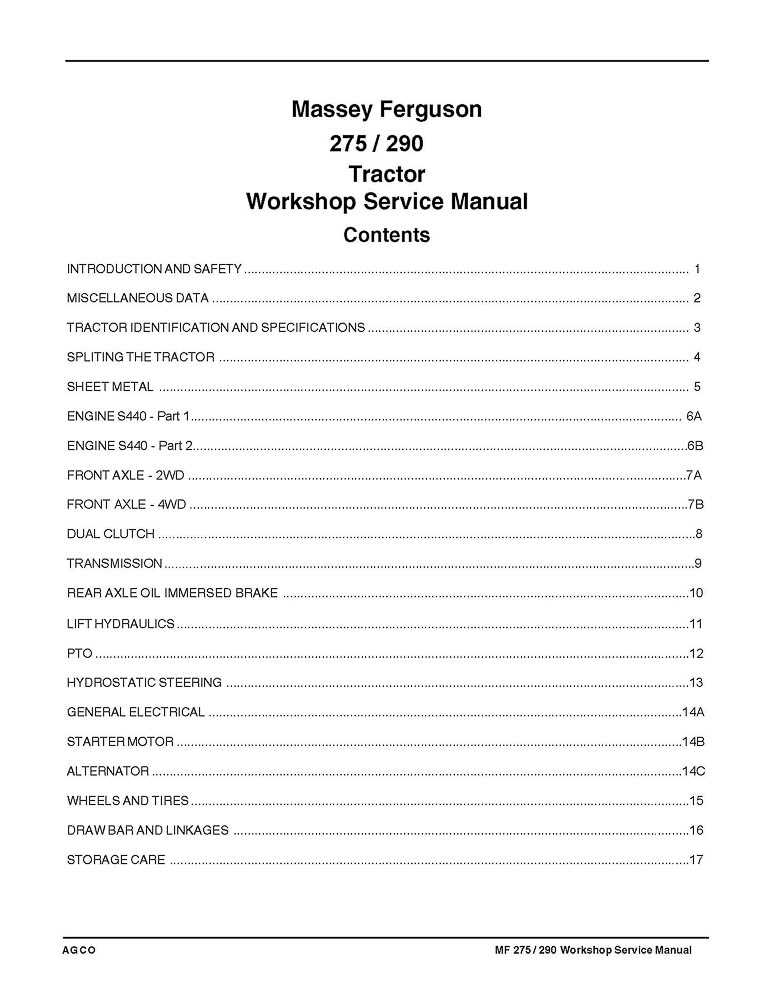

- Service Publications: Often available through dealerships, these documents provide detailed instructions and diagrams specific to various models.

- Local Libraries: Many libraries carry resources that may include repair guides and manuals relevant to your machinery.