Understanding how to keep tools functioning at their best is essential for any enthusiast or professional who relies on dependable equipment. This guide provides key insights into optimizing performance and ensuring longevity through routine checks and adjustments.

For those encountering occasional hiccups or needing a full inspection, this resource covers essential steps for diagnosing potential issues, handling minor fixes, and maintaining efficiency. Attention to detail in upkeep not only prevents unexpected breakdowns but also enhances overall tool reliability.

Additionally, you’ll find practical advice on addressing common concerns, along with tips to help you feel confident in managing technical aspects. Each section is crafted to be clear and straightforward, assisting both new and experienced users alike in achieving effective results with ease.

Bostitch BTFP71875 Repair Manual Overview

This section provides essential insights into the maintenance and troubleshooting guidelines for ensuring the continued reliability and functionality of your tool. Here, we explore a variety of common service techniques, offering straightforward instructions for resolving typical challenges and prolonging the lifespan of the equipment.

Each segment focuses on key maintenance tips and effective problem-solving methods. By following these instructions, users can gain a deeper understanding of preventive care, helping to address frequent issues and optimize performance with minimal disruption.

Essential Tools for Bostitch Repairs

Performing maintenance on pneumatic devices requires a selection of specific equipment to ensure each component is handled effectively. Whether addressing a performance issue or conducting routine upkeep, having the correct instruments is key to a smooth process and effective results.

Primary Equipment for Disassembly and Reassembly

Among the essential items are screwdrivers, pliers, and Allen wrenches, which provide precision and control. Specialized wrenches often allow for easy access to tightly fitted parts, ensuring no damage during disassembly. Using these tools helps prevent wear and facilitates proper alignment upon reassembly.

Lubrication and Cleaning Supplies

Another important group includes items for cleaning and lubrication. Compressed air cans, soft brushes, and industrial-grade lubricants keep internal elements free of debris and ensure smooth movement. Proper lubrication not only prevents rust but also enhances overall efficiency, helping the tool maintain its optimal function over time.

Identifying Common Tool Performance Issues

Power tools often experience operational challenges that can affect their efficiency and reliability. Knowing the usual complications and understanding how to address them can extend the tool’s lifespan and maintain performance.

Irregular Firing or Air Leaks

One of the prevalent issues is irregular firing, which may result in incomplete or weakened operations. Additionally, air leaks can disrupt functionality, often occurring due to loose seals or worn-out components. Ensuring that seals are intact and checking for any potential component wear can often prevent these disruptions.

Fastener Jamming

Frequent jamming of fasteners is another common occurrence. This may be due to incorrect fastener size, improper loading, or even dirt accumulation within the chamber. Regular cleaning and verifying the compatibility of fasteners are essential steps to minimize jamming incidents and keep the tool running smoothly.

Step-by-Step Guide to Disassembly

In this section, we’ll walk through a methodical approach to taking apart the tool, ensuring each component is carefully removed and organized for reassembly. By following each step precisely, you’ll maintain the integrity of all parts and simplify the process of putting it back together.

Step 1: Power Down and Prep – Before starting, make sure the device is completely powered down and disconnected from any energy source. This is a critical safety measure.

Step 2: Remove External Housing – Begin by loosening and removing any screws on the outer casing. Gently pull apart the housing pieces, noting the position of each component as you go.

Step 3: Separate Major Assemblies – Identify the key assemblies within the tool, such as the motor and internal valves. Carefully detach each section, making sure to keep any smaller parts, like springs or screws, organized.

Step 4: Extract Internal Mechanisms – With the main assemblies removed, proceed to disassemble the inner mechanisms, handling each part cautiously to avoid damage. Keep track of each part’s location to streamline the reassembly process.

Step 5: Organize and Store Components – Once all pieces are separated, place them in a safe area, ideally labeled, to ensure no components are misplaced or mixed up. This organization will be crucial for a smooth reassembly.

Replacing Worn or Broken Parts

Ensuring the longevity and functionality of your equipment often involves identifying and replacing parts that show signs of wear or damage. Regular maintenance helps avoid unexpected breakdowns and extends the overall lifespan of the device.

When replacing components, follow these key steps:

- Identify Problematic Parts: Begin by carefully examining the tool for visible wear, cracks, or other signs that a part may require replacement.

- Gather Necessary Tools: Make sure you have the appropriate tools to disassemble and reassemble the sections involved, as using incorrect tools may cause further damage.

- Select Compatible Parts: Obtain replacement parts specifically designed for your model to ensure compatibility and proper fit.

- Follow Assembly Instructions: Carefully install each new part, following the recommended order to ensure every component aligns as needed for optimal function.

- Test Functionality: Once reassembled, run a test to confirm that the equipment operates smoothly and effectively with the new parts.

By systematically inspecting and replacing worn components, you can maintain the performance of your tool, ensuring it remains reliable for future tasks.

Maintaining Optimal Air Pressure

Ensuring that your pneumatic tool operates efficiently relies heavily on achieving the right air pressure. Proper air pressure is crucial for maximizing performance and prolonging the lifespan of the equipment. Regularly monitoring and adjusting the pressure levels will help maintain functionality and prevent potential issues that can arise from improper settings.

Consistent Monitoring: It’s essential to check the air pressure frequently, especially before starting any task. This practice ensures that the tool receives the correct amount of air to function effectively. Using a reliable gauge will provide accurate readings and help you avoid under or over-pressurization.

Adjusting Settings: If the pressure readings are not within the recommended range, adjustments should be made promptly. Increasing or decreasing the pressure is often straightforward, but it’s crucial to refer to the specifications provided by the manufacturer. Adhering to these guidelines will optimize performance and reduce wear and tear on the device.

Regular Maintenance: In addition to monitoring and adjusting air pressure, routine maintenance checks are vital. Inspecting hoses, connectors, and the compressor itself can prevent leaks and ensure that the system operates smoothly. Addressing any issues immediately will enhance efficiency and reduce downtime.

By prioritizing the management of air pressure, users can enjoy a seamless experience with their tools while ensuring longevity and reliable performance.

Troubleshooting Power and Performance Issues

Identifying and resolving power and performance challenges is crucial for maintaining the efficiency of your tool. This section provides insights into common issues and effective solutions to ensure optimal operation.

Common Symptoms

- Inconsistent power delivery

- Frequent stalling during operation

- Unusual noises while in use

- Overheating of components

Potential Solutions

- Check Power Source: Ensure that the device is plugged into a functioning outlet and that the power cord is not damaged.

- Inspect Air Supply: Confirm that the air intake is not blocked and that the compressor is functioning correctly.

- Examine Connections: Look for loose or corroded connections that could disrupt electrical flow.

- Review Operating Conditions: Make sure the tool is being used within recommended temperature and humidity ranges.

By systematically addressing these areas, you can enhance the reliability and performance of your equipment.

Cleaning Tips for Longer Lifespan

Regular maintenance is essential for ensuring the longevity and optimal performance of your equipment. By implementing effective cleaning techniques, you can minimize wear and tear, prevent malfunctions, and extend the lifespan of your tools. Here are some valuable suggestions to keep your device in top condition.

Routine Maintenance

Establish a consistent cleaning schedule to prevent the buildup of dust and debris. After each use, wipe down the surfaces with a soft cloth to remove any particles. This practice will help maintain cleanliness and improve overall functionality.

Deep Cleaning Techniques

For thorough cleaning, disassemble your device according to the manufacturer’s guidelines. Use compressed air to blow out dust from hard-to-reach areas, and a damp cloth to clean the exterior. Ensure all components are completely dry before reassembling.

| Cleaning Method | Frequency | Recommended Tools |

|---|---|---|

| Surface Wiping | After each use | Soft cloth |

| Compressed Air Cleaning | Monthly | Compressed air canister |

| Deep Cleaning | Every 6 months | Damp cloth, screwdriver |

Ensuring Safe Usage After Repairs

After addressing issues with your equipment, it is crucial to prioritize safety before returning it to operation. Proper handling and awareness of potential hazards can prevent accidents and ensure optimal performance.

To promote safe usage, consider the following guidelines:

- Thorough Inspection: Always conduct a detailed examination of the unit to ensure that all components are securely in place and functioning correctly.

- Check for Residual Damage: Verify that no additional problems have arisen during the repair process that could compromise safety.

- Follow Manufacturer’s Instructions: Adhere to any provided recommendations to ensure safe operation and longevity of the device.

- Use Appropriate Safety Gear: Equip yourself with necessary protective equipment, such as goggles and gloves, to minimize risk during usage.

- Monitor Performance: Pay attention to any unusual sounds or behaviors during initial use, which may indicate further issues.

By implementing these practices, you can enhance safety and functionality, leading to a more reliable experience with your device.

Reassembling the BTFP71875 Correctly

Proper assembly of your tool is crucial for optimal performance and longevity. This section provides essential steps and guidelines to ensure that each component is fitted accurately, maintaining functionality and safety. Following the outlined process will help avoid common mistakes that can arise during reassembly.

| Step | Description |

|---|---|

| 1 | Begin by gathering all parts and tools required for the assembly. Ensure that everything is clean and in good condition. |

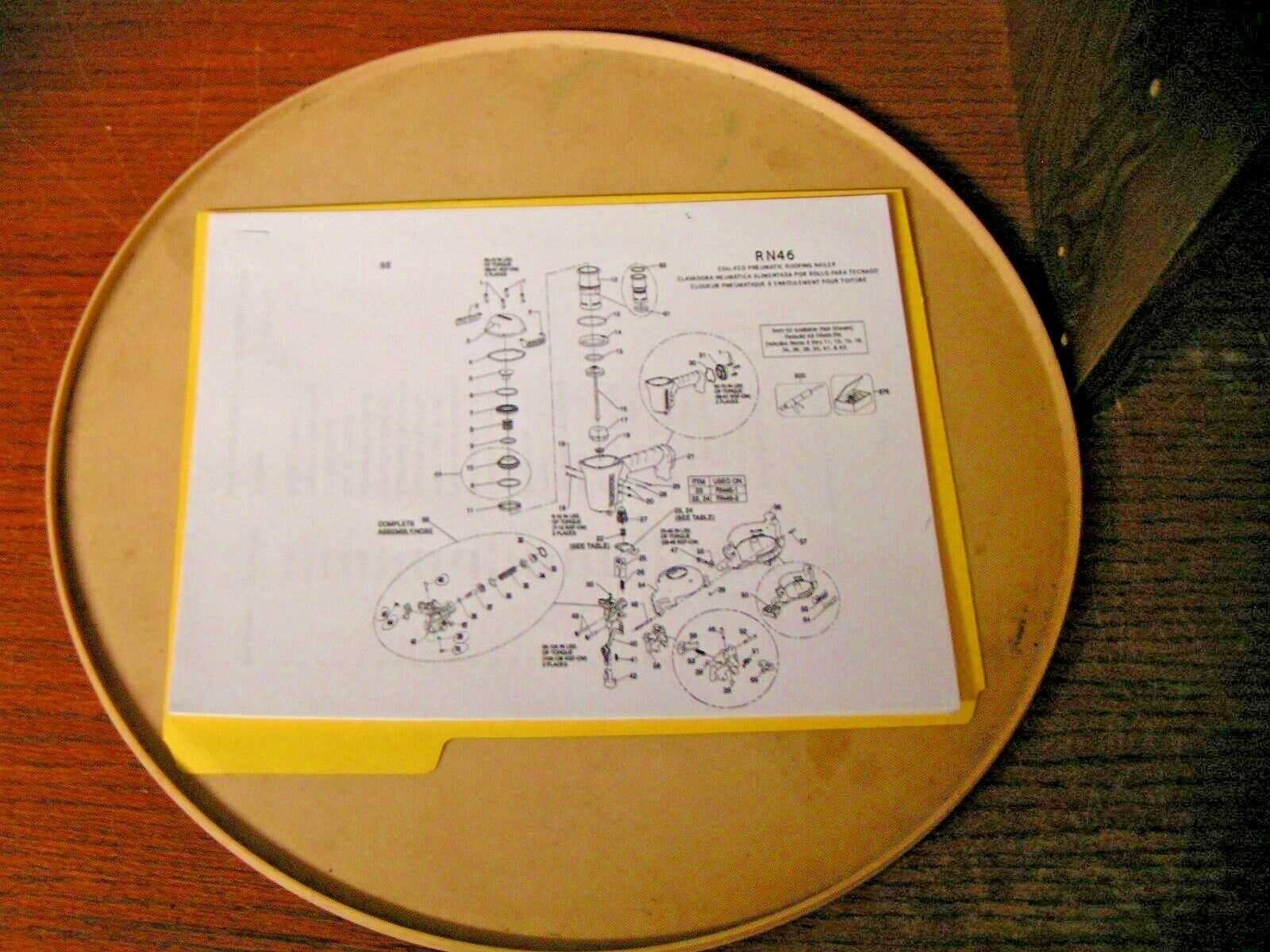

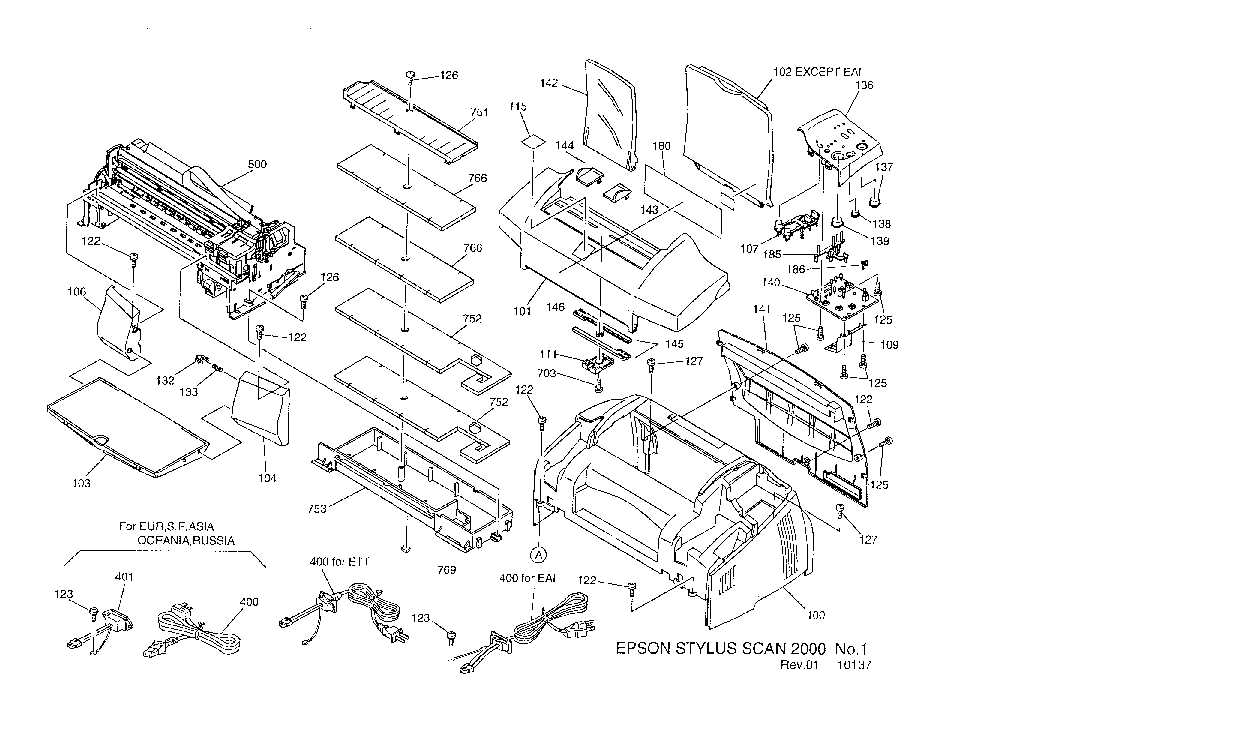

| 2 | Refer to the exploded diagram of the tool to familiarize yourself with the arrangement of components. |

| 3 | Start assembling from the base, ensuring each part locks into place securely before moving on to the next. |

| 4 | Pay special attention to alignment; misaligned components can lead to malfunctions. |

| 5 | Once all parts are connected, perform a final check to confirm that no pieces are loose or improperly installed. |

| 6 | Conduct a test run to verify that the assembly is functioning correctly and to identify any potential issues. |

Testing and Adjusting Settings Post-Repair

After completing maintenance on your equipment, it is essential to verify its functionality and ensure optimal performance. This involves a systematic approach to assess various settings and make necessary adjustments for efficient operation.

The following steps can guide you through the testing and calibration process:

- Initial Power-On Check: Start by powering on the device and observing any unusual noises or behaviors. This can indicate underlying issues that need addressing.

- Functional Testing: Perform a series of operational tests to confirm that all functions are working as intended. This may include:

- Checking pressure settings

- Verifying speed controls

- Ensuring safety mechanisms engage properly

- Pressure levels

- Timing intervals

- Operational speeds

By following these steps, you can effectively ensure that your equipment operates smoothly and efficiently after maintenance work has been completed.

Preventative Maintenance to Avoid Future Repairs

Implementing regular upkeep practices is essential for prolonging the life of tools and equipment. By adhering to a structured maintenance routine, one can significantly reduce the risk of breakdowns and enhance overall performance. This proactive approach not only saves time but also minimizes costs associated with unexpected issues.

Key Maintenance Practices

- Regular Cleaning: Keep tools free from dust and debris to ensure optimal functionality.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear.

- Inspection: Periodically check for signs of damage or wear and replace any faulty components immediately.

- Proper Storage: Store equipment in a dry, secure location to prevent rust and physical damage.

Monitoring Performance

- Track Usage: Maintain a log of how often and in what conditions the equipment is used.

- Listen for Unusual Sounds: Pay attention to any strange noises that may indicate a problem.

- Observe Functionality: Regularly assess the performance to identify any decline in efficiency.