Understanding the intricacies of maintaining specialized machinery is crucial for ensuring optimal performance and longevity. This section provides insights into the processes involved in the upkeep of these complex devices. By following best practices, users can effectively address common challenges and enhance the functionality of their equipment.

Proper maintenance not only prolongs the lifespan of the machinery but also improves safety and efficiency. A systematic approach to care and troubleshooting can prevent potential issues, allowing operators to focus on their primary tasks without interruptions.

Throughout this guide, readers will discover various techniques and recommendations for managing and resolving typical problems that may arise during operation. By equipping oneself with the right knowledge, one can confidently navigate the complexities of equipment upkeep and ensure reliable performance.

Common Issues with Gmp J2

The machinery in question often encounters various challenges that can affect its performance and reliability. Understanding these common problems is essential for effective troubleshooting and maintenance. Below are some frequently observed issues that operators and technicians may face.

Mechanical Failures

Mechanical components are susceptible to wear and tear, which can lead to operational disruptions. Identifying the signs of fatigue early can prevent more significant malfunctions.

Electrical Malfunctions

Electrical systems are critical for the functionality of the equipment. Issues such as short circuits or wiring problems can hinder performance and may require immediate attention.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Wear and Tear | Unusual noises, decreased efficiency | Regular inspection and timely replacement of parts |

| Electrical Short | Failure to start, blown fuses | Check wiring and replace damaged components |

| Hydraulic Leak | Fluid loss, poor performance | Inspect hoses and seals; repair or replace as needed |

Essential Tools for Repairs

When it comes to maintaining and fixing equipment, having the right instruments at hand is crucial for efficiency and effectiveness. The appropriate tools not only enhance the quality of work but also ensure safety during the process. A well-equipped workshop can significantly streamline tasks, making it easier to address any issues that may arise.

Basic Hand Tools

Every technician should have a set of basic hand tools, including screwdrivers, wrenches, and pliers. These instruments are fundamental for various tasks, from tightening screws to adjusting components. Investing in high-quality hand tools ensures durability and reliability, allowing for seamless operations.

Power Tools and Accessories

In addition to hand tools, power tools play a vital role in enhancing productivity. Drills, saws, and grinders can save time and effort, especially when dealing with larger projects. It’s essential to choose the right accessories for these tools to maximize their performance and ensure safety during usage.

Step-by-Step Repair Guide

This section offers a comprehensive approach to addressing issues effectively and efficiently. By following these systematic instructions, users can enhance the functionality and longevity of their equipment. The outlined steps will provide clear guidance for tackling common problems that may arise during operation.

1. Assess the Situation: Begin by evaluating the current condition of the equipment. Look for visible signs of wear or damage that may indicate underlying issues.

2. Gather Necessary Tools: Prepare a selection of tools that will be required for the task. This may include wrenches, screwdrivers, and replacement parts.

3. Disconnect Power: Ensure the device is unplugged or disconnected from any power source to avoid accidents while working on it.

4. Disassemble Components: Carefully remove the outer casing and any relevant parts to access the internal mechanisms. Keep track of screws and small pieces for reassembly.

5. Identify Problem Areas: Examine the internal components for damage or malfunction. Look for broken wires, worn-out parts, or blockages that may be causing issues.

6. Replace or Repair Parts: If damaged components are found, replace them with new parts or attempt to fix them, depending on the severity of the damage.

7. Reassemble the Unit: Once repairs are made, carefully put the equipment back together, ensuring all pieces are securely fastened and in the correct order.

8. Test Functionality: Reconnect the power source and test the device to ensure it operates as expected. Make adjustments if necessary.

9. Document the Process: Keep a record of the steps taken and any parts replaced for future reference. This documentation can be helpful for subsequent maintenance.

Maintenance Tips for Longevity

To ensure the extended lifespan of your equipment, regular upkeep is essential. Implementing simple practices can significantly enhance performance and reliability. By following these guidelines, you can avoid unnecessary repairs and costly replacements.

Regular Cleaning: Keeping the machinery clean is vital. Dust and debris can cause wear and tear over time. Make it a habit to remove any buildup from surfaces and components to maintain optimal functionality.

Routine Inspections: Schedule periodic checks to identify potential issues before they escalate. Inspecting belts, hoses, and connections can help you catch problems early, ensuring the equipment operates smoothly.

Proper Lubrication: Ensure that all moving parts are adequately lubricated. This prevents friction and reduces the risk of overheating, which can lead to premature failure. Use the recommended lubricants to achieve the best results.

Follow Operating Guidelines: Adhering to the manufacturer’s operational instructions is crucial. Overloading or misusing the equipment can lead to significant damage. Familiarize yourself with the recommended usage practices to promote longevity.

Storage Considerations: When not in use, store the equipment in a dry and secure environment. Exposure to harsh conditions can accelerate deterioration. Protect your investment by providing a suitable storage solution.

Identifying Parts and Components

Understanding the various elements and mechanisms of equipment is essential for effective maintenance and troubleshooting. Recognizing individual parts enables users to operate machinery more efficiently and make informed decisions when issues arise. This section will guide you in discerning the different components that make up your device, ensuring you have the knowledge to address any concerns that may develop over time.

Key Elements of the Equipment

The machinery comprises several key elements, each serving a specific purpose. Familiarity with these parts not only aids in daily usage but also enhances safety. For example, the control panel allows users to adjust settings easily, while the power supply unit ensures reliable operation. Knowing these functions helps prevent mishandling and optimizes performance.

Components and Their Functions

Every component within the machinery plays a vital role in its overall functionality. Understanding these roles can aid in troubleshooting and maintenance. For instance, the drive system is crucial for movement, while sensors monitor various conditions, providing real-time data. Identifying and comprehending the function of each part empowers users to address issues proactively and maintain optimal operation.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is crucial for maintaining optimal performance in various machinery. This section aims to provide guidance on effectively diagnosing faults and implementing solutions to restore functionality.

Common Symptoms of Electrical Issues

Recognizing the signs of electrical malfunctions can significantly aid in troubleshooting. Some prevalent indicators include:

| Symptoms | Possible Causes |

|---|---|

| Device not powering on | Faulty power source, blown fuse, or damaged wiring |

| Intermittent operation | Loose connections, corroded terminals, or overloaded circuits |

| Unusual noises | Faulty components, grounding issues, or mechanical failures |

Steps for Diagnosing Electrical Faults

To systematically approach troubleshooting, follow these essential steps:

- Check the power supply for stability and proper voltage.

- Inspect all connections for signs of wear or damage.

- Utilize a multimeter to measure resistance and continuity in circuits.

- Test individual components to determine functionality.

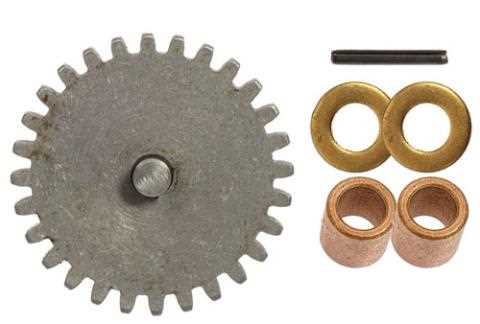

Replacing Worn-Out Parts

When components begin to degrade, timely replacement is essential to maintain optimal performance and safety. Addressing worn-out elements not only enhances the functionality of the equipment but also extends its lifespan.

Identifying parts that require replacement involves regular inspections. Signs of wear may include:

- Unusual noises during operation

- Decreased efficiency

- Visible damage or cracks

- Leaking fluids

Once the need for replacement is established, follow these steps:

- Gather the necessary tools and replacement components.

- Ensure the equipment is powered off and safely secured.

- Remove the damaged part, taking care to avoid further damage to surrounding components.

- Install the new part, ensuring it is correctly aligned and secured.

- Test the equipment to verify proper operation.

Regular maintenance and timely replacement of worn components are crucial for optimal operation and longevity of the machinery.

Safety Precautions During Repairs

When engaging in maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines can help ensure a secure environment, allowing for effective and efficient work. Proper preparation and awareness of potential hazards play a crucial role in safeguarding both personnel and equipment.

Personal Protective Equipment

Wearing appropriate protective gear is vital when conducting any form of servicing. This includes items such as gloves, goggles, and ear protection, which shield against injuries from sharp objects, harmful substances, and excessive noise. Ensuring that all team members are equipped with the necessary safety gear can significantly reduce the risk of accidents.

Work Environment Management

Maintaining a clean and organized workspace is crucial for preventing mishaps. Clear away any unnecessary tools or materials that may obstruct movement or pose tripping hazards. Additionally, ensuring proper lighting can enhance visibility, allowing workers to identify potential dangers and perform tasks with greater precision.

Upgrading Your Gmp J2

Enhancing the performance and functionality of your equipment can significantly improve efficiency and user experience. This process often involves integrating modern components or implementing modifications that align with current standards. By upgrading, you not only extend the lifespan of the device but also ensure it operates at peak capacity.

Identifying Key Improvements

Begin by assessing the existing features and pinpointing areas that require enhancement. Consider aspects such as speed, durability, and usability. Upgrading components like motors or control systems can lead to substantial performance gains. Researching the latest technology and trends in the industry will provide valuable insights into what modifications are feasible and beneficial.

Implementation Steps

Once you have determined the necessary upgrades, outline a clear implementation plan. This includes gathering the required tools and materials, ensuring compatibility, and following precise installation procedures. It is advisable to consult with professionals or refer to detailed guidelines to avoid common pitfalls during the upgrade process. Testing the modified equipment thoroughly will confirm that all enhancements are functioning as intended.

Frequently Asked Questions

This section addresses common inquiries related to the operation and maintenance of the equipment. Here, you will find answers to typical questions that users often have, which can help enhance your understanding and ensure optimal performance.

What should I do if I encounter an issue?

If a problem arises, first check the user guide for troubleshooting tips. Often, common challenges can be resolved by following the outlined steps. If the issue persists, consider consulting a professional technician for further assistance.

How often should maintenance be performed?

Regular maintenance is essential for ensuring longevity and efficiency. It is recommended to conduct checks at least every few months, depending on the frequency of use. Keeping up with routine inspections can prevent more significant issues down the line.

Where to Find Replacement Parts

Locating suitable components for maintenance or upgrades can be a straightforward task with the right resources. Various outlets offer a wide selection of parts to ensure optimal functionality of your equipment.

Online marketplaces are an excellent starting point. Websites specializing in industrial supplies often feature comprehensive catalogs that include numerous parts, along with detailed descriptions and specifications. Additionally, manufacturers’ official websites may provide access to authorized distributors or direct purchasing options.

Local retailers that focus on hardware and machinery can also be valuable. These shops frequently stock essential components and may offer the benefit of personalized assistance from knowledgeable staff. Networking with professionals in the industry can lead to recommendations for reliable suppliers who specialize in specific parts.

Lastly, online forums and community groups dedicated to enthusiasts and professionals alike can be informative. Members often share tips on sourcing components, along with experiences regarding quality and compatibility, helping you make informed decisions.

Resources for Further Learning

Enhancing your understanding of technical subjects is crucial for effective problem-solving and innovation. This section presents a variety of materials that can deepen your knowledge and skills in the relevant field.

Online Courses and Webinars

Participating in online courses and webinars can provide valuable insights from industry experts. Many platforms offer specialized training that covers essential concepts and practical applications, allowing learners to gain hands-on experience.

Books and Publications

Reading comprehensive literature is another excellent way to expand your knowledge base. Look for recent publications and manuals that address modern challenges and solutions in the industry. These resources often include case studies and best practices that can enhance your learning.