Owning a recreational vehicle can be a thrilling experience, but it also comes with the responsibility of regular upkeep. Ensuring your all-terrain vehicle remains in peak condition involves understanding its components and following systematic procedures for maintenance and troubleshooting.

This guide serves as an essential resource for enthusiasts looking to enhance their knowledge about vehicle care. By delving into various aspects of operation, from routine inspections to complex repairs, users can develop a deeper appreciation for their machine while ensuring its longevity and performance.

With practical tips and clear instructions, this resource empowers owners to tackle common issues confidently. Whether you are a seasoned mechanic or a newcomer, the information provided here will equip you with the tools needed for effective maintenance and problem-solving.

Understanding the 2000 Polaris Xplorer 400

This section delves into a popular all-terrain vehicle renowned for its robust features and reliable performance. Designed for adventure enthusiasts, this model combines power and agility, making it suitable for various terrains and conditions. Whether navigating rugged trails or tackling off-road challenges, this machine is engineered to deliver a thrilling riding experience.

Equipped with a capable engine and sturdy construction, this vehicle stands out in the recreational market. Its user-friendly design caters to both seasoned riders and newcomers, ensuring a smooth operation and maintenance experience.

| Feature | Description |

|---|---|

| Engine Type | Four-stroke, single-cylinder engine providing ample torque and horsepower. |

| Transmission | Automatic transmission for easy shifting and enhanced riding comfort. |

| Suspension | Independent front and rear suspension for improved stability and control. |

| Braking System | Hydraulic disc brakes ensuring reliable stopping power on diverse terrains. |

| Fuel Capacity | Generous fuel tank allowing extended rides without frequent refueling. |

Understanding the intricate components and functionalities of this model is essential for maximizing its performance and longevity. With the right knowledge and care, riders can enjoy countless adventures with confidence.

Key Features and Specifications

This section provides an overview of the essential characteristics and technical details of the all-terrain vehicle. Understanding these attributes is crucial for enthusiasts and mechanics alike, as they highlight the machine’s performance capabilities and design intricacies.

Engine: The unit is equipped with a robust powerplant designed to deliver impressive torque and horsepower, ensuring reliable performance across varied terrains. The liquid-cooled system enhances efficiency and longevity.

Transmission: Featuring an automatic transmission, this vehicle allows for seamless gear transitions, offering an enjoyable driving experience without the need for manual shifting. The selectable two-wheel and four-wheel drive options provide versatility for different driving conditions.

Suspension: The advanced suspension system includes independent front and rear components, designed to absorb shocks and maintain stability on uneven surfaces. This feature contributes to enhanced rider comfort and control.

Dimensions: With a compact yet sturdy frame, the vehicle balances agility and stability. Its design accommodates both beginner and experienced riders, making it suitable for various skill levels.

Fuel Capacity: A generous fuel tank allows for extended rides without frequent refueling, making it ideal for long adventures in the great outdoors.

Braking System: Equipped with an efficient braking mechanism, the vehicle ensures reliable stopping power, enhancing safety during all types of riding conditions.

Common Issues Faced by Owners

Many enthusiasts encounter a variety of challenges when maintaining their all-terrain vehicles. Understanding these common problems can help owners diagnose issues promptly and enhance their riding experience. Below are some frequent concerns that may arise, along with potential solutions.

| Issue | Description | Possible Solution |

|---|---|---|

| Starting Problems | Difficulty in starting the engine can be frustrating and is often caused by battery issues or faulty ignition systems. | Check the battery charge and connections; inspect the ignition components for wear. |

| Overheating | Excessive heat can lead to performance issues, usually due to coolant leaks or clogged cooling systems. | Inspect coolant levels and hoses; clean or replace the radiator as necessary. |

| Suspension Issues | Owners may notice a decrease in ride quality due to worn-out suspension components. | Regularly inspect and replace shocks or springs that show signs of damage. |

| Brake Problems | Inadequate braking performance can stem from worn pads or fluid leaks. | Check brake pads for wear and ensure there are no leaks in the hydraulic system. |

| Electrical Failures | Malfunctions in the electrical system can lead to various performance issues. | Inspect wiring and connections; replace any damaged components to restore functionality. |

Maintenance Tips for Longevity

Ensuring the longevity of your off-road vehicle involves a combination of regular upkeep and attentive practices. By following a systematic approach to maintenance, you can enhance performance and extend the lifespan of your machine.

- Regular Oil Changes: Frequent oil changes are essential for keeping the engine running smoothly. Use high-quality oil and replace filters to prevent buildup of contaminants.

- Check Fluid Levels: Regularly inspect coolant, brake fluid, and transmission fluid levels. Maintaining appropriate levels helps prevent overheating and ensures optimal functionality.

- Inspect Tires: Keep tires properly inflated and check for any signs of wear. Rotating tires and ensuring adequate tread depth can improve handling and safety.

- Clean Air Filter: A clean air filter is crucial for optimal airflow to the engine. Regularly inspect and replace it to maintain performance.

- Battery Maintenance: Check the battery for corrosion and ensure connections are tight. A well-maintained battery prevents starting issues and electrical problems.

- Regular Inspection: Periodically inspect the vehicle for any signs of wear or damage. Addressing issues early can prevent more significant problems down the line.

Implementing these maintenance practices can lead to improved performance, enhanced reliability, and a prolonged lifespan for your vehicle. Make upkeep a priority to enjoy a smoother and more enjoyable riding experience.

Step-by-Step Repair Processes

When it comes to addressing issues with your all-terrain vehicle, a systematic approach is essential for effective troubleshooting and restoration. Following a series of well-defined steps ensures that each problem is thoroughly assessed and resolved, enhancing both performance and longevity.

1. Initial Assessment: Begin by observing any unusual sounds, vibrations, or performance issues. Document these symptoms to help narrow down potential causes.

2. Gathering Tools: Collect the necessary tools and equipment, including wrenches, screwdrivers, and diagnostic devices. Having everything on hand will streamline the process and minimize interruptions.

3. Disassembly: Carefully remove any panels or components that obstruct access to the area requiring attention. Label parts as you go to avoid confusion during reassembly.

4. Inspection: Examine the affected components for wear, damage, or corrosion. Pay close attention to connections and joints, as these are common areas for issues to arise.

5. Replacement or Repair: Depending on the findings, either replace faulty parts with new or refurbished ones, or carry out necessary repairs. Ensure that all replacements match the original specifications for optimal performance.

6. Reassembly: Methodically put everything back together, using the labels you created earlier to ensure proper placement. Double-check that all fasteners are secure.

7. Testing: After reassembly, conduct thorough tests to confirm that the problems have been resolved. Take the vehicle for a test ride to ensure everything functions correctly.

8. Maintenance: Finally, implement a regular maintenance schedule to prevent future issues. Keeping up with routine checks and servicing will help maintain the vehicle’s performance over time.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and restoring your vehicle effectively. A well-equipped workspace enhances efficiency and ensures that tasks are completed with precision. Understanding the necessary tools can significantly simplify the process, making it easier to address various mechanical challenges.

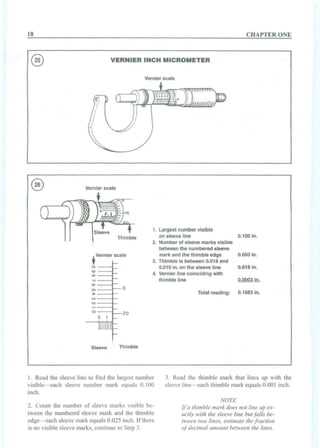

Start with basic hand tools, including wrenches, sockets, and screwdrivers, which are vital for loosening or tightening components. A reliable set of pliers can assist in gripping and manipulating parts, while an adjustable wrench adds versatility. Additionally, a torque wrench is essential for applying the correct amount of force to bolts, preventing damage from over-tightening.

For more intricate tasks, consider investing in diagnostic tools. These devices help identify issues within the system, allowing for more targeted interventions. A multimeter is invaluable for checking electrical connections and ensuring proper function across various components.

Furthermore, a sturdy workbench and adequate lighting contribute to a safer and more organized environment. Keeping tools neatly arranged not only streamlines the workflow but also minimizes the risk of accidents. Finally, protective gear, such as gloves and safety glasses, should never be overlooked to ensure personal safety during any maintenance activity.

Safety Precautions During Repairs

When undertaking maintenance tasks on your vehicle, ensuring safety is paramount. Adopting proper precautions helps prevent accidents and injuries while allowing you to work efficiently. This section outlines essential guidelines to follow during the servicing process.

Personal Protective Equipment

Always wear appropriate personal protective gear. This includes gloves, safety goggles, and sturdy footwear. Such equipment shields you from sharp objects, chemical spills, and potential hazards. Additionally, long sleeves and trousers are advisable to protect your skin from cuts and abrasions.

Work Environment Considerations

Maintain a clean and organized workspace. Clutter can lead to slips and falls, so ensure all tools are stored safely when not in use. Proper lighting is also crucial; it helps in clearly seeing all components and identifying any issues. Lastly, ensure good ventilation, especially when working with chemicals or fuels, to avoid inhaling harmful fumes.

Electrical System Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving issues related to the electrical components of your all-terrain vehicle. A systematic method is essential for identifying faults, ensuring that all electrical systems function properly and efficiently.

Begin by inspecting the battery. Check for proper voltage using a multimeter; a healthy battery should read around 12.6 volts. Ensure that connections are clean and tight, as corrosion or loose terminals can lead to performance problems.

If the vehicle fails to start, examine the starter motor and solenoid. Test the starter by applying direct power to it; if it does not engage, replacement may be necessary. Additionally, inspect the fuses and wiring for any signs of damage or wear that could interrupt electrical flow.

Next, evaluate the ignition system. Check the spark plug for wear or fouling, and replace it if necessary. Ensure that the ignition coil is functioning correctly by measuring its resistance with a multimeter. An abnormal reading indicates that the coil may need to be replaced.

Finally, review all lighting and accessory systems. Ensure that bulbs are functioning and that wiring harnesses are intact. A systematic inspection of switches and connectors will help identify any shorts or faulty components, enabling effective troubleshooting and repair.

Engine Overhaul Procedures Explained

Overhauling an engine is a meticulous process aimed at restoring optimal performance and efficiency. This procedure involves a series of systematic steps that ensure each component functions as intended, ultimately extending the lifespan of the power unit. Understanding the detailed phases of this undertaking is essential for achieving successful results.

The following outlines the primary steps involved in the overhaul process:

- Preparation:

- Gather necessary tools and equipment.

- Ensure a clean and organized workspace.

- Review specifications and guidelines for the engine model.

- Disassembly:

- Carefully remove external components such as the air intake, exhaust, and electrical systems.

- Document the disassembly process for reassembly reference.

- Take note of any worn or damaged parts during removal.

- Inspection:

- Evaluate all components for wear, cracks, or damage.

- Measure tolerances and clearances using precision tools.

- Determine which parts require replacement or refurbishment.

- Reconditioning:

- Clean all parts thoroughly to remove debris and contaminants.

- Repair or replace worn components as necessary.

- Rebuild critical systems such as the fuel and lubrication systems.

- Reassembly:

- Follow the documented steps from disassembly to ensure proper alignment.

- Utilize new gaskets and seals to prevent leaks.

- Tighten fasteners to specified torque values for secure fitment.

- Testing:

- Perform initial startup checks to ensure functionality.

- Monitor for unusual noises or leaks during operation.

- Conduct a thorough performance test to assess engine responsiveness.

Following these procedures diligently not only enhances the engine’s performance but also contributes to its longevity, ensuring reliable operation for many miles to come.

Suspension and Steering Adjustments

Proper tuning of the suspension and steering system is essential for maintaining optimal handling and ride comfort. Adjustments can enhance performance, ensuring a smoother experience over various terrains. Regular evaluation and modification of these components can prevent excessive wear and improve overall vehicle dynamics.

Suspension settings affect how the vehicle responds to bumps and turns. Steering adjustments influence maneuverability and stability. Understanding the key elements of these systems allows for effective customization based on personal preferences and riding conditions.

| Adjustment Type | Description | Recommended Practices |

|---|---|---|

| Shock Absorber Tuning | Modifying preload and damping settings to suit terrain. | Test ride after each adjustment; start with moderate settings. |

| Front Suspension Height | Adjusting fork height for better weight distribution. | Ensure even alignment; consult specifications for ideal height. |

| Steering Alignment | Ensuring wheels are parallel for precise handling. | Check after any suspension modifications; adjust camber and toe as needed. |

| Wheel Spacing | Adjusting wheel offsets for stability and control. | Consider track width for improved cornering performance. |

Regular maintenance and adjustments can significantly enhance the functionality and longevity of the vehicle’s suspension and steering systems. Stay proactive in these areas to ensure a safe and enjoyable ride.

Transmission Service and Care

The proper maintenance and attention to the transmission system are essential for ensuring optimal performance and longevity of your all-terrain vehicle. Regular service not only enhances the efficiency of power transfer but also helps in preventing potential issues that could lead to costly repairs.

Routine Inspections: Regularly check the transmission fluid level and quality. Low or contaminated fluid can significantly affect performance. Ensure that there are no leaks or signs of wear in the seals and gaskets.

Fluid Changes: Changing the transmission fluid at recommended intervals is crucial. Fresh fluid helps to maintain smooth operation and protects internal components from wear. Always use the recommended type of fluid for your vehicle.

Filter Maintenance: If your system has a filter, inspect and replace it as needed. A clogged filter can restrict fluid flow, leading to overheating and potential damage to the transmission.

Adjustments: Periodic adjustments may be necessary to ensure proper engagement and shifting. Follow the manufacturer’s specifications for settings to achieve optimal performance.

Temperature Management: Monitor transmission temperature, especially during heavy use. Excessive heat can cause fluid breakdown and damage. If overheating occurs, allow the system to cool and investigate potential causes.

Finding Replacement Parts Easily

Locating the right components for your all-terrain vehicle can be a straightforward process when you know where to look. With a variety of resources available, enthusiasts and owners can source the necessary parts to keep their machines running smoothly. This section provides helpful tips to streamline the search for suitable replacements.

Utilizing Online Resources

One of the most effective ways to find components is through online platforms. Websites dedicated to automotive parts often feature comprehensive catalogs, making it easy to browse and compare options. Make sure to use specific model information and descriptions when searching to filter results accurately. Additionally, joining online forums or communities focused on similar vehicles can provide valuable insights and recommendations for trusted suppliers.

Local Dealerships and Parts Stores

Visiting local dealerships or specialty parts stores can also yield positive results. These establishments typically have access to a range of original and aftermarket parts. Speaking directly with knowledgeable staff can lead to discovering additional resources or alternatives you may not have considered. Remember to keep a list of part numbers or specific details to facilitate the conversation and ensure you find what you need.

Upgrades for Enhanced Performance

Improving the capabilities of your all-terrain vehicle can significantly enhance your riding experience. By focusing on key components, you can achieve better handling, increased power, and improved overall performance. This section explores various modifications that can help you maximize the potential of your machine.

Performance Enhancements

One of the primary areas to consider for upgrades includes the engine and exhaust system. Upgrading to a high-performance exhaust can reduce back pressure and increase horsepower. Additionally, a reprogrammed engine control unit (ECU) can optimize fuel delivery for better efficiency and response.

Suspension and Handling

Investing in a premium suspension system is essential for achieving better handling and comfort. Adjustable shocks and high-quality springs can provide a smoother ride over rough terrain. This improvement not only enhances comfort but also allows for better traction during challenging conditions.

| Upgrade | Benefit |

|---|---|

| High-Performance Exhaust | Increases horsepower and reduces weight |

| ECU Reprogramming | Optimizes fuel delivery and enhances throttle response |

| Adjustable Suspension | Improves ride comfort and handling |

| High-Quality Tires | Enhances grip and stability on various terrains |