Understanding the intricacies of power tools is essential for anyone looking to enhance their efficiency and prolong the lifespan of their equipment. Proper maintenance not only ensures optimal performance but also minimizes the risk of unexpected breakdowns. This section delves into the fundamental aspects of keeping your tools in peak condition, offering insights into troubleshooting common issues and implementing effective solutions.

In the realm of construction and craftsmanship, having a well-functioning device is crucial for achieving precise results. When complications arise, it is vital to identify the root causes and address them promptly. This guide aims to equip users with the knowledge necessary to diagnose problems accurately and perform essential upkeep, ensuring that their tools remain reliable and ready for any project.

By following systematic approaches to maintenance and repair, individuals can not only save time and resources but also develop a deeper understanding of their tools. This empowers users to tackle repairs with confidence, enhancing their overall craftsmanship. Whether you are a seasoned professional or a DIY enthusiast, this resource will serve as a valuable companion in your journey toward tool mastery.

Understanding Hitachi Nail Guns

This section aims to provide a comprehensive overview of a specific category of tools designed for fastening tasks in various construction and woodworking projects. These devices are essential for enhancing efficiency and precision in applications where speed and accuracy are paramount.

Key Features: These instruments are equipped with advanced mechanisms that allow for rapid insertion of fasteners, reducing manual labor and improving overall productivity. Their design often includes adjustable settings to accommodate different materials and fastening depths, catering to a wide range of tasks.

Types: There are various models available, each tailored for specific applications, such as framing, finishing, or roofing. Understanding the differences between these variations can significantly impact project outcomes and tool performance.

Safety Considerations: Proper usage and maintenance are crucial to ensure user safety and extend the lifespan of the equipment. Familiarity with operational guidelines and safety protocols can prevent accidents and ensure effective functioning.

Common Issues with Nail Guns

Tools that fasten materials can experience a variety of challenges that affect their performance. Understanding these common problems can help users maintain efficiency and ensure a smoother workflow.

- Jamming: One of the most frequent issues is the occurrence of jams, where the fasteners become stuck in the mechanism. This can be caused by:

- Incorrect loading of fasteners

- Debris in the loading area

- Worn-out components

- Misfires: Another prevalent problem is misfiring, which can lead to inconsistent results. Causes include:

- Low power supply

- Faulty trigger mechanism

- Incompatible fasteners

- Poor penetration: When fasteners do not drive deep enough, it can compromise the integrity of the work. Factors contributing to this issue are:

- Insufficient air pressure

- Incorrect depth settings

- Inappropriate fastener length

- Leakage: Air or fluid leaks can reduce the tool’s efficiency. Common sources include:

- Worn seals

- Poorly connected hoses

- Damaged fittings

- Excessive noise: An increase in operational noise can indicate underlying issues, such as:

- Loose parts

- Lack of lubrication

- Worn components

phpCopy code

Regular maintenance and timely troubleshooting can mitigate these issues, ensuring optimal performance and longevity of the equipment.

Essential Tools for Repair

When it comes to maintaining and restoring tools, having the right equipment on hand is crucial. The effectiveness and efficiency of the process can be greatly enhanced by utilizing specific instruments designed for various tasks. Understanding which items are necessary can make the difference between a simple fix and a time-consuming challenge.

Basic Toolkit: A comprehensive toolkit should include screwdrivers, pliers, and wrenches in different sizes. These fundamental items are indispensable for loosening or tightening components.

Cleaning Supplies: Keeping components free from dust and debris is essential. A set of brushes, cloths, and appropriate cleaning solutions will help maintain optimal performance.

Replacement Parts: Having a stock of commonly used parts ensures that you can quickly address any issues that arise. This foresight can prevent delays and keep your equipment functioning smoothly.

Safety Gear: Never overlook the importance of personal protective equipment. Gloves, goggles, and ear protection safeguard you during maintenance tasks.

Specialized Tools: Depending on the complexity of the job, certain advanced tools may be required. Consider investing in multimeters or air compressors for specific functionalities.

By equipping yourself with these essential tools, you can approach any maintenance task with confidence, ensuring that your equipment remains in top condition for years to come.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues with your tool. Following these outlined steps will help you effectively address any problems and ensure optimal performance.

1. Safety First: Before starting any work, make sure to disconnect the power source and wear appropriate safety gear. This will protect you from potential hazards during the process.

2. Identify the Problem: Carefully observe the tool’s performance. Common issues may include malfunctioning mechanisms or unusual noises. Take note of any specific symptoms to guide your troubleshooting.

3. Gather Necessary Tools: Assemble all required tools and replacement parts. This may include screwdrivers, wrenches, and any specific components needed for the task.

4. Disassemble the Unit: Follow the manufacturer’s guidelines to dismantle the device. Keep track of all screws and components to avoid confusion during reassembly.

5. Inspect Components: Examine each part for wear or damage. Look for cracks, breaks, or excessive buildup of debris that could hinder functionality.

6. Clean and Replace: Clean any dirty areas and replace damaged parts. Ensure that all components are compatible and meet the required specifications.

7. Reassemble: Carefully put the unit back together, ensuring all parts are aligned correctly. Double-check that no components are left loose.

8. Test the Tool: Once reassembled, reconnect the power source and conduct a test run. Observe its operation closely to ensure everything is functioning smoothly.

9. Regular Maintenance: Implement a routine maintenance schedule to keep your equipment in top shape. Regular checks and cleaning can prevent future issues.

By following these steps, you can effectively troubleshoot and enhance the longevity of your tool, ensuring it remains reliable for your projects.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance is essential for both personal safety and the longevity of the equipment. Adhering to specific guidelines can prevent accidents and facilitate a smoother process. This section outlines critical measures to take before and during any service tasks.

General Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and ear protection.

- Ensure the workspace is well-lit and organized to minimize hazards.

- Disconnect the power source or remove batteries before beginning any service work.

- Keep the area free of clutter and unnecessary tools to prevent trips and falls.

Handling Tools and Components

- Use tools specifically designed for the task to avoid damage and ensure efficiency.

- Inspect all tools before use for any signs of wear or malfunction.

- Store tools properly after use to prevent accidents.

- Follow the manufacturer’s guidelines for handling and disposing of any components safely.

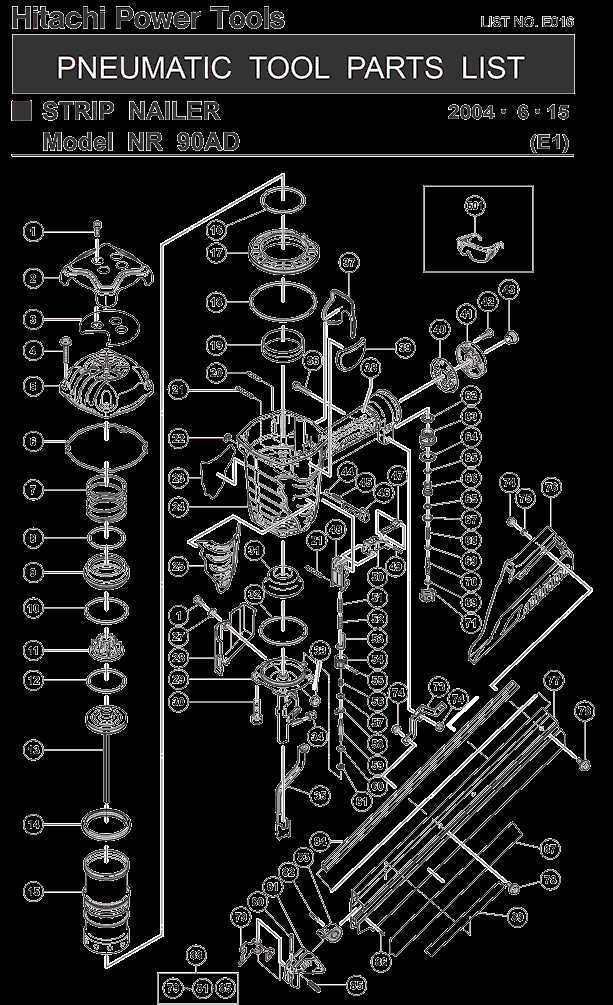

Identifying Nail Gun Components

Understanding the various elements of a fastening tool is essential for effective maintenance and troubleshooting. Each component plays a crucial role in the overall functionality, and recognizing their specific purposes can enhance both performance and safety during use.

1. Power Source: This element is vital as it provides the necessary energy to drive fasteners. It can be pneumatic, electric, or gas-powered, each offering distinct advantages depending on the application.

2. Firing Mechanism: This component is responsible for the action that propels the fastener into the material. There are typically two types: contact and sequential, with each allowing for different styles of operation and precision.

3. Magazine: The magazine holds the fasteners before they are driven into the material. Understanding how to load and unload it correctly is important to ensure a smooth workflow.

4. Safety Features: These are crucial for preventing accidental discharge. Familiarity with the safety mechanisms helps to promote safe handling and operation of the tool.

5. Trigger: The trigger activates the driving mechanism. Knowing the difference between a trigger that allows single or multiple fasteners to be driven with one press can influence project efficiency.

6. Exhaust Port: This area releases air or gas after each operation. Proper awareness of its location helps in avoiding discomfort or disruption during use.

By becoming familiar with these essential parts, users can enhance their experience and ensure that their fastening tool operates smoothly and efficiently.

Maintaining Your Nail Gun

Proper upkeep of your fastening tool is essential for optimal performance and longevity. Regular maintenance ensures that it operates efficiently and minimizes the likelihood of malfunctions. Adopting a systematic approach to care can save you time and money in the long run.

Routine Checks

Implementing a schedule for routine inspections can help identify potential issues before they escalate. Here are some key areas to focus on:

- Inspect the housing for any signs of wear or damage.

- Check the trigger mechanism for responsiveness.

- Examine the air supply and connection for leaks.

- Ensure that all fasteners are properly aligned and secured.

Cleaning and Lubrication

Regular cleaning and lubrication are crucial for maintaining functionality. Follow these steps to keep your tool in top shape:

- Disconnect the power source before cleaning.

- Use a soft brush to remove dust and debris from vents and moving parts.

- Apply appropriate lubricant to the necessary components as specified in the guidelines.

- Wipe down exterior surfaces to prevent rust and corrosion.

By following these maintenance practices, you can ensure that your fastening tool remains reliable and effective for all your projects.

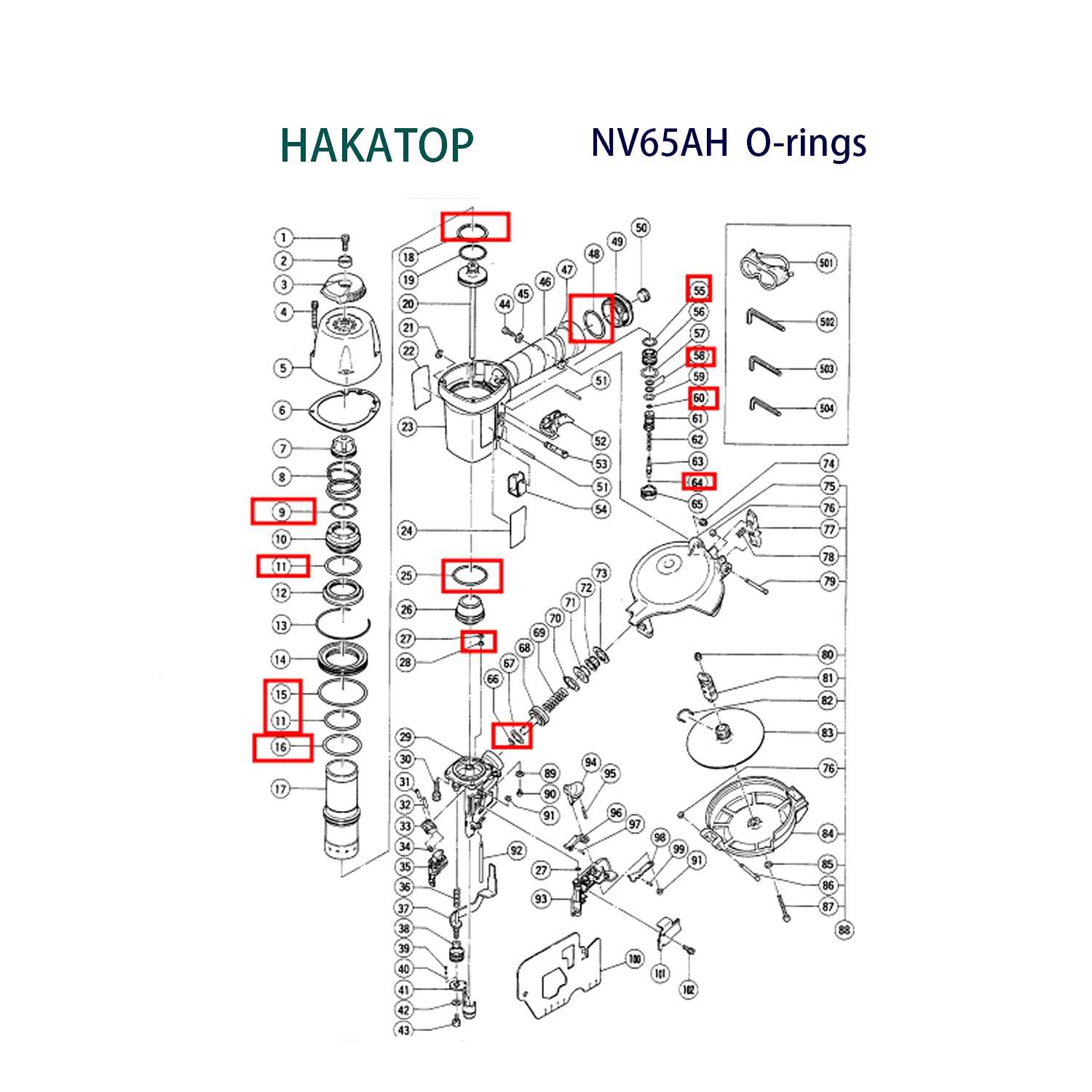

Replacing Worn-Out Parts

Maintaining the efficiency of your tool often requires attention to components that experience wear over time. Identifying and substituting these fatigued elements is crucial for ensuring optimal performance and extending the lifespan of your equipment.

First, regularly inspect the parts for any signs of damage or degradation. Components such as seals, triggers, and driving mechanisms are commonly affected by prolonged use. Being proactive in identifying issues can save you time and resources in the long run.

Next, gather the necessary replacement parts that match the specifications of your device. Consult the specifications guide or a trusted source to ensure compatibility. Quality replacements can significantly enhance the functionality and reliability of your tool.

Finally, follow the appropriate procedures for installation. Proper alignment and secure fittings are essential to avoid further issues. Once replaced, test the tool to confirm that it operates smoothly and efficiently. Regular maintenance and timely replacements will help you achieve consistent results in your projects.

Troubleshooting Air Leaks

Addressing issues related to air loss is crucial for optimal performance. Identifying and rectifying these leaks can enhance efficiency and prolong the lifespan of your equipment. Below are common sources of air leakage along with methods to troubleshoot them effectively.

| Common Source | Symptoms | Troubleshooting Steps |

|---|---|---|

| Hoses | Weak air pressure, inconsistent operation | Inspect hoses for cracks or abrasions; replace damaged sections. |

| Connections | Hissing sounds, air loss | Tighten fittings and ensure secure connections; apply thread sealant if necessary. |

| Seals and Gaskets | Reduced efficiency, visible wear | Examine seals for wear or damage; replace as needed to restore airtight integrity. |

| Valves | Erratic performance, pressure fluctuations | Check valves for proper operation; clean or replace faulty components. |

By systematically investigating these areas, you can resolve air leaks and ensure smooth functionality of your equipment. Regular maintenance and vigilance will contribute to avoiding such issues in the future.

Adjusting Nail Depth Settings

Properly setting the depth of your fastening tool is essential for achieving optimal results in your projects. This adjustment ensures that each fastener is driven to the correct depth, preventing issues such as overdriving or underdriving. Understanding how to make these adjustments can enhance both the effectiveness and safety of your work.

Follow these steps to adjust the depth settings effectively:

- Identify the Depth Adjustment Mechanism: Locate the mechanism on your device, which may vary by model. Common types include a dial, a lever, or a screw.

- Test the Current Setting: Perform a trial run with a scrap piece of material to assess the existing depth. This will give you a baseline for adjustment.

- Make Adjustments: Depending on your findings, either increase or decrease the depth. Turn the dial clockwise to deepen the setting or counterclockwise to lessen it.

- Re-Test: After adjusting, perform another test on the scrap material to ensure the fasteners are set correctly.

- Fine-Tune as Necessary: Repeat the process if the results are not satisfactory, making incremental adjustments for precision.

By following these guidelines, you can achieve consistent and accurate results in your fastening tasks. Regularly checking and adjusting the depth settings is a good practice to maintain quality in your work.

Cleaning and Lubrication Tips

Proper maintenance of your tool is essential for ensuring optimal performance and longevity. Regular cleaning and appropriate lubrication are key practices that can prevent wear and tear, reduce the likelihood of malfunctions, and enhance overall efficiency.

Cleaning should be performed after each use. Start by removing any debris or residue from the exterior. Use a soft cloth or brush to gently wipe down surfaces, paying special attention to air vents and moving parts. For deeper cleaning, disassemble the unit according to the manufacturer’s instructions and clean each component with a suitable solvent. Ensure that all parts are completely dry before reassembly.

When it comes to lubrication, choose high-quality oils specifically designed for your tool type. Apply a few drops to the moving parts, following the guidelines provided by the manufacturer. Avoid over-lubricating, as excess oil can attract dirt and debris, leading to potential blockages. Regularly inspect and refresh the lubricant to maintain smooth operation.

By incorporating these simple yet effective practices into your routine, you can significantly extend the lifespan of your tool and ensure reliable performance during every project.

When to Seek Professional Help

Understanding when to engage a specialist can save time and prevent further complications. Some situations require expert intervention due to the complexity or potential hazards involved. Recognizing these scenarios is essential for maintaining equipment effectively.

Signs You Need a Professional

- Persistent malfunction after basic troubleshooting.

- Unusual sounds or leaks that indicate serious issues.

- Frequent misfires or inconsistent performance.

- Visible wear or damage to components.

Benefits of Consulting an Expert

- Access to specialized knowledge and tools.

- Guaranteed safety during maintenance or fixes.

- Potentially lower long-term costs by preventing further damage.

- Timely resolution of complex issues.

Resources for Further Assistance

When dealing with tools and equipment, having access to additional resources can significantly enhance your understanding and troubleshooting capabilities. Whether you are facing operational challenges or looking to enhance your skills, numerous platforms can provide valuable information and support.

Online Communities and Forums

Engaging with online communities can be an excellent way to gather insights from experienced users. Forums dedicated to equipment enthusiasts often feature discussions about common issues, solutions, and best practices. Participating in these platforms allows you to ask questions and receive guidance tailored to your specific needs.

Instructional Videos and Tutorials

Visual learning can be incredibly effective. Numerous video platforms host tutorials that cover a wide range of topics related to tool usage and maintenance. These resources often provide step-by-step guidance, making complex processes easier to understand and follow.