Over time, even the most cherished photography gear may need some attention. Components can experience wear, and sometimes, a bit of care is required to restore functionality and ensure a smooth experience. In this guide, we explore how to maintain these essentials, providing insights for extending their operational life and keeping every element in top condition.

We’ll walk through the steps involved in servicing this critical part of your setup, covering essential tools, detailed steps, and tips on handling the intricate parts safely. By the end, you’ll gain a better understanding of how to approach care for these items and the practical measures that can help avoid common issues down the line.

Whether you’re a seasoned professional or just starting out in photography, maintaining your equipment can make a significant difference in performance. Proper handling and occasional adjustments can enhance longevity, ensuring you capture moments with clarity and precision for years to come.

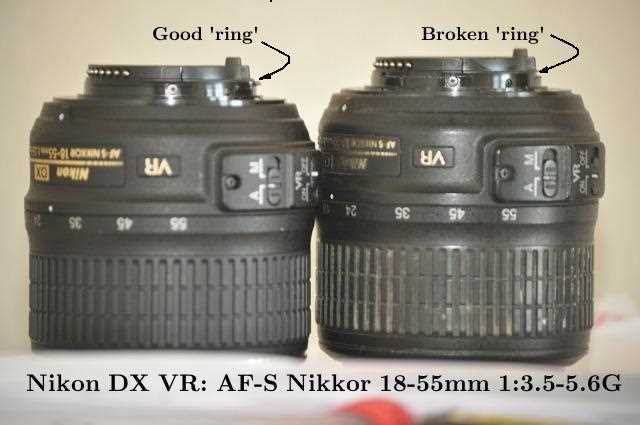

Nikon 18-55mm Lens Repair Guide

When dealing with small photography equipment, addressing maintenance issues often requires a steady hand and careful attention. Here, we explore methods to troubleshoot common problems, ensuring smoother operation and extended device lifespan.

- Start by examining any visible signs of wear or dust accumulation. Regular cleaning can prevent minor issues from developing into larger mechanical problems.

- If parts feel stiff or do not move smoothly, carefully inspect for loose screws or misaligned components, which are easily adjusted with basic tools.

- For cases involving blurred visuals, it may be necessary to check the internal elements. Delicate re-positioning can help restore clarity without professional intervention.

Remember to handle each piece carefully, as precision components require gentle adjustments. Proper reassembly and secure alignment can ensure the continued quality of your device.

Understanding Common Lens Issues

Many optical tools encounter similar challenges over time, impacting their clarity and functionality. Recognizing the symptoms early can help in addressing them effectively and extend the equipment’s operational life.

Typical Functional Problems

Optical devices may show signs of wear in several areas. A few frequent issues include erratic focus, obstructed zoom mechanisms, and degraded image quality. Addressing these promptly helps prevent further complications.

- Inconsistent Focusing: One common issue is difficulty maintaining sharpness across various ranges, often due to internal misalignment or minor abrasions on the glass.

- Stiff or Loose Movement: Moving parts may become harder to adjust or too loose over time, typically caused by dust, debris, or wear in the internal components.

- Reduced Sharpness: Dulling or blurring may occur when components are not perfectly aligned or have accumulated grime, requiring a thorough cleaning.

Common Environmental Effects

External factors like humidity, temperature, and accidental impacts contribute significantly to optical wear. Keeping these in mind when handling and storing equipment is essential.

Tools Needed for Lens Repair

Successfully working on precision optical devices requires specific tools to ensure accuracy and avoid damage. Each tool has a unique role in maintaining the quality and functionality of the equipment throughout the repair process.

Tool Purpose Small Screwdriver Set Used to carefully handle the miniature screws, allowing for easy disassembly and reassembly. Rubber Suction Tool Provides a firm grip to remove sensitive parts without scratching or bending delicate components. Microfiber Cloth Ideal for cleaning surfaces, this cloth ensures dust-free parts and avoids scratching sensitive glass elements. Compressed Air Rem Disassembling the Lens Safely

Before beginning any disassembly, ensuring a safe approach is crucial. Handling delicate parts demands a steady hand and awareness of each component’s place within the overall structure. Proper preparation helps avoid accidental damage and keeps parts in order for reassembly.

Preparation and Tools

To begin, gather all necessary tools and ensure a clean, organized workspace. Common tools might include precision screwdrivers, a small prying tool, and tweezers. Having these ready beforehand makes each step smoother, reducing the risk of losing small parts. Cleanliness is also essential; dust or debris could interfere with the reassembly process.

Step-by-Step Process

Start with the outermost parts, gently loosening screws and removing parts one at a time. Take note of each component’s orientation, as reassembly will require precise alignment. Avoid forcing any part; if something feels stuck,

Cleaning Internal Lens Elements

Keeping the inner parts of optical equipment free from dust and smudges ensures optimal image quality. Proper maintenance prevents issues such as light scatter, which can impact overall clarity and detail in captured scenes. Internal cleaning requires a steady hand and attention to small, delicate components, as improper handling could cause more harm than good.

Preparing for Cleaning

Begin by gathering the essential tools, including a soft, microfiber cloth, a gentle air blower, and suitable cleaning solutions for sensitive glass surfaces. Always work in a clean, dust-free area to minimize the chance of new particles settling on the surfaces. Handle each component with care, keeping fingertips away from any glass elements to avoid oil transfer.

Step-by-Step Cleaning Guide

First, use the air blower to remove any loose particles. This step is essential to prevent scratching when wiping. Next, lightly mois

Replacing Damaged Lens Parts

When a specific component of your optical equipment suffers from wear or damage, it becomes essential to address the issue promptly. This process not only restores functionality but also enhances the overall performance of the device. Understanding the steps involved in substituting affected elements can help ensure a successful outcome.

Before beginning the process, gather all necessary tools and replacement components. Having everything organized will streamline the task and reduce the risk of mishaps. Below is a table that outlines the basic tools required for the substitution process.

Tool Description Precision Screwdriver Set Essential for removing screws and accessing internal parts. Tweezers Helpful for handling small components delicately. Cleaning Cloth Used for wiping down surfaces and ensuring cleanliness. Replacement Components Ensure you have the correct parts to replace the damaged ones. Once you have assembled the required items, follow the outlined procedure carefully to replace the damaged parts. This will not only restore your device’s functionality but also prolong its lifespan.

Adjusting Focus and Zoom Mechanisms

Fine-tuning the focus and zoom functionalities is essential for achieving sharp and accurate images. This process involves adjusting various components to ensure smooth operation and optimal performance. Proper alignment of these mechanisms can significantly enhance the overall imaging experience.

To begin, inspect the focus assembly for any signs of misalignment or obstruction. Gently clean the moving parts to remove dust or debris that may hinder smooth movement. Next, check the zoom mechanism, ensuring that it extends and retracts freely without resistance. If any stiffness is present, consider applying a small amount of lubricant designed for precision instruments.

Once these components are clean and free-moving, test the adjustments. Aim at a target with clear lines and details, and slowly adjust the focus to verify clarity. Repeat this process for the zoom, ensuring that the desired framing is achieved effortlessly. Consistent testing and adjustments are crucial to maintain the functionality and reliability of these vital features.

Reassembling the Lens Components

Reassembling optical elements after disassembly is a critical step in ensuring proper functionality and performance. This process requires careful attention to detail and a methodical approach to prevent any damage or misalignment.

Begin by organizing all components systematically, ensuring that each piece is free from dust and debris. Utilizing a clean, well-lit workspace can significantly enhance visibility and minimize errors. It’s essential to refer to a detailed guide or schematic to understand the correct order and orientation of each element.

Next, gently position the components, ensuring they fit snugly without excessive force. Check alignment frequently as you proceed, making adjustments as needed. Once all pieces are in place, secure them using the appropriate screws or fasteners, taking care not to overtighten and cause damage.

Finally, conduct a thorough inspection to confirm that everything is assembled correctly. A careful evaluation will help identify any potential issues before reinstallation, ensuring optimal performance of the optical device.

Testing Functionality Post-Repair

After servicing optical equipment, it is essential to verify its performance to ensure everything is functioning as intended. This assessment helps in identifying any issues that may have arisen during the maintenance process. The following steps provide a comprehensive approach to testing the equipment thoroughly.

Test Description Expected Outcome Focusing Accuracy Check if the device can focus correctly on different objects at varying distances. Sharp images at all distances Zoom Functionality Test the zoom mechanism to ensure it operates smoothly across the entire range. Fluid movement without sticking Image Quality Evaluate the clarity and color balance of photos taken at different apertures. No distortions or color shifts Auto-Focus Performance Assess the speed and accuracy of the auto-focus feature in various lighting conditions. Quick and precise focusing Stabilization Function Test any stabilization systems by capturing images in motion or low-light situations. Steady images with minimal blur By performing these evaluations, one can ensure that the optical device is functioning properly and meets expected standards for quality and usability. Regular assessments are vital for maintaining optimal performance over time.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of your photographic equipment. By following simple yet effective practices, you can ensure that your gear remains in optimal condition for years to come. Regular maintenance not only improves functionality but also prevents potential issues that may arise over time.

Regular Cleaning

Keeping your equipment clean is crucial. Dust and debris can accumulate and affect performance. Here are some tips:

- Use a soft brush or blower to remove dust.

- Wipe the exterior with a microfiber cloth.

- Check for moisture and avoid exposing your gear to extreme conditions.

Proper Storage

How you store your equipment can greatly influence its longevity. Consider these storage practices:

- Store in a dry, cool place away from direct sunlight.

- Use padded cases to protect against impacts.

- Remove batteries if the device will not be used for an extended period.

When to Seek Professional Help

There are instances when attempting to address issues with your optical equipment may not be the best approach. Understanding when to turn to an expert can save you time and potentially costly mistakes. Professional technicians possess the necessary skills and tools to handle complex situations that may arise during usage.

Signs Indicating Expert Assistance is Needed

Recognizing the warning signs that suggest a professional should be consulted is crucial for maintaining your device’s functionality. Common indicators include:

Indicator Description Persistent Malfunction If issues continue despite your attempts to fix them, it’s time to call in an expert. Physical Damage Visible cracks or misalignment can often require specialized tools to repair properly. Unusual Noises Strange sounds during operation may indicate internal problems that need immediate attention. Benefits of Consulting a Professional

Opting for a professional service can lead to improved performance and longevity of your equipment. Technicians can diagnose issues accurately and provide solutions that may not be apparent to the average user. In many cases, this proactive approach can prevent more significant problems down the line.