In the world of automotive engineering, understanding the intricacies of complex mechanical systems is essential for effective maintenance and performance enhancement. This section delves into the essential techniques and knowledge required for the thorough examination and revitalization of a specific type of automatic gear system, renowned for its robust design and widespread application.

Equipped with detailed insights and systematic procedures, this guide aims to empower enthusiasts and professionals alike. It will cover the vital components, common issues, and solutions that can restore functionality and extend the lifespan of the device. Through a methodical approach, readers will gain the confidence to tackle challenges and implement improvements effectively.

Whether you are a seasoned mechanic or an eager novice, this resource will provide valuable information that demystifies the complexities involved. By grasping the core principles and practices, you can enhance your skills and ensure optimal performance for the vehicles you work with.

Turbo 400 Transmission Overview

This section provides an insightful look into a highly regarded automatic shifting system known for its durability and performance. Designed for various vehicles, it combines advanced engineering with reliability, making it a popular choice among automotive enthusiasts and professionals alike.

The system features a robust design, incorporating multiple gears that allow for smooth transitions and optimal power delivery. Its construction is tailored to handle substantial torque, ensuring longevity even under demanding conditions. Maintaining this assembly is essential for maximizing efficiency and performance.

Understanding its components is crucial for anyone looking to enhance their knowledge or undertake service tasks. From the valve body to the pump, each part plays a significant role in the overall functionality, contributing to seamless operation. By familiarizing oneself with these elements, one can appreciate the intricacies that make this system a favored option in the automotive industry.

Common Issues with Turbo 400

When it comes to performance in high-powered vehicles, certain components can encounter frequent difficulties. Understanding these challenges is essential for maintaining efficiency and longevity. Below are some prevalent problems that can arise in these complex systems.

Fluid Leaks: One of the most common concerns is leakage of hydraulic fluid. This can lead to insufficient lubrication and overheating. Regular inspections can help identify cracks or worn seals that may be the culprits.

Slipping: Drivers may experience a sensation of slipping during acceleration. This occurs when the system fails to engage properly, often due to worn clutches or low fluid levels. Prompt attention is necessary to avoid further damage.

Shifting Issues: Difficulty in shifting gears is another frequent problem. Erratic or delayed gear changes can signal malfunctioning solenoids or a need for adjustment in the linkage. Timely diagnostics can prevent more severe complications.

No Engagement: In some instances, the mechanism may fail to engage at all. This can be caused by internal wear or electronic failures, requiring thorough examination to pinpoint the issue.

Overheating: Overheating can lead to significant damage. Insufficient cooling due to clogged filters or malfunctioning coolers can exacerbate this issue. Keeping the system well-maintained is crucial to avoid overheating.

Being aware of these potential issues can help owners take proactive measures to ensure optimal performance and durability in their vehicles.

Tools Needed for Repair

When undertaking the task of overhauling complex machinery, having the right equipment is crucial. The correct tools not only streamline the process but also ensure precision and safety. For an effective restoration, a well-organized workspace combined with essential instruments can make a significant difference.

Essential Hand Tools: A comprehensive set of hand tools is vital for disassembly and reassembly. Items such as wrenches, screwdrivers, and pliers are fundamental. Additionally, a torque wrench is necessary for applying the correct tension to fasteners.

Specialized Equipment: Depending on the complexity of the task, certain specialized devices may be required. These can include pullers for removing components and gauges for measuring clearances and tolerances accurately.

Cleaning Supplies: Maintaining cleanliness during the process is important. Cleaning agents, brushes, and lint-free cloths help ensure that all parts are free from debris and contaminants before reassembly.

Safety Gear: Always prioritize safety by using appropriate protective gear. This includes gloves, goggles, and a mask to shield against harmful substances and ensure a safe working environment.

Having these tools at hand will facilitate a smoother workflow, making the entire process more efficient and effective.

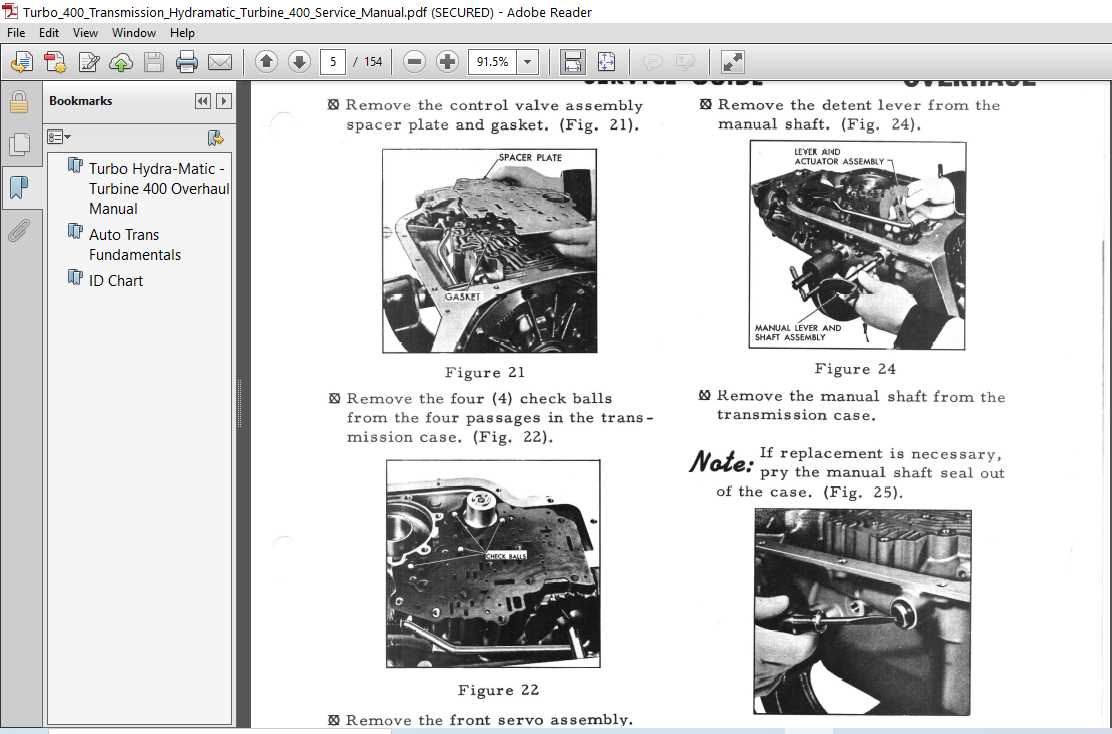

Step-by-Step Disassembly Process

This section outlines the detailed procedure for breaking down a complex assembly, ensuring each stage is approached with care to avoid damage and ensure a smooth reassembly. Following a systematic approach is essential for understanding the intricacies involved.

- Preparation:

- Gather necessary tools and workspace.

- Ensure a clean and organized environment.

- Initial Inspection:

- Check for visible signs of wear or damage.

- Document any irregularities for future reference.

- Remove External Components:

- Detach any external fittings and hoses.

- Take off covers and protective panels carefully.

- Disassemble Internal Parts:

- Begin with major sections, noting their arrangement.

- Carefully label and store all components.

- Final Review:

- Inspect each part for damage.

- Make notes for reassembly, focusing on order and orientation.

Completing this process methodically will facilitate a better understanding of the assembly’s functionality and enhance the effectiveness of any subsequent work.

Identifying Worn Components

Recognizing degraded parts is crucial for ensuring optimal performance in automotive systems. Over time, components can wear down due to friction, heat, and general use, leading to inefficiencies and potential failures. Early identification can save both time and resources in maintenance efforts.

Several signs indicate that components may be worn:

- Visual Inspection: Look for obvious signs such as cracks, fraying, or discoloration.

- Unusual Noises: Listen for grinding, whining, or clunking sounds that were not present before.

- Fluid Leaks: Check for any leaks, as they may suggest seals or gaskets are compromised.

- Inconsistent Performance: Noticeable changes in responsiveness or functionality can indicate issues.

To ensure a thorough evaluation, consider the following steps:

- Conduct a detailed visual assessment of all accessible components.

- Use diagnostic tools to measure performance metrics.

- Listen for irregular sounds during operation.

- Check for any abnormal fluid levels or colors.

Regular monitoring and timely intervention can help maintain the integrity of your automotive system, prolonging its lifespan and enhancing reliability.

Reassembly Best Practices

Reassembling complex mechanical components requires careful attention to detail and a systematic approach. Ensuring that each piece is correctly positioned and secured is crucial for optimal performance. Following best practices during this phase can prevent future issues and enhance the longevity of the assembly.

Before starting, gather all necessary tools and components in a clean workspace. Organizing parts and fasteners by type and size can save time and reduce the risk of misplacing essential items. It’s beneficial to refer to documentation or diagrams that outline the assembly sequence, allowing for a clear understanding of how each part fits together.

When reassembling, apply the recommended lubricants to moving parts to ensure smooth operation. Take care to avoid over-tightening fasteners, as this can lead to damage. Instead, follow torque specifications closely to maintain integrity. Additionally, utilizing a sequence for tightening can help evenly distribute pressure across components.

After assembly, double-check all connections and ensure that no tools or materials are left inside the unit. Conduct a thorough inspection to confirm that everything is aligned correctly. Testing the assembly under controlled conditions before full operation can help identify any potential issues early on.

Fluid Types and Specifications

Understanding the various liquids used in automotive systems is crucial for optimal performance and longevity. Each type of fluid serves specific functions, including lubrication, cooling, and hydraulic support. Selecting the appropriate liquid is vital to ensure smooth operation and prevent damage.

Types of Fluids

- Automatic Fluid: Designed for systems requiring hydraulic operation, providing necessary pressure and lubrication.

- Synthetic Fluid: Offers enhanced thermal stability and protection, often preferred for high-performance applications.

- Conventional Fluid: Typically derived from refined petroleum, suitable for standard use but may require more frequent changes.

Specifications to Consider

- Viscosity: The thickness of the fluid, impacting flow and temperature performance.

- Temperature Range: The operating temperatures at which the fluid remains effective, crucial for varying climates.

- Additive Packages: Chemicals included to enhance properties like wear resistance and oxidation stability.

Choosing the right liquid involves considering these specifications to match the system’s requirements, ensuring optimal functionality and durability.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your vehicle’s power delivery system requires a proactive approach to upkeep. Regular attention to various components can significantly enhance performance and prevent premature failures. Implementing simple maintenance practices can save time and money in the long run.

Regular Fluid Checks

One of the most critical aspects of maintenance involves routine inspections of the fluid levels. Ensure that the fluid is clean and at the appropriate level. Contaminated or low fluid can lead to overheating and increased wear. Consider replacing the fluid as recommended in your vehicle’s specifications to maintain optimal function.

Inspection of Components

Regularly examine the related parts for any signs of wear or damage. This includes checking seals, gaskets, and hoses for leaks. Addressing issues promptly can prevent larger problems down the line. Keep an eye on any unusual noises or performance changes, as these can indicate underlying issues that require immediate attention.

Performance Upgrades for Turbo 400

Enhancing the capabilities of your vehicle’s automatic gearbox can significantly improve overall performance and driving experience. By focusing on specific upgrades, you can achieve better responsiveness, durability, and power handling. Here are some effective modifications to consider for optimal results.

- Fluid Improvements:

- Upgrade to high-performance synthetic fluids to reduce friction and improve cooling.

- Consider adding a deep sump pan to increase fluid capacity and enhance cooling efficiency.

- Shift Kit Installation:

- Install a shift kit to improve shift timing and firmness, enhancing acceleration.

- Choose a kit that suits your driving style, whether for street use or racing applications.

- Clutch and Band Enhancements:

- Upgrade to high-performance clutches and bands to increase holding power and longevity.

- Ensure proper adjustment to maximize the benefits of these components.

- Converter Modifications:

- Consider a higher stall torque converter to improve acceleration and performance during take-off.

- Choose a converter that matches your engine’s power band for optimal results.

- Cooling System Enhancements:

- Install an auxiliary cooler to maintain optimal operating temperatures during heavy use.

- Ensure all cooling lines are in good condition to prevent leaks and maintain efficiency.

By implementing these enhancements, you can transform your vehicle’s performance, making it more responsive and capable of handling increased power. Always consult with a professional to ensure compatibility and proper installation for the best results.

Troubleshooting After Repair

After completing the overhaul of your vehicle’s shifting mechanism, it’s crucial to ensure everything functions as intended. Addressing issues promptly can prevent further complications and ensure longevity. This section will guide you through common problems and their solutions to help maintain optimal performance.

Common Issues to Look For

- Fluid Leaks: Check for any signs of leakage around seals and gaskets.

- Unusual Noises: Listen for grinding, whining, or clunking sounds that may indicate internal problems.

- Shifting Difficulties: Pay attention to any hesitation or slipping during gear changes.

- Overheating: Monitor temperature levels; excessive heat can indicate a problem.

Steps to Diagnose

- Inspect the fluid level and condition; ensure it is clean and filled to the appropriate level.

- Examine all connections for tightness and integrity.

- Test the operation under different driving conditions to identify inconsistencies.

- Utilize diagnostic tools to check for error codes if applicable.

Following these guidelines will help you identify and resolve any issues that may arise post-overhaul, ensuring a smooth driving experience.