In today’s world, having a reliable source of portable energy is essential for a variety of situations, from outdoor adventures to emergency preparedness. Ensuring that your device operates at peak efficiency not only enhances its performance but also prolongs its lifespan. This section aims to provide you with valuable insights and guidance to keep your equipment in optimal condition.

Whether you’re dealing with minor issues or looking to perform regular maintenance, understanding the intricacies of your power unit can save you time and resources. By familiarizing yourself with the inner workings and potential challenges, you can tackle problems confidently and effectively. This knowledge empowers you to make informed decisions and maintain a dependable energy source for all your needs.

From troubleshooting common malfunctions to executing basic upkeep tasks, this guide will equip you with the necessary tools and techniques. Embracing a proactive approach to care will not only enhance functionality but also ensure that your energy solution is ready whenever you need it. Dive into the details and take charge of your portable power experience!

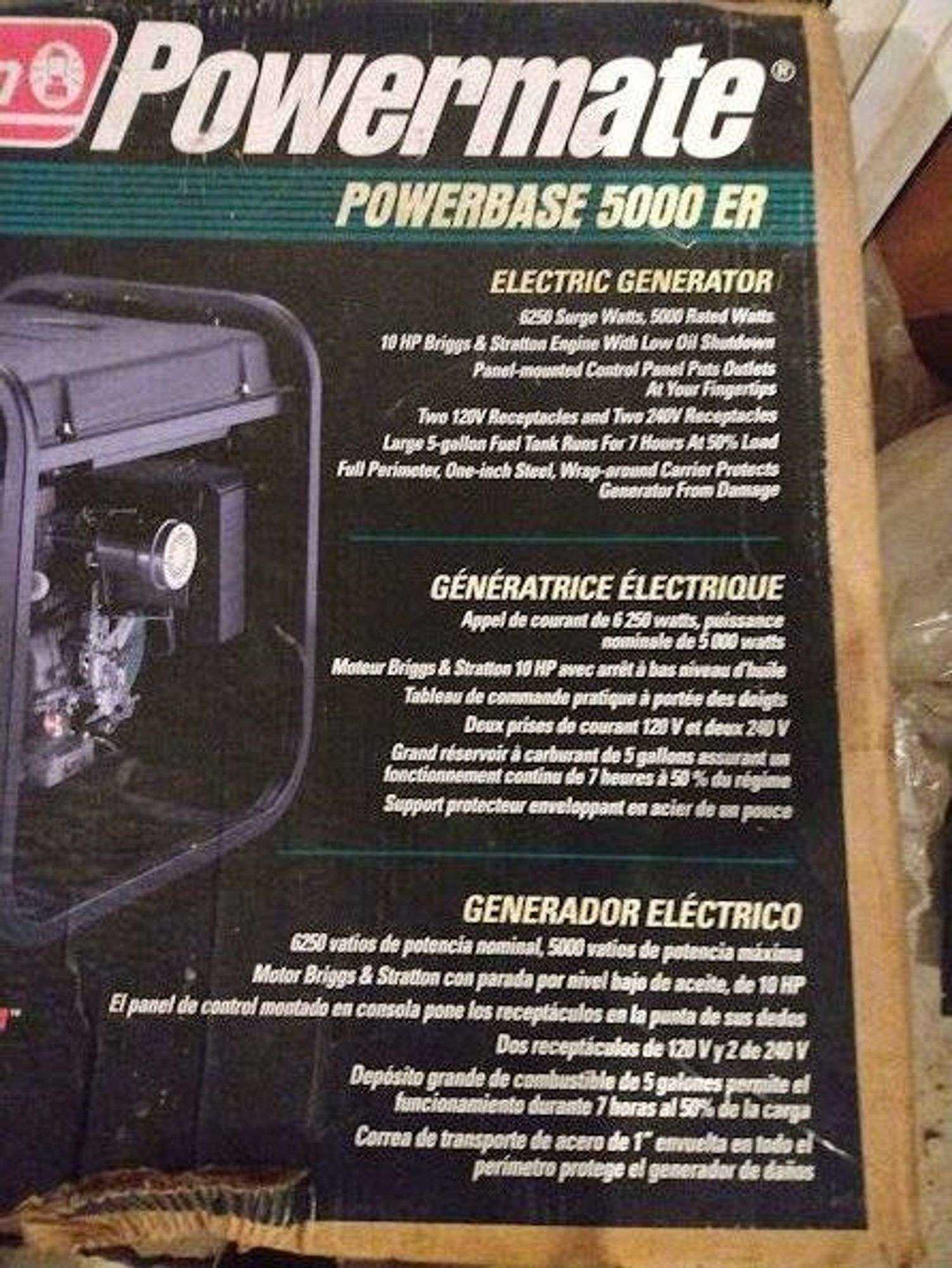

Coleman Powermate 5000 Overview

This section provides a comprehensive introduction to a reliable power solution designed for versatility and efficiency. Engineered for various applications, it serves as a dependable source of electricity, catering to both residential and commercial needs. Understanding its features and functionality is essential for maximizing its potential.

With a robust design, this model is built to withstand the rigors of outdoor use while ensuring a steady output of energy. Users will appreciate its ease of operation and maintenance, making it suitable for both novices and experienced individuals alike. The compact structure enhances portability, allowing for convenient transportation to different locations.

Equipped with advanced safety mechanisms, this unit prioritizes user protection without compromising performance. Its fuel efficiency stands out, ensuring that users can operate it for extended periods without frequent refueling. Overall, this power source exemplifies a blend of reliability, durability, and practicality.

Common Issues with the Generator

When operating a power-producing machine, users may encounter a variety of challenges that can affect performance and reliability. Recognizing these common problems can help in troubleshooting and ensuring efficient operation.

Engine Starting Difficulties

One of the most frequent issues faced by operators is the inability to start the engine. This can stem from various factors such as fuel delivery problems, battery issues, or ignition system failures. Regular maintenance and inspection of these components can help prevent such inconveniences.

Power Output Fluctuations

Another common concern is inconsistent power delivery. Users may notice fluctuations in voltage or frequency, which can disrupt the operation of connected devices. This issue may arise from load imbalances, worn-out parts, or electrical connections that require attention.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Starting Problems | Poor fuel flow, dead battery, faulty ignition | Check fuel lines, replace battery, inspect ignition |

| Power Fluctuations | Load imbalances, worn components, loose connections | Distribute load evenly, replace parts, tighten connections |

| Excessive Noise | Loose parts, engine wear, exhaust issues | Tighten components, conduct maintenance, check exhaust |

| Overheating | Insufficient cooling, dirty air filters, low oil levels | Clean filters, check oil levels, inspect cooling system |

Essential Tools for Repairs

When it comes to maintaining and fixing portable power devices, having the right tools on hand is crucial. The following items not only enhance efficiency but also ensure safety during the maintenance process. A well-equipped toolbox can make a significant difference in the quality of your work.

Basic Hand Tools

- Screwdrivers: A set of flathead and Phillips screwdrivers in various sizes.

- Wrenches: Adjustable and socket wrenches for loosening and tightening bolts.

- Pliers: Needle-nose and regular pliers for gripping and bending wires.

- Utility Knife: For cutting through insulation and other materials.

Specialized Tools

- Multimeter: Essential for testing voltage, current, and resistance.

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

- Oil Filter Wrench: Useful for removing and replacing oil filters easily.

- Fuel Line Clamp: Prevents fuel spillage during maintenance tasks.

Equipping yourself with these essential tools can lead to successful maintenance projects, prolonging the life of your equipment and enhancing its performance.

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to diagnosing and resolving common issues associated with portable power units. By following these steps, users can efficiently identify problems and implement solutions to restore functionality.

-

Initial Inspection

- Check for visible damage or loose components.

- Ensure that all connections are secure.

- Inspect the fuel level and quality.

-

Electrical Components

- Examine the battery for charge and corrosion.

- Test fuses and circuit breakers for continuity.

- Inspect wiring for wear or short circuits.

-

Fuel System

- Ensure that the fuel is fresh and appropriate for the unit.

- Inspect the fuel lines for leaks or blockages.

- Clean or replace the fuel filter if necessary.

-

Air Filter and Exhaust

- Check the air filter for dirt and debris.

- Clean or replace the air filter as needed.

- Inspect the exhaust system for blockages.

-

Starting Mechanism

- Ensure the choke is set correctly.

- Test the pull start or electric start functionality.

- Listen for unusual sounds when attempting to start.

By systematically following these steps, users can effectively troubleshoot and resolve issues, ensuring optimal performance of their power unit.

Replacing the Spark Plug

One of the essential maintenance tasks for ensuring optimal performance in your equipment is the replacement of the spark plug. Over time, these components can wear out, leading to issues such as difficulty starting or poor fuel efficiency. Regularly checking and replacing the spark plug is vital for keeping the engine running smoothly and efficiently.

To begin, ensure that the machine is turned off and cool. Locate the spark plug, which is typically situated on the engine’s cylinder head. Using a spark plug wrench, carefully remove the old plug by turning it counterclockwise. Inspect the old plug for signs of wear or damage, such as carbon buildup or cracks, which may indicate the need for replacement.

Next, take the new spark plug and check its gap using a feeler gauge to ensure it matches the manufacturer’s specifications. This is crucial for proper ignition. Once confirmed, insert the new plug into the socket and tighten it securely, taking care not to overtighten, as this can damage the threads.

Finally, reconnect any wires that were removed during the process. After replacing the spark plug, start the engine to ensure it runs smoothly. Regular maintenance, including spark plug replacement, will enhance the longevity and reliability of your equipment.

Fuel System Maintenance Tips

Proper upkeep of the fuel system is essential for ensuring optimal performance and longevity of your outdoor equipment. Regular attention to this critical component helps prevent issues such as clogs, leaks, and inefficient operation. Here are some key practices to keep your fuel system in top condition.

Regular Inspection

- Check fuel lines for cracks or leaks.

- Inspect the fuel filter and replace it if it’s clogged or dirty.

- Look for any signs of corrosion or damage on connectors and fittings.

Fuel Quality Management

- Use fresh fuel to prevent degradation and the formation of harmful deposits.

- Avoid mixing old fuel with new; dispose of stale fuel properly.

- Consider using fuel stabilizers to prolong shelf life, especially during storage.

By following these guidelines, you can enhance the reliability and efficiency of your equipment, ensuring it runs smoothly when you need it most.

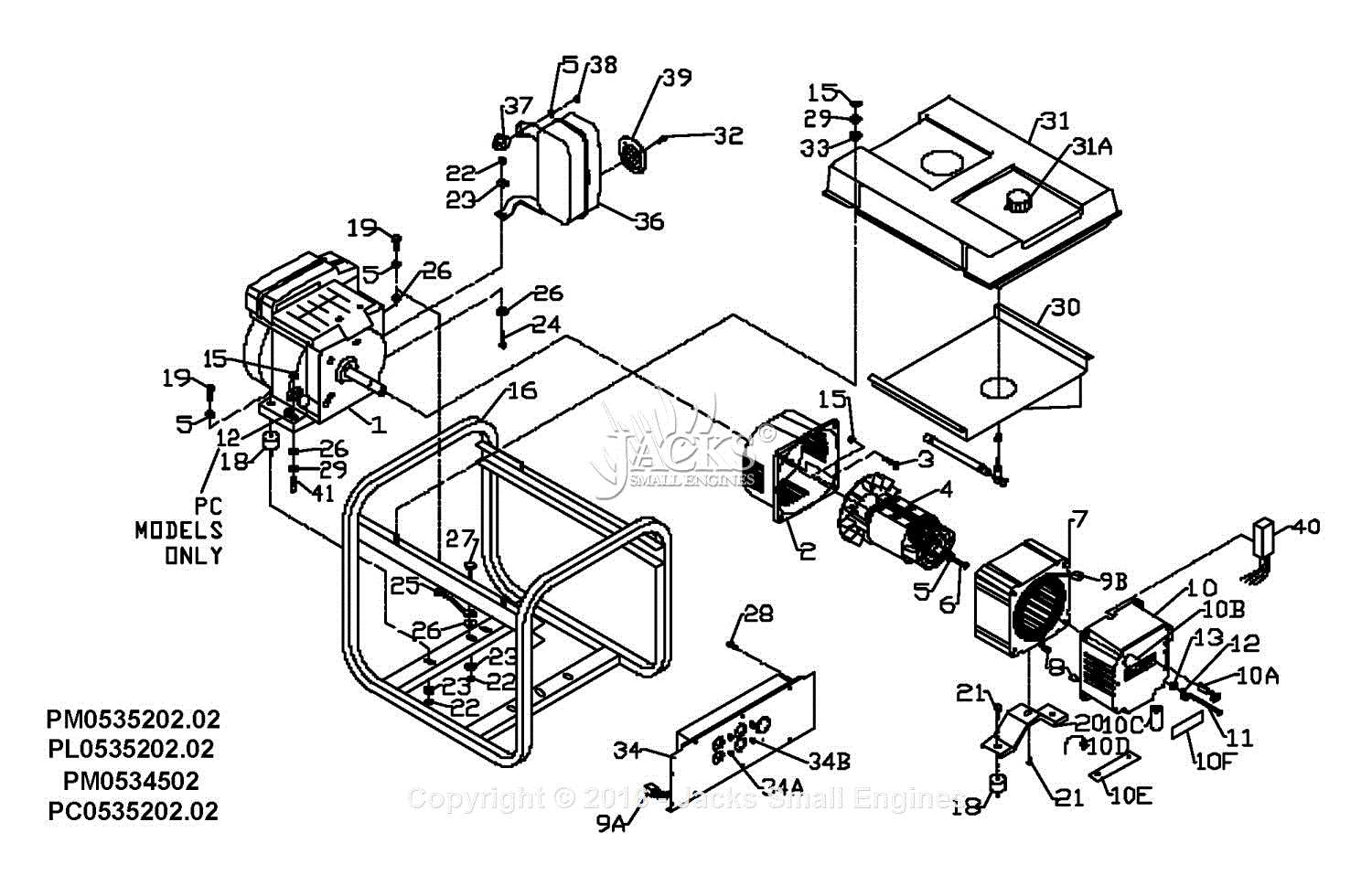

Electrical Component Diagnostics

Diagnosing electrical components is crucial for maintaining optimal performance and ensuring safety in any power-generating apparatus. This process involves identifying faults, verifying functionality, and assessing the integrity of various parts to prevent operational failures.

Common Electrical Issues

- Faulty wiring connections

- Defective circuit breakers

- Worn-out fuses

- Malfunctioning ignition systems

- Inconsistent voltage output

Diagnostic Steps

- Inspect wiring for signs of damage or corrosion.

- Test continuity using a multimeter.

- Check voltage levels at various points.

- Examine connectors and terminals for secure fits.

- Replace any faulty components identified during testing.

Oil Change Procedures Explained

Maintaining optimal performance of your machine requires regular oil changes. This essential task ensures the internal components remain well-lubricated, preventing wear and tear and extending the lifespan of the equipment. Following a systematic approach will help you perform this procedure effectively and safely.

Preparation Steps

Before starting the oil change, gather the necessary tools and materials:

- Fresh oil appropriate for your model

- Oil filter (if applicable)

- Wrench or socket set

- Oil catch pan

- Funnel

- Rags for cleanup

- Protective gloves and eyewear

Procedure Steps

- Ensure the unit is turned off and has cooled down.

- Locate the oil drain plug, typically found at the bottom of the engine.

- Position the oil catch pan beneath the drain plug.

- Remove the drain plug carefully and allow the old oil to drain completely into the pan.

- If replacing the oil filter, remove it using the wrench and install the new filter.

- Once drained, replace the drain plug securely.

- Using the funnel, pour the fresh oil into the designated fill port. Refer to the owner’s manual for the correct oil type and amount.

- Check the oil level using the dipstick, adding more oil if necessary.

- Start the machine and let it run for a few minutes, checking for leaks around the drain plug and filter.

- Dispose of the old oil and filter responsibly, following local regulations.

Regular oil changes are crucial for maintaining the efficiency and reliability of your machinery. By adhering to these steps, you can ensure that your equipment remains in optimal condition.

Safety Precautions During Repair

Ensuring safety is paramount when engaging in maintenance tasks involving machinery. Proper precautions help prevent accidents, injuries, and damage to the equipment. Familiarizing oneself with essential safety guidelines is crucial for anyone undertaking such activities.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes safety goggles to protect the eyes from debris, gloves to prevent cuts and abrasions, and sturdy footwear to guard against heavy objects. Additionally, using hearing protection can be beneficial when working with loud machinery.

Work Environment Considerations

Maintaining a clean and organized workspace is vital for safety. Ensure that the area is well-lit and free from clutter. Keep flammable materials away from the work zone, and ensure proper ventilation if working in enclosed spaces. Always have a fire extinguisher nearby and be aware of emergency procedures.

Frequently Asked Questions

This section addresses common inquiries that users may have regarding the maintenance and troubleshooting of portable energy sources. Here, you will find essential information that can help resolve typical issues and enhance your understanding of proper usage.

What should I do if my unit won’t start?

If your device fails to start, check the fuel levels, ensure the ignition switch is in the correct position, and inspect the battery. Additionally, verify that all connections are secure and that there are no obstructions in the air intake or exhaust.

How often should I perform maintenance?

Regular maintenance is crucial for optimal performance. It is generally recommended to conduct a thorough inspection and servicing every 100 hours of use or at least once a year, whichever comes first.

What type of fuel is recommended?

Most portable power sources operate best with unleaded gasoline. However, it is essential to consult the specifications to confirm the appropriate fuel type for your specific model.

Can I run my equipment during a rainstorm?

It is advisable to avoid operating your device in wet conditions to prevent electrical hazards. If operation in adverse weather is necessary, use appropriate protective measures to shield the equipment from moisture.

What are the signs of a failing component?

Common indicators include unusual noises, frequent stalling, or difficulty starting. If you notice these symptoms, it may be time to check specific parts or seek professional assistance.

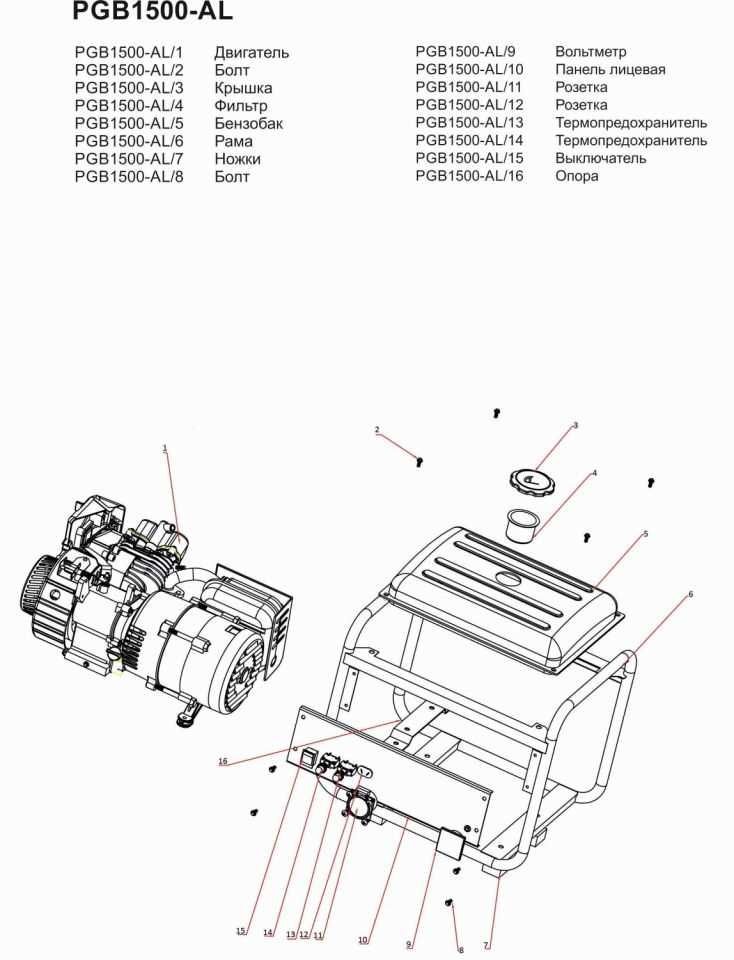

Where to Find Replacement Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Whether you need to replace worn-out items or upgrade existing ones, several sources can help you locate the necessary parts. Here are some effective options to consider:

- Online Retailers: Many e-commerce platforms specialize in outdoor equipment and parts. Search for specific models to find compatible items.

- Manufacturer’s Website: Visiting the official site often provides direct access to parts catalogs, manuals, and purchase options.

- Local Hardware Stores: Many stores carry a range of replacement parts for various machines. Speak with staff for assistance in finding what you need.

- Specialty Shops: Look for shops that focus specifically on outdoor or power equipment. They often have knowledgeable staff and a broad selection of parts.

- Second-Hand Marketplaces: Websites and apps that facilitate second-hand sales can be a treasure trove for hard-to-find components at lower prices.

- Forums and Online Communities: Engaging with enthusiasts and experts in online groups can lead to recommendations for where to find specific items.

By exploring these avenues, you can ensure that your equipment remains in optimal condition with the right replacements.

Preventative Maintenance Best Practices

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By adhering to a structured maintenance routine, you can identify potential issues before they escalate, thus minimizing downtime and costly repairs. This section outlines key strategies to keep your machinery in peak condition.

Routine Inspections

Conducting frequent assessments of your equipment can help detect wear and tear early on. Pay attention to components that experience high levels of stress, such as belts and filters. Regular checks will allow you to maintain functionality and safety.

Fluid Management

Monitoring and changing fluids is critical for the efficient operation of machinery. Ensure that oil, fuel, and coolant levels are consistently checked and replaced as necessary. Clean fluids help in reducing friction and preventing overheating.

| Task | Frequency | Notes |

|---|---|---|

| Inspect belts and hoses | Monthly | Look for cracks or wear |

| Change oil | Every 50 hours | Use recommended oil type |

| Check fuel filters | Every 100 hours | Replace if clogged |

| Clean air filter | Every 25 hours | Ensure proper airflow |