In the world of timekeeping, maintaining the functionality of intricate mechanisms is essential for ensuring accuracy and longevity. This guide provides insights into the essential practices for upkeep and rejuvenation of sophisticated timepieces, allowing enthusiasts and collectors to preserve the artistry and craftsmanship inherent in these mechanical wonders.

Understanding the internal workings and potential issues that can arise is crucial for anyone involved in the stewardship of such devices. This resource aims to demystify the processes involved in enhancing performance, tackling common challenges, and performing necessary adjustments to maintain the integrity of these cherished items.

Whether you are a seasoned collector or a newcomer eager to explore the nuances of mechanical timekeeping, this guide offers valuable tips and techniques. From routine checks to troubleshooting, the information herein will empower you to undertake tasks with confidence and precision, safeguarding the beauty and function of your treasured possessions.

Understanding Hermle Clocks

The intricate craftsmanship of timekeeping devices has fascinated enthusiasts for centuries. These remarkable mechanisms combine artistry with precision engineering, resulting in instruments that not only serve practical purposes but also add elegance to any environment. By exploring the key elements and features of these devices, one can gain a deeper appreciation for their functionality and design.

History and Craftsmanship

With origins dating back to the late 20th century, these creations have evolved significantly. The skilled artisans who design and assemble them incorporate traditional techniques alongside modern technology. This blend ensures each piece is not only reliable but also visually appealing, often becoming cherished heirlooms passed down through generations.

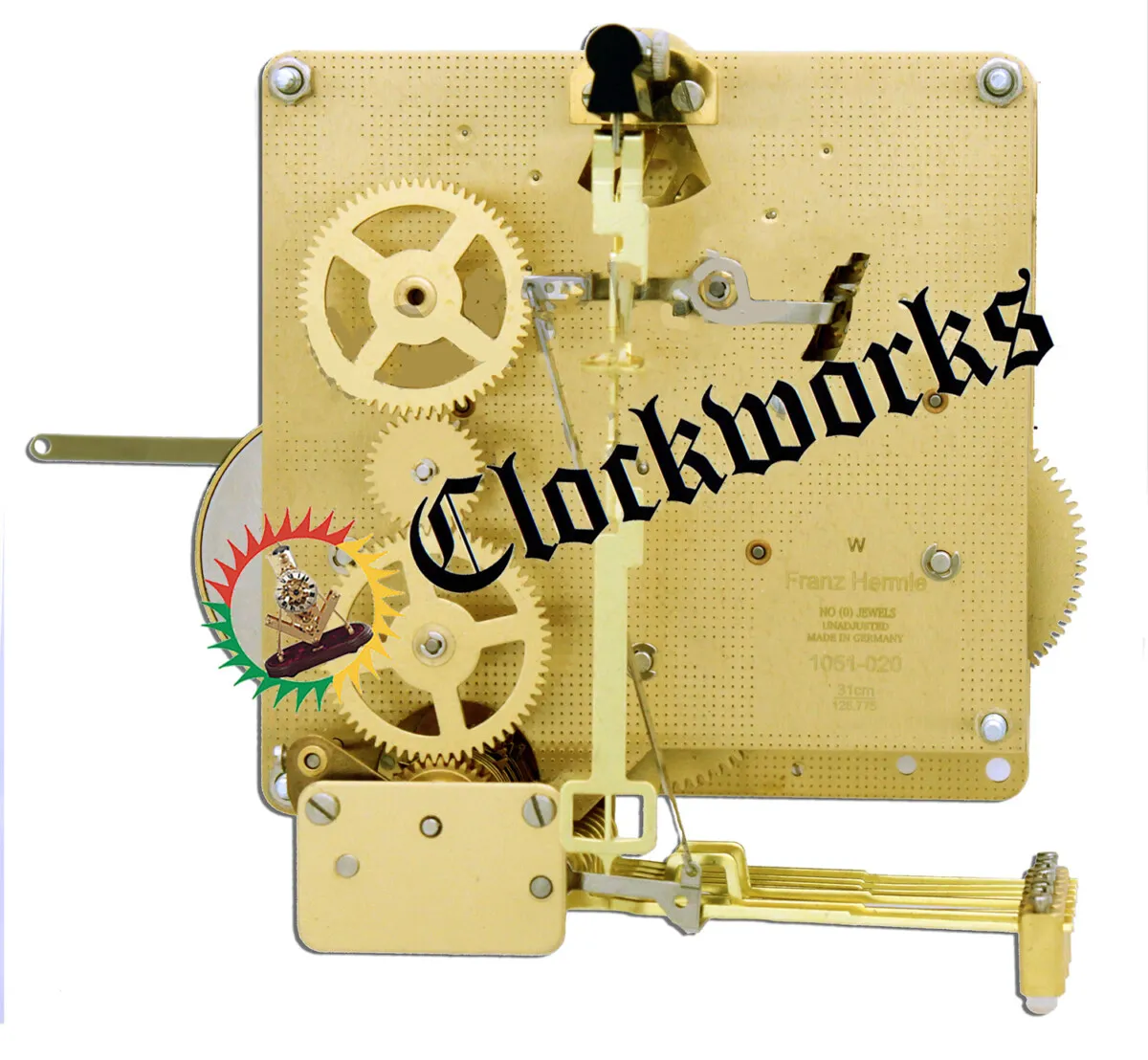

Mechanisms and Functionality

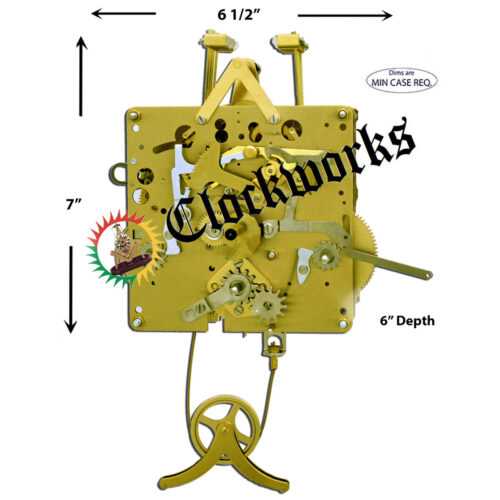

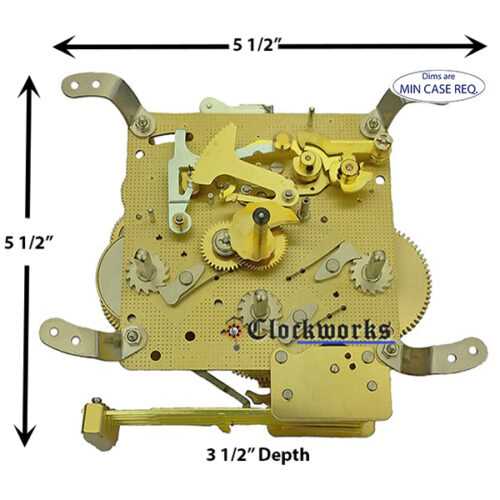

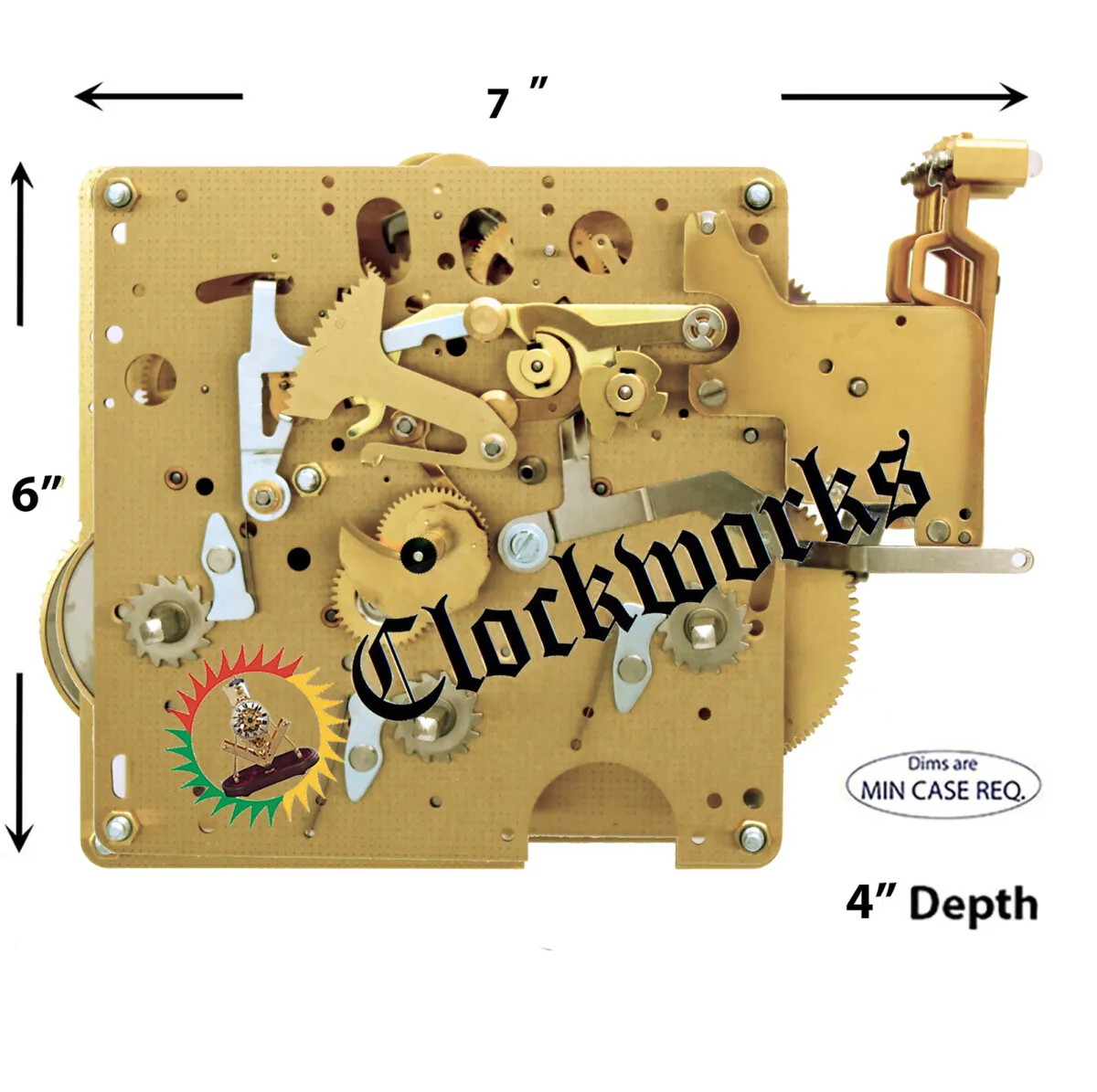

At the heart of every timepiece lies a complex mechanism that governs its operation. These intricate systems, often powered by weights or springs, rely on precise gear arrangements to maintain accurate time. Understanding the basic principles of how these mechanisms function can enhance one’s ability to troubleshoot issues and perform essential maintenance when necessary.

Common Issues with Hermle Timepieces

Timepieces are intricate mechanisms that can encounter various challenges over time. Understanding these common problems can help enthusiasts maintain their treasured items in optimal condition. This section highlights typical issues faced by these exquisite timekeepers, offering insights into potential causes and solutions.

| Issue | Description | Potential Solutions |

|---|---|---|

| Accuracy Problems | Inconsistent timekeeping can lead to significant deviations from the correct time. | Regularly check and adjust the pendulum length, ensuring proper weight distribution. |

| Ticking Noises | Unusual ticking sounds may indicate misalignment or lack of lubrication within the mechanism. | Carefully inspect the movement, applying appropriate lubricant to reduce friction. |

| Sticking Mechanism | When the gears or pendulum do not move freely, it can halt the entire function of the timepiece. | Disassemble the movement, clean all components, and reassemble them with care. |

| Cosmetic Wear | Surface scratches or discoloration can detract from the overall appearance. | Utilize polishing compounds designed for metals and woods to restore the finish. |

| Power Issues | Problems with the winding mechanism can lead to inconsistent power supply. | Inspect the mainspring and winding mechanism for wear and replace if necessary. |

Essential Tools for Clock Maintenance

Proper upkeep of timekeeping instruments requires a variety of specialized implements. These tools not only facilitate routine checks but also assist in addressing minor issues that may arise over time. Having the right equipment on hand is crucial for ensuring longevity and accuracy.

- Screwdrivers: A set of precision screwdrivers is essential for accessing various components. Both flathead and Phillips types are necessary for different types of fasteners.

- Wrenches: Adjustable wrenches can help secure or loosen nuts and bolts, making it easier to adjust mechanical parts.

- Pliers: Needle-nose pliers are particularly useful for gripping small components and wires in tight spaces.

- Cleaning Supplies: Soft brushes and lint-free cloths are vital for dusting and cleaning delicate mechanisms without causing damage.

- Lubricants: Appropriate oils and greases are important for reducing friction in moving parts, ensuring smooth operation.

- Magnifying Glass: A magnifying tool aids in inspecting intricate details and identifying potential issues that are difficult to see with the naked eye.

Having these essential tools readily available can significantly enhance the maintenance process, allowing for efficient adjustments and prolonging the lifespan of intricate timepieces.

Disassembling Hermle Clock Mechanisms

The process of taking apart intricate timekeeping devices requires careful attention and methodical techniques. Each component must be handled with precision to avoid damage while ensuring a thorough understanding of the internal workings. This section outlines the steps involved in effectively disassembling such mechanisms, facilitating maintenance and restoration tasks.

Preparation and Tools

Before beginning the disassembly, it is essential to gather the necessary tools. Standard items include screwdrivers of various sizes, pliers, and a soft cloth to protect delicate surfaces. Organizing a workspace is also vital; having a clean and well-lit area will help in managing small parts and components. Ensure that you have a suitable container for storing screws and other small pieces to prevent loss during the process.

Step-by-Step Disassembly

Begin by removing the outer casing, typically secured with screws or clips. Carefully lift it away to expose the internal assembly. Proceed to detach the movement from its housing by loosening any securing screws. Take note of the positioning of each part as you remove them, as this will assist during reassembly. Documenting the process with photographs can also provide a helpful reference. Continue disassembling components systematically, ensuring to handle fragile parts, such as gears and springs, with care to prevent bending or breakage.

Repairing Movement Malfunctions

Addressing issues within the mechanisms of timekeeping devices requires a systematic approach to identify and correct operational failures. Common symptoms often include irregular ticking, sudden halts, or inaccurate timekeeping. Understanding the underlying causes is essential for restoring proper function.

Below are typical movement malfunctions and suggested solutions:

| Malfunction | Possible Cause | Recommended Action |

|---|---|---|

| Irregular Ticking | Dirty gears or lack of lubrication | Clean and lubricate the movement components |

| Device Stops | Obstruction or damaged components | Inspect for blockages and replace any damaged parts |

| Timekeeping Errors | Misaligned gears or faulty escapement | Realign gears and assess the escapement mechanism |

| Noise During Operation | Worn-out bearings or components | Replace worn parts and ensure proper assembly |

Consistent maintenance and timely intervention can significantly extend the life of these intricate mechanisms. Always ensure to follow best practices when addressing these issues to maintain optimal performance.

Replacing Clock Components Effectively

Maintaining the functionality of timekeeping devices often requires the replacement of various elements. Understanding the procedure and best practices for this task can significantly enhance the longevity and performance of these intricate mechanisms. This section focuses on the efficient techniques for swapping out parts, ensuring optimal results and minimal disruption.

Essential Tools for Component Replacement

Before embarking on the replacement process, it is crucial to gather the necessary tools. The right equipment will facilitate a smoother transition and help prevent damage to delicate parts. Consider including the following:

- Screwdrivers (various sizes)

- Pliers

- Tweezers

- Lubricant

- Cotton swabs

- Replacement parts

Step-by-Step Replacement Process

Follow these guidelines to ensure a successful component exchange:

- Disassemble Carefully: Begin by gently removing the outer casing to expose the inner workings. Take note of each screw and its location.

- Identify Faulty Parts: Inspect the components thoroughly to determine which elements require replacement.

- Remove Damaged Parts: Using appropriate tools, carefully detach the malfunctioning components without causing damage to surrounding elements.

- Install New Parts: Position the new components in their designated spots, ensuring a secure fit. Apply lubricant to moving parts if necessary.

- Reassemble: Once all replacements are in place, carefully reattach the casing and tighten all screws.

- Test Functionality: After reassembly, check the device’s performance to confirm that the replacements are functioning as intended.

Following these steps will enhance the efficiency of the replacement process, ultimately leading to improved performance and longevity of the timekeeping mechanism.

Lubrication Techniques for Smooth Operation

Proper lubrication is essential for ensuring the seamless functioning of precision mechanisms. A well-executed lubrication routine not only enhances the efficiency of moving parts but also extends the lifespan of the entire system. Understanding the various methods and materials used for lubrication is crucial for maintaining optimal performance.

Types of Lubricants

There are several types of lubricants available, each designed for specific applications. Oils are commonly used for their ability to penetrate tight spaces and reduce friction between moving components. Greases, on the other hand, provide longer-lasting protection due to their thicker consistency, making them ideal for areas subject to higher loads. Choosing the right type of lubricant is vital for achieving the desired level of performance.

Application Techniques

Applying lubricant effectively requires attention to detail. It is essential to ensure that the lubricant reaches all necessary areas without over-application, which can lead to buildup and attract dust. Using a precision applicator allows for targeted delivery, minimizing waste. Additionally, performing regular inspections can help determine when reapplication is necessary, keeping the mechanism in peak condition.

Calibrating Time Accuracy

Ensuring precise timekeeping is essential for any timepiece. Achieving optimal performance involves careful adjustments and monitoring. The process of calibration enhances the reliability of the mechanism and helps maintain its functionality over the years.

To effectively calibrate time accuracy, follow these steps:

- Initial Assessment: Examine the current timekeeping status. Note any discrepancies in the time displayed compared to a reliable reference.

- Identify Adjustment Points: Familiarize yourself with the adjustment mechanisms. These may include gears, weights, or pendulums, depending on the specific type.

- Make Adjustments: Carefully modify the components to correct timekeeping. For instance, altering the position of the pendulum or adjusting the tension of a spring can impact accuracy.

- Monitor Performance: After adjustments, observe the timepiece over a specified period. Record any variations and further refine as needed.

- Final Calibration: Once the desired accuracy is achieved, finalize the calibration by securing all components to prevent any future shifts.

Regular maintenance and periodic calibration are crucial to sustaining the reliability of your timepiece. By adhering to these guidelines, one can enjoy consistent and accurate timekeeping for years to come.

Caring for Clock Cases and Glass

Maintaining the exterior elements of timepieces is essential for preserving their beauty and functionality. A well-cared-for case not only enhances the visual appeal but also protects the intricate mechanisms within. Regular attention to these surfaces can prevent damage and ensure longevity.

To keep the housing in optimal condition, it is crucial to dust regularly using a soft, lint-free cloth. This practice helps remove dust particles that can accumulate over time, potentially causing scratches or dulling the finish. For deeper cleaning, a slightly damp cloth with a mild detergent can be employed, followed by thorough drying to avoid moisture retention.

Glass components should be treated with equal care. Using a glass cleaner and a microfiber cloth, one can effectively eliminate fingerprints and smudges without leaving streaks. Avoid harsh chemicals that may scratch or damage the surface. Regular polishing will maintain clarity, allowing the intricate interior to be admired fully.

Protection from direct sunlight is also vital, as prolonged exposure can lead to fading or discoloration of the materials. Consider placing the timepiece in a location that minimizes exposure to harsh light. By following these guidelines, the exterior elements will remain stunning, reflecting the craftsmanship that lies within.

Preserving Antique Hermle Clocks

Maintaining the integrity of vintage timepieces requires a deep understanding of their unique characteristics and materials. These treasured artifacts reflect history and craftsmanship, making their preservation essential for future generations. Proper care can extend their lifespan and ensure they remain functional while retaining their aesthetic appeal.

Environmental Considerations

To protect these delicate instruments, it’s crucial to keep them in a stable environment. Fluctuations in temperature and humidity can cause damage to the internal mechanisms and outer finishes. Ideal conditions include a cool, dry space away from direct sunlight and drafts. Regularly monitoring these factors can help prevent deterioration.

Routine Maintenance Practices

Implementing a consistent maintenance schedule is vital. Dusting the exterior with a soft cloth helps preserve the finish, while periodic inspections of the internal components can identify potential issues early on. Engaging a professional for thorough evaluations and necessary adjustments ensures optimal performance and longevity of these exquisite artifacts.

Finding Replacement Parts

Locating suitable components for your timepiece can be a challenging task. However, understanding where to search and what to look for can greatly enhance your experience. Quality parts are essential for maintaining functionality and aesthetic appeal, ensuring your treasured piece continues to operate smoothly.

Online Resources

The internet offers a vast array of platforms dedicated to providing components for various mechanisms. Here are some effective ways to utilize online resources:

- Visit specialized websites that focus on horology and provide a selection of parts.

- Explore online marketplaces where both new and used components are available.

- Join forums or community groups where enthusiasts share their knowledge and resources.

Local Shops and Experts

Sometimes, personal interaction can yield better results. Consider these options for local sourcing:

- Search for antique shops or specialty stores that may carry a selection of parts.

- Consult with local artisans who specialize in mechanical devices; they often have valuable insights and may offer repair services as well.

- Attend local fairs or exhibitions focused on timepieces, as vendors often display parts for sale.

By exploring both online and local avenues, you can enhance your chances of finding the right components to keep your beloved mechanism in prime condition.

Consulting Professional Repair Services

When faced with intricate mechanical issues, seeking expertise from qualified professionals can be beneficial. These skilled individuals possess the necessary training and experience to address problems effectively, ensuring that your timekeeping device remains in optimal condition. Engaging with specialists not only guarantees high-quality workmanship but also provides peace of mind, knowing that your item is in capable hands.

Benefits of Professional Consultation

Engaging experts in the field can yield numerous advantages. Firstly, they are equipped with specialized tools and techniques tailored for precise diagnostics. Secondly, their extensive knowledge allows for accurate identification of issues, which can prevent potential future complications. Furthermore, entrusting your item to professionals can extend its longevity, preserving its functionality and aesthetic appeal.

Factors to Consider When Choosing Professionals

Selecting the right expert is crucial for achieving satisfactory outcomes. Here are essential aspects to consider:

| Criteria | Description |

|---|---|

| Experience | Look for technicians with a proven track record in handling similar mechanisms. |

| Reputation | Research customer reviews and testimonials to gauge the quality of service. |

| Certifications | Verify that the professionals hold relevant qualifications and certifications. |

| Warranty | Inquire about warranties on repairs to e |