Maintaining small power units is crucial for ensuring their longevity and optimal performance. This section delves into the intricacies of upkeep and troubleshooting, providing valuable insights for users aiming to enhance their mechanical knowledge. Understanding the inner workings of your equipment can significantly extend its lifespan and improve efficiency.

From basic care techniques to more intricate solutions, this guide covers a wide range of topics relevant to those who operate such machines. Readers will find step-by-step instructions designed to facilitate a deeper understanding of common issues, enabling confident and effective handling of challenges that may arise during use. The emphasis is on practical solutions that can be applied with minimal prior experience.

Equipped with the right information, users can take proactive measures to address potential problems before they escalate. This resource serves as a companion for anyone looking to dive into the world of engine maintenance, offering clarity and support every step of the way.

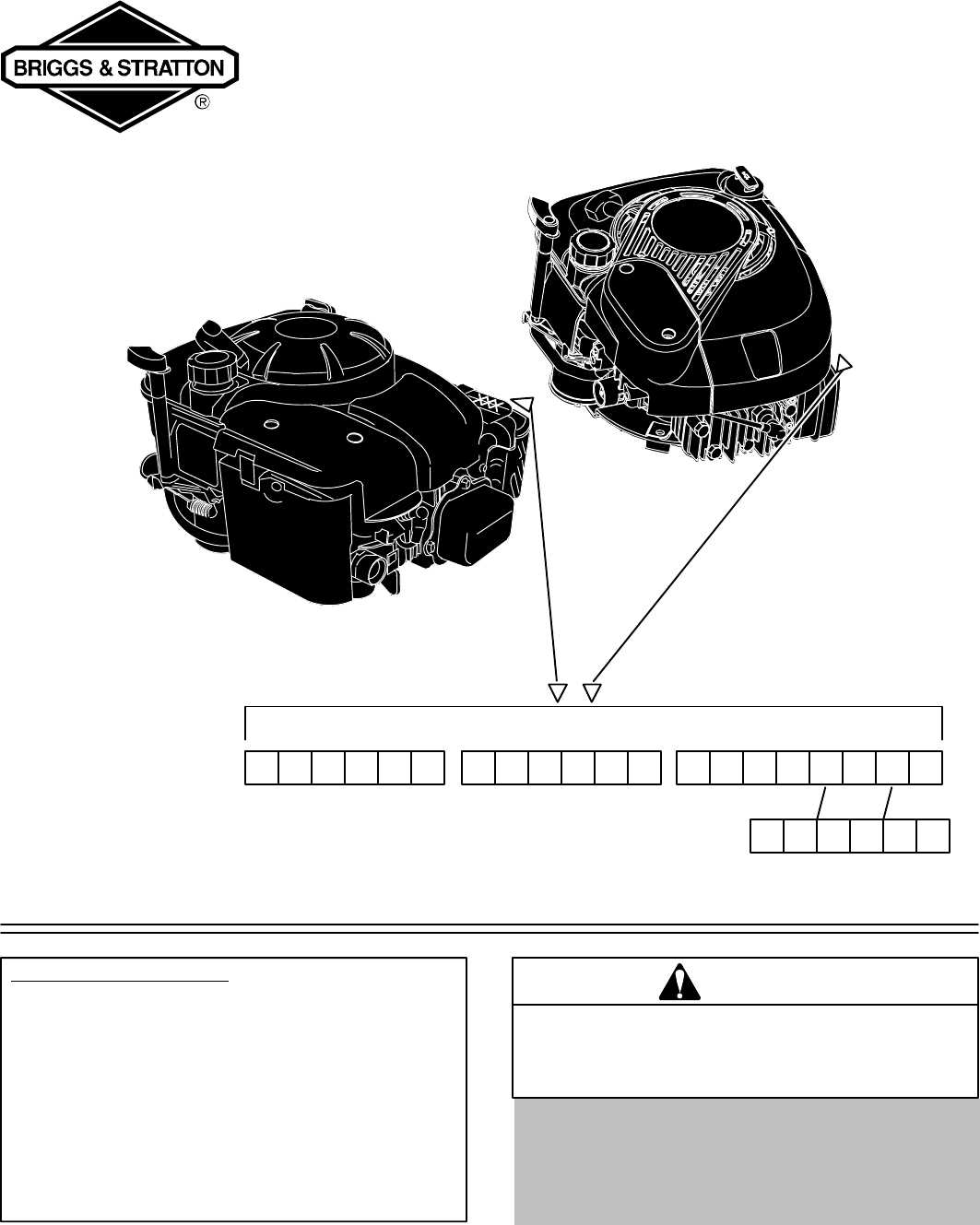

Understanding Briggs and Stratton 450 Series

This section delves into the key features and functionalities of a popular engine model known for its reliability and efficiency. Designed for various applications, it serves as a dependable power source for outdoor equipment. A comprehensive understanding of its components, operation, and maintenance will enhance performance and longevity.

Key specifications and characteristics are essential for effective operation. Below is a table summarizing important details about this engine model:

| Feature | Description |

|---|---|

| Cylinder Displacement | Provides adequate power for small machinery. |

| Power Output | Delivers consistent energy for efficient functioning. |

| Fuel Type | Utilizes readily available gasoline for convenience. |

| Cooling System | Equipped with air cooling to maintain optimal temperatures. |

| Starting Mechanism | Features an easy-to-use recoil starter for quick ignition. |

Familiarity with these elements is crucial for optimal usage and troubleshooting. Regular maintenance checks can significantly prolong the lifespan of the engine, ensuring it operates smoothly for years to come.

Common Issues with 148cc Engines

Engines in the 148cc category can encounter a variety of challenges that may hinder their performance. Understanding these common problems can help users maintain their equipment effectively and ensure optimal operation.

- Starting Difficulties: Many users experience trouble when attempting to start their engines. This can stem from:

- Weak battery

- Clogged fuel lines

- Defective ignition components

- Overheating: Overheating can lead to severe damage if not addressed. Causes may include:

- Insufficient oil levels

- Blocked cooling fins

- Faulty cooling system

- Fuel Issues: Problems with fuel can significantly affect engine performance. Common fuel-related concerns are:

- Contaminated fuel

- Improper fuel mixture

- Old or stale fuel

- Excessive Vibration: Excessive shaking can indicate underlying issues such as:

- Loose components

- Imbalanced blades or attachments

- Worn engine mounts

- Oil Leaks: Leaking oil can pose serious problems. Common sources of leaks include:

- Worn gaskets

- Damaged seals

- Punctured oil pans

lessCopy code

Being aware of these potential issues allows users to take preventive measures and address problems promptly, ensuring the longevity and reliability of their engines.

Essential Tools for Effective Repairs

Having the right instruments at hand is crucial for successful maintenance tasks. Whether addressing minor adjustments or significant overhauls, the effectiveness of your work greatly depends on the tools you utilize. Below are key items that should be part of every toolkit for optimal performance.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, ensures you can tackle different fasteners with ease.

- Wrenches: Both adjustable and fixed types are necessary for loosening or tightening bolts securely.

- Pliers: Needle-nose and standard pliers are indispensable for gripping and manipulating small parts.

- Socket Set: A comprehensive socket set will enable you to work on a wide range of nuts and bolts efficiently.

- Torque Wrench: This tool is essential for applying the correct amount of force to fasteners, preventing damage.

- Multimeter: Ideal for diagnosing electrical issues, helping you identify problems quickly.

- Cleaning Supplies: Brushes, cloths, and solvents are necessary for maintaining cleanliness and functionality.

- Protective Gear: Safety glasses, gloves, and ear protection ensure you remain safe while working.

By equipping yourself with these fundamental tools, you’ll be well-prepared to handle various maintenance tasks effectively and efficiently.

Step-by-Step Maintenance Guidelines

Regular upkeep of your small engine equipment is essential to ensure optimal performance and longevity. Following a structured maintenance routine can prevent issues and enhance efficiency, making your tasks easier and more enjoyable.

1. Routine Inspections

Start by performing frequent checks on the engine. Look for signs of wear, loose connections, or any leaks. Ensure that the air filter is clean, as a clogged filter can impede airflow and reduce power output.

2. Oil Change

Changing the lubricant is a critical task that should be done regularly. Always consult the owner’s guide for the recommended oil type and change intervals. To begin, ensure the engine is cool, then drain the old oil and refill with fresh lubricant, making sure to check the level with the dipstick.

Additionally, replace the oil filter if applicable, to maintain the engine’s cleanliness and efficiency.

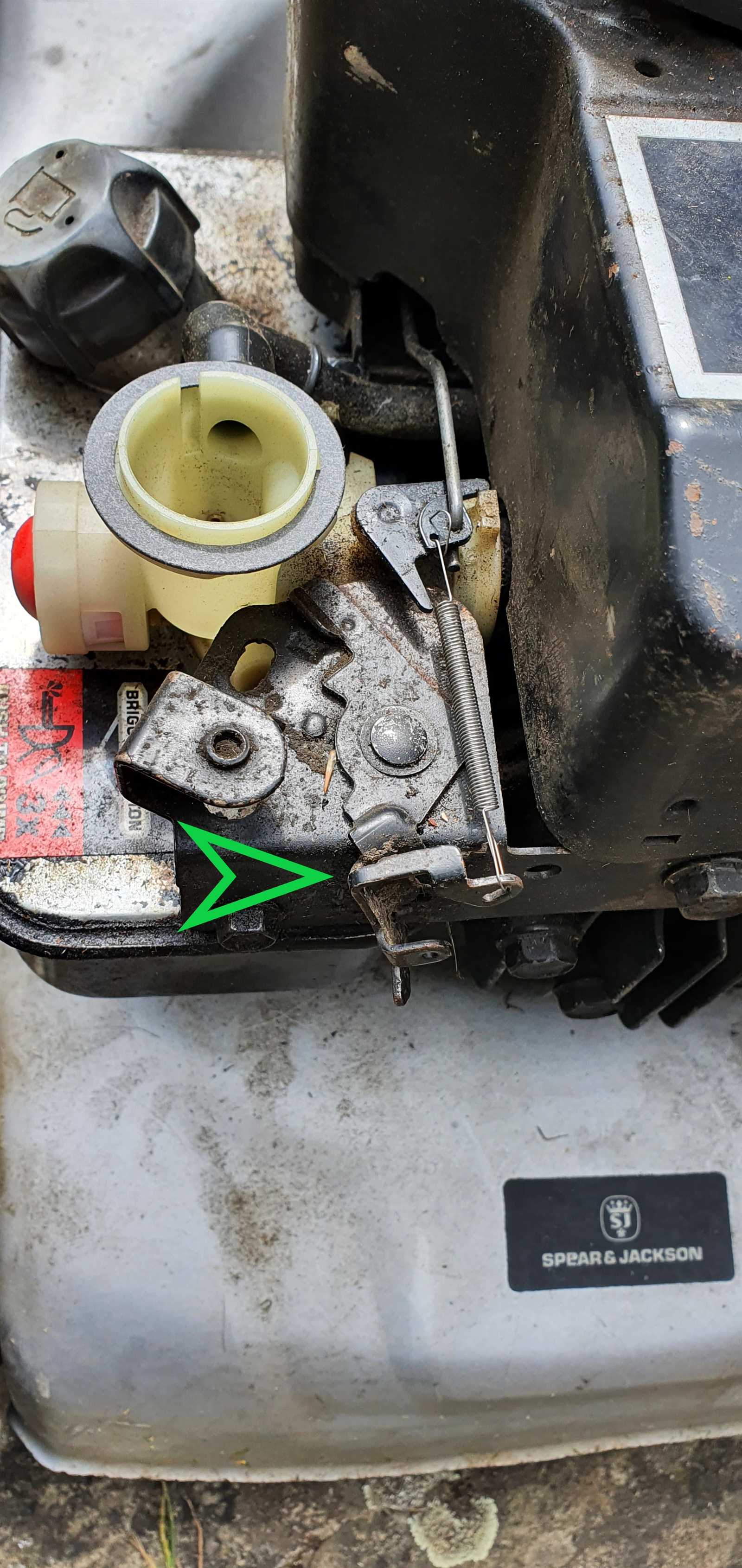

Diagnosing Engine Performance Problems

Identifying issues related to engine functionality can be a complex task, requiring careful observation and methodical analysis. By understanding common symptoms and employing systematic troubleshooting techniques, one can effectively determine the root cause of performance deficiencies.

Key indicators of engine trouble may include:

- Difficulty starting

- Inefficient power output

- Unusual noises

- Excessive vibration

- Overheating

To systematically diagnose these performance issues, consider the following steps:

- Visual Inspection: Begin with a thorough visual check for leaks, loose connections, or damaged components.

- Check Fuel Quality: Ensure that the fuel is fresh and free from contaminants.

- Examine Air Filters: Dirty or clogged filters can restrict airflow, leading to poor combustion.

- Inspect Spark Plug: A worn or fouled spark plug can hinder ignition, affecting overall performance.

- Test Compression: Low compression can indicate internal issues; using a compression gauge can provide valuable insight.

By following these diagnostic steps, one can narrow down potential problems and take appropriate corrective measures, ultimately enhancing engine performance and longevity.

How to Change Oil Properly

Regular maintenance of your equipment includes proper oil changes to ensure optimal performance and longevity. This process is essential for keeping the engine lubricated and functioning smoothly. Here’s a step-by-step guide to help you complete this task efficiently.

Required Tools and Materials

Before starting, gather the following tools and materials:

| Item | Purpose |

|---|---|

| Oil drain pan | To collect used oil |

| Wrench | For loosening the drain plug |

| Funnel | To pour new oil without spills |

| New oil | To replace the old oil |

| Rags | For cleaning any spills |

Steps to Change Oil

Follow these steps for a successful oil change:

- Ensure the equipment is off and cool to prevent burns.

- Locate the oil drain plug and position the drain pan underneath.

- Using the wrench, carefully remove the drain plug and allow the old oil to flow into the pan.

- Once drained, replace the drain plug and tighten securely.

- Using the funnel, pour the new oil into the designated fill area.

- Check the oil level with the dipstick to ensure it’s within the recommended range.

- Dispose of the used oil properly at a recycling center.

By following these steps, you’ll ensure that your engine runs smoothly and efficiently, reducing the risk of damage and extending its lifespan.

Replacing Spark Plugs Explained

Changing out the ignition components is crucial for maintaining optimal performance in small engines. This process can enhance efficiency and ensure reliable starting. Regular inspections will help identify when a replacement is necessary, thus preventing potential issues down the line.

When replacing these components, it’s essential to follow specific steps to avoid complications. Here’s a straightforward guide to facilitate this task:

| Step | Description |

|---|---|

| 1 | Ensure the engine is cool and disconnect the spark plug wire to avoid accidental starts. |

| 2 | Using a socket wrench, carefully unscrew the old plug from the engine. |

| 3 | Inspect the old plug for wear or damage to understand the engine’s condition. |

| 4 | Compare the old plug with the new one to ensure compatibility before installation. |

| 5 | Hand-tighten the new plug into place, then secure it with a wrench, ensuring not to over-tighten. |

| 6 | Reattach the spark plug wire, ensuring a snug connection. |

By following these steps, you can maintain the efficiency and reliability of your equipment, ensuring smooth operation for years to come.

Fuel System Cleaning Procedures

Maintaining the fuel system is essential for optimal performance and longevity of small engines. Over time, contaminants and deposits can accumulate, leading to decreased efficiency and potential operational issues. Regular cleaning helps ensure proper fuel flow and combustion, ultimately enhancing the functionality of the engine.

Step-by-Step Cleaning Process

Begin by disconnecting the spark plug to prevent accidental starts. Drain the fuel tank completely, then remove the fuel filter and any accessible hoses. Use a suitable cleaning solvent to flush the tank and filter, ensuring all residues are eliminated. Clean the fuel lines with compressed air or a specialized cleaning tool to remove any blockages.

Final Checks and Reassembly

After cleaning, inspect all components for wear or damage, replacing any parts as necessary. Reassemble the system in reverse order, ensuring all connections are secure. Refill the tank with fresh fuel, reconnect the spark plug, and perform a test run to verify that the system operates smoothly.

Safety Precautions During Repairs

When undertaking maintenance tasks on outdoor equipment, ensuring safety is paramount. Proper precautions help prevent accidents and injuries, creating a secure environment for both the individual performing the work and those nearby. Following essential guidelines not only protects physical well-being but also enhances the effectiveness of the task at hand.

Before starting any work, it is crucial to equip oneself with the right protective gear. This includes items such as gloves, goggles, and sturdy footwear. Familiarizing oneself with the equipment’s specifications and understanding the risks involved can further mitigate potential hazards.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use gloves, goggles, and appropriate footwear to shield against injuries. |

| Work in a Well-Ventilated Area | Ensure adequate airflow to avoid inhalation of harmful fumes. |

| Disconnect Power Sources | Always unplug or remove batteries before beginning maintenance to prevent accidental starts. |

| Keep Work Area Clean | A tidy workspace reduces the risk of slips, trips, and falls. |

| Use the Right Tools | Select appropriate tools for the job to avoid injuries and equipment damage. |

By adhering to these guidelines, individuals can ensure a safer working experience, allowing for efficient and effective maintenance activities. Taking time to prioritize safety ultimately leads to better outcomes and fewer mishaps during servicing tasks.

Upgrading Components for Better Performance

Enhancing the efficiency of small engines can significantly improve their functionality and longevity. By focusing on specific elements, users can achieve noticeable gains in power and fuel efficiency. This section explores various upgrades that can be implemented to elevate performance levels.

When considering modifications, it is essential to prioritize components that directly influence engine output. Below is a table summarizing some common upgrades and their benefits:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Air Filter | High-Performance Filter | Increased airflow, improved combustion |

| Exhaust System | Performance Muffler | Reduced back pressure, enhanced power |

| Spark Plug | Iridium Plug | Better ignition, smoother operation |

| Carburetor | Upgraded Carburetor | Improved fuel atomization, increased responsiveness |

| Cylinder Head | Porting and Polishing | Optimized airflow, enhanced torque |

Implementing these upgrades can lead to improved performance characteristics, making the equipment more reliable and enjoyable to use. Always ensure that modifications align with specific requirements and operational standards for best results.

Where to Find Replacement Parts

Locating suitable components for maintenance or repairs can greatly enhance the longevity and performance of your equipment. Understanding the various sources available for procuring these parts will ensure you find exactly what you need to keep your machinery running smoothly.

Online Retailers

The internet offers a plethora of options for purchasing replacement items. Numerous e-commerce websites specialize in outdoor equipment and tools, making it convenient to compare prices and read reviews.

| Website | Specialty | Link |

|---|---|---|

| Amazon | General Parts | Visit |

| eBay | Used and New Items | Visit |

| Home Depot | Home Improvement | Visit |

Local Retail Outlets

If you prefer a hands-on approach, visiting local shops can be beneficial. These outlets often have knowledgeable staff who can assist in identifying the correct components and may offer installation services.

| Store Name | Type of Parts | Location |

|---|---|---|

| ACE Hardware | General Supplies | Various Locations |

| Tractor Supply Co. | Agricultural and Outdoor | Various Locations |

| Walmart | Affordable Options | Various Locations |