When it comes to the longevity and efficiency of your vehicle, understanding the intricacies of its transmission system is crucial. This essential component plays a vital role in transferring power from the engine to the wheels, ensuring a smooth and responsive driving experience. Regular upkeep and knowledge of potential issues can significantly enhance performance and prevent costly repairs down the road.

In this comprehensive guide, we will delve into the nuances of servicing and troubleshooting the automatic transmission system. By familiarizing yourself with the mechanisms and common problems, you can empower yourself to maintain optimal functionality and extend the life of your vehicle’s drivetrain.

From understanding fluid characteristics to recognizing warning signs of malfunction, this resource will equip you with the necessary insights and practical steps. Whether you’re a seasoned mechanic or a curious car owner, this information will be invaluable in navigating the complexities of transmission care.

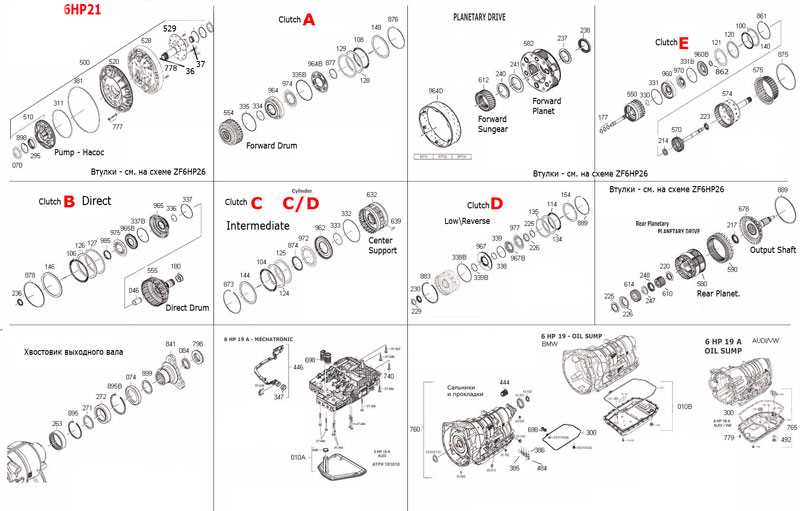

Understanding the ZF 5HP19 Transmission

The ZF transmission system represents a sophisticated engineering solution designed for seamless power transfer in modern vehicles. This unit operates with a blend of hydraulic and electronic controls, ensuring smooth gear shifts and optimal performance under varying driving conditions. Its design incorporates advanced technology that enhances fuel efficiency while maintaining driving comfort.

This particular transmission features a combination of five forward gears and a reverse gear, offering a wide range of ratios to suit different driving scenarios. The incorporation of an adaptive control strategy allows the system to learn driver behavior, optimizing gear selection for a personalized driving experience. As a result, this unit is known for its reliability and durability in diverse automotive applications.

Understanding the intricacies of this transmission is crucial for maintenance and troubleshooting. Key components include the valve body, torque converter, and electronic control unit, each playing a vital role in the overall functionality. Familiarity with these elements can significantly aid in diagnosing issues and ensuring the longevity of the transmission.

In summary, the ZF transmission is a prime example of modern automotive engineering, offering a harmonious balance between performance, efficiency, and user satisfaction. Recognizing its operational principles and components is essential for anyone involved in vehicle maintenance or performance enhancement.

Common Issues with ZF 5HP19

The automatic transmission system is a critical component in many vehicles, and like any complex machinery, it can encounter various problems over time. Understanding these potential issues is essential for maintenance and longevity. Below are some of the most frequently reported complications associated with this transmission type.

Frequent Problems

- Shifting Delays: Many users experience hesitations during gear changes, which can indicate underlying issues.

- Fluid Leaks: Leaks from seals and gaskets can lead to inadequate lubrication and overheating.

- Rough Engagement: Rough or harsh shifting can be a sign of worn components or low fluid levels.

- Warning Lights: Dashboard alerts may illuminate, signaling the need for immediate attention to prevent further damage.

Maintenance Tips

- Regularly check and replace the transmission fluid to ensure optimal performance.

- Inspect seals and gaskets periodically to prevent leaks.

- Address any warning lights promptly to avoid escalating issues.

- Consider professional diagnostics if unusual behavior is observed.

Tools Needed for Repairs

When tackling mechanical issues, having the right instruments is essential for a successful outcome. This section outlines the various equipment that will aid in diagnosing and fixing problems effectively. Each tool plays a critical role in ensuring precision and safety throughout the process.

Essential Hand Tools

Basic hand tools form the foundation of any repair endeavor. A set of wrenches, screwdrivers, and pliers will be indispensable. Additionally, a torque wrench is crucial for applying the correct amount of force to fasteners, preventing damage or improper assembly. Consider also having a hammer and a utility knife handy for various tasks.

Diagnostic Instruments

To accurately identify issues, diagnostic tools are invaluable. An OBD-II scanner can provide insights into electronic systems, while a multimeter helps in assessing electrical components. Fluid pressure gauges and temperature sensors are also useful for evaluating performance under different conditions.

Step-by-Step Disassembly Process

Disassembling a complex assembly requires careful planning and methodical execution. This section outlines a systematic approach to separating components, ensuring that each step is clear and manageable. By following these instructions, you’ll be able to understand the structure and functionality of the unit, making the process more efficient and less prone to errors.

Begin by gathering the necessary tools and creating a clean workspace. Ensure that all components are easily accessible and that you have a designated area for small parts. Start with the exterior, removing any covers or shields that obstruct access to internal mechanisms. Take note of how each part is attached, whether through screws, clips, or other fasteners.

Once the outer casing is removed, proceed to detach the internal sections. Work methodically, taking care to label or document the order of disassembly. This will be invaluable during reassembly. Pay close attention to wiring and connections, carefully disconnecting them to avoid damage. If applicable, remove fluid reservoirs or other interchangeable components first, as they can simplify access to the main assembly.

As you continue, focus on one subsystem at a time. This will help maintain organization and clarity. Utilize a magnetic tray or small containers to keep screws and fasteners sorted. If any components appear particularly stubborn, apply a penetrating lubricant to ease removal without risking breakage.

Finally, after all parts are detached, conduct a visual inspection to identify any wear or damage. Document any findings to assist in future assembly or repairs. Following this structured approach will ensure a successful disassembly experience, paving the way for further evaluation or refurbishment.

Identifying Worn Components

Recognizing deteriorated parts is crucial for maintaining optimal performance in automotive systems. Early detection can prevent further damage and costly repairs. This section will guide you through common indicators and methods for identifying these compromised components.

To effectively assess the condition of various elements, consider the following signs of wear:

- Unusual Noises: Grinding, whining, or clunking sounds during operation may suggest wear in gears or bearings.

- Fluid Leaks: Spots of fluid beneath the vehicle can indicate seal or gasket failure.

- Slipping or Hesitation: A noticeable delay in response when accelerating may point to problems in transmission engagement.

Utilizing specific diagnostic techniques can further aid in the identification process:

- Visual Inspection: Regularly examine components for signs of damage, discoloration, or deformation.

- Operational Testing: Conduct tests under various conditions to observe performance anomalies.

- Measurement Tools: Use calipers and gauges to check for tolerances and deviations from specifications.

By being vigilant and employing these strategies, you can extend the lifespan of critical parts and ensure the system operates smoothly.

Reassembly Techniques for Success

Successfully reassembling complex mechanical systems requires a strategic approach and attention to detail. Ensuring that each component is correctly positioned and secured is crucial for optimal performance. Here are some key techniques to enhance your reassembly process.

- Organize Components: Before starting, lay out all parts systematically. Group similar items together to streamline the process.

- Refer to Documentation: Use available resources, such as diagrams and specifications, to understand the correct order and orientation of parts.

- Clean Surfaces: Ensure all mating surfaces are free of debris and contaminants to promote proper sealing and function.

- Use Appropriate Tools: Select the right tools for the job. This can prevent damage to components and enhance assembly efficiency.

Following a systematic approach will help mitigate errors and improve the longevity of the system. Consider these additional steps:

- Take Notes: Document your process as you disassemble to make reassembly intuitive.

- Apply Lubrication: Use appropriate lubricants on moving parts to ensure smooth operation.

- Double-Check Alignment: Regularly verify that components are aligned correctly before securing them in place.

- Test After Assembly: Conduct thorough testing to confirm that everything functions as intended.

By implementing these techniques, you will increase the likelihood of achieving a successful and efficient assembly, leading to a well-functioning system.

Fluid Replacement and Maintenance Tips

Maintaining the optimal condition of your vehicle’s transmission fluid is essential for ensuring smooth operation and longevity. Regular checks and timely replacements can prevent unnecessary wear and enhance performance. Here are some key strategies to keep in mind.

- Check Fluid Levels Regularly: Make it a habit to inspect fluid levels frequently. Low fluid can lead to overheating and increased friction.

- Monitor Fluid Condition: Pay attention to the color and smell of the fluid. A burnt odor or dark color indicates the need for a change.

- Follow Manufacturer Guidelines: Always refer to the specifications provided by the vehicle manufacturer regarding fluid type and replacement intervals.

When it’s time to replace the fluid, consider the following steps:

- Gather Necessary Tools: Ensure you have the right tools, including a drain pan, funnel, and the appropriate fluid.

- Drain Old Fluid: Safely drain the old fluid from the transmission, making sure to capture it in a suitable container.

- Replace Filters: If applicable, change the transmission filters to prevent contaminants from mixing with the new fluid.

- Add New Fluid: Carefully add the new transmission fluid, following the recommended procedures for your specific vehicle.

In addition to fluid replacement, regular maintenance practices can further extend the lifespan of your transmission:

- Perform Regular Inspections: Look for leaks, unusual noises, or performance issues that may indicate a problem.

- Schedule Professional Services: Consider having a professional technician inspect and service the transmission periodically.

- Drive Responsibly: Avoid aggressive driving habits, as they can increase wear and tear on transmission components.

Testing the Transmission Post-Repair

After addressing the issues within the gear system, it is essential to evaluate its performance to ensure everything is functioning as expected. This process involves a series of checks and tests to confirm that the unit operates smoothly and reliably under various conditions.

Initial Inspection

Begin with a thorough visual examination of the assembly. Look for any signs of leakage, loose connections, or misalignments that could indicate improper installation or unresolved issues. Ensure all components are secure and correctly positioned.

Fluid Level Check

Verify that the fluid level is appropriate, as this is crucial for optimal operation. The transmission should be filled to the manufacturer’s specifications, as insufficient fluid can lead to inadequate lubrication and overheating.

Performance Testing

Conduct a series of test drives under varying conditions. Pay close attention to shifting patterns, responsiveness, and any unusual noises. A smooth transition between gears is vital; any hesitation or abrupt changes may suggest further underlying problems.

Diagnostic Scan

Utilize a diagnostic tool to check for any fault codes that might not be apparent during manual inspection. This step helps identify electronic issues that could affect performance, allowing for timely adjustments if necessary.

Heat Management

Monitor the temperature of the transmission during operation. Overheating can indicate inadequate fluid circulation or a malfunctioning cooler. Maintaining appropriate temperatures is essential for longevity and performance.

Final Evaluation

After completing the tests, compile your findings to determine if the unit meets the required standards. Any discrepancies should be addressed promptly to avoid future complications, ensuring a reliable and efficient driving experience.

Common Missteps to Avoid

When tackling complex mechanical tasks, it is crucial to steer clear of frequent errors that can lead to significant setbacks. Understanding these pitfalls not only saves time but also enhances the overall success of the undertaking. Being aware of common misjudgments can prevent unnecessary complications and ensure a smoother process.

Neglecting Preliminary Research

One of the most prevalent mistakes is failing to conduct thorough research before beginning the task. Knowledge of the system and its intricacies is essential. Without this understanding, individuals may overlook critical steps, resulting in complications that could have been easily avoided. Invest time in learning about the components and potential challenges to streamline the process.

Ignoring Proper Tools and Techniques

Another significant error is the use of inadequate tools or improper methods. Employing the right equipment is vital for achieving optimal results. Using substandard tools can not only hinder progress but also damage components. Always ensure that you have the necessary tools and follow recommended techniques to maintain efficiency and protect the integrity of the system.

Upgrades and Performance Enhancements

Improving the efficiency and responsiveness of automatic transmissions can significantly enhance the overall driving experience. Various modifications and optimizations can be implemented to boost performance, making vehicles more agile and enjoyable to drive. These upgrades often focus on enhancing fluid dynamics, improving component durability, and refining electronic control systems.

Transmission Fluid and Filters

One of the simplest yet most effective upgrades involves the use of high-quality transmission fluid and filters. Specialized fluids can provide better lubrication and heat resistance, leading to smoother shifting and prolonged component life. Regular replacement of filters ensures that contaminants do not impede performance, maintaining optimal operation.

Electronic Tuning and Shift Kits

Integrating electronic tuning can result in noticeable improvements in shift quality and speed. Custom tuning can adjust the transmission’s shift points and firmness, leading to a more responsive driving experience. Additionally, installing shift kits can modify the internal components to enhance precision and reduce shift times, further elevating overall performance.

Cost Considerations for Repairs

When addressing issues related to automotive transmission systems, understanding the financial implications is crucial. Expenses can vary widely based on multiple factors, including parts, labor, and the extent of the work required. Evaluating these elements helps in making informed decisions that can impact overall vehicle maintenance budgets.

Here are some key factors influencing costs:

| Factor | Description |

|---|---|

| Parts Quality | Choosing between original equipment manufacturer (OEM) and aftermarket components can significantly affect the total expenditure. |

| Labor Rates | Labor costs vary by location and shop, influencing the final price for services rendered. |

| Severity of Issue | Minor adjustments may cost less compared to major overhauls, impacting budget planning. |

| Diagnostic Fees | Initial assessments may incur costs, which should be factored into the overall expenditure. |

By carefully analyzing these considerations, vehicle owners can better anticipate the financial requirements associated with maintaining their transmission systems. Making strategic choices can lead to more efficient budgeting and potentially lower costs over time.

Resources for Further Learning

Enhancing your knowledge in automotive technology can be both rewarding and essential for anyone interested in vehicle maintenance and diagnostics. Accessing the right materials can significantly aid in understanding complex systems and their functions. Below are several valuable resources that can provide deeper insights and practical skills.

Books and Publications: Consider investing in comprehensive guides and textbooks that cover automotive engineering principles. Look for publications focusing on transmission systems, as these often include detailed explanations and diagrams. Libraries and online platforms may have a range of books tailored to both novices and experienced individuals.

Online Courses: Numerous platforms offer structured courses in automotive technology. These courses often include video tutorials, quizzes, and community discussions, enabling learners to grasp concepts at their own pace. Search for programs specifically addressing transmission components and their intricacies.

Forums and Community Groups: Engaging with online communities can be incredibly beneficial. Forums dedicated to automotive discussions provide a space to ask questions, share experiences, and learn from others. Participating in these communities fosters collaboration and knowledge sharing.

Video Tutorials: Visual learners may find that video tutorials on platforms like YouTube can be especially helpful. Many automotive experts and enthusiasts share their expertise through step-by-step videos, covering various topics related to vehicle systems. This format allows viewers to see techniques in action.

Workshops and Seminars: Attending local workshops or seminars can offer hands-on experience. Look for events hosted by automotive colleges or industry professionals that focus on specific vehicle technologies. These gatherings often provide valuable networking opportunities and direct access to expert knowledge.