When it comes to keeping your gardening tools in top condition, understanding their intricate workings is essential. Regular upkeep not only prolongs the lifespan of these devices but also ensures optimal performance during use. This section delves into the specifics of maintaining your essential outdoor equipment, focusing on common issues and effective solutions.

By familiarizing yourself with the components and mechanisms, you empower yourself to tackle minor malfunctions and prevent potential breakdowns. A comprehensive understanding of your equipment can save you time and money, transforming routine maintenance into a straightforward task.

This guide offers detailed insights into troubleshooting, adjustment, and replacement procedures, ensuring that you have the necessary knowledge to handle your tools effectively. With the right approach, even those unfamiliar with machinery can gain confidence in managing their equipment’s care.

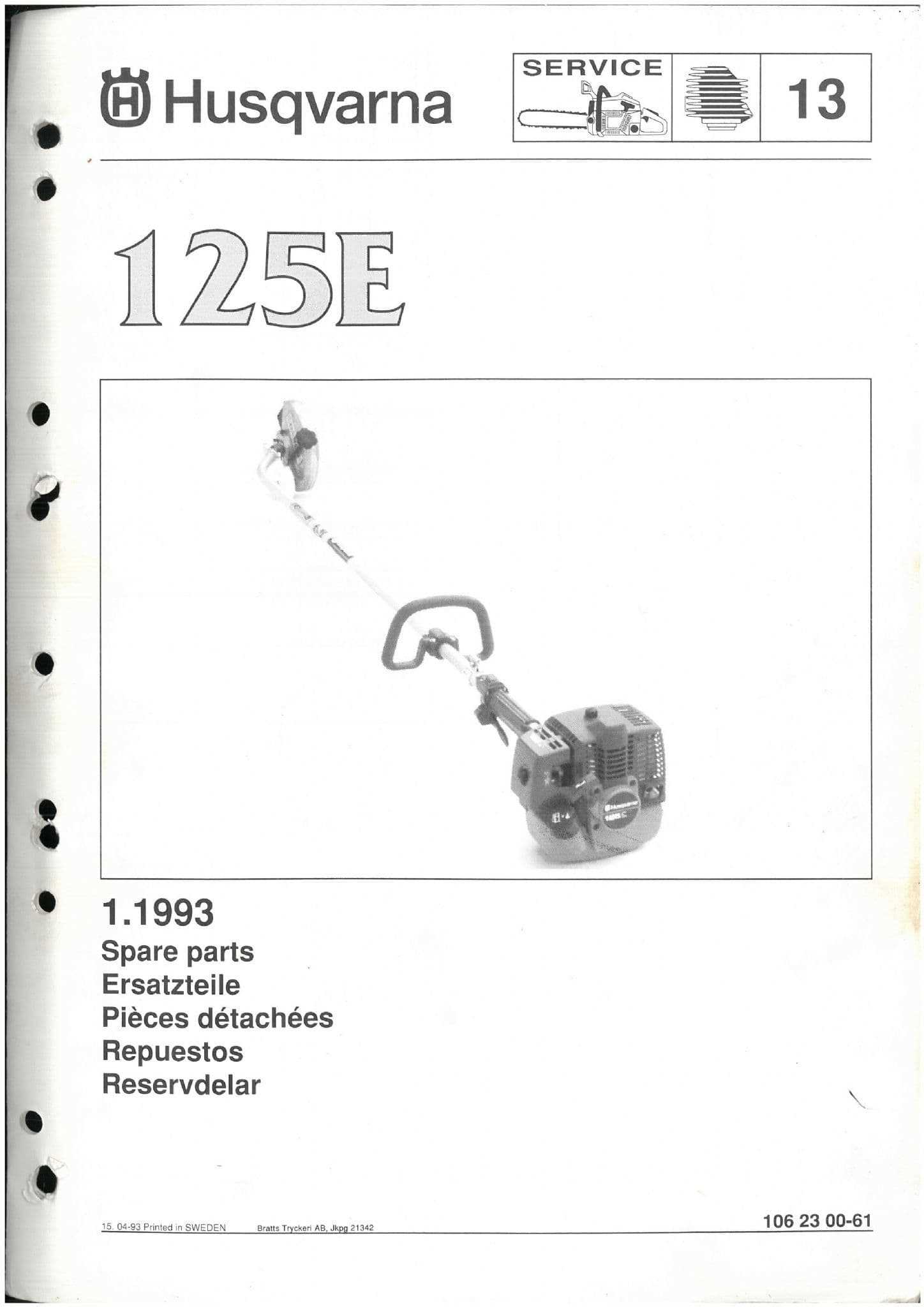

Overview of Husqvarna 322L Features

This lightweight and versatile trimmer is designed for both efficiency and ease of use, making it an ideal choice for homeowners and professionals alike. Its combination of power and innovative features allows users to tackle various landscaping tasks with precision and comfort.

Powerful Engine: Equipped with a robust engine, this device delivers impressive performance while maintaining fuel efficiency. The design ensures that users can complete their work quickly without sacrificing reliability.

Ergonomic Design: The trimmer boasts an ergonomic handle and a balanced frame, minimizing fatigue during extended use. This thoughtful design promotes comfort, allowing for longer operation without discomfort.

Versatile Cutting Options: With interchangeable cutting attachments, this equipment adapts easily to different tasks, from trimming grass to tackling thicker vegetation. Users can effortlessly switch between various heads to suit their specific needs.

Easy Start System: The advanced starting system simplifies the ignition process, ensuring that users can get to work quickly. This feature is particularly beneficial for those who may not have extensive experience with similar tools.

Durability: Built with high-quality materials, this trimmer is designed to withstand the rigors of regular use. Its rugged construction ensures longevity, making it a wise investment for anyone looking to maintain their outdoor space.

In summary, this equipment combines innovative engineering and user-friendly features, making it a top choice for effective and efficient outdoor maintenance.

Common Issues with the 322L Model

When operating a popular model of outdoor equipment, users may encounter several recurring problems that can affect performance and efficiency. Understanding these common issues can help in troubleshooting and maintaining optimal functionality.

Fuel System Problems

One frequent concern involves the fuel system. Users often report issues such as difficulty starting or stalling during operation. This can be attributed to clogged fuel filters or poor fuel quality. Regularly checking the fuel system components and ensuring clean, high-quality fuel can mitigate these problems.

Starter Mechanism Failures

Another prevalent issue is with the starter mechanism. Over time, users may notice that the starter rope becomes hard to pull or does not engage properly. This can be caused by frayed ropes or stuck pulleys. Regular maintenance and timely replacement of worn parts are essential to ensure reliable starting.

Step-by-Step Repair Process

This section outlines a systematic approach to fixing your equipment, ensuring that you can effectively address any issues that may arise. By following these detailed instructions, you can restore functionality and extend the lifespan of your tool.

Preparation

- Gather all necessary tools, such as wrenches, screwdrivers, and pliers.

- Ensure a clean, well-lit workspace to facilitate the process.

- Review any relevant guidelines or specifications for your model.

Disassembly

- Disconnect the power source to ensure safety.

- Remove any external attachments or accessories.

- Loosen and remove screws and fasteners carefully.

- Keep track of all parts and their arrangement for reassembly.

Once disassembled, inspect each component for wear or damage. Address any concerns as needed, either through replacement or repair. Follow this structured process to ensure a successful outcome.

Necessary Tools for Repair

When it comes to maintaining outdoor equipment, having the right instruments is essential for effective servicing and ensuring longevity. Utilizing appropriate tools not only simplifies the task but also enhances safety and efficiency. Below is a list of essential items needed for proper upkeep.

Basic Tools

- Wrenches: Various sizes to accommodate different fasteners.

- Screwdrivers: Both flathead and Phillips types for diverse screw heads.

- Socket Set: For loosening and tightening bolts easily.

- Pliers: Needle-nose and standard types for gripping and twisting.

Specialized Instruments

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

- Feeler Gauge: For measuring gaps and clearances accurately.

- Multimeter: Essential for electrical diagnostics and troubleshooting.

- Fuel Stabilizer: Helps in maintaining fuel quality for optimal performance.

By equipping yourself with these tools, you can perform maintenance tasks with confidence and ensure that your equipment runs smoothly for years to come.

Understanding the User Manual

The user guide serves as an essential resource for individuals seeking to operate and maintain their equipment effectively. It provides crucial information that enhances the user experience and ensures the longevity of the product. By familiarizing yourself with this document, you can unlock a wealth of knowledge that aids in troubleshooting and maximizing performance.

One of the primary sections typically includes safety instructions, emphasizing the importance of proper handling and precautionary measures. This information is vital for preventing accidents and ensuring a safe working environment. Additionally, understanding these guidelines can significantly reduce the risk of injury while using the machine.

Another key component of the guide is the operational overview. This section outlines the various features and functions of the equipment, providing step-by-step instructions for use. By following these directions, users can navigate the functionalities with confidence, ultimately enhancing efficiency and effectiveness.

Maintenance tips are also prominently featured in the documentation. Regular upkeep is crucial for the optimal performance of any machinery. The guide typically offers a detailed schedule and procedures for routine checks, ensuring that users can keep their equipment in prime condition.

In summary, the user guide is an invaluable tool that empowers users with the knowledge necessary for safe operation, efficient use, and proper maintenance. By taking the time to study this document, you can ensure a positive experience with your equipment and prolong its lifespan.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your outdoor power equipment requires consistent care and attention. Regular maintenance not only enhances efficiency but also extends the lifespan of the machine. By adopting a proactive approach, users can prevent potential issues and keep their equipment operating smoothly.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Clean Air Filter | Every 10 hours | Inspect and clean to ensure optimal airflow; replace if damaged. |

| Check Spark Plug | Every 25 hours | Examine for wear and replace if necessary to maintain engine performance. |

| Sharpen Blades | After every 25 hours of use | Keep blades sharp for cleaner cuts and reduced strain on the engine. |

| Inspect Fuel System | Seasonally | Check for leaks and ensure fuel is fresh; stale fuel can cause starting issues. |

| Lubricate Moving Parts | Every 20 hours | Use the recommended lubricant to reduce friction and prevent wear. |

Adhering to these guidelines can significantly improve the reliability and efficiency of your equipment. Remember to always consult the manufacturer’s recommendations for specific maintenance practices tailored to your model.

Troubleshooting Starting Problems

When your equipment fails to ignite, it can be frustrating. This section aims to help you identify common issues and offer potential solutions to get your device up and running smoothly.

- Fuel Issues:

- Check for stale fuel; replace if necessary.

- Inspect fuel lines for cracks or leaks.

- Ensure the fuel filter is clean and unclogged.

- Ignition System:

- Examine the spark plug for wear or carbon buildup.

- Test the ignition coil for functionality.

- Make sure connections are secure and corrosion-free.

- Air Supply:

- Check the air filter for dirt and blockages.

- Ensure the carburetor is clean and functioning properly.

- Starting Mechanism:

- Inspect the recoil starter for damage.

- Ensure the choke is set correctly.

- Test the battery or electrical connections if applicable.

By systematically examining these areas, you can delve into the root causes of starting difficulties and implement the ultimate fixes to restore performance.

Replacing the Trimmer Line

Maintaining optimal performance of your cutting tool often involves changing the line used for trimming. This task is essential to ensure efficient operation and to achieve the best results while landscaping or gardening. Over time, the line can wear down or break, requiring a timely replacement to avoid interruptions during use.

Step 1: Begin by gathering the necessary materials, including a new spool of trimmer line. Check the specifications to select the appropriate thickness and type for your equipment.

Step 2: Disconnect the tool from any power source to ensure safety. Locate the spool, which is typically situated at the head of the device.

Step 3: Remove the old line by either unwinding it from the spool or detaching the spool itself, depending on the design. Clean the area of any debris or grass clippings that may have accumulated.

Step 4: Cut a length of the new line, generally around the recommended size specified in the product details. Insert the line into the spool’s designated holes, ensuring it is wound tightly and evenly.

Step 5: Reattach the spool to the trimmer, ensuring it locks securely in place. Finally, trim any excess line that may extend beyond the cutting head.

With these steps completed, your cutting tool will be ready to deliver precise trimming once again, allowing for a more enjoyable and efficient experience in your outdoor projects.

Fuel System Maintenance Guidelines

Proper upkeep of the fuel system is crucial for the optimal performance of your equipment. Ensuring that this component is functioning efficiently not only enhances the longevity of the machinery but also minimizes the risk of operational issues. Regular maintenance practices will help in preventing common problems and will keep the engine running smoothly.

Regular Inspection

Perform routine checks on the fuel system to identify any signs of wear or damage. Look for leaks, cracks, or clogs in fuel lines and filters. Replacing any worn-out components promptly is essential to avoid further complications. Ensure that the fuel filter is clean and free from debris, as a clogged filter can lead to inadequate fuel flow.

Fuel Quality Management

Using high-quality fuel is paramount for maintaining engine efficiency. Always store fuel in a clean, dry container and avoid mixing different types of fuel. Consider adding fuel stabilizers to prevent degradation over time, especially if the equipment will not be used for an extended period. Keeping the fuel tank full can also help prevent condensation, which may lead to water accumulation and corrosion.

Cleaning and Caring for Components

Maintaining the functionality and longevity of your outdoor equipment requires regular attention to its various parts. Keeping components clean not only ensures optimal performance but also prevents potential damage caused by debris and buildup. This section highlights effective practices for the upkeep of essential parts.

Regular Cleaning Practices

To maintain peak performance, it’s important to regularly remove dirt, grass, and other residues from the machine. Utilize a soft brush or compressed air to clear away debris from air filters and cooling vents. For plastic and metal surfaces, a damp cloth with mild soap can effectively eliminate grime. Ensure all connections and fasteners are free from dust to prevent operational issues.

Component Inspection and Care

In addition to cleaning, periodic inspection of vital components is crucial. Check for signs of wear or damage, particularly in blades, fuel lines, and filters. Lubricate moving parts according to the manufacturer’s guidelines to reduce friction and wear. Addressing minor issues promptly can prevent more significant problems in the future, ensuring your equipment remains in excellent condition.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both personal well-being and equipment longevity. Proper precautions can prevent accidents and enhance the effectiveness of the work being performed.

Always wear appropriate protective gear, including gloves, goggles, and sturdy footwear, to shield yourself from potential hazards. This equipment helps minimize risks associated with sharp objects and flying debris.

Before starting any work, disconnect power sources to prevent accidental activation. This step is essential in avoiding injuries caused by unintended movements of the machinery.

Maintain a clean and organized workspace, ensuring tools and materials are within reach but not cluttered. This practice reduces the likelihood of trips or falls during the maintenance process.

Lastly, read all safety guidelines and manufacturer instructions thoroughly. Understanding specific recommendations can significantly impact the safety and efficiency of your tasks.

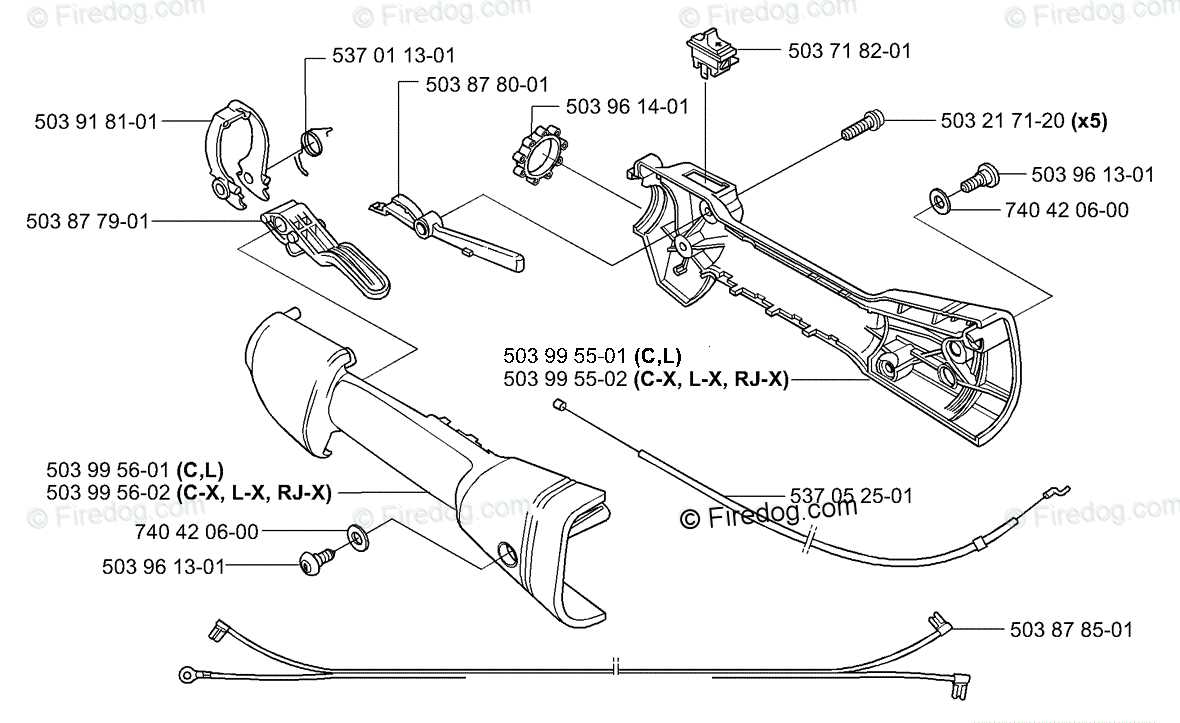

Where to Find Spare Parts

Locating replacement components for your equipment can be essential for maintaining its performance and longevity. There are various reliable sources to explore when searching for these essential items, ensuring you can keep your machine running smoothly.

Authorized dealers often provide the most accurate and high-quality components tailored for your specific model. Visiting their physical locations or browsing their online shops can yield a comprehensive selection of parts designed for optimal compatibility.

Additionally, numerous online marketplaces specialize in outdoor equipment. These platforms frequently offer competitive pricing and a wide array of options, allowing you to compare different sellers and read customer reviews before making a purchase.

Another viable option is aftermarket suppliers, who can provide alternatives that may be more affordable while still maintaining acceptable quality standards. It’s advisable to research the reputation of these suppliers to ensure you’re investing in durable and effective parts.

Lastly, local repair shops can be a valuable resource. They often carry a selection of commonly needed parts and may even have recommendations for sourcing harder-to-find items. Building a relationship with a trusted technician can also lead to insights on where to find the best deals.