In the realm of crafting, the ability to maintain and troubleshoot essential equipment is a valuable skill. When these vital tools encounter issues, knowing how to address their complexities can save time and resources. This section delves into the intricacies of keeping such instruments in optimal condition, ensuring they function smoothly for all creative endeavors.

Whether you’re a seasoned artisan or a novice enthusiast, having access to comprehensive resources can enhance your confidence in managing any problems that may arise. Detailed guidelines provide clarity and facilitate a deeper understanding of the components involved. By equipping yourself with the right knowledge, you can tackle challenges head-on and prolong the lifespan of your essential devices.

Ultimately, mastering the nuances of maintenance not only empowers you to resolve issues independently but also fosters a greater appreciation for the craftsmanship involved. As we explore various techniques and insights, you’ll discover how to navigate the complexities of your tools with ease and proficiency.

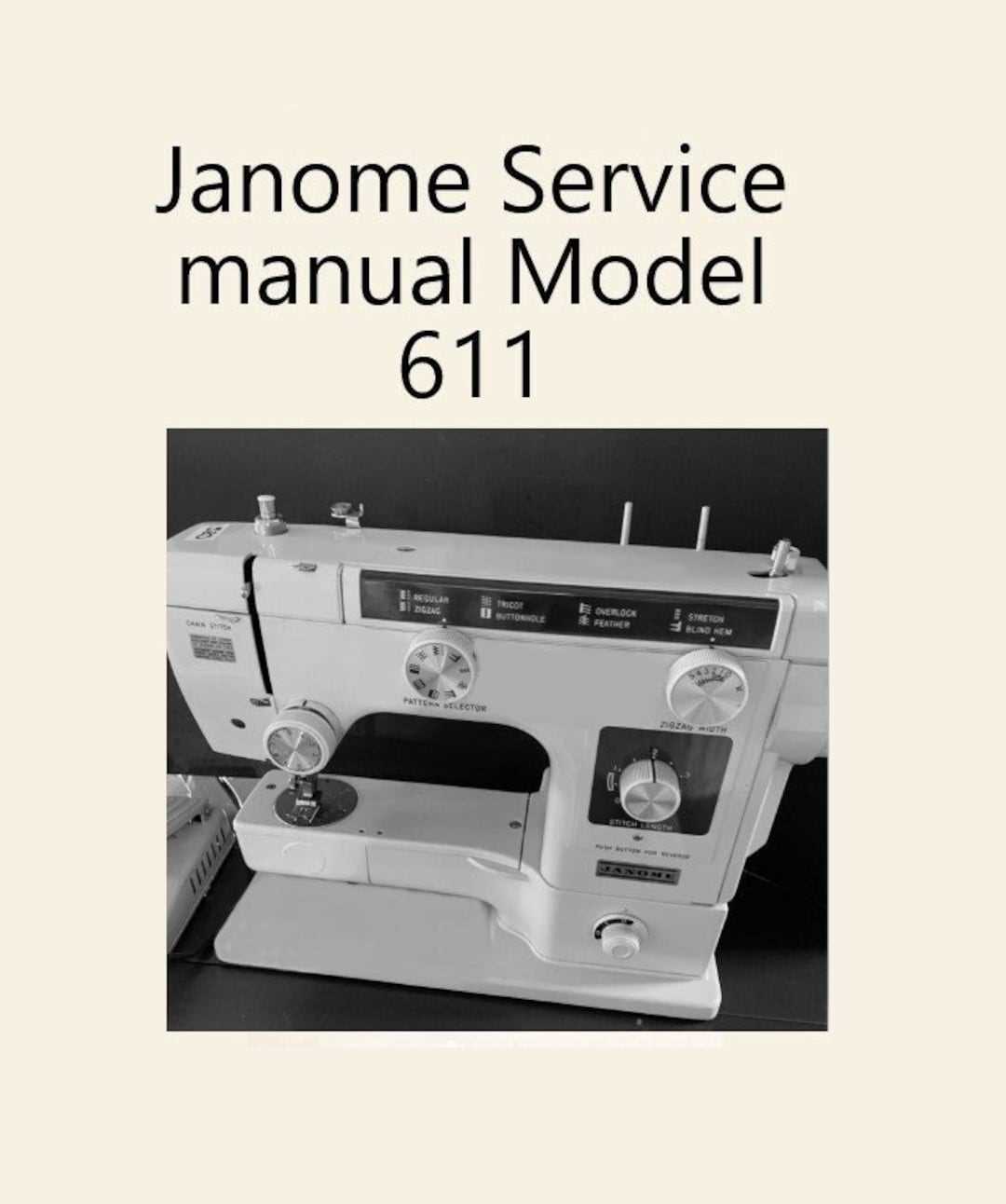

Understanding Sewing Machine Repair Manuals

When delving into the intricacies of textile equipment maintenance, it is essential to comprehend the significance of instructional guides. These resources serve as invaluable companions for enthusiasts and professionals alike, offering detailed insights into troubleshooting and upkeep.

Key Components of Instructional Guides

- Terminology: Familiarize yourself with common terms and phrases to enhance understanding.

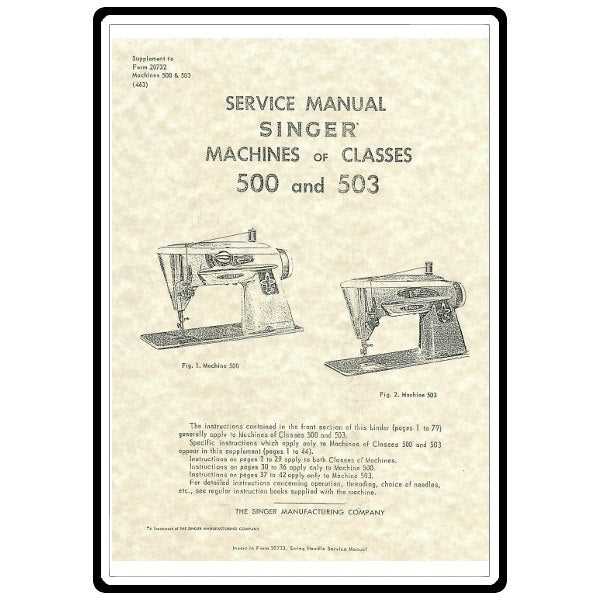

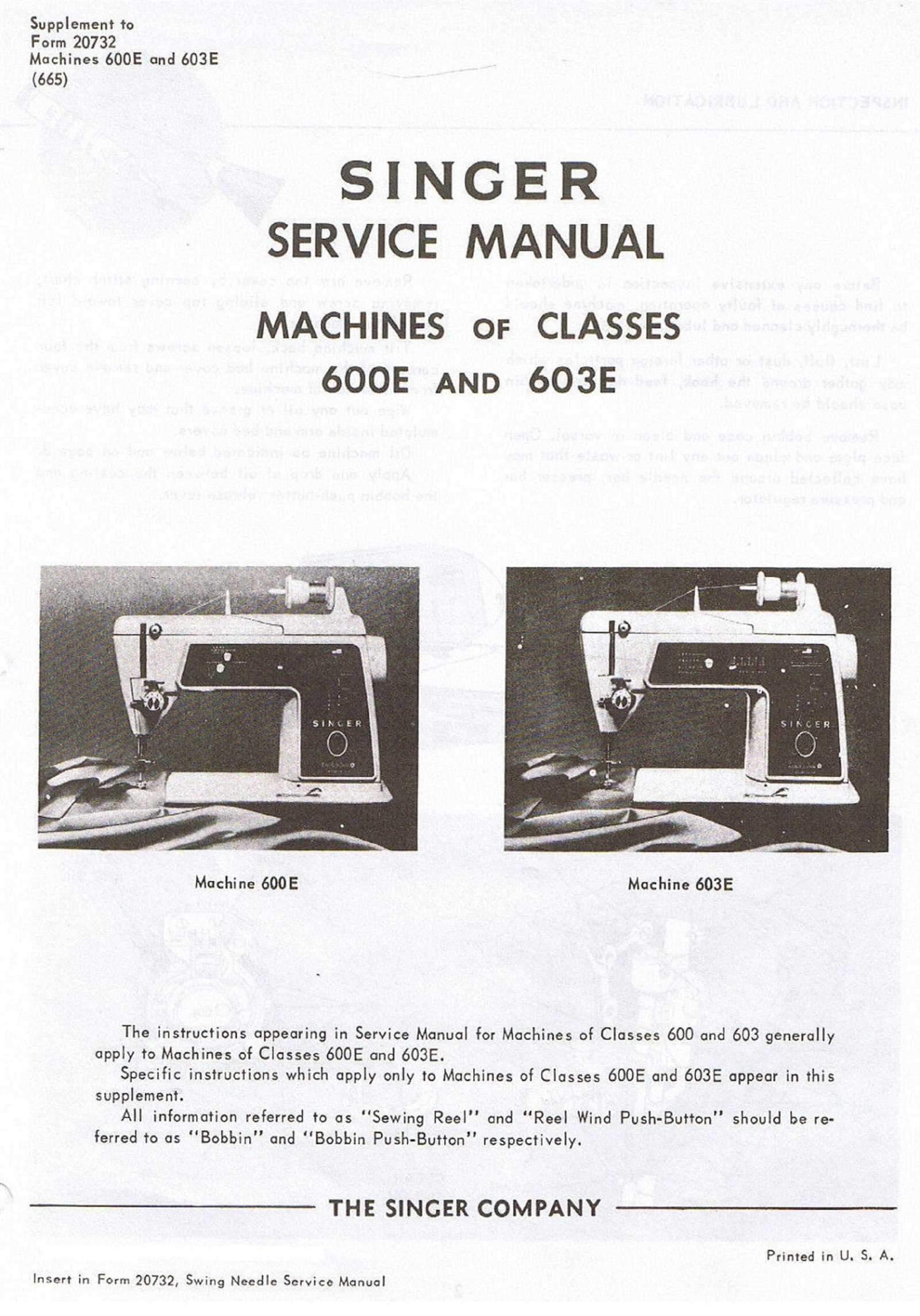

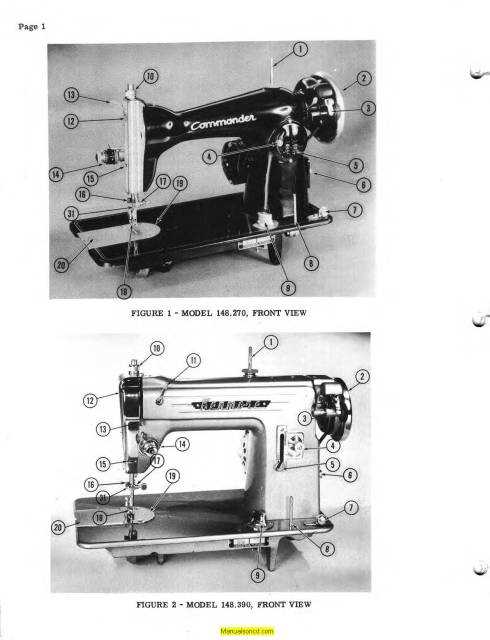

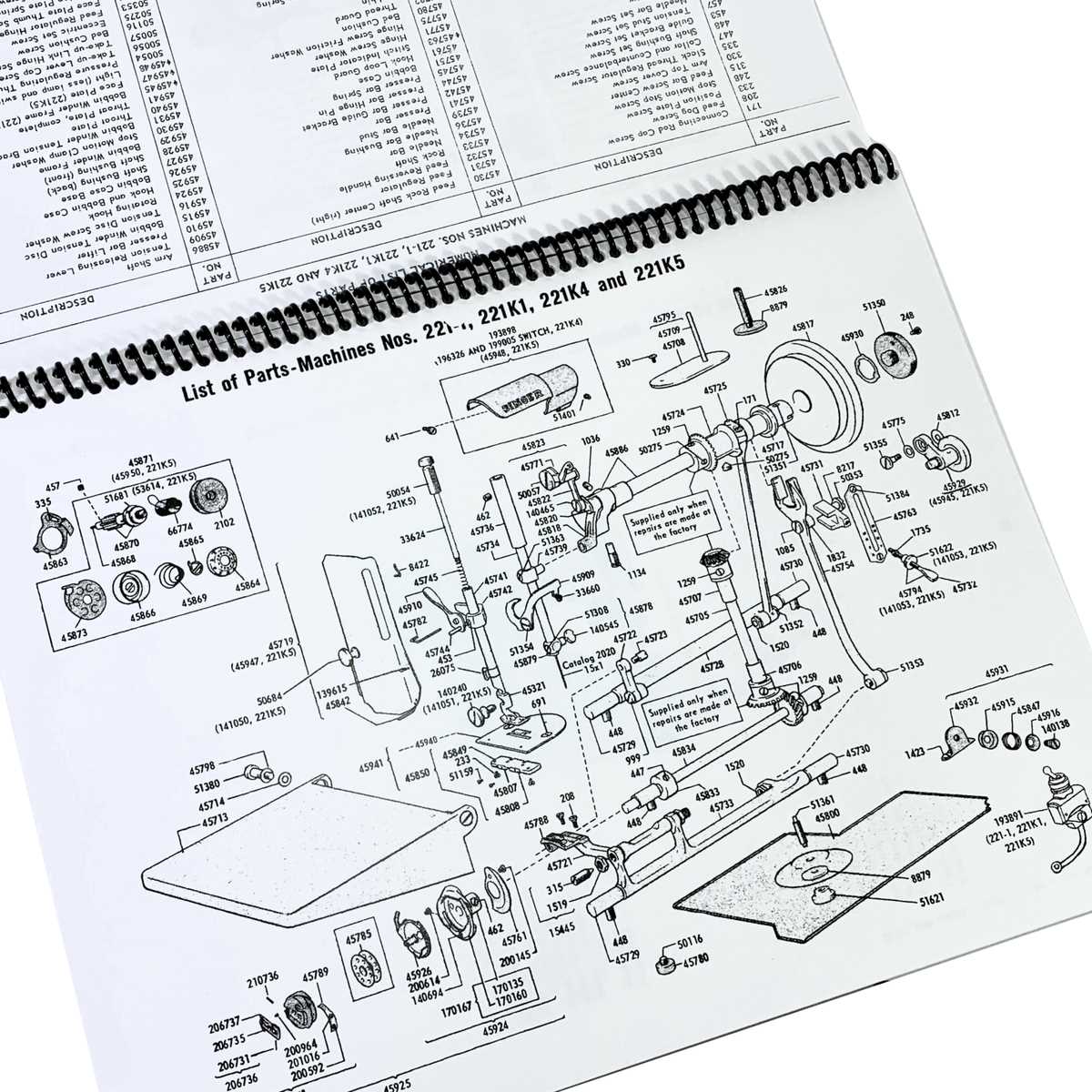

- Diagrams: Visual aids provide clarity on parts and assembly, making complex concepts more accessible.

- Troubleshooting Tips: Step-by-step advice helps identify and resolve common issues effectively.

- Maintenance Guidelines: Regular upkeep instructions prolong the lifespan of the equipment.

Utilizing Instructional Resources Effectively

- Start with Basics: Begin by reviewing the foundational aspects before moving on to advanced topics.

- Follow Sequentially: Adhere to the order presented in the guide for optimal results.

- Take Notes: Jot down important points to reinforce learning and enhance recall.

- Practice Regularly: Hands-on experience solidifies theoretical knowledge and builds confidence.

Importance of Repair Manuals for Users

Having a comprehensive guide is essential for anyone working with complex devices. These resources provide critical information that empowers users to troubleshoot issues effectively, ensuring longevity and optimal performance of their equipment. Understanding the content of these guides can significantly reduce downtime and enhance the overall user experience.

One of the primary benefits of such documentation is the accessibility of knowledge. Users can quickly reference instructions, maintenance tips, and common problems, which allows for prompt resolution. This capability fosters confidence and independence in handling technical challenges.

| Benefit | Description |

|---|---|

| Increased Efficiency | Users can quickly identify and resolve issues without external assistance. |

| Cost Savings | By performing simple fixes themselves, users can avoid costly professional services. |

| Extended Lifespan | Regular maintenance guided by these resources can prolong the life of the device. |

| Enhanced Knowledge | Users gain valuable insights into the functioning of their equipment, improving overall proficiency. |

Common Issues Addressed in Manuals

Users often encounter various challenges with their devices that require guidance for effective resolution. These resources typically cover a range of prevalent problems, offering step-by-step solutions to restore functionality and enhance performance. Understanding these common difficulties can empower individuals to tackle issues independently, minimizing downtime and frustration.

Among the most frequently discussed topics are thread jams, which can occur for several reasons, including improper threading or the use of unsuitable materials. Manuals usually provide clear instructions on how to identify and resolve such blockages, ensuring smooth operation.

Another common concern is inconsistent stitching quality, which may arise from tension discrepancies or dull needles. These guides often include detailed troubleshooting tips to help users adjust settings and achieve optimal results, promoting a more satisfying experience.

Additionally, users may face electrical or operational failures. Comprehensive resources typically outline diagnostic procedures, enabling individuals to pinpoint issues related to power supply or internal components. By following these guidelines, users can often restore their devices to working order without seeking external assistance.

Step-by-Step Repair Instructions

This section provides a structured approach to troubleshooting and fixing common issues encountered during the use of fabric stitching devices. Following these guidelines can enhance your skills and restore functionality effectively.

Preparation

- Gather necessary tools: screwdriver, lubricant, cleaning brush.

- Identify the problem: unusual noises, skipped stitches, or threading issues.

- Ensure a clean workspace: remove dust and debris around the area.

Troubleshooting Process

- Check the threading: make sure it is correctly placed and tensioned.

- Inspect the needle: replace if bent or dull.

- Clean the area: remove lint from the feed dogs and bobbin case.

- Lubricate moving parts: apply oil as recommended in the guidelines.

- Test functionality: run a few stitches to assess improvement.

Tools Needed for Sewing Machine Repairs

When it comes to maintaining your beloved crafting equipment, having the right tools is essential. A well-equipped workspace can make the process smoother and more efficient, ensuring that you can tackle various issues that may arise. Below is a list of essential instruments that will assist you in addressing common problems effectively.

| Tool | Description |

|---|---|

| Screwdrivers | Various sizes for loosening and tightening screws on the equipment. |

| Bobbin Winder | Useful for winding new bobbins with thread to ensure consistent stitching. |

| Needle Inserter | Aids in inserting and removing needles safely and easily. |

| Oil | Specialized lubricants designed to keep components functioning smoothly. |

| Brush | For cleaning dust and lint from the internal parts to prevent clogs. |

| Thread Snips | Small scissors specifically designed for cutting threads cleanly and efficiently. |

| Multimeter | A tool for checking electrical components and ensuring proper functioning. |

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety is paramount. Familiarizing yourself with potential hazards can significantly reduce the risk of accidents and injuries. Proper preparation and adherence to guidelines are essential for a secure and effective experience.

Always Disconnect Power: Before beginning any work, it is crucial to unplug the device. This simple step helps prevent unintentional activation, safeguarding against electrical shock or mechanical injury.

Use Appropriate Tools: Utilizing the right instruments not only facilitates efficiency but also minimizes the risk of accidents. Ensure that tools are in good condition and designed for the specific tasks at hand.

Wear Protective Gear: Safety equipment, such as gloves and goggles, can provide essential protection. These items help guard against sharp components and debris that may arise during disassembly or maintenance.

Work in a Well-Lit Area: Adequate lighting is essential for visibility, allowing you to spot potential hazards and avoid mistakes. A clean and organized workspace further enhances safety by reducing clutter and distractions.

Keep Children and Pets Away: To maintain a safe environment, ensure that young ones and animals are at a safe distance. This prevents accidental injuries and allows you to focus entirely on the task.

Follow Manufacturer Guidelines: Adhering to the original instructions is vital. These documents often contain specific safety warnings and procedural steps that help ensure safe practices.

How to Read Repair Manuals Effectively

Understanding technical documentation is crucial for successfully maintaining and fixing equipment. This process requires focus, familiarity with terms, and an organized approach. By honing your reading skills, you can navigate complex instructions with ease and enhance your troubleshooting abilities.

Start with the Basics: Before diving into detailed sections, take a moment to skim through the contents. Familiarize yourself with the structure and layout. This overview will help you identify the most relevant parts for your needs.

Highlight Key Terms: As you read, underline or highlight important terminology. Recognizing specific words can assist you in grasping the overall context and ensuring that you don’t miss crucial steps in the process.

Take Notes: Jotting down key points or creating summaries can reinforce your understanding. Consider keeping a dedicated notebook where you can compile insights and solutions for future reference.

Utilize Visuals: Pay attention to diagrams and images included in the documentation. Visual aids often clarify complex concepts and can provide guidance on assembly or disassembly, making instructions easier to follow.

Practice Patience: Technical texts may require multiple readings to fully comprehend. Don’t rush through the content; take your time to digest each section thoroughly. Revisiting tricky parts will enhance your confidence and proficiency.

Seek Additional Resources: If you encounter terms or concepts that are unclear, consider looking up supplementary materials. Online forums, video tutorials, and community discussions can offer valuable insights that complement the written content.

By employing these strategies, you can transform your approach to technical texts, making the maintenance process more manageable and effective.

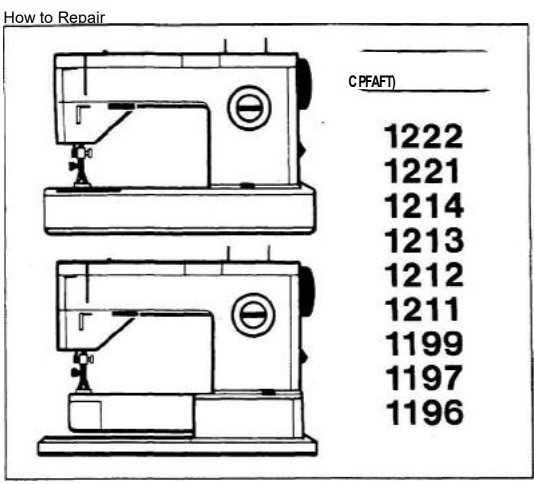

Types of Sewing Machines and Manuals

This section explores various categories of textile crafting equipment and the corresponding guides that accompany them. Understanding the distinctions between these devices can greatly enhance your crafting experience and ensure optimal functionality.

Categories of Textile Crafting Equipment

- Mechanical Devices

- Basic functionality with manual settings.

- Ideal for beginners and straightforward tasks.

- Electronic Devices

- Feature programmable settings and advanced features.

- Suitable for intricate designs and professional use.

- Overlock Equipment

- Specialized for edge finishing and fabric trimming.

- Essential for creating polished seams.

- Embroidery Devices

- Designed for decorative stitching and patterns.

- Often includes built-in designs and USB connectivity.

Importance of Instruction Guides

Having access to comprehensive guides is crucial for understanding the full capabilities of each type of device. These resources typically include:

- Setup instructions for initial use.

- Troubleshooting tips for common issues.

- Maintenance advice to prolong the lifespan.

- Project ideas to inspire creativity.

Familiarizing yourself with the specific guide related to your equipment can significantly improve your crafting outcomes.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of your equipment. Regular attention and care can significantly enhance performance and reduce the likelihood of issues. Here are some key practices to ensure your tools remain in excellent condition.

- Regular Cleaning: Remove dust and debris after each use to prevent buildup.

- Lubrication: Apply appropriate oils to moving parts to reduce friction and wear.

- Check Tension: Ensure that all threads are properly tensioned to avoid snags and breakage.

- Storage: Keep your equipment covered and in a dry environment to protect it from dust and moisture.

Following these guidelines can help maintain peak performance and prolong the lifespan of your tools.

- Inspect for Damage: Regularly examine all components for any signs of wear or damage.

- Use Quality Supplies: Invest in high-quality threads and accessories to reduce the risk of issues.

- Follow Manufacturer’s Recommendations: Adhere to specific guidelines provided by the manufacturer for best results.

By incorporating these simple yet effective maintenance strategies, you can ensure your equipment remains reliable for years to come.

DIY vs. Professional Repairs

When it comes to fixing equipment, individuals often face a choice between tackling the issue themselves or seeking expert assistance. Each approach has its unique advantages and drawbacks that can significantly influence the outcome of the process.

| Aspect | DIY Approach | Professional Assistance |

|---|---|---|

| Cost | Generally lower; involves only materials and tools. | Higher due to labor fees and potential service charges. |

| Time | May take longer if skills are lacking. | Typically quicker; experts know common issues well. |

| Skill Level | Requires some familiarity and confidence. | Provided by trained professionals with extensive knowledge. |

| Outcome | Results may vary; success depends on experience. | Usually consistent quality and reliable results. |

| Learning Opportunity | Great for skill-building and understanding the device. | Less opportunity for personal growth; more focused on resolution. |

Choosing between self-fixing and hiring a specialist depends on various factors, including budget, time availability, and personal expertise. Weighing these elements carefully can lead to a more satisfying and effective solution.

Finding Reliable Repair Manuals Online

Locating trustworthy resources for guidance can significantly enhance your understanding and proficiency in handling equipment. With the abundance of information available on the internet, distinguishing between credible sources and unreliable content is crucial for successful maintenance and troubleshooting.

Key Factors to Consider

When searching for dependable guides, it is essential to evaluate the following aspects:

| Factor | Description |

|---|---|

| Source Reputation | Check if the website is well-known and has positive reviews from users. |

| Expertise Level | Ensure the content is created by knowledgeable individuals or organizations in the field. |

| Update Frequency | Look for resources that are regularly updated to reflect the latest practices and techniques. |

| User Feedback | Read comments and ratings from other users to gauge the reliability of the information. |

Where to Look

Various platforms can provide valuable insights. Websites dedicated to hobbies, forums, and specialized online communities often have extensive discussions and guides. Additionally, video tutorials can offer visual aids that complement textual instructions, enhancing comprehension and skill development.

Frequently Asked Questions About Repairs

This section addresses common inquiries related to the maintenance and troubleshooting of your equipment. Whether you’re facing minor issues or major challenges, understanding these queries can help streamline the process and enhance your experience.

| Question | Answer |

|---|---|

| What should I do if the device won’t turn on? | Check the power source and ensure that all connections are secure. If it still doesn’t power up, inspect the cord for any damage. |

| How can I prevent future issues? | Regular cleaning and oiling are essential. Follow the guidelines provided in your reference documents for maintenance routines. |

| What are common signs that something is wrong? | Unusual noises, inconsistent performance, or error messages are all indicators that your device may need attention. |

| Can I fix minor problems myself? | Yes, many simple issues can be resolved with basic tools. Consult your guide for step-by-step instructions on troubleshooting. |

| When should I seek professional help? | If you encounter complex problems or if repairs require specialized knowledge, it’s advisable to consult a professional. |

Updating and Revising Your Manual

Keeping documentation current is essential for ensuring usability and accuracy. Regular updates allow for the incorporation of new information, improved techniques, and feedback from users. This practice not only enhances the clarity of the content but also maintains the relevance of the instructions provided.

Assessing the Need for Changes

Before embarking on the revision process, it’s important to evaluate the existing content critically. Look for areas that may have become outdated or unclear over time. Gathering input from those who utilize the guide can provide valuable insights into what modifications might enhance understanding and effectiveness.

Implementing Effective Updates

Once you have identified the necessary changes, proceed with a structured approach. Begin by prioritizing the most critical sections that require attention. Incorporate new information, ensuring it aligns with the overall style and tone of the document. Finally, conduct a thorough review to confirm that all updates contribute to the guide’s overall coherence and functionality.