This section aims to provide essential insights into the upkeep and troubleshooting processes of a sophisticated automotive model. Understanding the intricate components and systems is crucial for ensuring optimal performance and longevity.

By delving into the specifics of various functionalities, individuals can empower themselves with the knowledge needed to address common challenges. This resource serves as a valuable reference for both seasoned enthusiasts and newcomers alike.

Equipped with step-by-step instructions and practical advice, users will navigate through the complexities with confidence. The focus here is not just on resolving issues, but also on fostering a deeper appreciation for the engineering behind the vehicle.

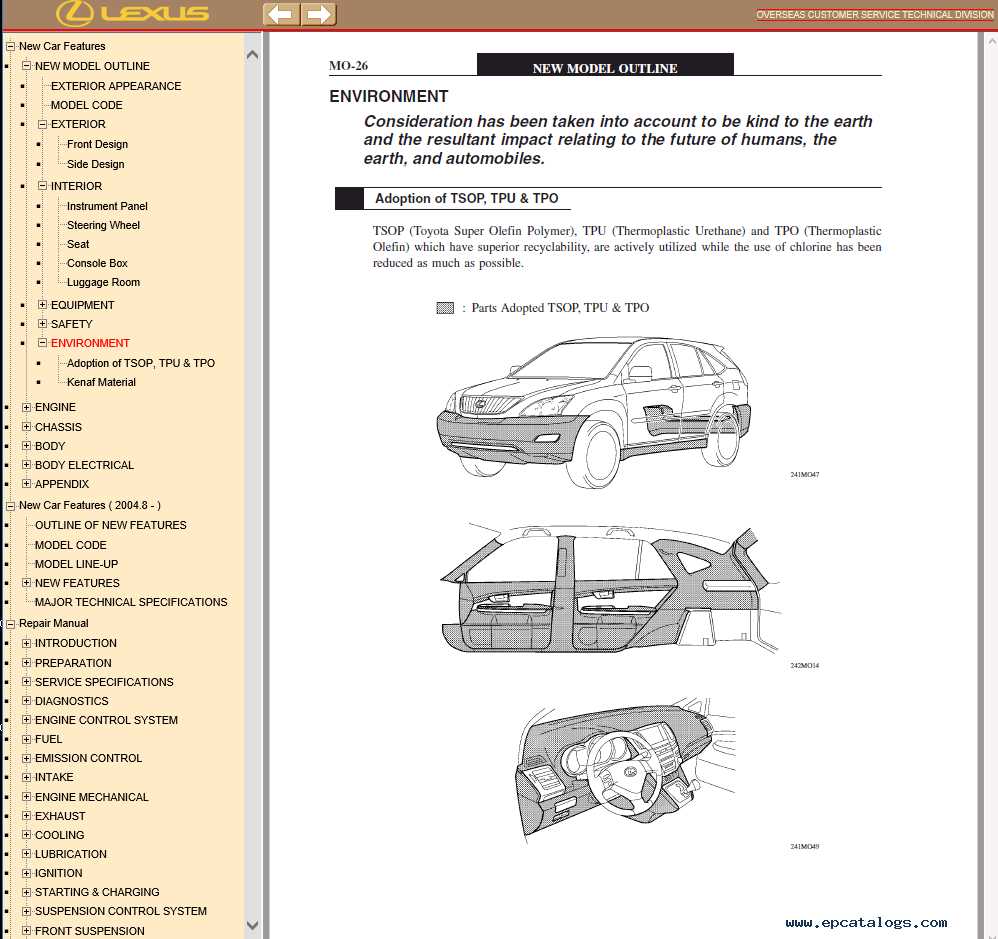

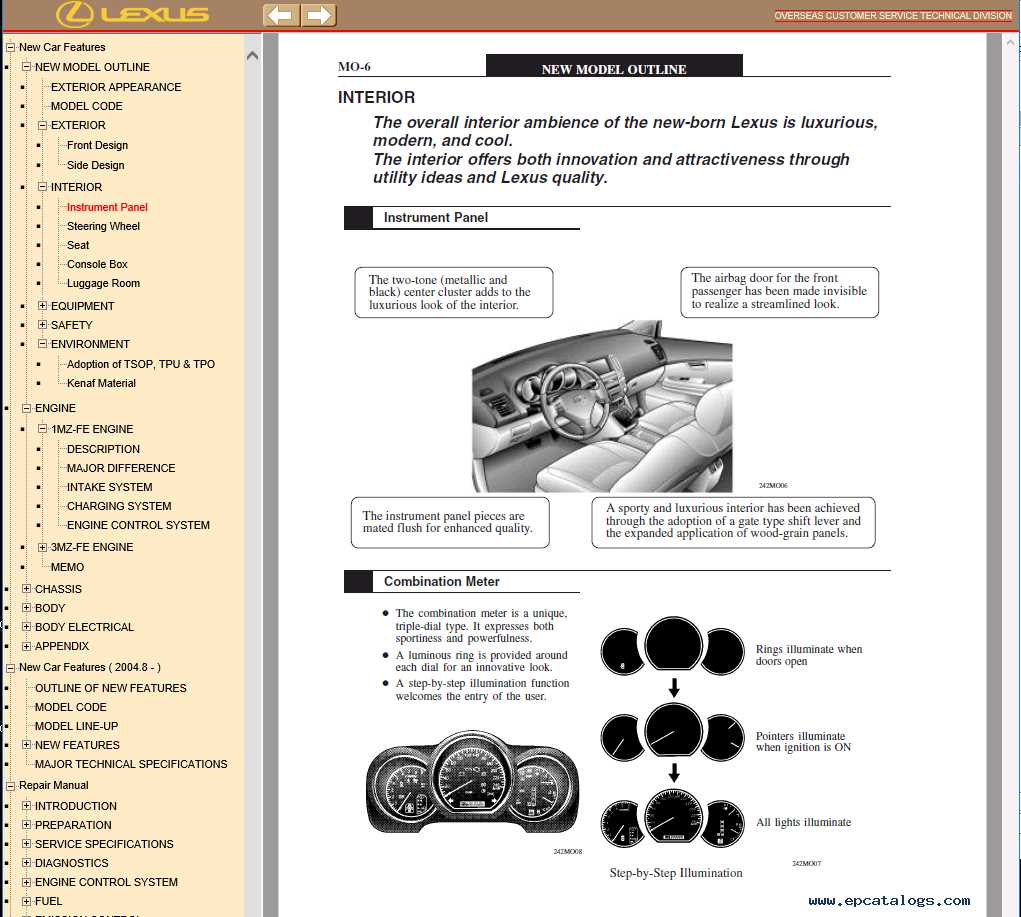

Overview of RX 350 Features

This section provides an insight into the various attributes and capabilities of the vehicle, emphasizing the advanced technology and comfort it offers to drivers and passengers alike. From cutting-edge safety mechanisms to luxurious interior amenities, this model is designed to enhance the driving experience.

Innovative Technology

The vehicle is equipped with state-of-the-art technological advancements that streamline navigation and connectivity. Features such as an intuitive infotainment system and driver-assistance technologies ensure a seamless interaction with the vehicle, enhancing overall convenience and safety.

Comfort and Luxury

In addition to technological prowess, the vehicle boasts a spacious and refined interior designed for maximum comfort. High-quality materials and thoughtful design elements contribute to a serene atmosphere, making long journeys enjoyable for all occupants.

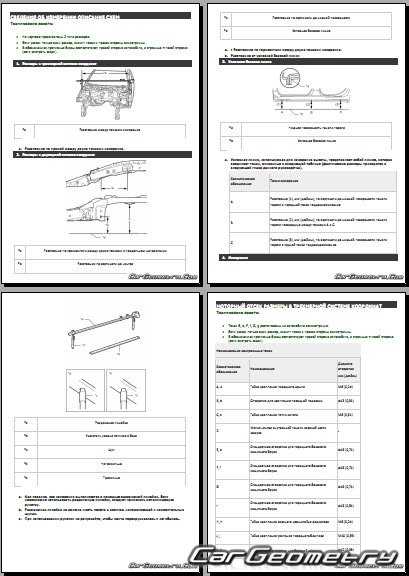

Common Issues with RX 350

Vehicles often present various challenges that can affect their performance and reliability. Understanding these common problems can help owners address them proactively and ensure a smoother driving experience. Below are some typical concerns associated with this model, along with their potential causes and solutions.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Engine Overheating | Low coolant level, faulty thermostat, or radiator issues | Check coolant levels, replace the thermostat, or inspect the radiator for leaks |

| Electrical Problems | Worn-out battery, faulty alternator, or loose connections | Test battery health, check the alternator output, and secure connections |

| Suspension Noise | Worn struts or shocks, damaged bushings | Inspect suspension components and replace worn parts as needed |

| Brake Issues | Worn brake pads, warped rotors | Replace brake pads and machine or replace rotors |

Being aware of these prevalent issues can empower owners to maintain their vehicles more effectively, reducing the likelihood of more serious complications in the future.

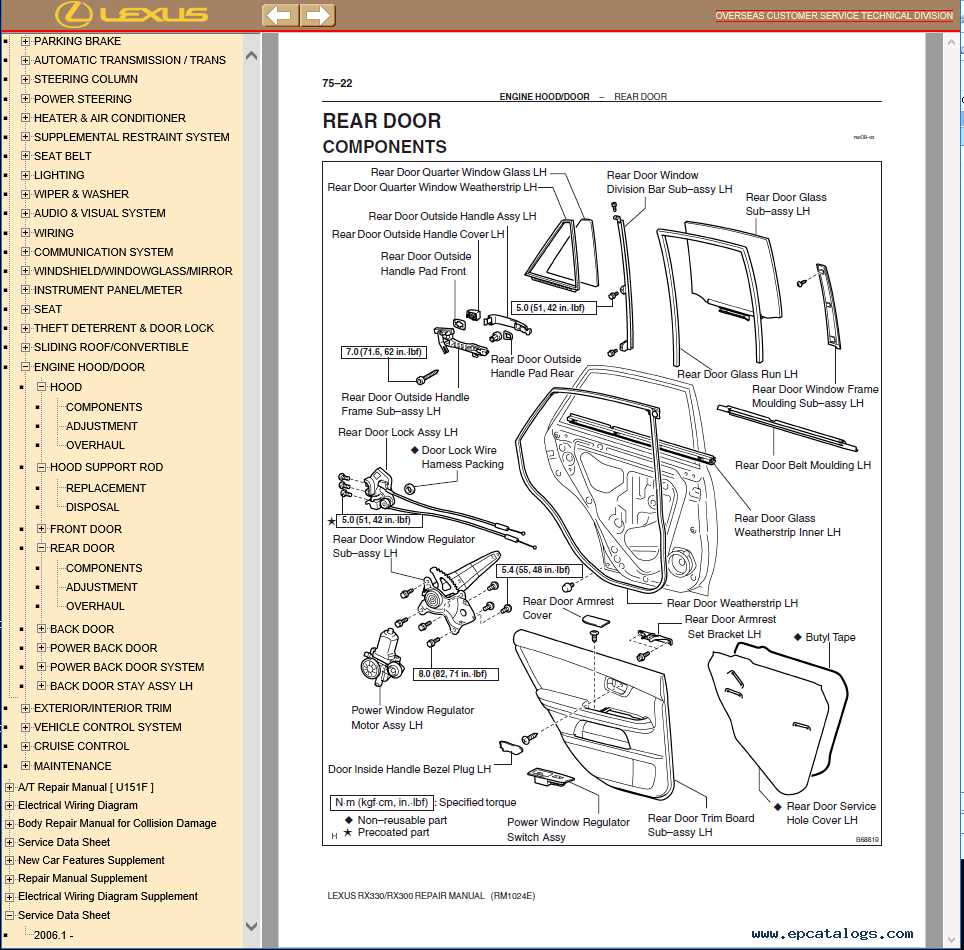

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments is crucial for efficiency and success. A well-equipped workspace can significantly streamline the process and enhance the quality of work performed. Various items are essential for addressing issues effectively and ensuring all tasks are executed with precision.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for disassembly and reassembly. Specialized equipment, like torque wrenches and diagnostic devices, can aid in identifying problems and verifying solutions. Additionally, safety gear, including gloves and goggles, should not be overlooked to ensure personal protection during the procedure.

Having an organized toolkit will facilitate smoother operations and allow for quick access to necessary items. Keeping a comprehensive inventory of all required tools is a prudent practice, ensuring that nothing is overlooked when the time comes to tackle any challenges that may arise.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your vehicle. Regular upkeep is essential for maintaining reliability and safety. Follow these detailed procedures to keep your automobile in excellent condition.

Start by performing a visual inspection to identify any noticeable issues. Pay close attention to fluid levels, tire pressure, and the condition of belts and hoses. Next, adhere to the recommended schedule for changing essential fluids such as engine oil, coolant, and brake fluid.

| Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 5,000 miles | Replace the oil filter and use high-quality engine oil. |

| Tire Rotation | Every 6,000 miles | Rotate tires to ensure even wear. |

| Brake Inspection | Every 12,000 miles | Check brake pads and rotors for wear and tear. |

| Battery Check | Every 6 months | Inspect terminals for corrosion and ensure secure connections. |

Following these guidelines will help you maintain your vehicle’s performance and enhance its lifespan. Regular attention to these details ensures a smooth driving experience and can prevent more significant issues down the line.

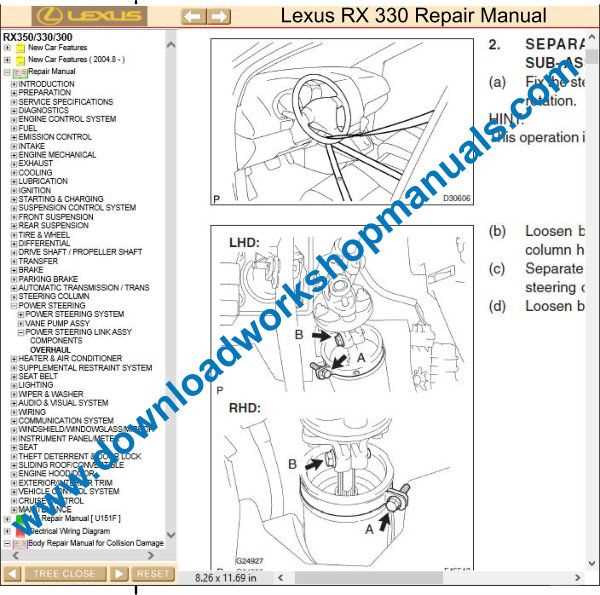

Engine Troubleshooting Techniques

When encountering issues with an automobile’s power source, it is essential to systematically identify and resolve problems to ensure optimal performance. Utilizing a methodical approach can help diagnose various symptoms effectively, leading to efficient solutions.

Observation is the first step in troubleshooting. Pay attention to any unusual sounds, vibrations, or warning indicators on the dashboard. Noting these details can provide crucial clues about underlying issues.

Next, visual inspections play a vital role. Examine components such as hoses, belts, and connections for signs of wear or damage. Look for leaks or corrosion that might affect functionality.

Implementing diagnostic tools can significantly enhance the troubleshooting process. Scanners and gauges can reveal error codes or performance metrics, guiding the technician toward specific areas requiring attention.

Finally, methodical testing of individual parts can help isolate problems. This may involve checking the ignition system, fuel delivery, and electrical connections to determine if they are functioning properly. By following these techniques, one can effectively address and resolve engine-related challenges.

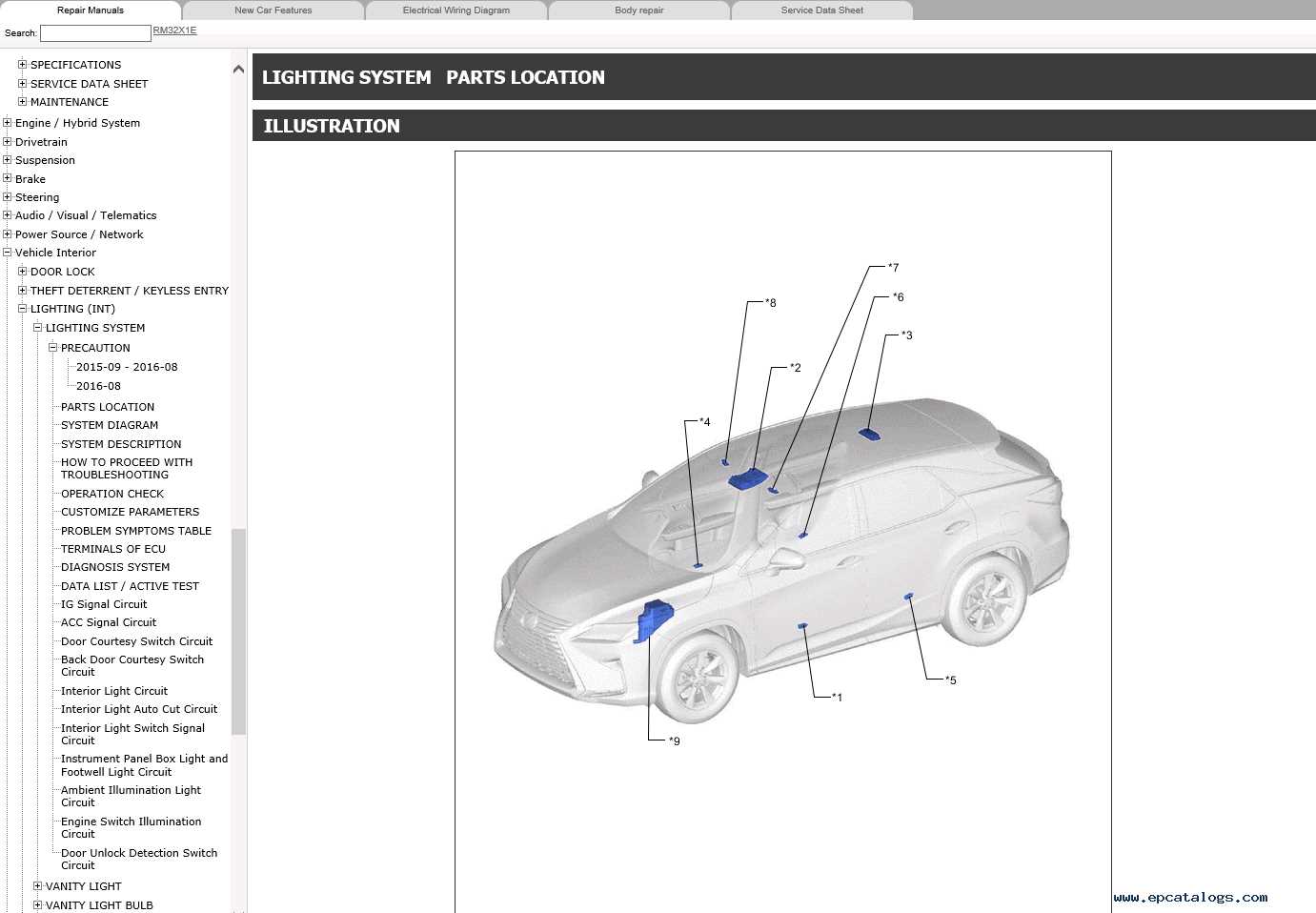

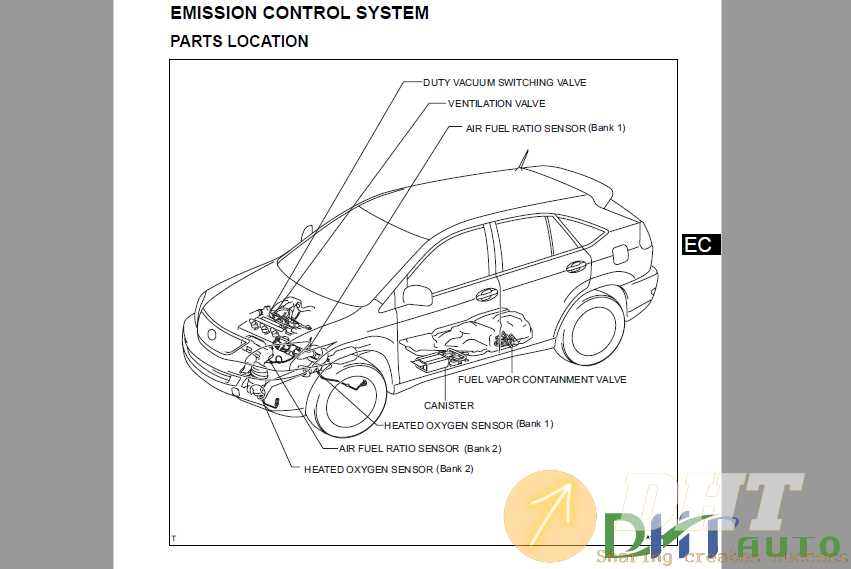

Electrical System Diagnostics

This section delves into the evaluation of the electrical components within the vehicle. By systematically examining the circuitry and connections, one can identify faults that may affect performance and functionality. Understanding these elements is crucial for ensuring optimal operation and longevity of the vehicle’s systems.

Common Electrical Issues

Various problems can arise within the electrical framework, often manifesting as symptoms that indicate underlying issues. Recognizing these signs is the first step toward effective troubleshooting.

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Dim Lights | Reduced brightness in headlights and interior lights | Weak battery or poor connections |

| Starting Problems | Engine fails to turn over or starts intermittently | Faulty starter or battery issues |

| Malfunctioning Accessories | Power windows or radio not functioning | Blown fuses or wiring faults |

Diagnostic Techniques

Utilizing various diagnostic tools is essential for accurately pinpointing electrical faults. Techniques such as multimeter testing, visual inspections, and software diagnostics can provide valuable insights into the condition of the vehicle’s electrical systems.

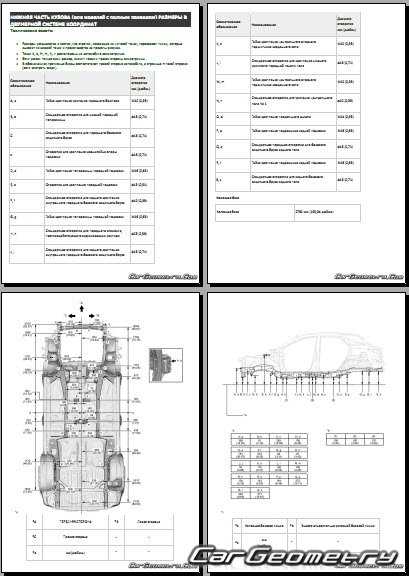

Suspension and Steering Repairs

This section focuses on the essential maintenance and adjustment processes required for a vehicle’s suspension and steering systems. Proper handling of these components is crucial for ensuring optimal driving performance and comfort.

Common Issues

- Worn out shock absorbers or struts

- Loose or damaged steering components

- Misalignment of wheels

- Excessive play in the steering wheel

Maintenance Tips

- Regularly inspect suspension parts for wear and tear.

- Ensure proper alignment to prevent uneven tire wear.

- Check fluid levels in the power steering system.

- Replace any damaged components promptly to maintain performance.

Following these guidelines will help in maintaining the integrity and functionality of the vehicle’s suspension and steering systems, contributing to a smoother and safer driving experience.

Brake System Inspection Procedures

The effectiveness of the stopping mechanism is crucial for vehicle safety. Regular examination of the components involved in this system helps ensure reliable performance and can prevent serious issues. Following a systematic approach to inspecting these elements is essential for maintaining optimal functionality.

Inspection Steps

- Begin by assessing the brake fluid level and condition.

- Examine the brake pads for wear and tear.

- Inspect the rotors for signs of scoring or uneven wear.

- Check the brake lines for any leaks or damage.

- Evaluate the calipers and pistons for proper operation.

Additional Considerations

- Ensure that the brake warning light on the dashboard functions correctly.

- Listen for unusual sounds when applying the brakes, which may indicate issues.

- Consider the age and mileage of the vehicle to determine if components need replacement.

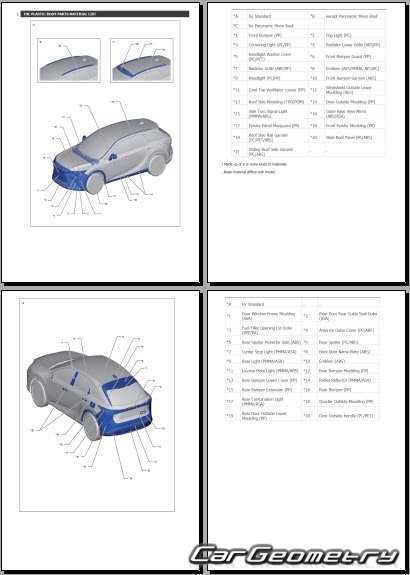

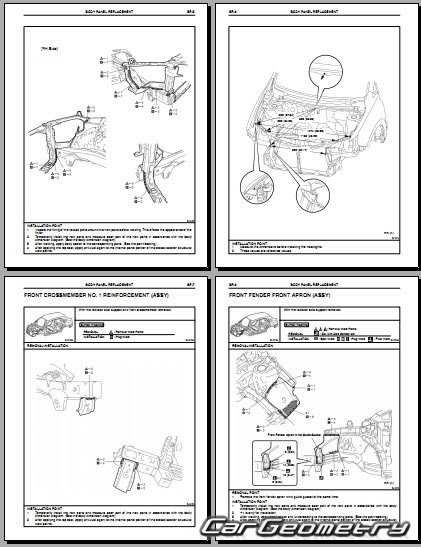

Bodywork and Paint Repair Tips

Maintaining the exterior of your vehicle is essential for both aesthetics and longevity. Whether it’s minor dings or paint imperfections, addressing these issues promptly can prevent further damage and keep your vehicle looking its best.

Here are some essential strategies to consider when tackling exterior blemishes:

- Assess the Damage: Begin by examining the affected area. Determine if the issue is superficial or requires more extensive intervention.

- Gather the Right Tools: Ensure you have all necessary materials, including sandpaper, primer, paint, and clear coat. This preparation helps streamline the process.

- Clean the Surface: Thoroughly wash the area to remove dirt and debris. A clean surface is crucial for effective adhesion of paints and coatings.

For paint touch-ups:

- Choose the Right Color: Match the paint color accurately to avoid noticeable repairs.

- Apply in Thin Layers: Use multiple light coats rather than one thick application to achieve a smooth finish.

- Allow Proper Drying Time: Follow the manufacturer’s guidelines for drying to ensure optimal results.

For dent removal:

- Use a Hairdryer: Heat the dented area for a few minutes to expand the metal, making it easier to manipulate.

- Employ a Plunger: For small dents, a plunger can help pull the metal back into shape.

- Consider Professional Help: If the damage is extensive, seeking assistance from a professional might be the best option.

By following these tips, you can effectively address bodywork issues and enhance the appearance of your vehicle, ensuring it remains in prime condition.

Fluid Changes and Recommendations

Maintaining optimal performance in your vehicle involves regular updates to essential liquids. Proper management of these substances not only enhances functionality but also prolongs the lifespan of various components.

Engine Oil: It is crucial to replace the engine lubricant at regular intervals. This ensures that the engine operates smoothly and reduces wear on internal parts. Refer to the manufacturer’s guidelines for the specific type and change frequency.

Transmission Fluid: Keeping the transmission fluid fresh is vital for smooth gear transitions. Periodic inspections and changes can prevent costly repairs and enhance overall driving experience.

Coolant: The cooling agent should be checked and replaced as needed to avoid overheating issues. A well-maintained cooling system is essential for optimal engine temperature control.

Brake Fluid: This fluid is critical for the safe operation of your braking system. Regularly checking and replacing brake fluid ensures responsiveness and prevents potential failures.

Consult the vehicle’s specifications for further details on recommended fluids and maintenance intervals. Following these guidelines will contribute to a reliable and enjoyable driving experience.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance on vehicles is crucial. Adhering to certain guidelines can prevent accidents and protect both the individual performing the work and the vehicle itself. Awareness of potential hazards and taking proactive measures are essential steps in this process.

Personal Protective Equipment

Wearing appropriate personal protective gear is fundamental. Items such as gloves, goggles, and sturdy footwear help shield against injuries. Additionally, using a mask can protect against inhaling harmful substances present during maintenance tasks.

Workspace Organization

Maintaining a clean and organized workspace significantly reduces risks. Tools and equipment should be stored properly to avoid tripping hazards. Adequate lighting is also vital to ensure visibility, enabling precise handling of components without mishaps.