The world of off-road machines offers thrill and adventure, yet it demands a solid understanding of maintenance and troubleshooting. Enthusiasts often find themselves in need of comprehensive resources to navigate the complexities of their vehicles. This section aims to provide essential insights into the upkeep and enhancement of these dynamic machines.

Whether you’re a novice or a seasoned rider, having access to detailed documentation is invaluable. These resources cover a variety of topics, from routine checks to intricate adjustments, ensuring that every enthusiast can keep their machine in optimal condition. With the right guidance, tackling challenges becomes manageable, allowing riders to focus on the thrill of the ride.

In this section, you will discover a wealth of information tailored to meet the needs of those who seek to maintain and improve their off-road experience. The focus will be on practical advice, step-by-step instructions, and expert tips that empower you to take charge of your machine’s performance and longevity.

Understanding the essential elements of maintenance documents is crucial for anyone looking to enhance their knowledge and skills in vehicle upkeep. These resources provide valuable information that can assist enthusiasts and professionals alike in ensuring optimal performance and longevity.

Key Sections to Include

- Introduction to Maintenance: A brief overview outlining the importance of regular upkeep.

- Tools and Equipment: A comprehensive list of necessary instruments for effective servicing.

- Safety Guidelines: Recommendations to ensure personal safety while performing tasks.

- Step-by-Step Procedures: Detailed instructions for common tasks such as tuning, oil changes, and part replacements.

Additional Resources

- Visual Aids: Diagrams and images to support the text and clarify complex procedures.

- Glossary of Terms: Definitions of specialized terminology to aid understanding.

- Maintenance Schedules: Suggested timelines for routine checks and services to keep performance at its best.

Choosing the Right Manual for You

Selecting the appropriate guide can significantly impact your maintenance and enhancement efforts. With various options available, it’s essential to identify which resource aligns best with your needs and experience level. Factors such as complexity, detail, and specific focus areas will play a crucial role in your decision-making process.

Begin by assessing your proficiency with mechanical tasks. Beginners may benefit from resources that break down processes into simple steps, while seasoned enthusiasts might prefer comprehensive texts that delve into advanced techniques. Additionally, consider whether you need a general overview or a detailed examination of particular components.

Another important aspect to contemplate is the format that suits you best. Some individuals prefer physical copies for easy reference during hands-on work, while others may opt for digital versions for their convenience and search capabilities. Understanding your learning style will aid in selecting the most effective resource.

Lastly, check for updates and reviews from fellow users to ensure the chosen guide remains relevant and accurate. Investing time in this selection process will ultimately enhance your experience and improve your outcomes.

Common Maintenance Tips for Dirt Bikes

Regular upkeep is essential for optimal performance and longevity of your two-wheeled off-road vehicle. By following a few key practices, you can ensure your machine remains in peak condition and ready for any adventure.

- Check Tire Pressure: Maintaining the correct tire inflation improves handling and reduces the risk of flats.

- Inspect the Chain: Keep the chain clean and well-lubricated to ensure smooth operation and prolong its lifespan.

- Change the Oil: Regular oil changes keep the engine running smoothly and prevent unnecessary wear.

- Clean the Air Filter: A clean filter enhances airflow to the engine, improving performance and efficiency.

- Inspect Brake Components: Regularly check pads and fluid levels to ensure reliable stopping power.

Incorporating these practices into your routine will help maintain functionality and enhance the riding experience.

Tools Needed for Basic Repairs

Having the right instruments is crucial for performing maintenance and addressing issues effectively. A well-equipped workspace can significantly enhance efficiency and ensure that tasks are completed accurately.

First, a comprehensive set of wrenches is essential for loosening and tightening various components. Additionally, screwdrivers in different sizes and types will assist in managing screws found throughout the assembly. Pliers will be useful for gripping, bending, or cutting materials as needed.

Moreover, a reliable jack or stand is vital for elevating the unit safely, providing access to undercarriage parts. A toolkit with a torque wrench ensures that fasteners are secured to the manufacturer’s specifications, preventing potential failures.

Lastly, having cleaning supplies such as brushes and rags is important for maintaining hygiene and functionality. With these tools, one can confidently tackle a range of tasks, enhancing performance and longevity.

Understanding Engine Overhaul Procedures

Performing a complete overhaul of a motor’s internal components is crucial for maintaining optimal performance and longevity. This intricate process involves disassembling various sections of the unit, inspecting each part for wear and tear, and replacing or refurbishing components as necessary. Mastery of these procedures ensures that the engine runs smoothly and efficiently, preventing potential failures down the line.

The following table outlines the key stages involved in the overhaul process:

| Stage | Description |

|---|---|

| Disassembly | Carefully removing external parts to access the internal components. |

| Inspection | Thorough examination of all parts for damage and wear. |

| Cleaning | Removing carbon deposits and contaminants from components. |

| Replacement | Substituting worn or damaged parts with new or refurbished items. |

| Reassembly | Carefully putting all components back together in the correct order. |

| Testing | Conducting tests to ensure proper functionality and performance. |

Understanding these stages allows individuals to approach engine maintenance with confidence, ensuring that each step is executed with precision for optimal results.

Troubleshooting Electrical Issues Effectively

Identifying and resolving electrical complications is essential for maintaining optimal performance in any motorized vehicle. A systematic approach can help isolate problems and facilitate repairs without extensive downtime.

Begin by following these key steps:

- Ensure the power source is functioning correctly.

- Inspect wiring for any visible damage or wear.

- Test connections to confirm they are secure and free of corrosion.

Common signs of electrical issues include:

- Inconsistent power delivery.

- Unexpected component failures.

- Unusual sounds or smells during operation.

Utilizing a multimeter can be beneficial in diagnosing issues. Check voltage levels at various points to pinpoint anomalies. Additionally, referencing technical documentation specific to the vehicle can provide insights into typical fault conditions and their remedies.

Regular maintenance and checks can significantly reduce the likelihood of encountering electrical challenges. Keeping connections clean and securing loose wires is vital for longevity and reliability.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance is essential for both the individual and the equipment involved. Adopting appropriate measures can prevent accidents and promote a smoother workflow.

Always wear protective gear, including gloves, goggles, and sturdy footwear. This minimizes the risk of injury from sharp objects, chemicals, or heavy components.

Organize your workspace to eliminate clutter and ensure easy access to tools. A tidy area reduces distractions and helps maintain focus on the task at hand.

Prior to commencing any work, disconnect the power source and ensure that the vehicle is stable. This step is crucial to prevent unexpected movements or electrical hazards.

Lastly, keep a fire extinguisher nearby and familiarize yourself with its usage. Being prepared for emergencies can make a significant difference in critical situations.

Where to Find Quality Resources

When it comes to maintaining your two-wheeled vehicle, having access to reliable materials is essential. Various sources provide comprehensive information, enabling enthusiasts and owners to tackle issues effectively. Understanding where to locate these valuable assets can make all the difference in ensuring optimal performance.

Online Platforms: The internet is a treasure trove of knowledge. Websites dedicated to motorized vehicles often feature articles, forums, and user-generated content that cover troubleshooting, maintenance tips, and more. These communities can be particularly helpful, as experienced individuals share their insights and solutions.

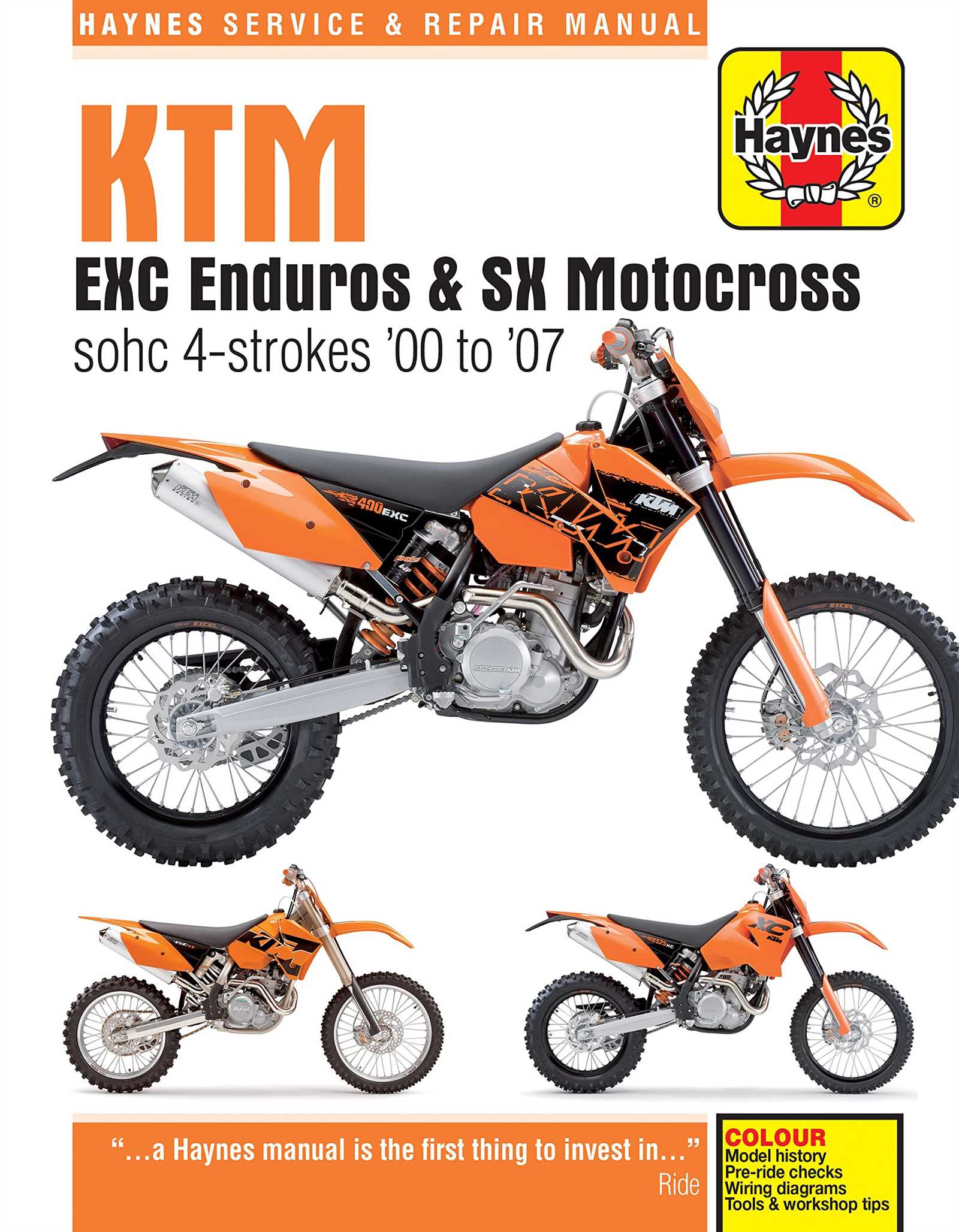

Books and Publications: Traditional literature remains a valuable resource. Look for titles from reputable authors and publishers that focus on maintenance techniques and specifications. These guides often provide in-depth explanations and step-by-step procedures that can enhance your understanding.

Local Workshops: Engaging with local experts can provide hands-on experience. Workshops and classes often cover essential skills and techniques, allowing you to learn directly from professionals. Networking with other enthusiasts in these settings can also lead to discovering additional resources.

Manufacturer Resources: Don’t overlook the information available directly from the manufacturer. Many brands offer official documentation that includes specifications, maintenance schedules, and troubleshooting tips tailored to their products. This ensures you’re getting accurate and relevant information.

By exploring these avenues, you can equip yourself with the knowledge needed to keep your vehicle in top condition, enhancing both performance and longevity.

Online vs. Printed Repair Manuals

The choice between digital resources and traditional books for maintenance guidance can significantly impact the experience of enthusiasts and professionals alike. Each format offers distinct advantages and drawbacks that cater to different preferences and needs.

Accessibility and Convenience

Digital resources provide unparalleled accessibility. With just a few clicks, users can access a vast array of information from anywhere, whether at home or in the garage. This immediacy is particularly beneficial for those who require quick solutions to urgent issues. In contrast, printed versions can be more cumbersome to manage, often requiring physical space and organization.

Usability and Experience

While online content is easily searchable and frequently updated, traditional publications can offer a tactile experience that many find comforting. Printed materials allow for easy annotations and can be less distracting, as they do not rely on electronic devices. Ultimately, the decision may hinge on individual learning styles and working environments.

Importance of Regular Maintenance Schedules

Establishing a consistent regimen for upkeep is vital for ensuring optimal performance and longevity of any machine. Regular attention not only enhances functionality but also significantly reduces the risk of unexpected breakdowns. A proactive approach can prevent minor issues from escalating into costly repairs, ultimately saving time and resources.

Enhanced Performance

Routine maintenance helps maintain the efficiency of components, ensuring that each part operates at its best. By adhering to a scheduled plan, users can experience improved responsiveness and reliability, leading to a more enjoyable experience.

Cost-Effectiveness

Investing time and effort in a maintenance schedule can lead to significant savings. Regular inspections and servicing allow for the early detection of potential issues, which can be addressed before they require extensive repairs. This not only conserves funds but also prolongs the lifespan of the equipment.