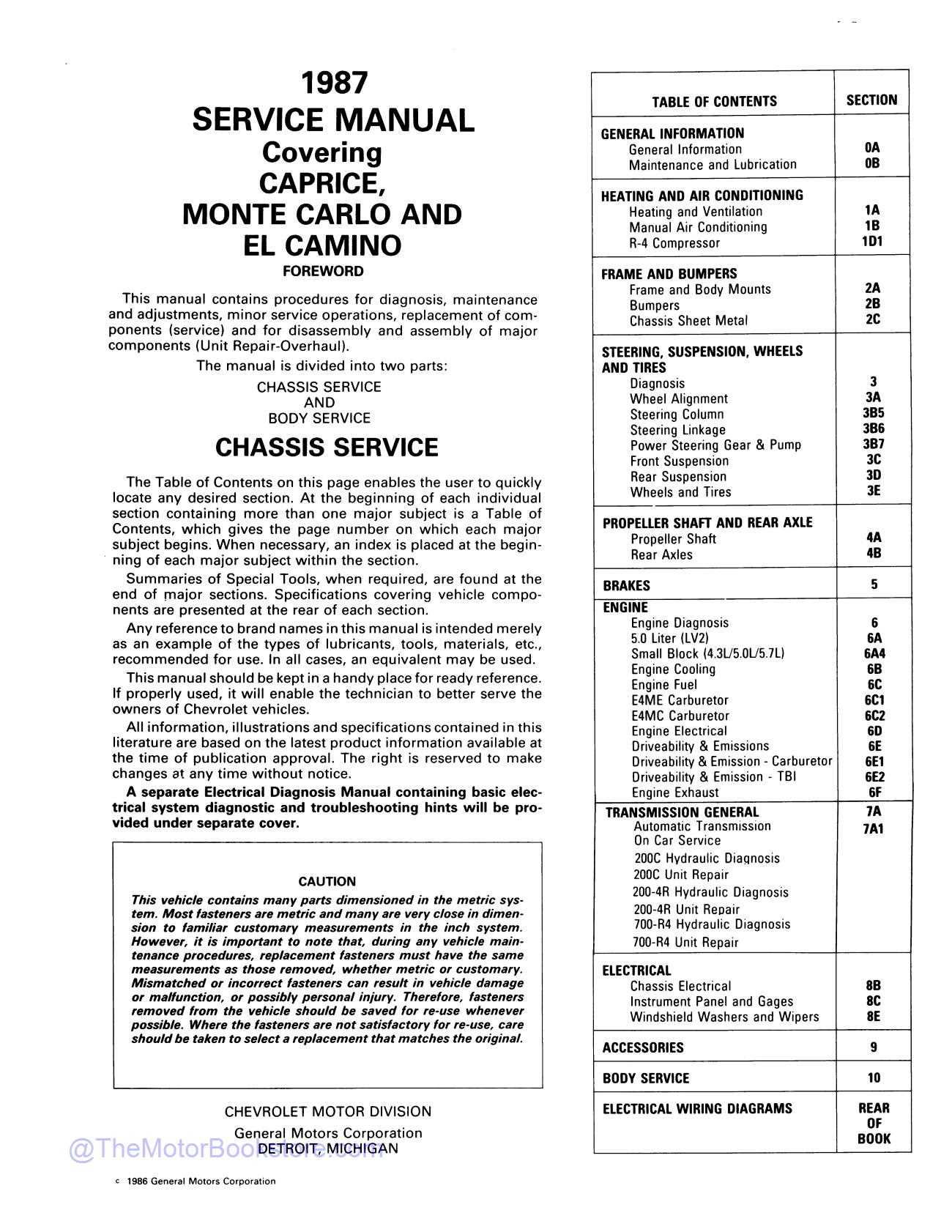

This section serves as an essential resource for enthusiasts and professionals alike, focusing on the intricacies of vehicle upkeep and troubleshooting. Whether you’re a seasoned mechanic or a dedicated DIYer, having access to detailed guidance can significantly enhance your experience and proficiency in handling various automotive challenges.

Understanding the components and systems of your vehicle is crucial for ensuring optimal performance and longevity. With the right information at your fingertips, you can navigate the complexities of maintenance tasks, from basic inspections to more intricate repairs. This guide aims to empower you with knowledge, helping you make informed decisions and tackle projects with confidence.

Additionally, the content provided here covers a range of topics, offering insights into common issues, preventative measures, and best practices. Each section is designed to facilitate a deeper understanding of the mechanisms at play, fostering a more rewarding relationship with your automobile.

Essential Tools for Chevy Caprice Repair

When maintaining and fixing your vehicle, having the right instruments at your disposal is crucial. This section outlines the fundamental implements needed for efficient diagnostics and maintenance tasks, ensuring optimal performance and longevity.

Basic Hand Tools

Every enthusiast should possess a set of essential hand tools. Wrenches, screwdrivers, and pliers are indispensable for a variety of tasks, from tightening loose components to replacing worn parts. A comprehensive socket set can also facilitate easier access to hard-to-reach bolts and nuts.

Diagnostic Equipment

To effectively troubleshoot issues, advanced diagnostic equipment is necessary. An OBD-II scanner can provide valuable insights into engine performance, helping identify error codes and potential malfunctions. Additionally, a multimeter is useful for assessing electrical systems and ensuring proper voltage levels.

Understanding Common Issues with Caprice

Vehicles often encounter various challenges that can affect performance and reliability. Identifying these issues early can help maintain optimal functioning and enhance the driving experience. This section explores frequent complications that owners may face, providing insights into symptoms and potential solutions.

Electrical Problems

One of the prevalent challenges involves electrical systems. Issues such as faulty wiring or malfunctioning components can lead to inconsistent operation of features, including lighting and dashboard indicators. Regular diagnostics can help pinpoint these faults, ensuring a smoother ride.

Engine Performance

Another area of concern relates to engine functionality. Symptoms like stalling, unusual noises, or decreased power output can indicate underlying issues. Routine maintenance and timely inspections can prevent serious complications, promoting longevity and efficiency in performance.

Step-by-Step Guide to Engine Maintenance

Proper upkeep of your vehicle’s power unit is essential for optimal performance and longevity. Following a systematic approach ensures that key components function smoothly and any potential issues are addressed promptly.

- Check Engine Oil:

- Locate the dipstick and remove it.

- Wipe it clean and reinsert it to measure the oil level.

- Add oil if necessary, ensuring it’s the correct type.

- Inspect Air Filter:

- Remove the air filter cover.

- Take out the filter and check for dirt or damage.

- Replace it if it appears clogged or worn.

- Examine Belts and Hoses:

- Look for signs of wear, cracks, or fraying on belts.

- Check hoses for leaks or softness.

- Replace any components that show signs of deterioration.

- Change Fuel Filter:

- Locate the fuel filter and detach it carefully.

- Install the new filter, ensuring it’s positioned correctly.

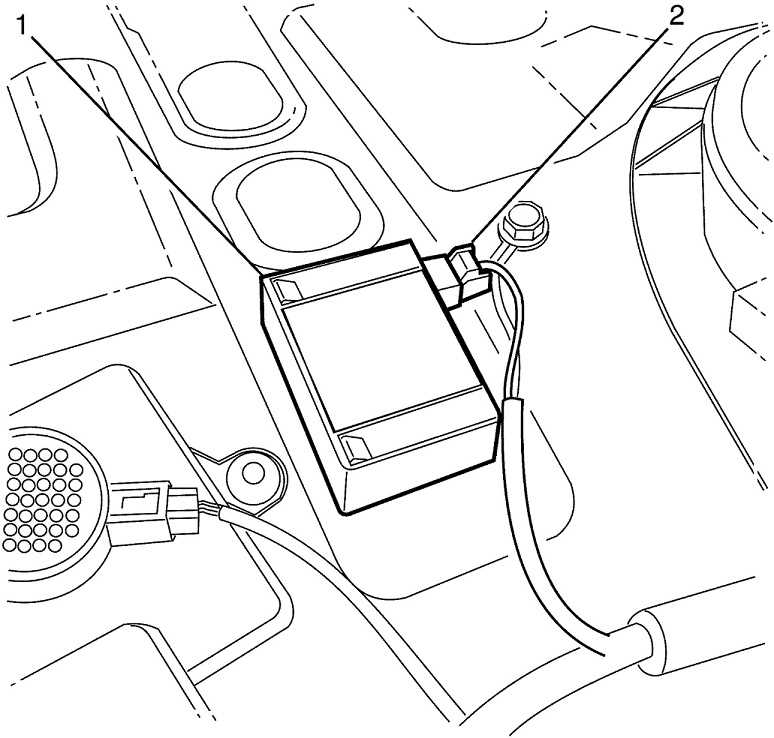

- Examine Battery Condition:

- Check for corrosion on terminals.

- Ensure connections are tight.

- Test the battery’s voltage if necessary.

Regular attention to these tasks will enhance your engine’s efficiency and help avoid costly repairs down the line.

How to Troubleshoot Electrical Problems

Tackling issues related to electrical systems can be daunting, but understanding a few fundamental steps can make the process more manageable. This guide provides insights into identifying and resolving common electrical malfunctions in your vehicle.

Begin with the Basics: Start by checking the simplest components. Ensure that all fuses are intact and that connections are secure. A loose wire or blown fuse can often be the root of the problem.

Use a Multimeter: A multimeter is an invaluable tool for diagnosing electrical issues. It allows you to measure voltage, current, and resistance, helping you pinpoint where the fault lies. Make sure to familiarize yourself with its functions before usage.

Check Ground Connections: Poor grounding can lead to various electrical failures. Inspect ground connections for corrosion or looseness, as these can disrupt the circuit and cause malfunctions.

Look for Signs of Wear: Inspect wiring harnesses for any signs of fraying or damage. Worn-out wires can create shorts or open circuits, leading to erratic behavior in electrical systems.

Consult the Diagram: Refer to electrical schematics to understand the layout of the system. This can provide clarity on which components to test and help you navigate the complexities of the wiring.

By following these steps, you can systematically identify and address electrical issues, ensuring your vehicle operates smoothly.

Replacing Brake Components: A How-To

Maintaining optimal functionality of your vehicle’s stopping system is crucial for safety and performance. This guide outlines the essential steps to effectively change out the braking parts, ensuring reliable operation on the road.

Before beginning, gather the necessary tools and components. Ensure that the vehicle is parked on a level surface and that all safety precautions are observed. Below is a list of common components you may need to replace during this process.

| Component | Description |

|---|---|

| Brake Pads | Friction material that presses against the rotors to slow down the vehicle. |

| Brake Rotors | Metal discs that the brake pads grip to create stopping power. |

| Brake Calipers | Housings that hold the brake pads and squeeze them against the rotors. |

| Brake Lines | Hoses that transport hydraulic fluid to the calipers. |

Follow the outlined procedures carefully for a successful replacement, starting with removing the wheel to access the braking system. Make sure to check each component for wear and tear, replacing any that do not meet safety standards.

Fluid Changes: Importance and Procedure

Regularly updating essential liquids in a vehicle is crucial for maintaining optimal performance and longevity. These substances play a vital role in ensuring that various systems operate smoothly, preventing wear and tear that can lead to costly repairs. Understanding when and how to perform these updates is key for any vehicle owner.

Significance of Regular Fluid Replacement

Over time, fluids can degrade, losing their effectiveness and potentially causing damage to components. Fresh fluids ensure proper lubrication, cooling, and hydraulic function, which are all necessary for reliable operation. Neglecting this maintenance can result in decreased efficiency and performance issues, making it imperative to adhere to a schedule for replacement.

Procedure for Changing Fluids

The process typically involves draining the old liquid, inspecting the components for any signs of damage, and filling with the appropriate new substance. It is essential to use products that meet the manufacturer’s specifications. Following the correct steps will not only enhance performance but also prolong the life of the vehicle.

Suspension System: Inspection and Repair

The suspension framework of a vehicle plays a critical role in maintaining ride quality and handling characteristics. Regular examination and maintenance of this system are essential to ensure safety and performance. This section outlines the key aspects to consider when assessing and addressing potential issues within the suspension assembly.

Key Components to Inspect

- Shock Absorbers and Struts

- Control Arms

- Ball Joints

- Springs

- Anti-Sway Bars

Steps for Thorough Evaluation

- Begin with a visual inspection for signs of wear, such as cracks or leaks.

- Check for any abnormal noises during operation, which may indicate worn components.

- Test the vehicle’s ride height to ensure proper alignment and balance.

- Assess the condition of bushings and mounts for deterioration.

- Perform a bounce test to evaluate the effectiveness of shock absorbers.

Addressing issues promptly can enhance the longevity of the suspension system and improve overall driving dynamics. Regular maintenance and timely interventions are key to sustaining optimal performance.

Maintaining the Transmission: Key Tips

Ensuring the longevity and optimal performance of your vehicle’s transmission system is crucial for a smooth driving experience. Regular attention and care can prevent costly repairs and enhance efficiency. Here are essential practices to keep in mind for effective transmission maintenance.

Regular Fluid Checks

Monitoring the transmission fluid level is fundamental for proper operation. Insufficient fluid can lead to overheating and potential damage. It’s advisable to check the fluid level regularly and replace it according to the manufacturer’s recommendations.

Filter Replacement

Changing the transmission filter is vital to avoid debris buildup, which can hinder performance. A clean filter ensures smooth fluid flow and reduces the risk of damage. Follow guidelines for replacement intervals to maintain system integrity.

| Maintenance Task | Frequency |

|---|---|

| Fluid Check | Monthly |

| Fluid Change | Every 30,000 miles |

| Filter Replacement | Every 15,000 miles |

Bodywork Repair: Techniques and Tools

When it comes to restoring the exterior of a vehicle, various methods and instruments play a crucial role in achieving a flawless finish. Understanding these techniques is essential for anyone looking to enhance the aesthetic appeal and longevity of their automobile.

Essential Techniques

Several techniques can be employed to address common imperfections in the vehicle’s surface. From dent removal to paint touch-ups, each method requires specific skills and approaches. The choice of technique often depends on the extent of damage and the materials used in the car’s construction.

Key Tools Used

A variety of tools are indispensable for effective bodywork. These instruments enable precision and efficiency in the repair process, ensuring high-quality results. Below is a summary of commonly used tools in the field:

| Tool Name | Purpose |

|---|---|

| Pulling Tool | Used for extracting dents from metal surfaces. |

| Body Filler | Utilized for filling small imperfections and creating a smooth finish. |

| Sanding Block | Essential for smoothing out body filler and paint surfaces. |

| Paint Sprayer | Enables even application of paint for a seamless look. |

| Heat Gun | Helps in softening materials for easier manipulation and application. |

Upgrading Performance: Options and Considerations

Enhancing the capabilities of a vehicle involves exploring various avenues that can significantly impact its efficiency and responsiveness. From engine modifications to weight reduction strategies, there are numerous methods to achieve a more dynamic driving experience.

Engine Enhancements: One of the most effective ways to boost performance is by focusing on the heart of the vehicle–the engine. Consider upgrading components such as the intake system, exhaust system, and engine management software. These alterations can lead to improved airflow and better fuel combustion.

Suspension and Handling: Upgrading the suspension system can greatly affect handling and stability. Installing performance shocks and springs can enhance cornering ability and provide a smoother ride. Additionally, anti-sway bars can reduce body roll during turns, leading to a more controlled driving experience.

Weight Management: Reducing the overall weight of the vehicle can lead to noticeable improvements in speed and agility. Consider removing unnecessary components or replacing heavy parts with lightweight alternatives. Carbon fiber and aluminum are excellent materials for achieving this goal.

Braking System: Performance enhancements should not neglect the braking system. Upgrading to high-performance brake pads and rotors can significantly improve stopping power, ensuring that enhanced speed can be matched with adequate control.

When contemplating these enhancements, it’s essential to consider the balance between performance and reliability. Each modification may require adjustments in other areas, and thorough research is vital to ensure compatibility and optimal results.