The upkeep of utility vehicles is essential for ensuring optimal performance and longevity. This guide serves as a comprehensive resource for individuals seeking to enhance their knowledge of maintenance practices. By understanding key components and service procedures, owners can effectively address common issues and prevent potential breakdowns.

In this section, readers will discover detailed insights into the inner workings of their vehicles, covering everything from routine checks to more complex repairs. The focus will be on empowering users with the knowledge needed to confidently tackle maintenance tasks, ensuring their vehicles remain in top condition.

By following the outlined procedures and recommendations, users will not only extend the life of their machinery but also enhance overall safety and reliability. A well-maintained vehicle not only performs better but also provides peace of mind for its operator.

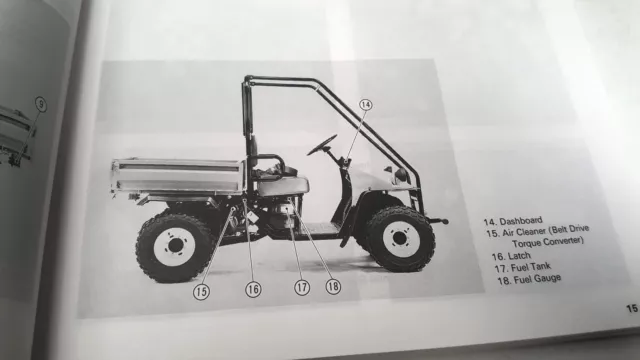

Kawasaki Mule 550 Overview

This section provides a comprehensive understanding of a versatile utility vehicle designed for various tasks and environments. Known for its durability and functionality, this model has become a popular choice for both recreational and professional use.

Key features include:

- Robust construction suitable for off-road applications.

- Powerful engine offering reliable performance.

- Ample cargo space for transporting tools and materials.

- Comfortable seating arrangement for multiple passengers.

Additionally, this vehicle is equipped with:

- An efficient drivetrain for optimal handling.

- Versatile attachment options to enhance functionality.

- User-friendly controls for easy operation.

Whether navigating rugged terrains or performing essential tasks, this utility vehicle delivers exceptional reliability and performance.

Common Issues and Solutions

Every vehicle experiences a range of challenges over time, and understanding these can significantly enhance the longevity and performance of your machine. Identifying frequent problems allows owners to address issues promptly, ensuring optimal functionality and reducing downtime.

Engine Starting Difficulties: A common concern is trouble starting the engine. This may stem from a drained battery or faulty connections. Checking the battery voltage and ensuring all connections are secure can often resolve the issue.

Transmission Problems: Slipping or difficulty shifting gears can indicate transmission issues. Regular fluid checks and replacements, along with ensuring proper linkage adjustments, can help maintain smooth operation.

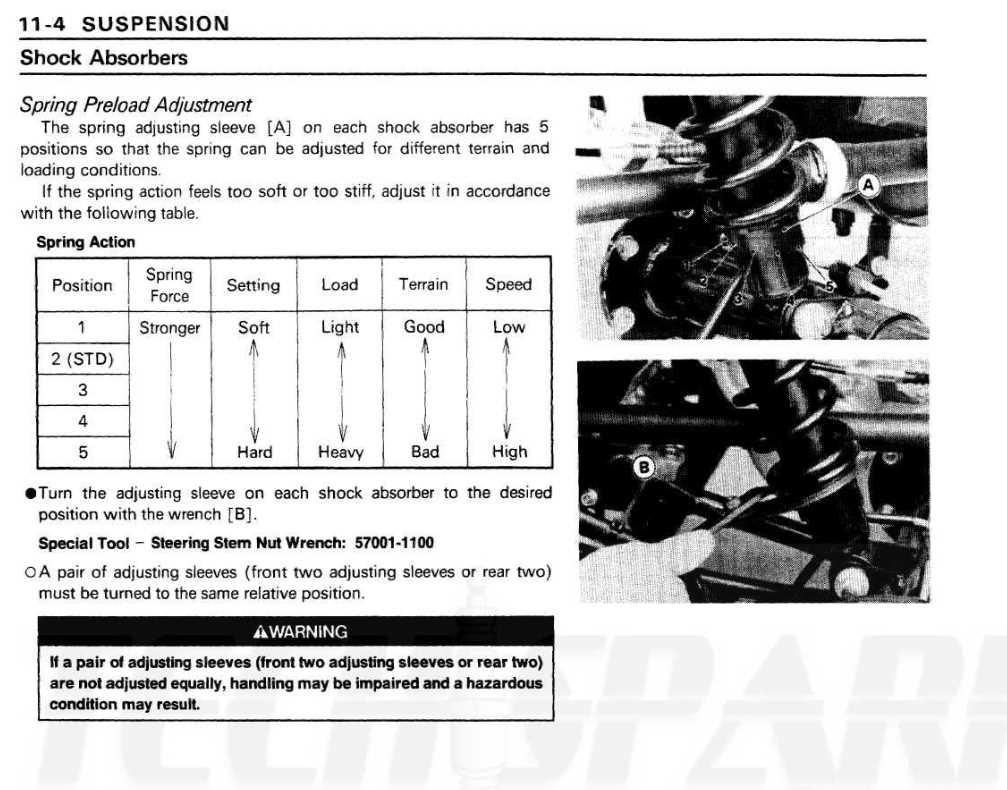

Suspension Wear: Over time, components of the suspension may wear down, leading to a rough ride. Inspecting bushings and shock absorbers regularly allows for early detection and replacement, enhancing comfort and stability.

Overheating: If the engine overheats, it could be due to low coolant levels or a malfunctioning thermostat. Regularly checking coolant levels and inspecting the cooling system can prevent serious damage.

By being aware of these prevalent issues and implementing proactive measures, owners can ensure their vehicle remains in excellent condition for years to come.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your utility vehicle requires a proactive approach to upkeep and care. Regular maintenance not only enhances reliability but also prevents costly repairs in the long run. Here are essential strategies to maintain your machine effectively.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Check and change engine oil | Every 50 hours of operation | Reduces engine wear and improves efficiency |

| Inspect air filter | Every 100 hours | Ensures proper airflow and prevents dirt buildup |

| Examine brake system | Every 200 hours | Enhances safety and performance |

| Check tire pressure and condition | Monthly | Improves handling and extends tire life |

| Inspect battery terminals | Monthly | Prevents starting issues and ensures electrical system reliability |

| Clean and lubricate moving parts | Every 100 hours | Reduces friction and prolongs component life |

Following these maintenance guidelines will help ensure that your vehicle operates smoothly for many years. Regular attention to these tasks will enhance performance and enhance your overall experience.

Essential Tools for Repairs

When undertaking maintenance or fixing tasks, having the right instruments is crucial for achieving effective results. A well-equipped toolbox ensures that you can tackle various challenges efficiently and safely. Below are some indispensable items that will enhance your ability to address mechanical issues effectively.

Basic Hand Tools

- Wrenches: Adjustable and socket varieties are essential for loosening and tightening bolts.

- Screwdrivers: A set with different sizes and types is necessary for various fasteners.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Hammers: Ideal for driving nails and fitting parts together.

Specialized Instruments

- Torque Wrench: Ensures that bolts are tightened to the correct specifications, preventing damage.

- Multimeter: Essential for electrical troubleshooting and checking voltage, current, and resistance.

- Diagnostic Tools: Devices that can read error codes and provide insights into mechanical performance.

- Lift or Jack: Necessary for elevating the vehicle to access underneath safely.

Step-by-Step Troubleshooting Guide

This section provides a structured approach to identifying and resolving common issues that may arise during operation. Following a systematic method can help pinpoint the root cause of problems efficiently.

-

Identify the Symptoms:

Start by noting the specific issues you are experiencing. Common symptoms include:

- Engine not starting

- Unusual noises

- Poor performance

-

Check Fuel Levels:

Ensure that there is sufficient fuel in the tank. A low fuel level can lead to starting issues or poor performance.

-

Inspect Battery Condition:

Examine the battery for corrosion, loose connections, or signs of damage. A weak or dead battery can prevent starting.

-

Examine Electrical Components:

Look for frayed wires, blown fuses, or malfunctioning switches. These can contribute to various electrical problems.

-

Check Fluid Levels:

Inspect oil, coolant, and other fluid levels. Low fluid levels can lead to overheating or mechanical failures.

-

Perform Routine Maintenance:

Ensure that filters, spark plugs, and belts are in good condition and have been serviced regularly.

-

Consult the Documentation:

If problems persist, refer to the specific guidelines available in the comprehensive reference material for detailed troubleshooting steps.

By following this systematic troubleshooting guide, you can effectively address and resolve many common challenges encountered during use.

Parts Replacement Procedures

This section provides a comprehensive guide for the systematic replacement of components in utility vehicles. Proper procedures ensure the longevity and optimal performance of the machinery, allowing for effective maintenance and reduced downtime.

Preparation Steps

- Gather necessary tools and replacement parts.

- Ensure the vehicle is parked on a level surface and securely supported.

- Disconnect the battery to prevent electrical issues.

Replacement Process

- Identify the component that requires replacement.

- Follow these general steps:

- Remove any obstructing parts.

- Detach the faulty component carefully.

- Install the new part, ensuring proper alignment.

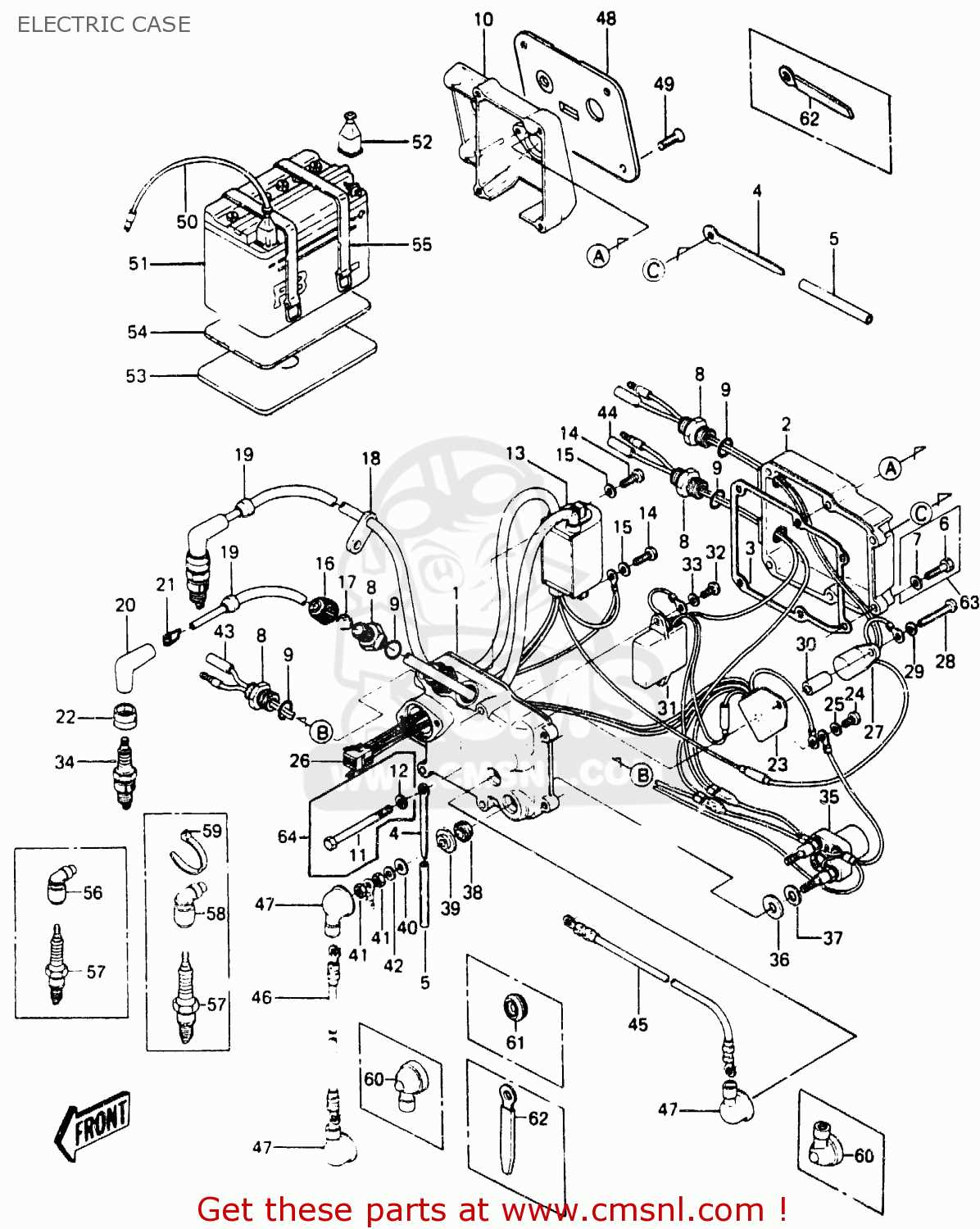

Electrical System Diagnostics

Accurate assessment of an electrical system is crucial for ensuring optimal performance and reliability. This section focuses on identifying potential issues through systematic testing and analysis. Understanding the components and their interactions will facilitate effective troubleshooting and maintenance.

Begin by checking the power source, ensuring voltage levels meet specifications. Use a multimeter to measure voltage across terminals and verify proper connections. Inspect wiring for signs of wear or damage, which can lead to intermittent faults.

Next, evaluate switches and relays. Test their operation to confirm they are engaging and disengaging as intended. A malfunctioning switch can disrupt the flow of electricity, leading to operational failures.

Examine the grounding system, as poor connections can cause erratic behavior. Ensure all grounding points are clean and securely attached to the frame, reducing the risk of electrical noise and interference.

Lastly, if discrepancies arise, consult schematic diagrams for a comprehensive understanding of the circuitry. This resource will aid in pinpointing exact locations for further inspection, allowing for targeted diagnostics and repairs.

Fluid Changes and Recommendations

Maintaining optimal performance in any utility vehicle involves regular changes of various fluids. These essential tasks ensure that the machinery operates smoothly, preventing potential issues and prolonging lifespan. Understanding when and how to change fluids is crucial for efficient operation.

The following table outlines the recommended fluids, their specifications, and suggested change intervals:

| Fluid Type | Recommended Specification | Change Interval |

|---|---|---|

| Engine Oil | SAE 10W-40 | Every 100 hours of operation or annually |

| Transmission Fluid | ATF (Automatic Transmission Fluid) | Every 1,000 miles or annually |

| Cooling System Fluid | 50/50 Antifreeze and Water | Every two years |

| Brake Fluid | DOT 3 or DOT 4 | Every two years or as needed |

Adhering to these guidelines will help ensure that the vehicle runs efficiently, minimizing wear and tear and maximizing performance.

Improving Performance and Efficiency

Enhancing the capabilities and functionality of utility vehicles involves several key strategies. By focusing on maintenance and optimization, operators can ensure their machines run smoothly and effectively, providing better results in various applications.

Regular Maintenance Practices

- Check and replace air filters regularly to ensure optimal airflow.

- Maintain proper fluid levels, including oil and coolant, to prevent overheating and wear.

- Inspect and adjust tire pressure to improve traction and reduce fuel consumption.

- Examine belts and hoses for signs of wear and replace them as necessary.

Performance Enhancements

- Upgrade to high-performance exhaust systems to increase engine efficiency.

- Consider tuning the engine for improved power output.

- Install a fuel management system to monitor and optimize fuel usage.

- Implement weight reduction techniques, such as removing unnecessary accessories.

By applying these strategies, users can significantly enhance the performance and efficiency of their vehicles, leading to improved productivity and longevity.

Safety Precautions During Repairs

When engaging in maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions can ensure that the environment remains secure and that the individual performing the work is protected from potential hazards. Awareness and adherence to safety guidelines will lead to a more effective and efficient workflow.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and steel-toed boots, which help shield against cuts, chemical exposure, and falling objects. Additionally, it is essential to work in a well-ventilated area, especially when handling fuels or solvents, to minimize inhalation risks.

Before starting any task, ensure that the vehicle is turned off and securely stabilized. Utilize wheel chocks and jack stands to prevent unintended movement. Familiarize yourself with the tools and components you will be handling, and ensure they are in good working condition. Keeping the workspace organized can also reduce the likelihood of accidents caused by clutter or misplaced tools.

Lastly, always refer to the manufacturer’s guidelines and specifications. Understanding the particular needs of the machine ensures that you use the correct procedures and avoid unnecessary risks. By integrating these safety measures, you can contribute to a secure and productive maintenance experience.

Resources for Further Assistance

When facing challenges with your vehicle, having access to reliable resources can make all the difference. There are numerous platforms available that provide valuable support, from expert advice to community forums where enthusiasts share their experiences.

Online Forums: Engaging with online communities dedicated to similar vehicles can offer insights and practical tips. Members often discuss common issues, solutions, and modifications, making these forums a great place for advice.

Service Centers: Authorized service providers possess the knowledge and expertise to address specific concerns. They can perform diagnostics and repairs using manufacturer-approved techniques and parts.

Instructional Videos: Numerous video tutorials on platforms like YouTube illustrate repair procedures and maintenance techniques step-by-step. These resources can visually guide you through processes that may seem daunting.

Manufacturer’s Website: The official website often contains technical bulletins, FAQs, and contact information for customer support. This can be an invaluable resource for troubleshooting and acquiring official documents.

Books and Guides: Comprehensive manuals and handbooks are available for purchase, providing detailed information on various aspects of vehicle maintenance and repair. These texts can serve as excellent references.