In the world of outdoor equipment, understanding the intricacies of machinery is essential for ensuring optimal performance and longevity. Whether you are a seasoned user or a newcomer to this realm, having access to detailed instructions can significantly enhance your experience and satisfaction. This section delves into the essential aspects of upkeep and problem resolution, equipping you with the knowledge needed to tackle common issues.

Proper care of your tools not only boosts their efficiency but also minimizes the risk of unexpected breakdowns. From routine checks to more complex adjustments, a comprehensive understanding of the mechanisms at play can save time and resources. This guide aims to illuminate the key procedures involved, empowering users to handle their devices with confidence.

Additionally, recognizing signs of wear and knowing how to address them promptly can prevent more significant complications down the line. By following systematic approaches to troubleshooting, you can maintain your equipment in peak condition. Join us as we explore the fundamental techniques and insights necessary for effective management and resolution of typical challenges faced by users.

Understanding the Stihl FS55R Model

The equipment in question represents a powerful tool designed for efficient grass cutting and landscape maintenance. Its robust engineering ensures durability and performance, making it a preferred choice for both homeowners and professionals alike.

This particular model is equipped with a high-performance engine that delivers impressive torque, allowing users to tackle thick vegetation with ease. The lightweight design enhances maneuverability, making it suitable for extended use without causing fatigue.

Additionally, the ease of operation is a significant advantage. The intuitive controls and well-placed features ensure that even novice users can achieve optimal results with minimal effort. Regular maintenance and understanding of the components can further extend the lifespan of this exceptional tool.

In summary, the discussed equipment stands out for its combination of power, efficiency, and user-friendly design, making it an essential addition to any gardening arsenal.

Common Issues and Solutions

This section addresses frequent problems encountered with outdoor power equipment and offers practical solutions to help users troubleshoot effectively. Understanding these common issues can enhance the longevity and performance of your machine.

Engine Performance Problems

- Starting Difficulties:

- Check fuel levels; ensure fresh fuel is being used.

- Inspect the spark plug for wear or damage; replace if necessary.

- Examine the air filter; a clogged filter can restrict airflow.

- Loss of Power:

- Ensure the throttle is functioning correctly.

- Check for blockages in the exhaust system.

- Inspect fuel lines for leaks or kinks.

Cutting Issues

- Uneven Cutting:

- Verify that the cutting head is properly aligned.

- Check for dull blades; sharpen or replace them as needed.

- Adjust the cutting height settings for uniformity.

- Excessive Vibration:

- Inspect the cutting attachment for damage or wear.

- Ensure all fasteners are tightened to prevent movement.

- Examine the equipment for any misalignment issues.

Tools Required for Repair

When undertaking maintenance on outdoor power equipment, having the right tools is essential for effective and safe servicing. A well-equipped toolkit not only simplifies the process but also ensures that tasks are completed accurately and efficiently. Below is a list of tools commonly needed for such tasks.

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types for removing and securing screws.

- Pliers: Useful for gripping, twisting, and cutting wires or small parts.

- Socket Set: Essential for working with nuts and bolts in hard-to-reach areas.

- Fuel Container: For safely transporting and storing fuel during maintenance.

Additionally, some specialized equipment may be necessary depending on the specific issues encountered:

- Torque Wrench: Ensures bolts are tightened to manufacturer specifications.

- Feeler Gauge: Helps in measuring small gaps or clearances accurately.

- Multimeter: For diagnosing electrical issues and checking components.

- Safety Gear: Always wear gloves, goggles, and ear protection while working.

Having these tools readily available will make the process of servicing much smoother and help maintain the longevity of your equipment.

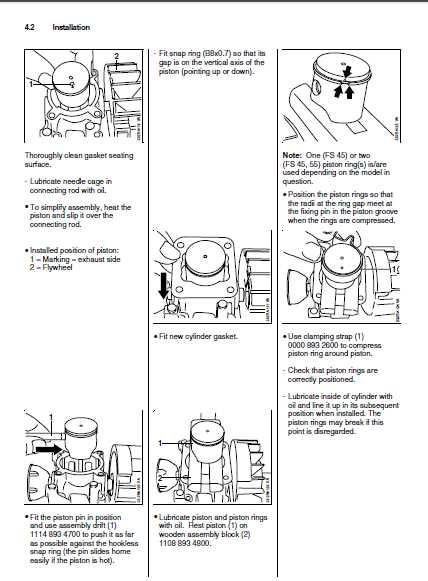

Step-by-Step Disassembly Guide

This section provides a detailed approach for safely taking apart the equipment for maintenance or troubleshooting. Proper disassembly is crucial to understand the internal components and ensure effective repairs or replacements. Following these instructions carefully will help prevent damage and facilitate a smoother reassembly process.

Preparation for Disassembly

Before beginning the disassembly process, gather all necessary tools such as screwdrivers, wrenches, and pliers. Ensure that the unit is turned off and disconnected from any power source. A clean workspace will help you organize the parts as they are removed, making it easier to reassemble later.

Step-by-Step Procedure

Start by removing any external covers, taking care to note the location of screws and clips. Next, detach the fuel tank and lines to avoid spills. Proceed to remove the cutting head, followed by the drive shaft and other internal components. Document each step with photos or notes to ensure you remember how to put everything back together. Always handle parts gently to avoid stripping screws or damaging connections.

How to Replace the Fuel Filter

Maintaining the performance of your equipment often involves ensuring that the fuel system is clean and efficient. One essential component in this system is the fuel filter, which plays a crucial role in preventing dirt and debris from entering the engine. Regular replacement of this part can enhance overall functionality and extend the lifespan of your machinery.

Tools and Materials Needed

Before starting the replacement process, gather the following tools and materials:

- New fuel filter

- Fuel line pliers

- Container for fuel

- Gloves and safety goggles

Step-by-Step Replacement Process

1. Prepare the Area: Ensure the equipment is turned off and cool to prevent any accidents. Work in a well-ventilated space.

2. Access the Fuel Filter: Depending on the model, you may need to remove the fuel tank cover or other components to reach the filter.

3. Disconnect the Old Filter: Use fuel line pliers to carefully detach the old filter from the fuel lines. Be cautious as fuel may spill; have the container ready to catch any excess.

4. Install the New Filter: Attach the new filter securely to the fuel lines, ensuring that it is oriented correctly according to the flow direction indicated on the filter.

5. Reassemble the Equipment: Once the new filter is in place, reattach any covers or components you had to remove earlier.

6. Test the System: After reassembly, start the engine and check for leaks around the new filter. Ensure the machine runs smoothly.

Regularly replacing the fuel filter is a simple yet vital maintenance task that contributes to the efficiency and longevity of your machinery. Following these steps will help you ensure that your equipment operates at its best.

Maintaining the Cutting Head

Proper upkeep of the cutting attachment is essential for optimal performance and longevity of your equipment. Regular maintenance not only enhances cutting efficiency but also reduces wear and tear, ensuring safe and effective operation. This section outlines key practices to keep the cutting head in top condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect for Damage | Before Each Use | Check the cutting head for cracks or wear. Replace any damaged components immediately to prevent further issues. |

| Clean the Cutting Head | After Each Use | Remove debris, grass, and dirt from the cutting head to maintain performance and prevent clogs. |

| Sharpen Blades | Every 5 Hours of Use | Ensure blades are sharp for effective cutting. Dull blades can lead to excessive strain on the engine. |

| Check Line Feed | Weekly | Verify that the cutting line feeds correctly. Replace or adjust as necessary to avoid interruptions during operation. |

| Lubricate Moving Parts | Monthly | Apply appropriate lubricant to moving components to reduce friction and enhance functionality. |

By adhering to these maintenance guidelines, you can significantly extend the life of the cutting head and ensure it operates efficiently, providing you with a reliable tool for your tasks.

Reassembling the Trimmer Correctly

Proper reassembly of your cutting tool is crucial for optimal performance and longevity. Following a systematic approach ensures that each component is securely positioned and functions effectively. This section outlines essential steps and tips for putting your equipment back together.

Before you begin, gather all necessary tools and components in a clean workspace. This will help you maintain organization and avoid losing any small parts. Here are the key steps to follow:

- Examine all parts for wear or damage.

- Start with the main housing; ensure any seals or gaskets are intact.

- Carefully insert the engine into the housing, aligning all mounting points.

- Securely fasten bolts and screws in a crisscross pattern to distribute pressure evenly.

- Attach the fuel tank, ensuring that all connections are tight and leak-free.

- Reassemble the cutting head, verifying that the line is correctly threaded through the spool.

It is essential to refer to the original specifications or guidelines for torque settings and assembly order. After reassembly, perform a thorough inspection to ensure everything is in place. This diligence will help prevent future issues and enhance the performance of your tool.

Finally, before using the equipment, run a test on a low setting to ensure everything operates smoothly. If you encounter any unusual noises or vibrations, recheck your assembly to identify any potential misalignments.

Troubleshooting Engine Problems

When facing issues with a small engine, it is essential to identify and rectify the underlying causes effectively. This section provides guidance on common problems and potential solutions, enabling users to restore optimal performance.

Several factors can lead to engine malfunctions. Here are the typical symptoms and recommended actions to address them:

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Engine Won’t Start | Empty fuel tank or stale fuel | Refill with fresh fuel |

| Engine Runs Rough | Clogged air filter | Clean or replace the air filter |

| Loss of Power | Dirty spark plug | Inspect and clean or replace the spark plug |

| Overheating | Blocked cooling fins | Clear debris from the cooling area |

| Excessive Smoke | Oil mixed with fuel | Check oil levels and mix ratio |

By systematically diagnosing these issues, users can enhance the functionality and lifespan of their equipment. Regular maintenance and prompt attention to problems will ensure reliable operation.

Importance of Regular Maintenance

Routine upkeep is essential for ensuring the longevity and optimal performance of equipment. By adhering to a systematic maintenance schedule, users can prevent potential issues and enhance the overall efficiency of their machines. Regular attention not only extends the lifespan but also safeguards against unexpected breakdowns, ultimately saving time and resources.

Benefits of Consistent Upkeep

Engaging in periodic maintenance offers several advantages. Here are some key benefits:

| Benefit | Description |

|---|---|

| Improved Performance | Well-maintained equipment operates more efficiently, providing better results during use. |

| Increased Longevity | Regular checks and servicing can significantly extend the lifespan of the machinery. |

| Cost Savings | Preventative measures can reduce the need for expensive repairs and replacements. |

| Safety Assurance | Proper maintenance minimizes the risk of accidents and injuries associated with malfunctioning tools. |

Best Practices for Maintenance

To achieve the best results, it is important to follow recommended practices. This includes cleaning, inspecting parts, and replacing worn components as necessary. Keeping a log of maintenance activities can also be beneficial, providing a clear history of care and attention given to the equipment.

Identifying Electrical Issues

Recognizing electrical problems in outdoor equipment is crucial for maintaining optimal performance. Various symptoms can indicate underlying issues, and timely identification can prevent further damage and ensure efficient operation.

Common Symptoms of Electrical Problems

- Unresponsive engine start

- Inconsistent power output

- Frequent fuse blowouts

- Visible damage to wiring or connectors

Steps to Diagnose Issues

- Inspect the ignition system for wear or corrosion.

- Examine the battery for proper voltage and connections.

- Check all wiring for signs of fraying or disconnection.

- Test the fuses to ensure they are functioning correctly.

Upgrading Components for Performance

Enhancing the efficiency of outdoor power equipment often involves optimizing its various components. By selecting high-quality parts and implementing thoughtful upgrades, users can significantly improve both the performance and longevity of their machines. This approach not only maximizes productivity but also ensures a smoother operation under demanding conditions.

Engine Enhancements can lead to noticeable improvements in power output. Upgrading to a high-performance air filter and a more efficient exhaust system can enhance airflow, resulting in better combustion and increased horsepower. Additionally, using premium fuels can help maintain optimal engine performance over time.

Cutting Tools play a crucial role in the overall effectiveness of the equipment. Investing in sharper, more durable blades or cutting attachments can reduce wear and tear, allowing for cleaner cuts and less effort during operation. Choosing the right type of blade for specific tasks can also lead to improved results and efficiency.

Vibration Dampening components can enhance user comfort and reduce fatigue during prolonged use. Upgrading to advanced handles or grips designed to absorb shock can make a significant difference in handling, allowing operators to work longer without discomfort.

Finally, fuel delivery systems are essential for maintaining consistent power. Upgrading to a high-flow carburetor or precision fuel injectors can ensure a steady supply of fuel, optimizing engine performance and efficiency. By addressing these key areas, users can experience a marked improvement in their equipment’s capabilities.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on outdoor equipment is paramount. Proper precautions can prevent accidents and promote a secure working environment. By following guidelines, individuals can minimize risks associated with the task at hand.

- Wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling fumes or dust.

- Ensure the equipment is turned off and disconnected from any power source before starting any work.

Before beginning any tasks, familiarize yourself with the components and their functions. This knowledge can help you avoid unnecessary hazards.

- Keep the workspace organized to prevent tripping hazards and misplaced tools.

- Be cautious of sharp edges and moving parts during disassembly and assembly.

- Handle fuel and oil carefully, storing them in designated containers away from heat sources.

Regularly inspect your tools for wear or damage to ensure they operate safely. Adhering to these safety measures will contribute to a successful and accident-free maintenance experience.