Ensuring the longevity and optimal performance of your off-road vehicle is essential for an enjoyable experience. This section provides valuable insights and instructions for keeping your machine in peak condition. Regular upkeep not only enhances reliability but also contributes to safety during your adventures.

Understanding the essential components and their functions is crucial for any operator. Familiarizing yourself with the various systems can help in diagnosing issues early and implementing effective solutions. By gaining knowledge about your vehicle, you can better appreciate its capabilities and limitations.

Comprehensive guidelines are outlined to assist you in troubleshooting common challenges and performing necessary adjustments. Following these practices will empower you to tackle minor repairs confidently, ensuring your vehicle remains a trusted companion on all your journeys.

This section provides a comprehensive overview of a specific type of all-terrain vehicle, focusing on its key components, functionality, and maintenance practices. By gaining insight into this vehicle, users can enhance their understanding and ensure optimal performance.

Essential Components of Your Vehicle

Familiarizing yourself with the main parts is crucial for effective maintenance. Here are the primary elements to consider:

- Engine specifications and types

- Transmission and drivetrain systems

- Suspension features

- Electrical systems and wiring

Regular Maintenance Practices

Adopting a routine maintenance schedule can prolong the lifespan of your vehicle. Key tasks include:

- Oil and filter changes

- Inspection of brakes and tires

- Cleaning air filters

- Checking and adjusting fluid levels

Common Issues and Solutions

This section addresses typical problems that may arise with certain all-terrain vehicles, along with practical remedies to enhance performance and reliability.

- Engine Starting Difficulties:

- Check the fuel level and ensure it is fresh.

- Inspect the battery connections for corrosion and tightness.

- Examine the spark plugs for wear and replace if necessary.

- Overheating:

- Ensure the coolant level is adequate.

- Inspect the radiator for blockages or leaks.

- Check the thermostat functionality.

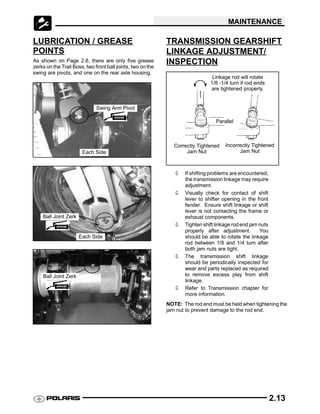

- Transmission Issues:

- Verify that the transmission fluid is at the correct level.

- Look for signs of leakage around seals and gaskets.

- Inspect shifting mechanisms for proper adjustment.

- Electrical Failures:

- Test the fuses and replace any that are blown.

- Examine wiring for fraying or disconnections.

- Ensure the ignition switch operates smoothly.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your vehicle requires consistent care and attention. By following a few essential practices, you can significantly extend the lifespan of your machinery and enhance its efficiency.

- Regular Inspections: Routinely check all components for signs of wear or damage. This includes belts, cables, and connections.

- Fluid Levels: Maintain proper fluid levels, including oil, coolant, and fuel. Regularly change oils and filters to ensure smooth operation.

- Cleanliness: Keep the machine clean by removing dirt, debris, and any build-up that could impede function.

- Proper Storage: When not in use, store the equipment in a dry, sheltered area to protect it from the elements.

- Tire Maintenance: Regularly inspect and maintain tire pressure and tread to ensure safe handling and performance.

Implementing these maintenance practices will not only help in avoiding unexpected breakdowns but also improve overall efficiency, making your equipment more reliable for years to come.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues and performing necessary fixes on your vehicle. Following these outlined procedures will help ensure proper functionality and longevity of the equipment.

Before commencing any tasks, gather the required tools and materials to facilitate a smooth process. Each step is designed to guide you through essential operations, promoting safety and efficiency.

| Step | Description |

|---|---|

| 1 | Inspect the vehicle for visible damage and identify the areas needing attention. |

| 2 | Gather all necessary tools, including wrenches, screwdrivers, and lubricants. |

| 3 | Follow specific disassembly instructions to access internal components carefully. |

| 4 | Replace or repair faulty parts, ensuring all connections are secure. |

| 5 | Reassemble the unit following the reverse order of disassembly. |

| 6 | Perform a thorough test to confirm all systems are functioning correctly. |

By adhering to these systematic guidelines, you can effectively address various concerns, ensuring your vehicle remains in optimal condition.

Tools Required for Repairs

When undertaking maintenance tasks, having the right implements is essential for achieving optimal outcomes. The appropriate equipment not only facilitates the process but also enhances safety and efficiency. Below is a list of commonly needed tools for effective servicing.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To adjust various screws in components. |

| Socket Set | For handling different sizes of fasteners. |

| Pliers | To grip and manipulate various parts securely. |

| Torque Wrench | To apply precise torque to fasteners. |

| Diagnostic Tools | For assessing system performance and issues. |

Electrical System Troubleshooting

The process of diagnosing issues within the electrical components is crucial for ensuring optimal performance. Various factors may contribute to malfunctions, and understanding these can lead to effective solutions.

Common problems include faulty wiring, insufficient connections, or defective components. Begin by inspecting the wiring harness for any signs of wear or damage. Check connections to ensure they are secure and free from corrosion.

Next, utilize a multimeter to measure voltage levels at various points in the system. This can help identify areas where power may not be reaching essential components. If voltage readings are low, consider tracing the circuit to locate potential breaks or shorts.

Lastly, pay attention to specific symptoms, such as flickering lights or unresponsive instruments, as these can provide valuable clues to the underlying issues. Addressing electrical faults promptly will enhance the reliability and safety of the entire system.

Engine Performance Enhancements

Improving the output and efficiency of your power unit can significantly enhance the overall experience of riding. Various modifications and upgrades can be implemented to achieve optimal performance levels, ensuring smoother operation and increased power delivery.

Upgrading Fuel System

One of the most effective ways to boost engine performance is by enhancing the fuel delivery system. Installing a high-performance fuel pump and larger injectors can ensure a better fuel-air mixture, which contributes to increased power output. Additionally, fine-tuning the fuel mapping can optimize combustion efficiency, resulting in improved throttle response.

Exhaust System Modifications

Another crucial area for performance enhancement is the exhaust system. Upgrading to a high-flow exhaust can reduce back pressure, allowing for better engine breathing. This not only increases power but also improves the sound quality of the engine. Consider adding a performance header for further gains, which can provide substantial improvements in torque and horsepower.

Suspension Adjustments Explained

Understanding the nuances of suspension modifications is crucial for optimizing performance and comfort in off-road vehicles. Proper adjustments can significantly enhance handling, stability, and overall ride quality, allowing for a more enjoyable experience on varied terrains.

Types of Suspension Adjustments

- Preload Adjustment: This setting influences the initial tension on the springs, affecting the vehicle’s ride height and responsiveness.

- Damping Adjustment: This controls how quickly the suspension reacts to bumps and irregularities, impacting ride comfort and handling precision.

- Compression Settings: These determine how the suspension compresses under load, essential for absorbing shocks effectively.

- Rebound Settings: This regulates how quickly the suspension returns to its original position after compression, crucial for maintaining control.

Steps for Effective Adjustments

- Start by reviewing the vehicle’s specifications and recommendations for optimal settings.

- Adjust preload to achieve the desired ride height and comfort level.

- Modify damping settings based on personal preference and terrain type.

- Test the adjustments on different surfaces, making further tweaks as necessary for best performance.

Regularly reviewing and adjusting suspension settings can lead to improved control and a smoother ride, enhancing the overall performance of the vehicle.

Safe Riding Practices

Ensuring a secure experience while operating an off-road vehicle requires adherence to essential guidelines. These practices not only enhance rider safety but also contribute to the longevity of the vehicle.

Pre-Ride Inspections

Before embarking on any journey, conduct a thorough examination of the vehicle to identify potential issues. Here are key points to check:

- Tire pressure and condition

- Fluid levels, including oil and coolant

- Brakes and lights functionality

- Battery status

- Overall structural integrity

Riding Techniques

Adopting proper riding techniques significantly enhances safety on the trail. Consider the following recommendations:

- Maintain a controlled speed, especially on uneven terrain.

- Always wear appropriate protective gear, such as helmets and gloves.

- Be aware of your surroundings, including other riders and obstacles.

- Avoid sharp turns at high speeds to prevent loss of control.

- Follow established trails and respect nature to ensure minimal environmental impact.

Parts Replacement Overview

Understanding the process of component substitution is essential for maintaining optimal functionality and performance. This section provides a comprehensive insight into the necessary steps and considerations involved in swapping out various parts of your vehicle.

Common Components Needing Replacement

Regular maintenance may lead to the need for exchanging specific parts due to wear and tear. Below are some frequently replaced components:

| Component | Reason for Replacement |

|---|---|

| Battery | Loss of charge capacity |

| Brake Pads | Worn out from usage |

| Air Filter | Clogged with debris |

| Fuel Filter | Contaminated with impurities |

Replacement Process Steps

To ensure effective replacement, follow these general guidelines:

- Gather necessary tools and new parts.

- Consult relevant specifications for compatibility.

- Carefully remove the old component.

- Install the new part, ensuring proper fit.

- Test functionality before finalizing.

Upgrades for Improved Performance

Enhancing the efficiency and capability of your vehicle can lead to a more enjoyable experience and better handling in various conditions. By implementing certain modifications, you can significantly boost the overall performance, ensuring that your machine operates at its best.

Engine Enhancements

One of the most effective ways to elevate performance is through engine upgrades. Consider installing a high-flow air intake system, which allows for better airflow and increased horsepower. Additionally, reprogramming the engine control unit (ECU) can optimize fuel delivery and ignition timing, further enhancing power output.

Suspension and Handling Modifications

Improving suspension components can also make a substantial difference in handling. Upgrading to adjustable shocks can provide better control over ride quality and responsiveness. Coupled with reinforced sway bars, these changes can enhance stability during turns and off-road adventures, providing a smoother and more confident ride.

Frequently Asked Questions

This section aims to address common inquiries regarding maintenance and troubleshooting for off-road vehicles. Here, you will find valuable insights and solutions to enhance your understanding and experience.

What should I do if my vehicle won’t start?

If your vehicle fails to initiate, check the battery connections and ensure the battery is adequately charged. Additionally, examine the ignition system and fuel supply for any obstructions.

How often should I change the oil?

Regular oil changes are essential for optimal performance. It is recommended to replace the oil after a specific number of operating hours or seasonally, depending on usage.

What are the signs of a malfunctioning engine?

Indicators of engine issues may include unusual noises, decreased power, or warning lights on the dashboard. Addressing these symptoms promptly can prevent further damage.

How can I improve fuel efficiency?

To enhance fuel economy, ensure your tires are properly inflated, maintain a steady speed, and regularly service the engine and fuel system.

Where can I find replacement parts?

Replacement components can be sourced from authorized dealers, online retailers, or local automotive shops specializing in off-road vehicles.