For those who frequently work with powerful tools, proper upkeep is crucial to ensure both safety and longevity. When devices start showing signs of wear or functionality issues, timely intervention can prevent more significant complications and extend their operational life. With a consistent maintenance approach, it’s possible to keep equipment running smoothly and to avoid unexpected breakdowns during critical tasks.

Key steps in tool maintenance involve assessing various parts for potential wear and making necessary adjustments. Checking fuel systems, cleaning essential components, and examining mechanical parts are all fundamental processes. By addressing these areas, users can optimize their tool’s performance, ensuring it functions as intended every time it’s needed.

Another important aspect is understanding common operational issues that might arise over time. Recognizing symptoms like reduced power, erratic performance, or starting difficulties can help in identifying areas that require attention. Equipped with the right information and strategies, tool owners can confidently handle regular upkeep, ensuring their equipment remains reliable and ready for action.

Poulan P3314 Chainsaw Repair Guide

Maintaining a powerful cutting tool effectively can significantly extend its service life and enhance its functionality. Regular upkeep and troubleshooting common issues are essential to ensuring that this equipment remains reliable and performs optimally. This guide offers insights into addressing standard challenges and improving overall machine efficiency, enabling users to manage maintenance confidently.

Common Issues and Troubleshooting Tips

To tackle frequent malfunctions, identifying symptoms like decreased power, unusual sounds, or hard starting is key. Ensuring the fuel system is clear, checking the spark plug condition, and verifying proper oiling are fundamental steps. These measures help mitigate performance drops and address wear-related concerns, enabling smoother operation.

Essential Maintenance Practices

Consistent cleaning of the air filter, sharpening cutting components, and checking for loose parts are crucial for sustaining functionality. Regular lubrication and proper storage protect against rust and debris buildup, allowing the equipment to handle demanding tasks. Adhering to these practices improves reliability and prevents premature wear, ensuring the tool remains ready for use.

Essential Safety Tips for Chainsaw Maintenance

Regular upkeep of cutting equipment is crucial for optimal performance and longevity. By adhering to essential safety practices, users can ensure a safer, more efficient working environment, reducing potential hazards associated with maintenance tasks.

1. Proper Tool Inspection

Before any maintenance, inspect the device thoroughly to identify any visible wear or damage. Check components such as the blade, bolts, and fasteners to ensure they are securely in place. Tightening any loose parts not only enhances functionality but also prevents unexpected malfunctions during operation.

2. Use of Protective Gear

When performing maintenance, wearing the right protective equipment is essential. Items like gloves, safety goggles, and long sleeves protect from accidental contact with sharp edges or debris. Proper attire minimizes risks, allowing for a more secure and comfortable maintenance process.

These safety measures contribute to a more reliable and user-friendly experience with cutting tools. Observing these tips consistently enhances both the effectiveness and safety of the equipment over time.

Understanding the Poulan P3314 Chainsaw Parts

Familiarizing yourself with each component of this cutting tool is essential for effective maintenance and extended usability. Knowing the function and arrangement of each part can prevent common malfunctions and ensure safe operation.

- Engine Assembly: The powerhouse of the device, it combines fuel and air to create the energy needed for rotation. Keeping this section clean and free of debris is critical for smooth operation.

- Guide Bar: This metal bar directs the cutting link’s movement, providing stability and control during cutting. Regular inspection for wear or damage helps maintain precision and safety.

- Chain: The sharp teeth of this element do the cutting work, rotating around the bar at high speed. Proper tension and sharpening are crucial for effective use and user protection.

- Chain Brake: This safety feature halts the chain’s rotation quickly if a kickback occurs. Regular checks ensure it functions when needed.

- Fuel and Oil Tanks: These reservoirs store fuel and bar oil, which lubricates the chain during use. Monitoring levels and preventing leaks prolong the device’s life and improve functionality.

- Air Filter: By keeping debris out of the engine, this part enhances performance and reduces the risk of internal wear. Clean

Step-by-Step Chain Replacement Process

Maintaining the cutting efficiency of your equipment often requires timely chain replacement. This guide will walk you through the process in a straightforward manner, ensuring the steps are safe and effective for reliable performance.

- Ensure the tool is fully powered down and disconnected from any power source to avoid accidental starts.

- Place the equipment on a stable, flat surface, allowing for easy access to the bar and chain components.

- Locate the fastening screws on the cover of the chain assembly and carefully remove them. Set the screws aside in a secure place for reassembly.

- Detach the cover, exposing the bar and the existing chain. Slide the bar slightly forward to relieve tension on the chain, making it easier to remove.

- Remove the old chain by carefully sliding it off the bar and guiding it around the drive sprocket.

- Position the new chain around the drive sprocket, ensuring that the cutting teeth face in the correct direction. Slide it along the bar groove until it sits evenly.

- Reposition the bar back to its original place, ensuring the chain is properly aligned within the grooves.

- Adjust the

How to Troubleshoot Engine Issues

Identifying and resolving engine problems is essential for ensuring the longevity and efficiency of any power tool. A systematic approach to diagnosis can help pinpoint and address common causes of malfunction.

- Check the Fuel System: Ensure the fuel tank has fresh, properly mixed fuel. Over time, old fuel can clog components, affecting performance. Also, inspect the fuel filter for debris that may be restricting flow.

- Inspect the Air Filter: A blocked air filter can limit airflow, causing the engine to perform poorly. Remove and clean the filter or replace it if it’s heavily clogged.

- Evaluate the Spark Plug: A worn or dirty spark plug can hinder ignition. Remove the spark plug, clean any residue, and check the gap for correct settings. Replace if necessary.

- Examine the Carburetor: The carburetor controls the air-fuel mix, and any blockage here can affect engine operation. Clean the carburetor carefully, or consider adjusting it to achieve optimal performance.

- Test the Compression: Low compression may indicate internal wear. Using a compression tester can reveal if the engine requires further mechanical inspection or repairs.

By following these steps, you can effectively troubleshoot engine issues, ensuring reliable performan

Effective Methods for Carburetor Cleaning

Maintaining optimal performance of small engines often hinges on the condition of the fuel delivery system. A clean fuel system is essential for efficient operation, preventing issues such as poor acceleration, stalling, or excessive fuel consumption. This section discusses practical techniques for effectively cleaning the carburetor, ensuring your engine runs smoothly.

1. Disassembly and Inspection

Begin by carefully disassembling the carburetor, taking note of the arrangement of parts. Inspect all components for signs of wear, damage, or corrosion. This initial assessment helps identify specific areas requiring attention and ensures that the cleaning process addresses all potential issues.

2. Use of Cleaning Solutions

Utilize a specialized carburetor cleaning solution designed to dissolve varnish and residue. Submerge the disassembled parts in the solution for the recommended duration, ensuring that all areas are thoroughly treated. For stubborn deposits, consider using a soft brush to gently scrub affected surfaces.

3. Compressed Air for Drying

After cleaning, use compressed air to blow out any remaining cleaning solution and debris. This step is crucial as it prevents contamination during reassembly. Ensure all passages and jets are clear, facilitating proper fuel flow when the engine is operational.

4. Reassembly and Testing

Once all parts are clean and dry, carefully reassemble the carburetor, following your initial notes for correct placement. After reassembly, test the engine to confirm that it runs smoothly. If issues persist, further inspection may be necessary to identify additional problems.

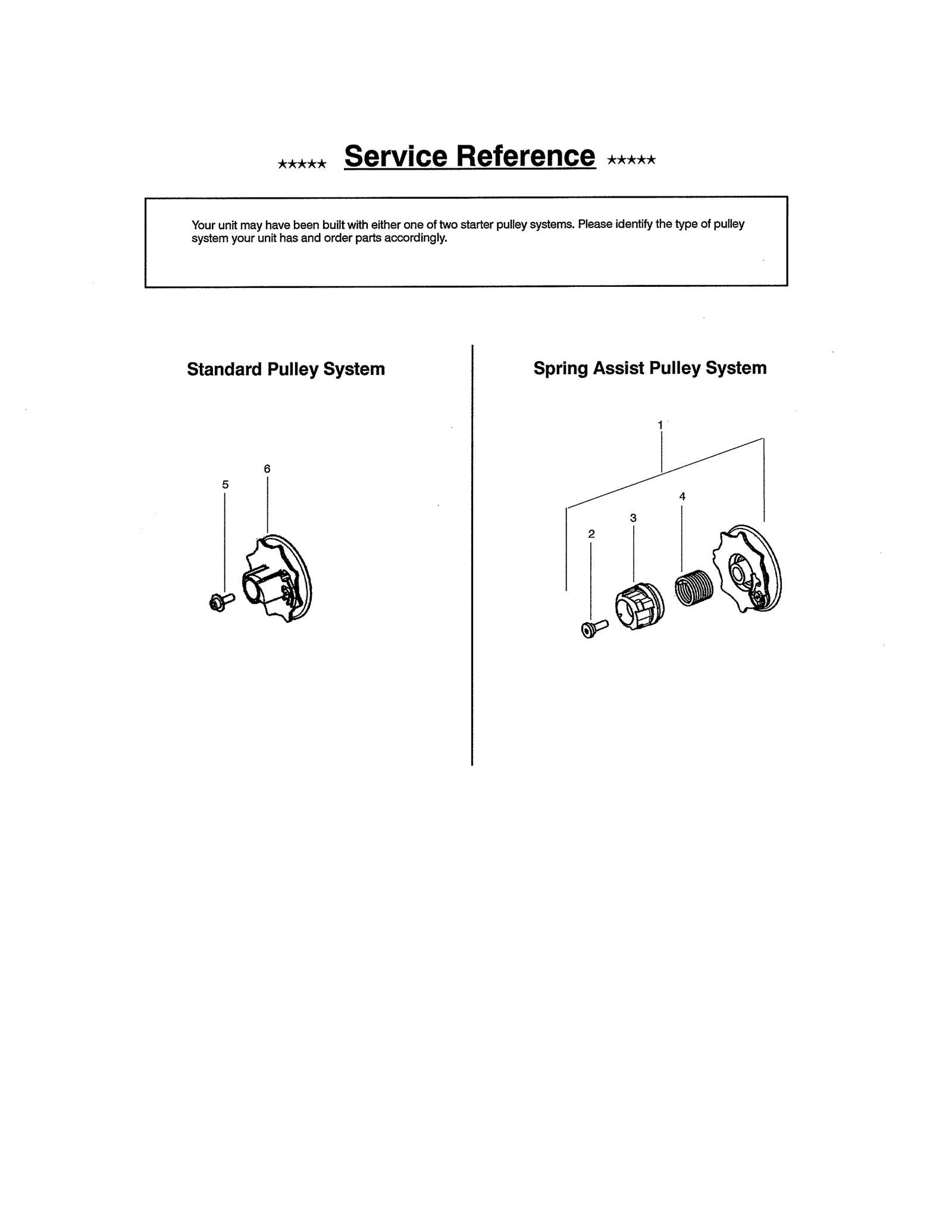

Fixing Common Starter Mechanism Problems

The starter mechanism is a crucial component in ensuring smooth operation of any outdoor power equipment. When issues arise with this system, it can hinder performance and lead to frustration for the user. This section will explore typical problems encountered with starter mechanisms and provide guidance on how to address them effectively.

Identifying Signs of Starter Failure

One of the first steps in troubleshooting is recognizing the symptoms that indicate a malfunctioning starter. Common signs include difficulty in pulling the starter cord, unusual noises when attempting to start the engine, or the engine failing to ignite altogether. Regular inspection of the starter assembly can help pinpoint these issues early, allowing for timely intervention.

Resolving Common Issues

To resolve problems with the starter system, it is essential to check various components systematically. Begin by examining the recoil spring and starter rope for wear or damage. If either part is compromised, replacing it can restore functionality. Additionally, ensure that the starter’s housing is free from debris and that all screws are securely fastened. Cleaning the components and lubricating moving parts can also significantly improve performance.

Guide to Adjusting the Chainsaw Tension

Proper tensioning of the cutting tool is essential for achieving optimal performance and safety during operation. Ensuring the correct amount of tightness allows for effective cutting while minimizing the risk of damage or accidents. This section provides a step-by-step approach to adjust the tension of the equipment effectively.

Understanding the Importance of Tension

Maintaining the right amount of tightness is crucial for various reasons:

- Improved cutting efficiency

- Reduced wear and tear on components

- Enhanced safety during use

Steps to Adjust Tension

Follow these guidelines to adjust the tension correctly:

- Ensure the tool is turned off and disconnected from any power source.

- Locate the tensioning mechanism, which is typically found near the guide bar.

- Use the appropriate tool to loosen the adjustment screws.

- Gently pull the guide bar away from the body to increase tension or push it back to decrease tension.

- Retighten the adjustment screws securely.

- Check the tension by pulling on the cutting element; it should move slightly but not too loosely.

Regularly checking and adjusting the tension not only prolongs the life of the equipment but also enhances user safety during operation.

Proper Fuel Mixing and Storage Tips

Maintaining optimal performance of your equipment requires careful attention to fuel preparation and storage. Correctly combining the necessary components ensures that your machine operates smoothly and efficiently. This section outlines essential practices to achieve the ideal fuel blend while providing guidance on safe storage methods.

Mixing Ratio: It is crucial to adhere to the recommended blending ratio of gasoline and oil specified for your device. A proper mix enhances lubrication and prevents engine damage. Typically, a 50:1 ratio is common, but always refer to the guidelines provided for your specific equipment.

Quality of Components: Use high-quality fuel and oil specifically designed for two-stroke engines. Avoid using old or contaminated fuel, as this can lead to performance issues. Fresh, clean fuel ensures efficient combustion and extends the life of your machinery.

Storage Practices: Store fuel in a cool, dry place away from direct sunlight. Utilize approved containers with proper seals to prevent leaks and contamination. Label the containers clearly with the contents and the mixing date to ensure safe handling and usage.

Regular Inspection: Periodically check your stored fuel for any signs of degradation or contamination. If the fuel has been stored for an extended period, it is advisable to dispose of it safely and prepare a new mixture to guarantee optimal performance.

Maintaining the Chainsaw’s Air Filter

Proper upkeep of the air filtration system is crucial for ensuring optimal performance and longevity of your cutting tool. A clean air filter allows the engine to breathe efficiently, preventing dirt and debris from entering the combustion chamber, which can lead to various operational issues.

Why Regular Maintenance is Essential

Regular maintenance of the air filtration system helps in several ways:

- Enhances engine performance

- Reduces fuel consumption

- Extends the lifespan of the equipment

- Prevents costly repairs

Steps to Maintain the Air Filter

Follow these steps to ensure your filtration system remains in top condition:

Step Description 1. Remove the Cover Unscrew and take off the cover protecting the air filter. 2. Inspect the Filter Check for visible dirt or damage. If it looks excessively dirty or torn, consider replacement. 3. Clean the Filter If reusable, clean it with soap and water or compressed air. Ensure it dries completely before reinstalling. 4. Reassemble Replace the air filter and secure the cover back in place. By following these guidelines, you can maintain a well-functioning air filtration system, ensuring that your equipment operates efficiently and reliably over time.

Diagnosing Spark Plug Malfunctions

Understanding issues with the ignition component is essential for optimal performance. Malfunctions can lead to poor engine operation, difficulty starting, and increased emissions. Identifying the signs of failure will help ensure efficient function and longevity of the equipment.

Common symptoms of a faulty ignition component include:

- Engine misfiring

- Difficulty starting

- Unusual exhaust emissions

- Reduced power output

To effectively diagnose problems, follow these steps:

- Visual Inspection: Examine the ignition part for signs of wear, cracks, or carbon buildup.

- Check Connections: Ensure all connections are tight and free of corrosion.

- Test Spark: Remove the component and ground it against the engine while pulling the starter. A strong spark indicates proper function.

- Assess Gapping: Measure the gap between the electrodes with a feeler gauge; adjust if necessary according to specifications.

- Replace if Necessary: If issues persist after testing, consider replacing the component for optimal performance.

By following these diagnostic steps, users can effectively troubleshoot ignition-related issues and maintain reliable operation of their equipment.

Lubricating and Replacing the Chain Bar

Maintaining proper lubrication and ensuring the timely replacement of the cutting component are crucial for the efficient functioning of any cutting tool. Regular attention to these aspects not only extends the lifespan of the equipment but also enhances safety and performance during operation.

Proper lubrication is vital to reduce friction between the moving parts and to prevent overheating. Using the appropriate lubricant helps in maintaining optimal performance. Here are the steps to effectively lubricate the cutting assembly:

Step Description 1 Ensure the tool is turned off and disconnected from the power source. 2 Add lubricant to the designated oil reservoir until it reaches the recommended level. 3 Run the tool briefly to allow the oil to circulate through the bar and chain. 4 Check for any leaks or insufficient oil flow. When the cutting edge becomes worn or damaged, it is necessary to replace it to maintain optimal functionality. Follow these guidelines to ensure a smooth replacement process:

Step Description 1 Turn off and disconnect the tool from the power supply. 2 Remove any covers that protect the cutting assembly. 3 Loosen the tensioning mechanism and detach the old component. 4 Install the new cutting edge, ensuring it is properly aligned. 5 Re-tension the assembly according to manufacturer specifications and replace any protective covers. Regular lubrication and timely replacement of the cutting edge will not only ensure efficient operation but also enhance safety, preventing potential accidents due to equipment malfunction.

Pro Tips for Prolonging Chainsaw Lifespan

Maintaining the longevity of your cutting tool requires a combination of proper care and attention to detail. By following a few essential practices, you can enhance performance and ensure that your equipment remains reliable over time.

Regular Cleaning: After each use, clean the exterior and air filter to prevent debris buildup. A clean machine operates more efficiently and reduces the risk of overheating.

Proper Lubrication: Regularly check and refill the lubrication system. Adequate oil ensures smooth operation and minimizes wear on moving parts, significantly extending service life.

Routine Inspections: Periodically inspect the cutting edge and other critical components for signs of wear or damage. Early detection allows for timely replacements, preventing further issues.

Safe Storage: Store your tool in a dry, cool place, away from direct sunlight and moisture. Proper storage conditions help prevent rust and deterioration of materials.

Use Appropriate Fuel: Always use the recommended fuel mixture to ensure optimal performance. Using improper fuel can lead to engine problems and reduce overall efficiency.

Follow Manufacturer Guidelines: Adhering to specific instructions provided by the manufacturer regarding maintenance and operation is crucial for achieving the best results and extending the lifespan of your tool.