Maintaining outdoor power equipment is crucial for ensuring longevity and optimal performance. Understanding the intricacies of these machines can help users effectively address common issues, thereby enhancing efficiency and safety during operation. This section aims to provide a comprehensive overview of troubleshooting and servicing techniques that every owner should know.

Comprehending the inner workings of your equipment is vital. With a variety of components working in harmony, familiarity with each part will empower users to diagnose problems with confidence. From the ignition system to the cutting mechanism, knowing how everything fits together is key to successful upkeep.

Practical insights into maintenance practices can save time and money. By learning to recognize early signs of wear and tear, users can prevent minor issues from escalating into major repairs. This guide will equip you with the necessary knowledge to keep your device running smoothly, ensuring that you can tackle any outdoor task with ease.

Husqvarna 445 Overview

This section provides an insight into a popular tool designed for efficient cutting and trimming tasks. Known for its balance of power and usability, this equipment caters to both professionals and enthusiasts, making it a preferred choice in various applications.

Key Features

- Lightweight design for improved maneuverability

- Powerful engine for enhanced cutting performance

- Ergonomic handle for comfortable grip during prolonged use

- Easy start system to minimize effort in ignition

- Durable construction for long-lasting reliability

Applications

- Tree trimming and felling

- Firewood cutting

- Landscaping projects

- General maintenance tasks

With its blend of efficiency and user-friendly features, this tool remains a reliable companion for a variety of outdoor tasks.

Common Issues with Chainsaw

When using a power tool designed for cutting wood, various challenges can arise that may hinder its performance. Understanding these common problems can help users troubleshoot effectively and maintain optimal functionality. This section outlines typical issues encountered during operation, offering insights into their causes and potential solutions.

Fuel System Problems

One prevalent issue involves the fuel system, which can lead to poor performance or failure to start. Contaminated or stale fuel often creates difficulties, as does the presence of air leaks in the fuel lines. Regularly checking the fuel mixture and ensuring that all connections are tight can prevent these complications.

Chain and Bar Issues

Another frequent concern is related to the cutting equipment itself. A dull or damaged chain can significantly affect cutting efficiency. Regular maintenance, such as sharpening or replacing the chain and ensuring the bar is properly lubricated, is essential for maintaining optimal cutting performance. Additionally, misalignment of the chain can cause undue wear and tear, necessitating periodic adjustments.

Essential Tools for Repair

Having the right instruments is crucial for effective maintenance and troubleshooting of your equipment. Proper tools not only enhance efficiency but also ensure safety during the process. Here, we outline the fundamental implements you will need to keep your device in optimal condition.

Basic Toolkit

- Screwdrivers: A set of both flathead and Phillips screwdrivers is essential for loosening and tightening various fasteners.

- Wrenches: Adjustable and socket wrenches are necessary for removing nuts and bolts.

- Pliers: Needle-nose and regular pliers help with gripping and bending tasks.

- Hex Keys: Often required for components with hexagonal screws.

Specialized Instruments

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Feeler Gauge: Useful for measuring gaps and ensuring proper alignment.

- Chain Brake Tool: Essential for maintaining the safety mechanisms of your device.

- Fuel Mix Bottle: For accurate measurement of oil and fuel mixtures, ensuring optimal performance.

Step-by-Step Maintenance Guide

Regular upkeep of your power tool is essential for optimal performance and longevity. Following a systematic approach to maintenance can help ensure safety, efficiency, and reliability. This guide outlines a series of straightforward steps to keep your equipment in top condition.

Cleaning and Inspection

Begin with a thorough cleaning. Remove any debris or buildup from the exterior, particularly around air intake and exhaust areas. Use a soft brush and cloth to avoid damaging sensitive components. After cleaning, conduct a visual inspection for any signs of wear, such as cracks or loose parts. Pay special attention to the cutting mechanism and ensure all components are securely fastened.

Lubrication and Replacement

Next, focus on lubrication. Apply appropriate oil to moving parts to minimize friction and prevent premature wear. Refer to the manufacturer’s recommendations for the correct type of lubricant. Additionally, check for parts that may need replacement, such as filters and spark plugs. Regularly replacing worn components can greatly enhance performance and efficiency. Taking these steps will help maintain the reliability of your equipment over time.

How to Replace the Chain

Changing the cutting element on your tool is essential for maintaining optimal performance. This process ensures that your equipment operates efficiently and safely, allowing for effective cutting tasks. Below are the steps to guide you through the replacement procedure.

Tools Needed

- Replacement cutting element

- Wrench or socket set

- Screwdriver

- Protective gloves

- Safety goggles

Steps to Follow

- Safety First: Before beginning, ensure the device is turned off and disconnected from any power source.

- Remove the Cover: Use a wrench to loosen and remove the cover that secures the cutting element in place.

- Detach the Old Chain: Carefully slide the old cutting element off the guide bar. Take note of how it was positioned for easier installation of the new one.

- Install the New Chain: Place the new cutting element onto the guide bar, ensuring it aligns correctly with the sprocket.

- Reattach the Cover: Secure the cover back onto the unit, tightening it sufficiently to hold everything in place.

- Check Tension: Ensure the new element has the proper tension for optimal performance.

- Test the Equipment: Before starting work, conduct a brief test to ensure everything is functioning correctly.

Following these steps will help ensure your tool remains in top condition, allowing for efficient operation in your cutting tasks.

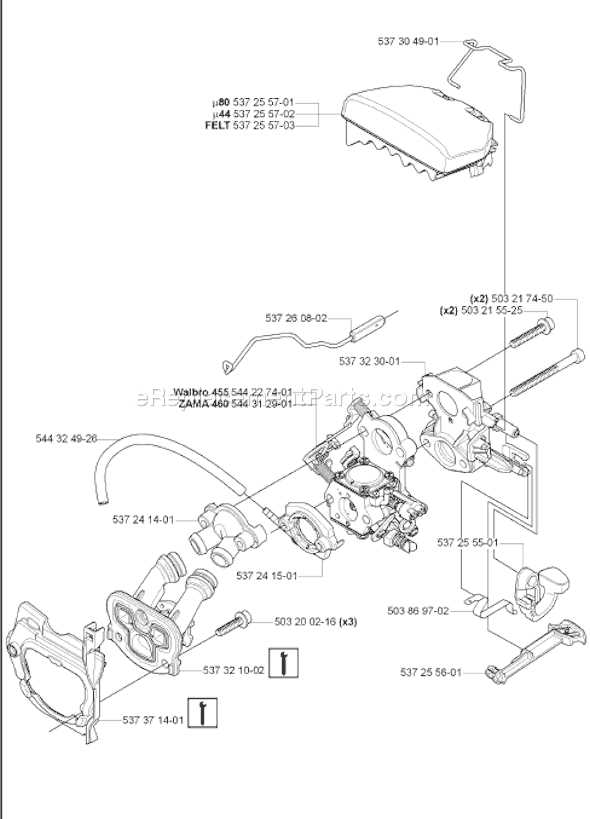

Cleaning the Air Filter

Maintaining optimal performance in power equipment is essential for longevity and efficiency. One crucial aspect of upkeep is ensuring the air intake system remains clean and free from debris. A well-maintained filter allows for proper airflow, which is vital for the engine’s operation. Neglecting this component can lead to reduced performance and potential damage.

Steps to Clean the Air Filter

Cleaning the air filter is a straightforward process that can significantly enhance the efficiency of your device. Follow these steps to ensure thorough cleaning:

| Step | Description |

|---|---|

| 1 | Remove the filter cover carefully, ensuring no damage to the securing clips. |

| 2 | Take out the air filter from its housing for inspection. |

| 3 | Use a soft brush or compressed air to remove dust and debris from the filter surface. |

| 4 | If the filter is heavily soiled, wash it in warm, soapy water, then rinse thoroughly. |

| 5 | Allow the filter to dry completely before reinstalling it in the device. |

| 6 | Reattach the filter cover securely, ensuring everything is in place. |

Frequency of Cleaning

The frequency of cleaning the air filter depends on usage and operating conditions. Regularly inspect the filter, especially in dusty environments, and clean it as needed to maintain optimal performance. A clean air filter contributes to a more efficient engine and prolongs the life of the equipment.

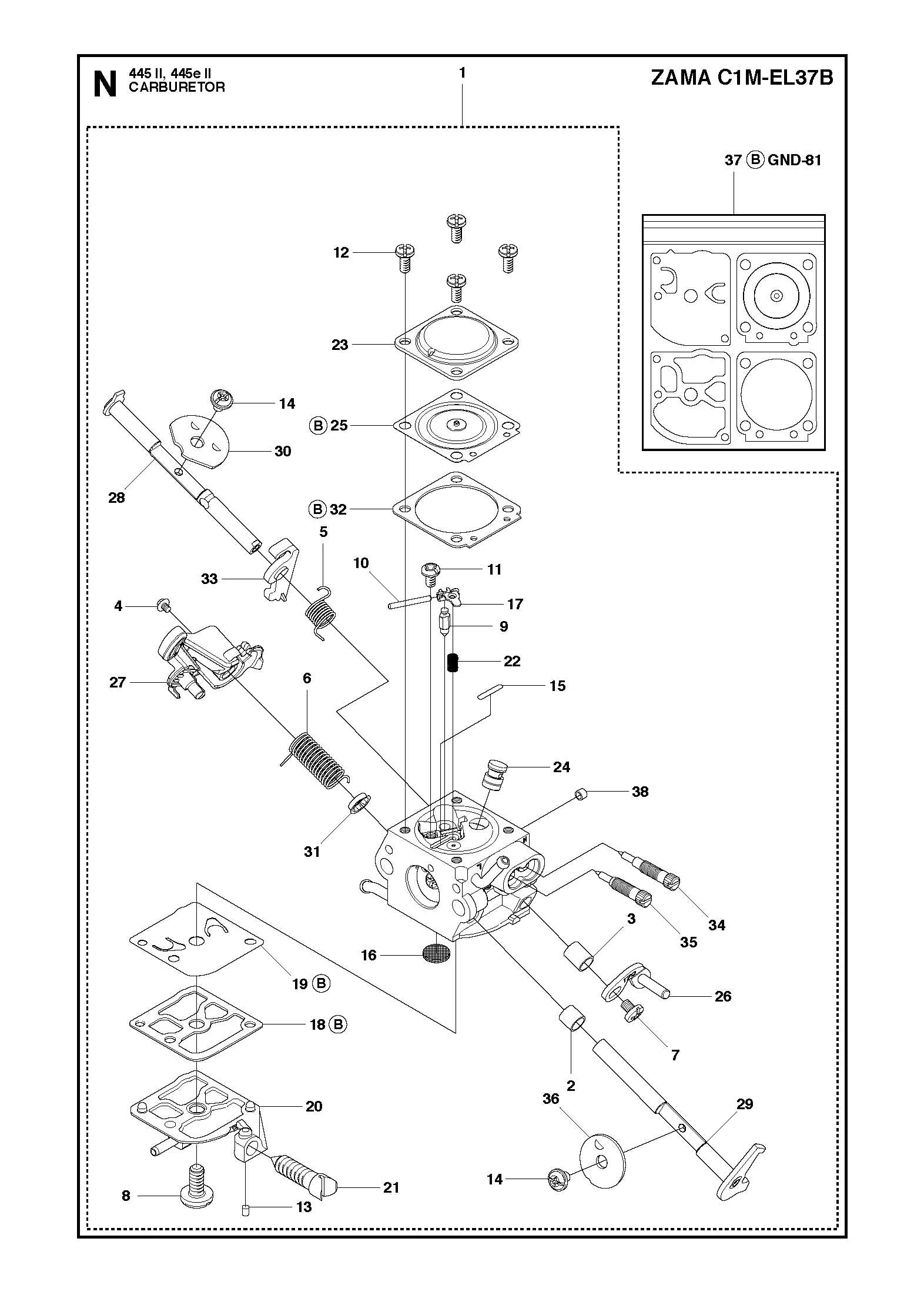

Fuel System Troubleshooting

Diagnosing issues within the fuel system is essential for optimal performance. Problems can arise due to various factors, such as improper fuel mixture, blockages, or component failures. Understanding the symptoms and their potential causes will aid in effective resolution.

Common Symptoms and Causes

| Symptom | Possible Cause |

|---|---|

| Difficulty starting | Incorrect fuel mixture or clogged fuel filter |

| Engine stalling | Air leaks or fuel line issues |

| Poor acceleration | Dirty carburetor or malfunctioning fuel pump |

| Excessive smoke | Rich fuel mixture or oil contamination |

Troubleshooting Steps

To effectively address fuel system issues, follow these steps: first, check the fuel mixture ratio, ensuring it adheres to the manufacturer’s specifications. Next, inspect the fuel filter for blockages and replace it if necessary. Additionally, examine the fuel lines for leaks or cracks, and clean or replace components as needed. Lastly, assess the carburetor for dirt or debris, which can impede performance.

Diagnosing Engine Problems

Identifying issues within an engine can be a complex task that requires a systematic approach. Understanding the various symptoms and their potential causes is crucial for effective troubleshooting. By carefully observing performance irregularities and conducting a thorough analysis, one can pinpoint the source of the malfunction.

Common Symptoms: Several indicators can signal engine trouble. These include difficulties in starting, erratic idling, unusual noises, and a noticeable decrease in power. Each symptom may relate to different underlying issues, making careful observation essential.

Fuel-Related Issues: One frequent cause of engine problems is fuel contamination or incorrect fuel mixture. Ensure that the fuel is clean and appropriate for the engine type. A clogged filter can also impede fuel flow, leading to performance issues.

Ignition System: A malfunctioning ignition system can prevent the engine from starting or cause it to misfire. Inspect spark plugs for wear and ensure that connections are secure. Replacing faulty components in the ignition system can restore proper function.

Airflow and Exhaust: Blockages in the air intake or exhaust systems can significantly affect performance. Regularly check for debris or damage in these areas. Adequate airflow is necessary for optimal combustion, so maintaining these pathways is vital.

By systematically examining these areas, one can effectively diagnose engine problems. Taking prompt action to address identified issues can prolong the lifespan of the equipment and ensure reliable performance.

Reassembling After Repair

Putting together the components after maintenance is a crucial step that ensures optimal performance and safety. Careful attention to detail during this phase can prevent issues down the line and prolong the lifespan of the equipment. This section will guide you through the essential steps to achieve a successful reassembly.

Before you start, gather all necessary tools and parts. Familiarize yourself with the layout of the disassembled components to ensure a smooth process. Following the correct sequence is vital to avoid complications.

| Step | Description |

|---|---|

| 1 | Begin with the base unit, ensuring that all seals and gaskets are correctly placed. |

| 2 | Carefully install the power unit, making sure to secure all fasteners to the recommended torque specifications. |

| 3 | Reattach the fuel system, checking for any signs of wear on hoses and connections. |

| 4 | Reconnect the ignition components, ensuring that wiring is not pinched or exposed. |

| 5 | Finally, inspect the assembled unit for any misalignments before performing a test run. |

Once everything is securely in place, perform a thorough check. It’s advisable to operate the equipment at a low setting initially to confirm proper functionality before full use. Following these steps diligently will enhance performance and reliability.

Safety Precautions to Follow

When operating powerful cutting equipment, adherence to safety protocols is essential to prevent accidents and ensure effective performance. Understanding and implementing safety measures can significantly reduce the risk of injury and enhance the user experience.

Essential Safety Gear

Before beginning any work, it is crucial to equip yourself with the appropriate protective gear. This minimizes exposure to potential hazards and provides a safeguard during operation.

| Safety Gear | Description |

|---|---|

| Helmet | Protects the head from falling debris. |

| Eye Protection | Prevents injury from flying particles. |

| Ear Protection | Reduces noise exposure that can lead to hearing loss. |

| Gloves | Offers grip and protects hands from cuts. |

| Leg Protection | Helps shield legs from accidental contact with cutting tools. |

Operational Guidelines

Following specific operational guidelines is vital for safe and effective usage. Familiarizing yourself with the equipment’s features and maintaining a safe working environment will further enhance safety.

- Always inspect the equipment before use to ensure it is in proper working condition.

- Maintain a clear workspace free from obstacles and hazards.

- Ensure proper handling techniques to maintain control during operation.

- Keep bystanders at a safe distance to prevent accidents.

When to Seek Professional Help

Understanding when to consult an expert is crucial for maintaining your equipment effectively. While many issues can be addressed with basic knowledge and tools, some problems require specialized skills and experience.

If you encounter persistent difficulties despite following troubleshooting steps, it may be time to reach out for assistance. Unusual noises, excessive vibrations, or smoke can indicate serious underlying issues that should not be ignored.

Additionally, if you’re unsure about the proper handling of components or lack confidence in your abilities, seeking professional guidance can prevent further damage and ensure safety. Ultimately, prioritizing expert support can save time and resources in the long run.

Parts Replacement and Upgrades

Maintaining optimal performance of your equipment often requires timely component replacements and thoughtful enhancements. Understanding when and how to replace parts can significantly extend the lifespan of your device, improve efficiency, and enhance overall functionality. This section delves into essential considerations for part substitutions and potential upgrades.

Identifying Wear and Tear

Recognizing the signs of deterioration is crucial. Common indicators include reduced power, unusual noises, and excessive vibrations. Regularly inspecting vital components such as the bar, chain, and air filter can help you pinpoint necessary replacements. Addressing these issues promptly not only prevents further damage but also ensures safety during operation.

Upgrading Components

In addition to standard replacements, consider upgrading certain parts for enhanced performance. Aftermarket options are available that can provide improved durability or efficiency. For instance, investing in a high-performance chain can lead to better cutting speed and precision. Always ensure that any upgrades are compatible with your device to maintain optimal performance.

In summary, staying proactive with parts replacement and considering upgrades can significantly impact the effectiveness and longevity of your equipment. Regular maintenance and thoughtful enhancements are key to ensuring reliable operation.

Resources for Further Learning

Expanding your knowledge on maintenance and troubleshooting can significantly enhance your skills. There are numerous avenues available for individuals seeking to deepen their understanding of tools and equipment care. This section highlights various resources that can aid in your educational journey.

Online Tutorials and Videos

Digital platforms offer a wealth of instructional content, ranging from basic operations to advanced techniques. Consider exploring the following resources:

| Resource | Description |

|---|---|

| YouTube | A variety of channels dedicated to tool maintenance, providing visual guidance and step-by-step demonstrations. |

| Online Forums | Communities where enthusiasts share tips, experiences, and advice on specific topics related to equipment care. |

| Instructional Blogs | Websites that focus on detailed guides, troubleshooting tips, and best practices in equipment handling. |

Books and Guides

Printed materials can serve as excellent references. Look for titles that cover maintenance techniques and safety practices to gain a comprehensive understanding:

| Title | Author |

|---|---|

| The Complete Guide to Tool Maintenance | Jane Doe |

| Safe Practices for Outdoor Equipment | John Smith |

| Expert Tips for Equipment Care | Emily Johnson |