In the realm of small machinery, understanding the intricacies of their upkeep is essential for longevity and optimal performance. This section provides valuable insights into the care and attention required to ensure that your equipment remains functional and efficient. Whether you are a seasoned operator or a novice, having access to detailed information can make a significant difference.

From routine inspections to more complex adjustments, this guide offers step-by-step instructions to address various challenges you may encounter. Emphasizing the importance of regular upkeep, the information presented will help you navigate potential issues, ensuring your equipment continues to operate smoothly.

Moreover, familiarizing yourself with the components and their functions will empower you to perform necessary tasks with confidence. With the right knowledge at your disposal, you can easily tackle maintenance responsibilities and enhance the overall performance of your machinery.

This section aims to provide a comprehensive understanding of a specific lawn care equipment model, highlighting its features, functionality, and overall significance in the gardening domain. Emphasizing its design, performance, and user-friendliness will give potential owners and enthusiasts valuable insights into its capabilities.

| Feature | Description |

|---|---|

| Type | Self-propelled mower designed for residential use. |

| Engine | Powerful four-stroke engine providing efficient performance. |

| Cutting Width | Equipped with a 21-inch cutting deck for effective grass management. |

| Height Adjustment | Convenient height adjustment settings for various grass types. |

| Weight | Moderate weight for ease of handling and maneuverability. |

| Maintenance | Simple maintenance requirements for prolonged lifespan. |

Common Issues with HR214

This section discusses frequent challenges faced by users of this specific lawn maintenance device. Understanding these problems can aid in effective troubleshooting and ensure optimal performance.

Some typical complications include engine difficulties, cutting inefficiencies, and issues with the self-propulsion mechanism. Identifying these concerns early can help prevent further damage and maintain functionality.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Won’t Start | Commonly results from fuel blockage or spark plug failure. | Check fuel levels, replace spark plugs, and ensure proper fuel flow. |

| Uneven Cutting | May occur due to dull blades or improper height adjustment. | Sharpen blades and adjust cutting height settings. |

| Self-Propulsion Issues | Can be caused by worn belts or a malfunctioning drive system. | Inspect belts for wear and replace if necessary, check the drive system. |

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance task, ensuring efficiency and effectiveness throughout the process. A well-equipped workspace not only simplifies the job but also enhances safety, reducing the likelihood of accidents and mistakes.

Basic Hand Tools

Among the primary implements, a set of hand tools is indispensable. Wrenches, screwdrivers, and pliers are fundamental for disassembling components and making adjustments. It’s wise to invest in high-quality items, as durability plays a significant role in their performance.

Specialized Instruments

In addition to standard hand tools, certain specialized instruments are necessary for more intricate tasks. Torque wrenches allow for precise tightening, while multimeters assist in diagnosing electrical issues. Having these specialized tools readily available can significantly streamline the troubleshooting process.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. This section provides a comprehensive guide to systematic care practices, allowing users to keep their machinery in peak condition. Following these detailed steps can help prevent issues and enhance overall efficiency.

1. Cleaning and Inspection: Begin by thoroughly cleaning the exterior surfaces to remove any dirt or debris. Afterward, inspect the components for wear and damage. Pay special attention to belts, filters, and any moving parts, as these are critical for functionality.

2. Lubrication: Proper lubrication of moving parts is vital to reduce friction and prevent overheating. Use the recommended lubricant and apply it to all necessary areas, ensuring that excess is wiped away to avoid attracting dirt.

3. Air Filter Maintenance: A clean air filter is crucial for optimal performance. Remove the filter and clean it according to the manufacturer’s specifications. If the filter is damaged or excessively dirty, consider replacing it to maintain efficient airflow.

4. Blade Care: Check the blades for sharpness and any signs of damage. Sharpen or replace the blades as needed to ensure clean cuts and prevent strain on the engine.

5. Fuel System Check: Examine the fuel system for leaks or blockages. Replace the fuel filter as per the guidelines and ensure that the fuel is fresh to promote smooth operation.

6. Battery Maintenance: If applicable, check the battery terminals for corrosion and ensure a secure connection. Regularly test the battery’s charge and replace it if necessary to avoid starting issues.

By adhering to these maintenance procedures, users can significantly enhance the reliability and performance of their equipment, ultimately extending its lifespan.

Engine Troubleshooting Tips

When encountering issues with your machinery’s power source, it’s essential to methodically identify and resolve the underlying problems. This section offers practical advice to assist in diagnosing common engine complications and provide solutions to ensure optimal performance.

Common Symptoms and Their Causes

- Engine Won’t Start:

- Check the fuel level and quality.

- Inspect the battery for charge and connections.

- Examine the ignition system components.

- Unusual Noises:

- Look for loose or damaged parts.

- Listen for abnormal sounds indicating internal wear.

- Check for debris around the engine that could interfere with operation.

- Overheating:

- Ensure proper coolant levels are maintained.

- Examine the radiator for blockages.

- Inspect the thermostat and water pump functionality.

Maintenance Practices

- Regularly change the oil and replace filters to maintain cleanliness.

- Perform periodic inspections of belts and hoses for signs of wear.

- Keep the engine compartment clean to prevent overheating and corrosion.

- Follow the manufacturer’s guidelines for service intervals.

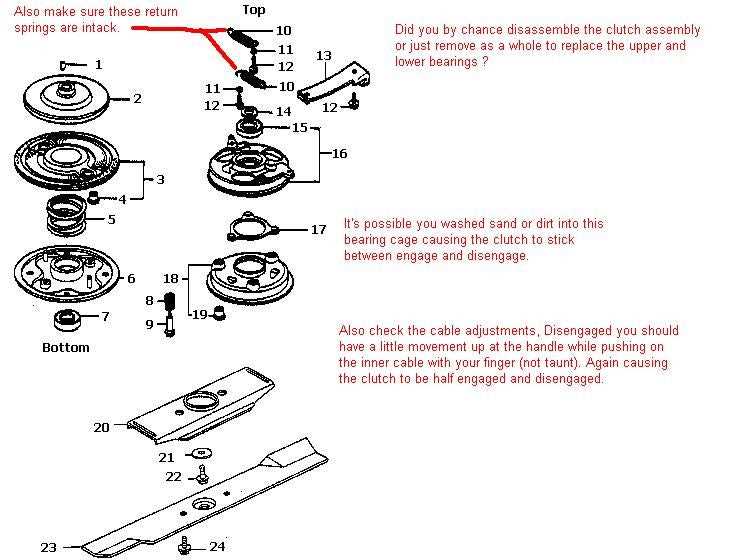

Replacing HR214 Blades Effectively

Ensuring optimal performance of your cutting device requires regular maintenance, particularly when it comes to changing the cutting edges. Dull or damaged blades can significantly reduce efficiency and affect the overall results. This section will guide you through the necessary steps to replace the cutting components seamlessly, enhancing functionality and achieving a cleaner cut.

Before beginning, gather the required tools, including a wrench, safety gloves, and a replacement set of cutting edges. It’s essential to disconnect the power source to avoid accidents during the process. Once you have prepared, carefully tilt the equipment for easy access to the blade assembly.

Loosen the fastening bolts using the wrench, ensuring not to strip them. After removing the old blades, clean the mounting area to eliminate debris and rust. Place the new cutting edges in position, aligning them correctly, and tighten the bolts securely. It’s advisable to check for any movement or wobble after installation to ensure stability during operation.

Finally, reconnect the power source and perform a brief test to confirm that everything is functioning correctly. Regularly inspecting and replacing these components will prolong the lifespan of your device and maintain its performance over time.

Understanding Electrical Components

This section delves into the essential aspects of electrical systems, highlighting their significance in ensuring optimal performance and functionality. A solid grasp of these elements is crucial for diagnosing issues, conducting maintenance, and enhancing overall efficiency.

Electrical components serve as the backbone of various machinery, facilitating the conversion and distribution of energy. Familiarity with these parts enables users to troubleshoot problems effectively and implement necessary upgrades.

| Component | Function | Common Issues |

|---|---|---|

| Battery | Stores electrical energy for starting and powering the system. | Weak charge, corrosion, and failure to hold a charge. |

| Switch | Controls the flow of electricity by opening or closing circuits. | Worn contacts and failure to engage. |

| Fuse | Protects the circuit by breaking the connection in case of overload. | Blown fuses and improper ratings. |

| Relay | Acts as a switch for controlling larger currents with lower voltage signals. | Sticking contacts and coil failure. |

| Motor | Converts electrical energy into mechanical movement. | Overheating, wear, and electrical shorts. |

Fuel System Maintenance Guidelines

Ensuring optimal performance of the fuel delivery system is essential for smooth operation and longevity of the equipment. Regular upkeep not only enhances efficiency but also prevents potential issues that could disrupt functionality. This section provides valuable insights into maintaining the components responsible for fuel management.

Routine Inspections

Conducting periodic evaluations of the fuel system is crucial. Check for any signs of wear, leaks, or blockages in hoses and connections. It is advisable to inspect the fuel filter regularly and replace it as needed to ensure proper flow and prevent contamination. Pay close attention to any unusual noises or performance changes, as these can indicate underlying problems.

Fuel Quality Management

Using clean, high-quality fuel is vital for the health of the system. Contaminants can lead to clogging and inefficiency. Regularly assess the fuel being used and consider implementing fuel stabilizers to prolong freshness, especially when the equipment is not in use for extended periods. Maintaining fuel integrity helps in avoiding costly repairs and ensures reliable performance.

Deck Cleaning and Care Techniques

Maintaining the surface area of your equipment is essential for optimal performance and longevity. Regular cleaning and proper care not only enhance appearance but also prevent wear and damage. This section will outline effective methods to ensure your equipment remains in top condition.

Essential Cleaning Supplies

Before starting the cleaning process, gather the necessary materials:

- Soft-bristle brush

- Bucket

- Mild detergent or specialized cleaner

- Garden hose or pressure washer

- Microfiber cloth or sponge

- Protective gloves

Cleaning Steps

- Begin by removing any debris or loose dirt using the soft-bristle brush.

- Mix a mild detergent with water in a bucket.

- Using a sponge or cloth, apply the cleaning solution to the surface, focusing on stains and buildup.

- Rinse thoroughly with a garden hose or pressure washer to remove all soap residue.

- Dry the surface with a microfiber cloth to prevent water spots.

Implementing these cleaning techniques regularly will help maintain the functionality and appearance of your equipment, ensuring it serves you well for years to come.

Winterizing Your Honda HR214

Preparing your outdoor equipment for the colder months is essential to ensure its longevity and optimal performance. This process involves several steps to protect vital components from the harsh winter conditions and prevent damage caused by moisture and freezing temperatures.

Essential Steps for Winter Preparation

Follow these key procedures to effectively safeguard your machine:

| Step | Description |

|---|---|

| Drain Fuel | Remove any remaining fuel from the tank to prevent deterioration and clogs in the fuel system. |

| Clean Thoroughly | Ensure all debris, grass, and dirt are removed from the exterior, especially from under the deck. |

| Inspect Blades | Check and sharpen the cutting edges to maintain efficiency when you resume use in spring. |

| Store Properly | Keep the equipment in a dry, sheltered area away from extreme temperatures to prevent rust and damage. |

Maintenance Tips

Regular maintenance during the winter months will ensure your machine is ready to go when the season changes. Consider periodic checks and make necessary adjustments to keep everything in optimal condition.

Finding Genuine Replacement Parts

Ensuring the longevity and efficiency of your equipment often hinges on sourcing authentic components. These parts are designed to meet the original specifications, providing optimal performance and reliability. When looking for substitutes, it’s crucial to identify trustworthy suppliers that offer quality alternatives to maintain your equipment in top condition.

To assist in your search, consider the following factors when selecting genuine components:

| Criteria | Description |

|---|---|

| Manufacturer Reputation | Choose parts from well-known brands with a history of reliability and quality. |

| Warranty | Opt for components that come with a warranty, indicating the manufacturer’s confidence in their product. |

| Customer Reviews | Check feedback from other users to gauge the performance and durability of the parts. |

| Compatibility | Ensure that the components are specifically designed to fit your equipment model for seamless integration. |

By focusing on these aspects, you can enhance your chances of acquiring quality parts that will extend the life and improve the functionality of your equipment.